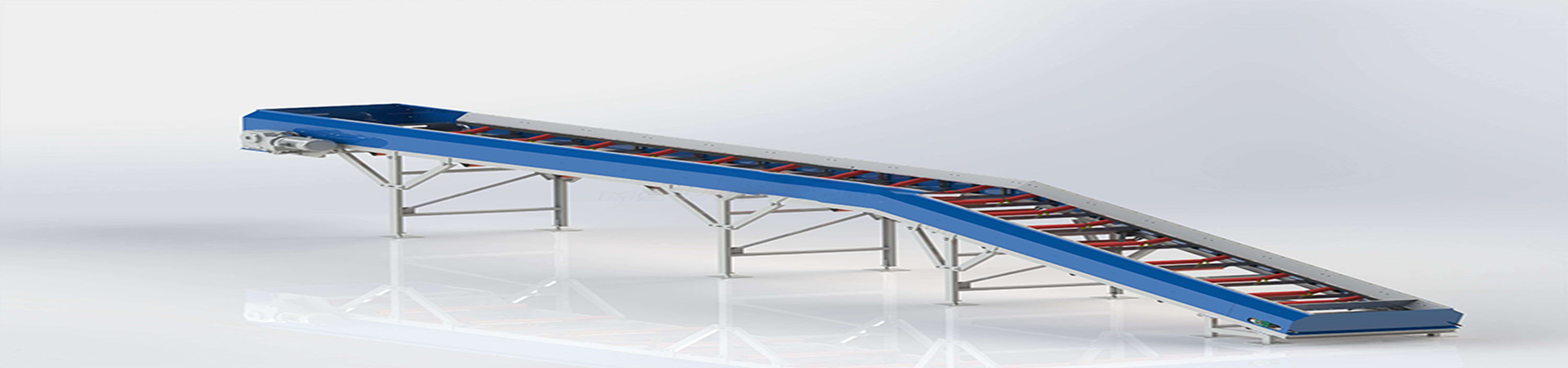

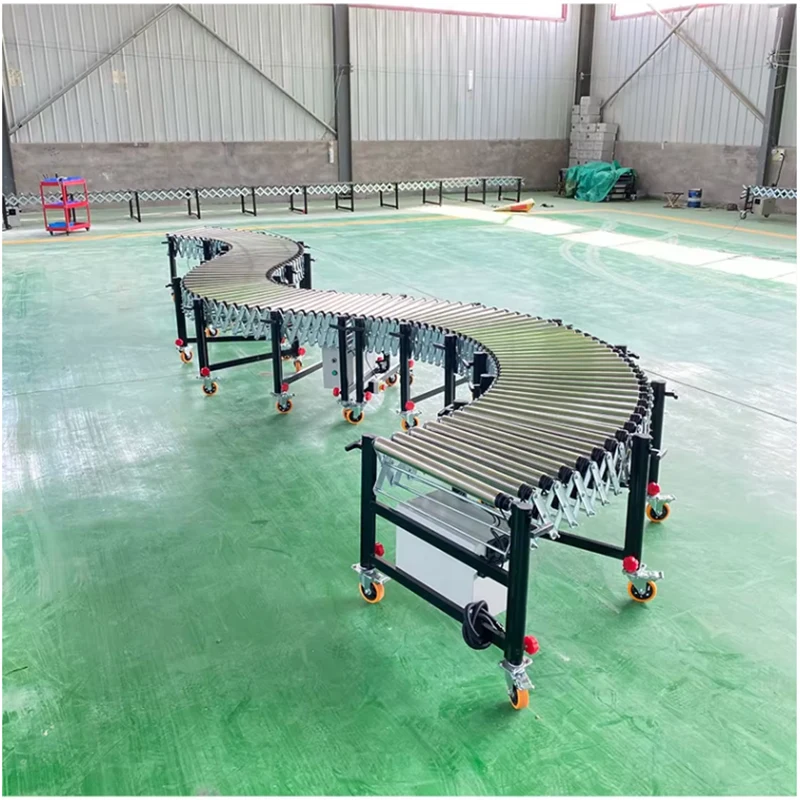

The high-quality fully automatic elastic roller conveyor is an intelligent conveying equipment that integrates advanced technology and innovative design. With its excellent performance and stable quality, it is widely used in logistics warehousing, e-commerce sorting, food processing, electronic manufacturing and other industries. It uses elastic rollers as core components and combines fully automatic control systems.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Free replacement parts

Free replacement parts

Get free replacement parts service and online technical support for 1 year after purchase. Additional shipping fees may apply. Additional shipping fees may apply.

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

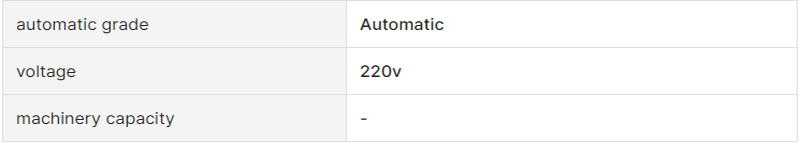

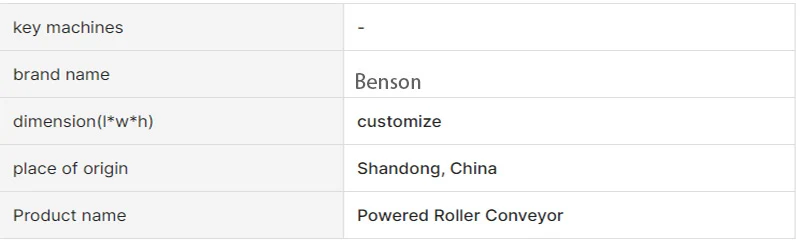

Industry-specific attributes

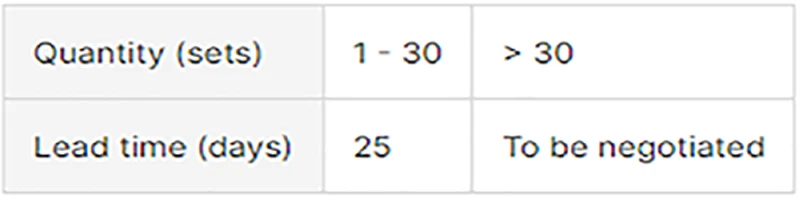

Lead time

Core advantages of high-quality fully automatic elastic roller conveyor for fertilizer

Highly elastic conveying design: It uses elastic rollers made of special materials, which have excellent buffering performance and can adapt to materials of different shapes, weights and surface materials. Whether it is fragile electronic products or irregular packaging items, they can be properly protected during the conveying process to reduce damage caused by collision.

Fully automatic intelligent control: Equipped with advanced PLC control system and sensor technology, it can realize functions such as automatic adjustment of conveying speed, automatic sorting of materials, and automatic alarm of abnormal conditions. Users can easily set conveying parameters through the human-computer interaction interface, flexibly adjust the operation mode according to actual production needs, and greatly improve the level of production automation.

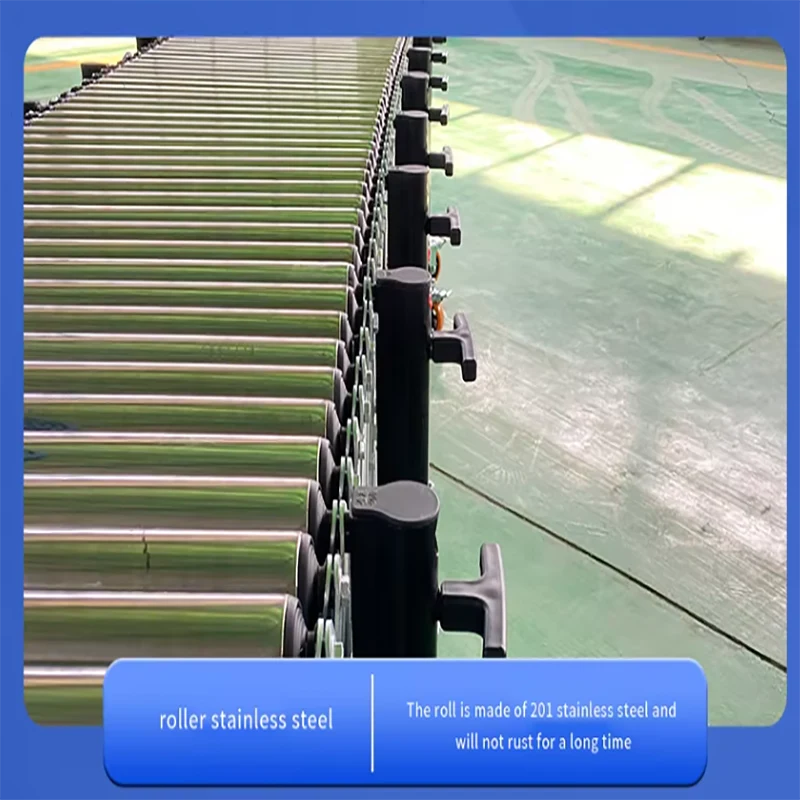

High precision and stability: The overall structure of the equipment has been precisely designed and strictly processed, the roller has high concentricity, runs smoothly without vibration, and has accurate positioning. Even in high-speed operation, it can ensure that the material is accurately conveyed to the specified position, effectively avoid problems such as material offset and jamming, and ensure the continuous and stable operation of the production line.

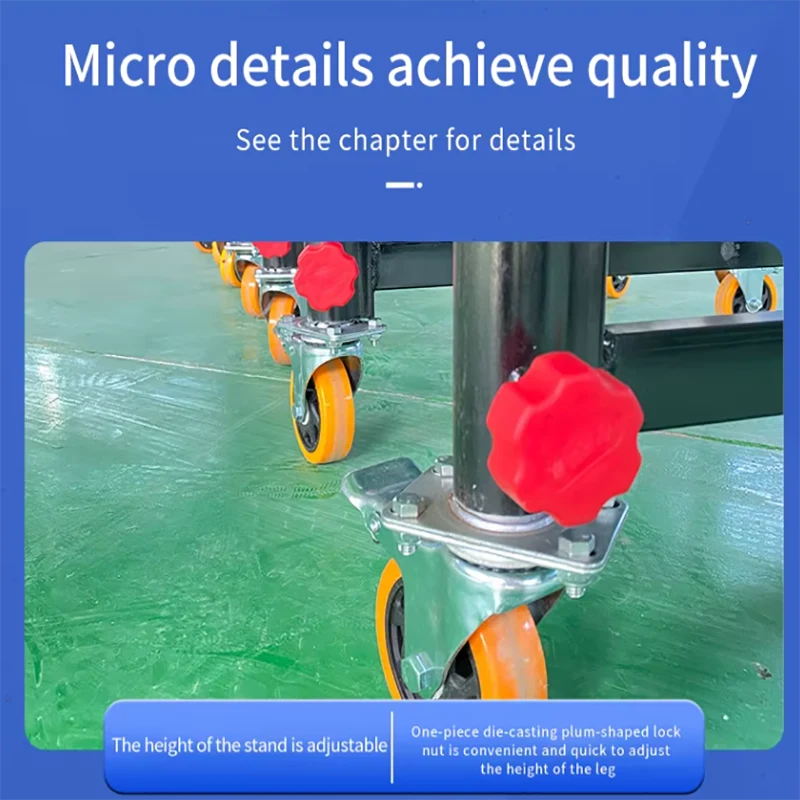

Modular design and flexible installation: The modular assembly method can be quickly customized and installed according to the customer's site space, conveying route and production process requirements. Whether it is straight conveying, turning conveying, or climbing conveying, it can be easily achieved, effectively saving installation time and cost.

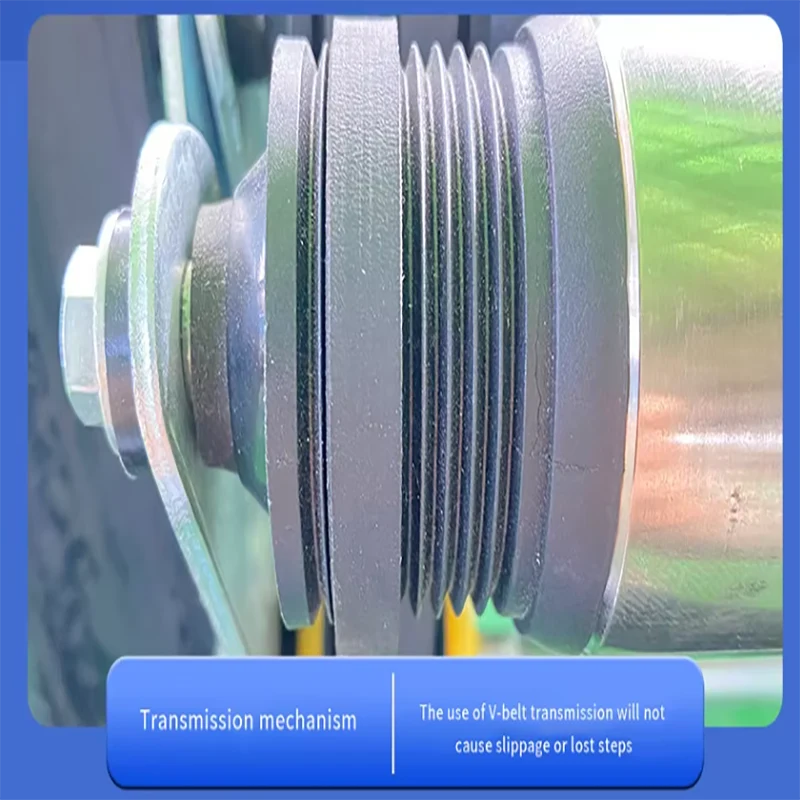

Energy saving and environmental protection: Equipped with high-efficiency energy-saving motors and optimized transmission systems, it reduces energy consumption while ensuring strong power output. In addition, the equipment has low operating noise, meets environmental protection standards, and creates a green production environment for enterprises.

After-sales service

We provide a full range of after-sales service guarantees:

- Installation and commissioning: Professional technical teams will install and commission equipment on site to ensure the normal operation of the equipment, and provide free training for operators.

- Regular maintenance: Provide regular equipment inspection and maintenance services to promptly discover and solve potential problems and extend the service life of the equipment.

- Spare parts supply: Adequate original spare parts inventory to ensure that parts can be replaced in time during equipment maintenance to reduce downtime.

Products Description

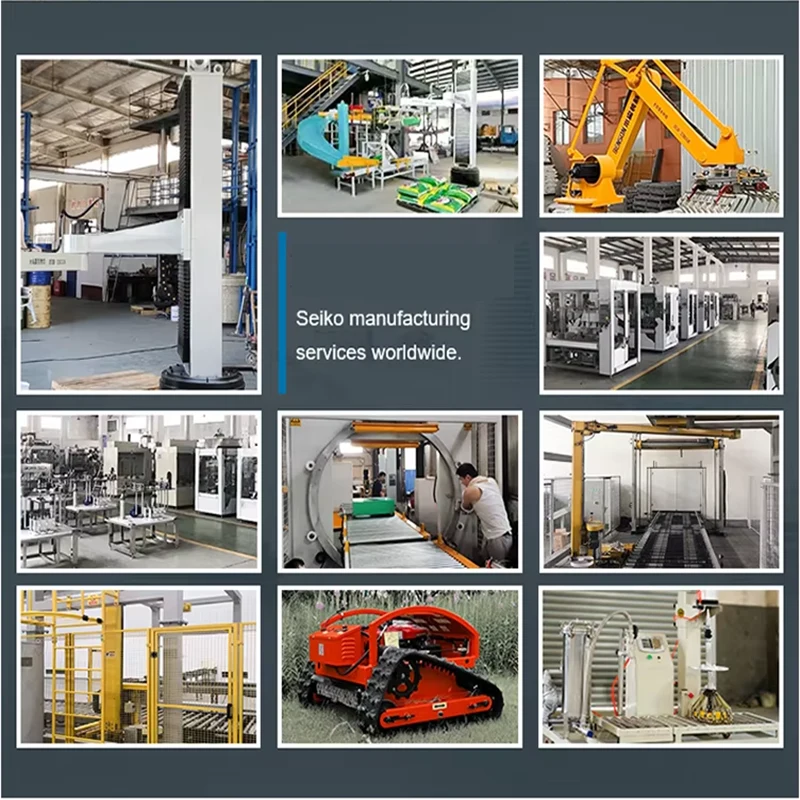

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

FAQ

Product Inquiry