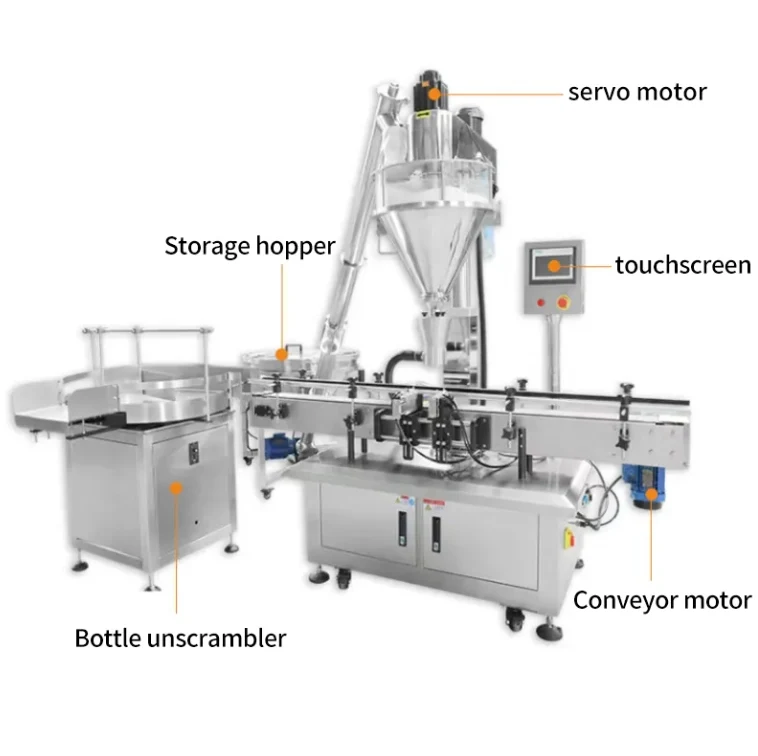

The high-precision semi-automatic powder filling machine is a specialized piece of equipment designed to achieve accurate and consistent filling of various powder materials. It combines manual operation with automated control systems. Operators are responsible for tasks such as placing containers, while the machine's automated components, including powder feeding mechanisms, weighing sensors, and filling nozzles, handle the powder metering and filling process. The machine typically features

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

High-precision Semi-automatic Powder Filling MachineAdvantages

1. High Precision:Equipped with advanced weighing sensors and control algorithms, it can achieve highly accurate powder filling. The precision of filling can reach within a very narrow tolerance range, ensuring that each container receives the exact amount of powder required, which is crucial for maintaining product quality and consistency.

2. Cost - Effective:As a semi-automatic device, it requires less investment compared to fully automatic filling machines while still delivering high - quality filling results. It reduces labor costs by minimizing manual filling efforts, and its relatively simple structure also cuts down on long - term maintenance and repair expenses.

3. Flexibility:Highly adaptable to different types of powder products and container sizes. It can be easily adjusted to meet various production needs, whether it's small - batch custom production or medium - scale commercial manufacturing. Operators can quickly change filling parameters and tooling to handle different powders and packaging requirements.

4. Ease of Operation:With an intuitive control interface and straightforward operation procedures, new operators can be trained to use the machine in a short time. The semi - automatic nature also allows operators to have direct control over the filling process, enabling them to respond promptly to any on - site changes or issues.

High-precision Semi-automatic Powder Filling MachineApplications

1. Pharmaceutical Industry:Used for filling pharmaceutical powders such as tablet - making raw materials, capsules, and medicinal powders. The high precision ensures accurate dosing, which is essential for the efficacy and safety of drugs.

2. Food Industry:Ideal for filling food powders like spices, coffee powder, milk powder, and nutritional supplements. It helps maintain product quality and compliance with food safety regulations by providing consistent filling amounts.

3. Cosmetics Industry:Applicable to filling cosmetic powders, including face powder, eyeshadow powder, and bath salts. The accuracy of filling contributes to the brand image and user experience of cosmetic products.

4. Chemical Industry:Can be used to fill various chemical powders, such as pigments, catalysts, and additives. It ensures the correct proportion of powders in chemical formulations, facilitating consistent product quality in chemical manufacturing.

High-precision Semi-automatic Powder Filling MachineCharacteristics

1. Compact Design:The machine has a relatively small footprint, making it suitable for installation in factories with limited space. Its compact structure also allows for easy relocation and integration into existing production lines.

2. Quick Changeover:Designed to enable rapid changeovers between different products or container sizes. Quick - release components and adjustable parts make it possible to switch production setups in a short time, enhancing production efficiency.

3. Low Maintenance:With a simple mechanical and electrical structure, the machine requires minimal maintenance. Regular cleaning and occasional component inspections are usually sufficient to keep it in good working condition, reducing downtime and maintenance costs.

4. Safety Features:Equipped with safety guards and sensors to prevent accidents during operation. For example, safety interlocks prevent the machine from operating when access doors are open, protecting operators from potential hazards.

Products Description

Product Inquiry