In high-intensity operation scenarios such as mining, port loading and unloading, and large-scale engineering construction, high-quality heavy-duty belt conveyors have become the core equipment for heavy-duty material transportation with their superb carrying capacity, stable and reliable operating performance, and super-long service life. It redefines the heavy-duty transportation standard with innovative design and precision manufacturing, and provides customers with efficient。

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

Get free replacement parts service and online technical support for 1 year after purchase. Additional shipping fees may apply. Additional shipping fees may apply.

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Core technology and structural advantages of high-quality heavy-duty belt conveyor

High-strength core components: using specially made thickened conveyor belts, high-strength polyester canvas or steel wire rope core as the skeleton material, the tensile strength is 3-5 times that of ordinary conveyor belts, and can easily carry hundreds of tons of materials; equipped with heavy-duty cast steel rollers and high-strength alloy steel frames to ensure the stability of the whole machine structure, without fear of extreme working conditions.

Intelligent drive system: equipped with high-power variable frequency drive device, with soft start, overload protection and precise speed regulation functions, effectively reducing the impact of starting current on the power grid; with high-precision gear reducer, the transmission efficiency is increased by 20%, and energy consumption is significantly reduced.

Excellent performance of high-quality heavy-duty belt conveyor

- Super load capacity: The maximum conveying capacity of a single conveyor can reach 5,000 tons/hour, and the conveying length exceeds 10 kilometers, meeting the continuous heavy-load transportation needs of mines, steel mills and other scenes.

- Extreme environment adaptability: The high temperature resistant type can operate stably in a high temperature environment of 200℃, and the cold resistant type is suitable for extremely cold areas of -40℃; for high humidity and strong corrosion conditions, special anti-corrosion coating and stainless steel materials are used, and the protection level reaches IP67.

- Low maintenance and long life: The key components adopt wear-resistant ceramic encapsulation technology, combined with the intelligent lubrication system to reduce component wear; the average trouble-free operation time of the whole machine exceeds 20,000 hours, and the maintenance cost is reduced by 40%.

High-quality heavy-duty belt conveyor intelligent safety guarantee

Full process monitoring system: integrated material blockage monitoring, conveyor belt tear detection, temperature abnormality alarm and more than 10 sensors, real-time transmission of equipment data through the Internet of Things platform, early warning of potential faults.

Multiple safety protection: equipped with emergency braking device, anti-deviation automatic correction mechanism, anti-tear protection device, all-round protection of equipment and personnel safety; support remote one-key shutdown, response time <0.5 seconds.

High-quality heavy-duty belt conveyors with multiple application scenarios

- Mining: Realize long-distance continuous transportation of ore from the mining face to the crushing station and the concentrator, greatly reducing the cost of material transportation.

- Port logistics: Efficiently complete the unloading, storage and loading of bulk cargo such as coal, ore, and grain, and improve the port throughput efficiency.

- Iron and steel smelting: In the processes of sintering, coking, and ironmaking, stably transport high-temperature sintered ore, coke and other materials to ensure the continuous operation of the production line.

- Large-scale infrastructure: Serving water conservancy and hydropower projects, open-pit mine stripping and other projects, solving the problem of large-scale transportation of earthwork and building materials.

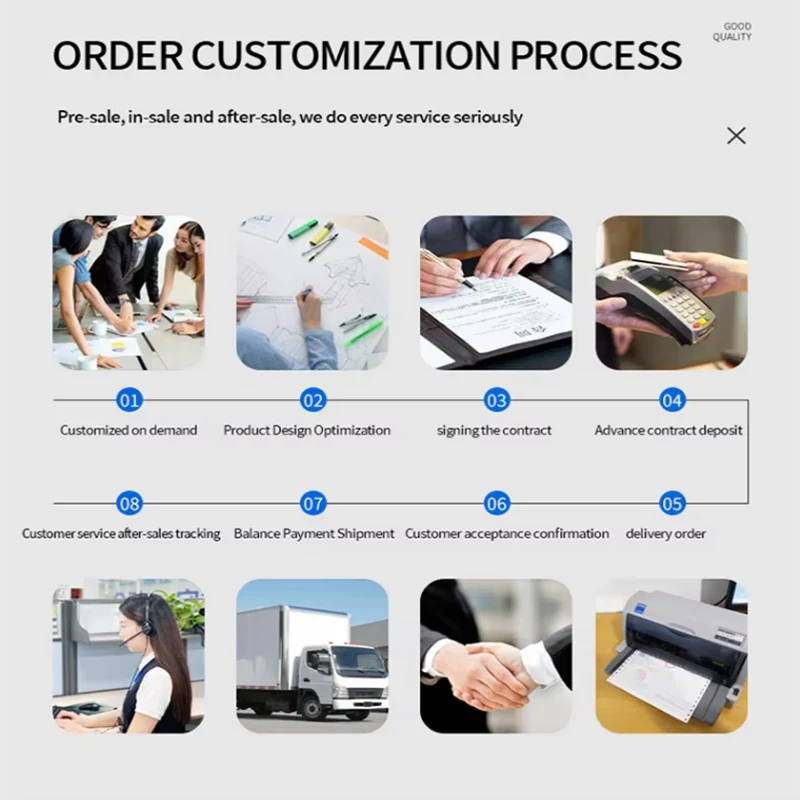

Customized service solutions for high-quality heavy-duty belt conveyors

We provide one-stop services from demand analysis, solution design to installation and commissioning: customize parameters such as climbing angle, bandwidth size, and conveying speed according to the customer's conveying distance, terrain conditions, material characteristics, etc.; support intelligent upgrades, access to the industrial Internet platform to realize remote equipment operation and maintenance and data visualization management, and create higher value for customers.

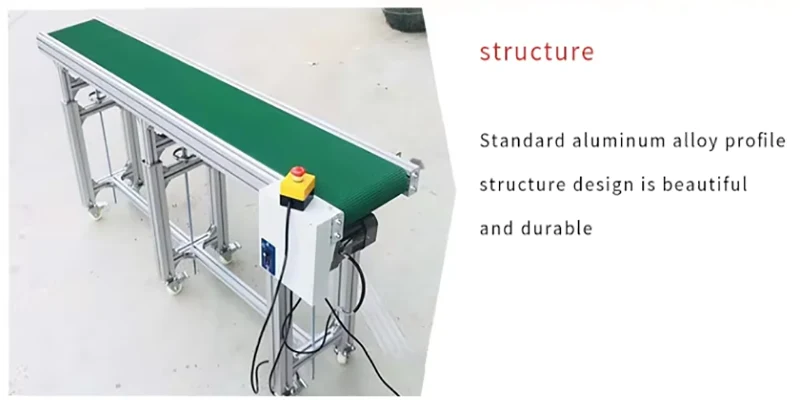

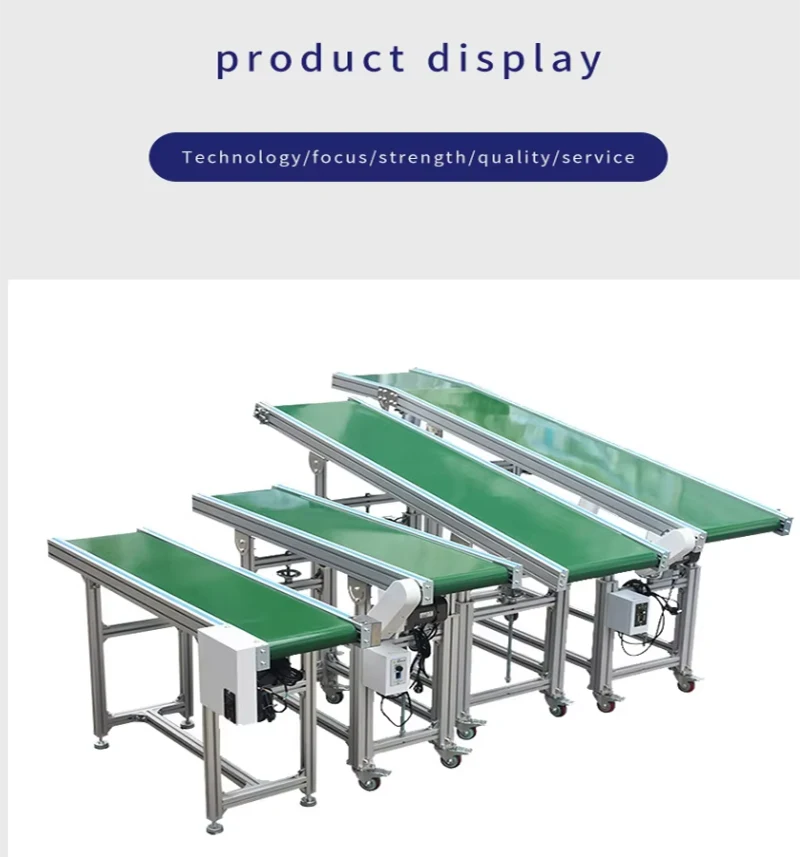

Products Description

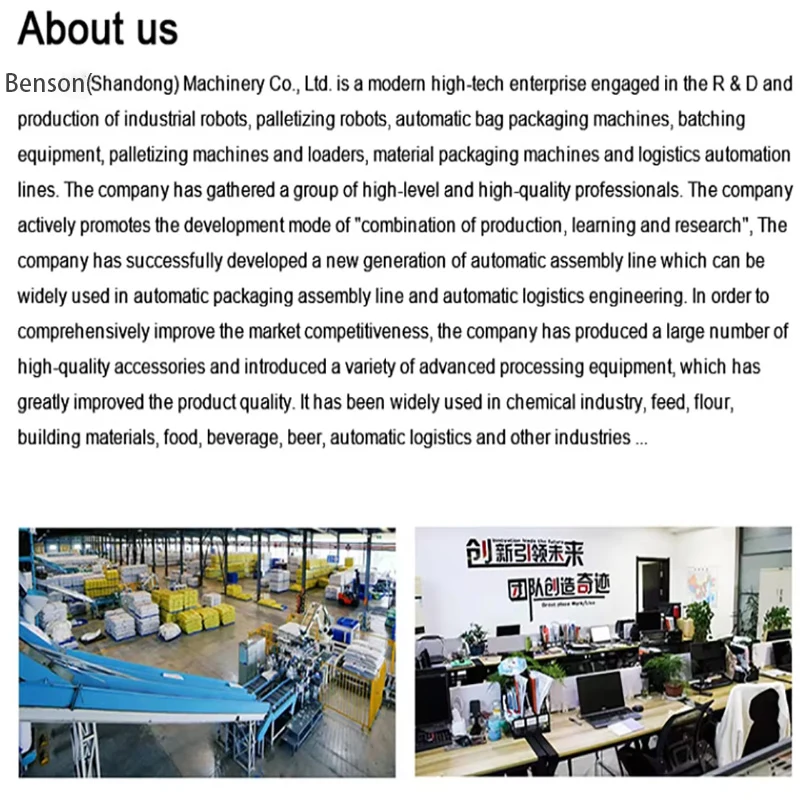

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry