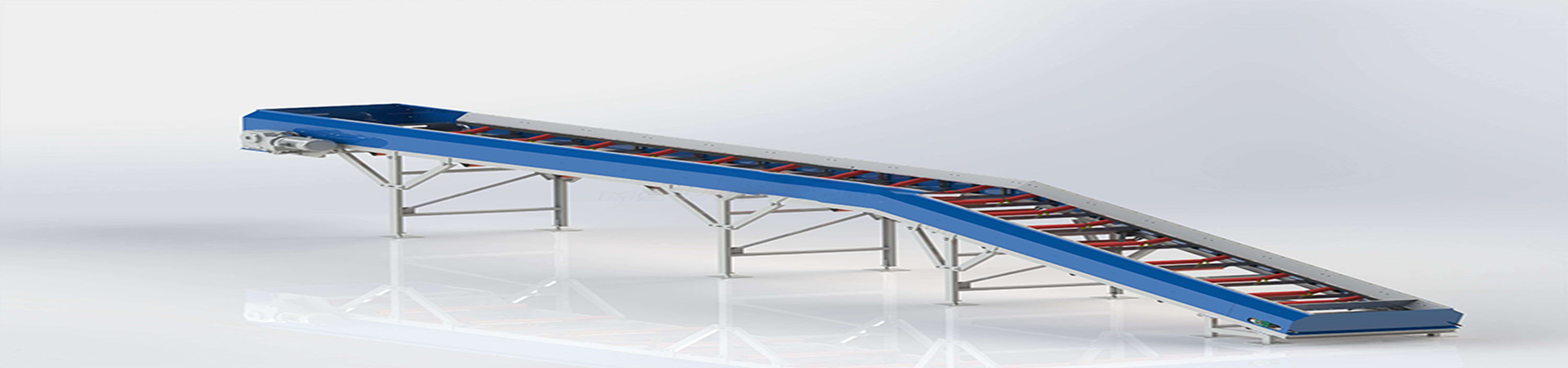

High-quality fully automatic tubular screw conveyor: intelligent and efficient material conveying solution

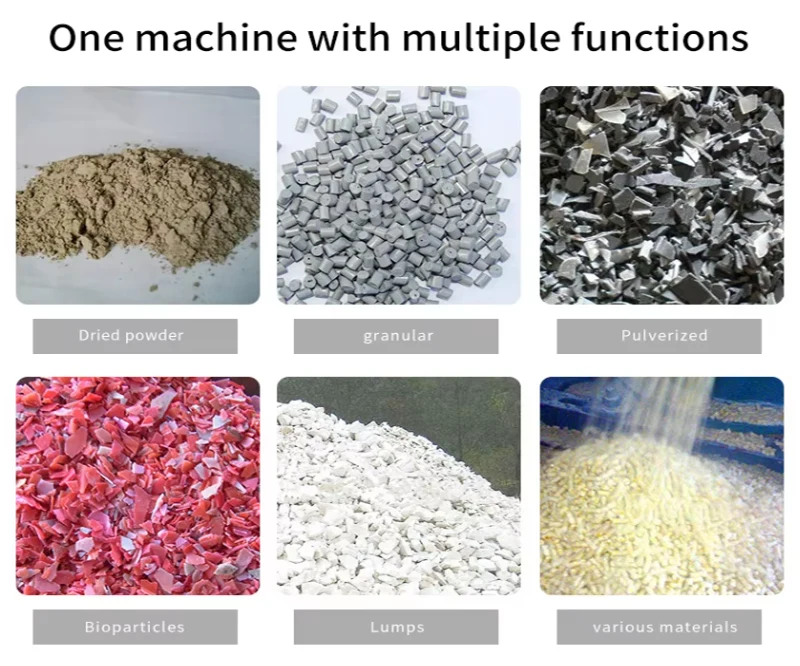

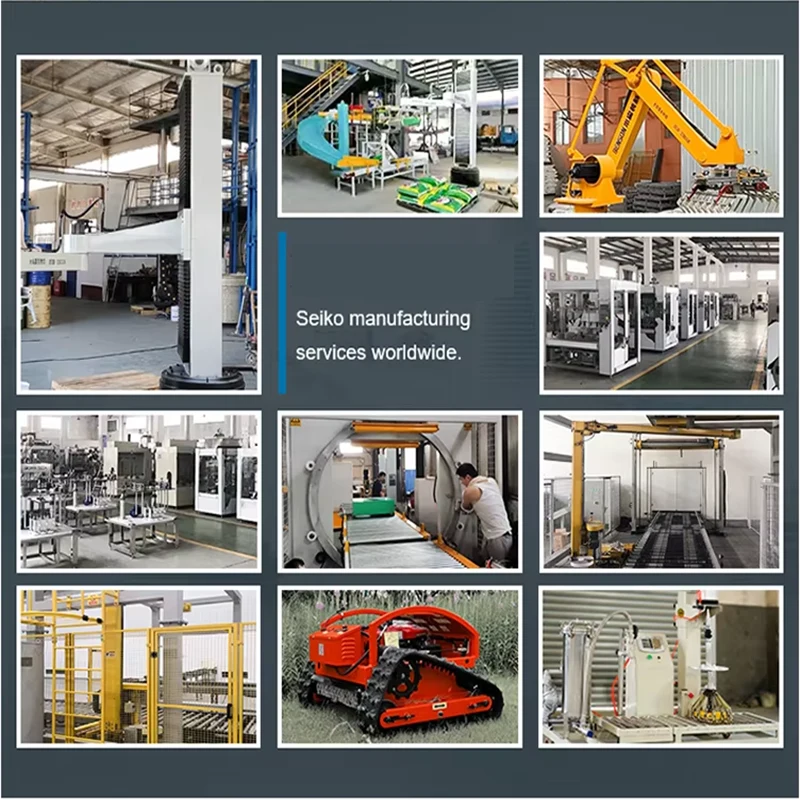

High-quality fully automatic tubular screw conveyor has become an ideal choice for continuous conveying of powdered, granular and small block materials in industrial production with its innovative design and intelligent technology.It is widely used in chemical, food, building materials, environmental protection and other industries, empowering enterprise production with its high efficiency,

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

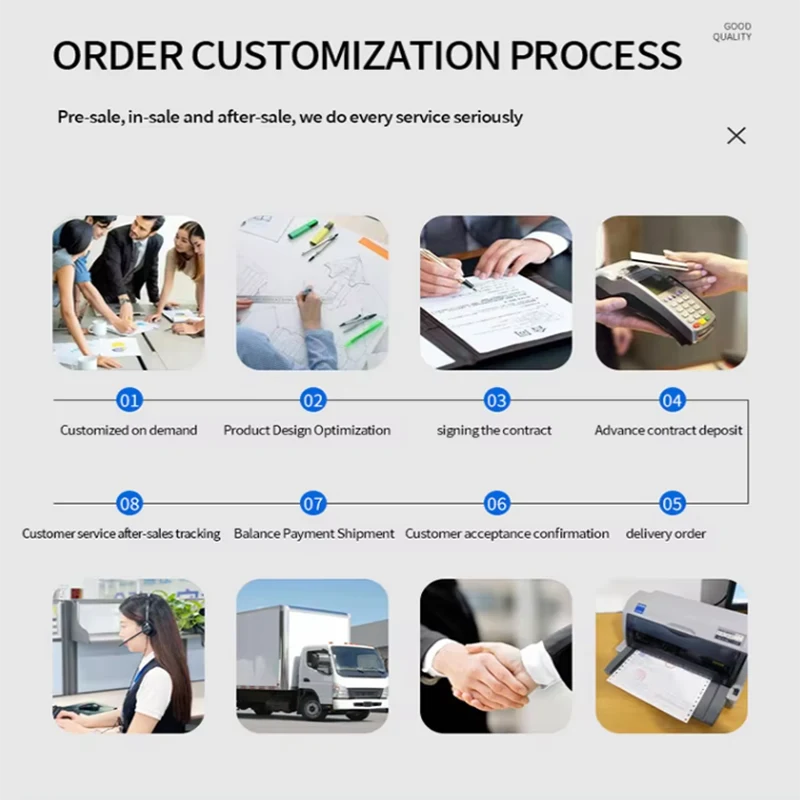

Service

Free replacement parts service

Get free replacement parts service and online technical support for 1 year after purchase. Additional shipping fees may apply. Additional shipping fees may apply.

Excellent structural design of high-quality fully automatic tubular screw conveyor

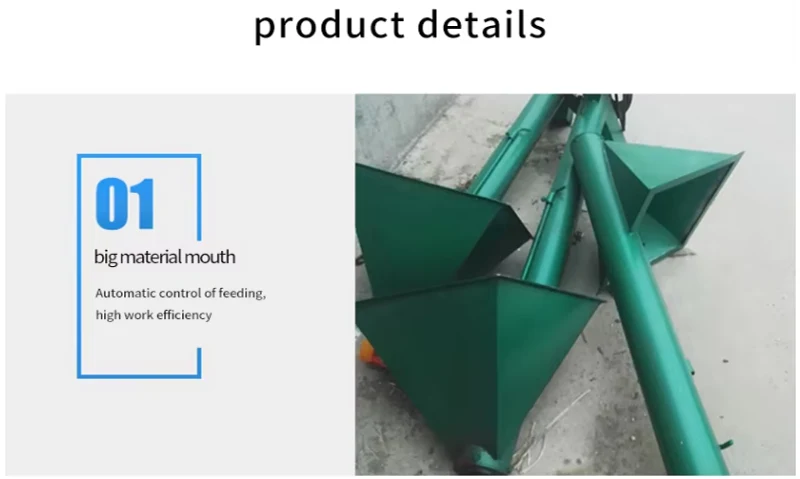

- Fully enclosed seamless pipe: The seamless tubular shell is made of high-strength carbon steel or food-grade stainless steel, which has strong sealing performance and can effectively prevent material spillage and dust flying, ensuring a clean and safe production environment. At the same time, it prevents materials from being damp, oxidized or contaminated during transportation. It is especially suitable for environmentally sensitive materials such as fine chemical raw materials and food additives.

- Precision spiral assembly: The spiral shaft is treated with special technology and has high hardness and wear resistance; the spiral blades are customized according to the characteristics of the material, and adopt variable pitch or equal pitch design to ensure uniform material transportation and avoid blockage and accumulation. For sticky or easy-to-agglomerate materials, belt spiral or toothed spiral blades can also be configured to enhance the material pushing ability.

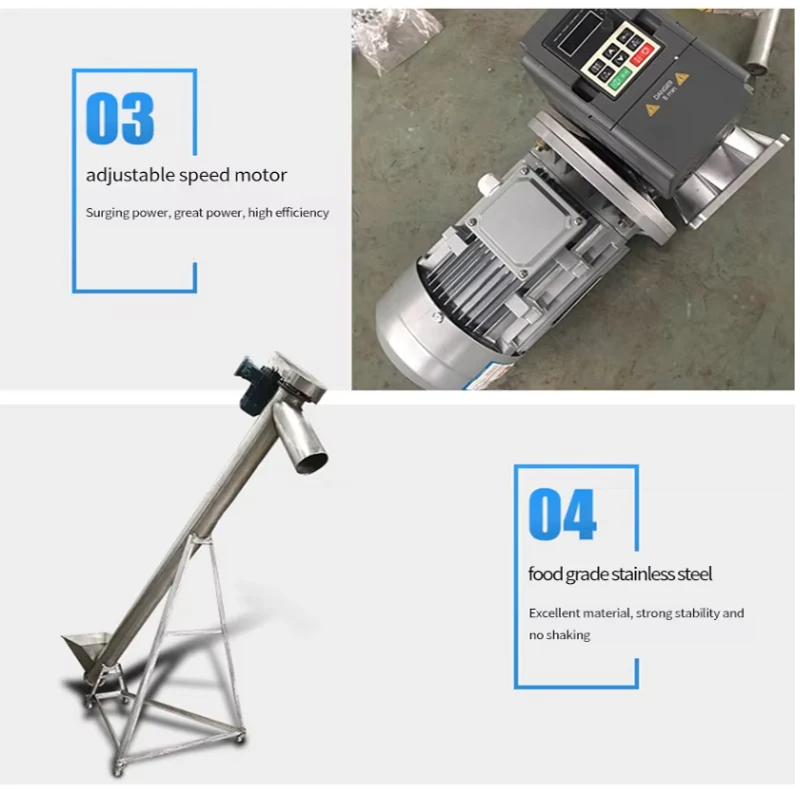

- Intelligent drive system: Equipped with servo motors and high-precision reducers, combined with PLC intelligent control systems, precise adjustment of conveying speed (0-100% stepless speed change) is achieved. Support remote control and Internet of Things functions, and the equipment operation status and parameters can be monitored in real time through mobile phone APP or central control system to achieve unattended automatic operation.

Core performance advantages of high-quality fully automatic tubular screw conveyors

- Efficient and stable conveying: Compared with traditional open conveying equipment, the closed tubular structure reduces the contact between materials and the outside world, reduces friction loss, and improves conveying efficiency by more than 35%. Continuous and stable conveying capacity ensures that the production line can run uninterruptedly for 24 hours to meet the needs of large-scale production.

- Intelligent fault warning: Built-in multiple sensors (such as temperature sensors, blockage sensors, overload sensors) monitor equipment operation data in real time. When an abnormality occurs, the system automatically alarms and triggers emergency shutdown protection, and pushes fault information through SMS or APP, which is convenient for maintenance personnel to quickly locate the problem and reduce downtime.

- Low maintenance cost: The whole machine has a compact structure, and key components are made of wear-resistant and corrosion-resistant materials with a service life of up to 8-10 years. Daily maintenance only requires regular lubrication of bearings and checking the status of seals. The replacement of wearing parts is convenient, which greatly reduces the operation and maintenance costs of enterprises.

- Green, environmentally friendly and energy-saving: Fully sealed conveying effectively reduces dust pollution and meets national environmental protection standards; the energy-saving drive system reduces energy consumption, saving more than 20% of electricity compared with similar products, helping enterprises achieve green and low-carbon production.

Multiple application fields of high-quality fully automatic tubular screw conveyors

- Chemical industry: suitable for conveying powdered or granular chemical raw materials such as soda ash, fertilizers, pigments, etc., to avoid material volatilization and cross-contamination, and ensure production safety and product quality.

- Food and medicine: Food-grade stainless steel material and sanitary design, in line with GMP standards, can safely convey materials such as flour, powdered sugar, and pharmaceutical particles to ensure a clean and pollution-free production process.

- Building materials and metallurgy: In the transportation of materials such as cement, coal powder, and mineral powder, it relies on its wear-resistant and impact-resistant characteristics to meet the continuous transportation needs of high-hardness and high-wear materials and improve production efficiency.

- Environmental protection treatment: used for the closed transportation of solid waste materials such as sludge and garbage incineration fly ash to prevent secondary pollution, and plays a key role in environmental protection projects such as garbage disposal and sewage treatment.

Products Description

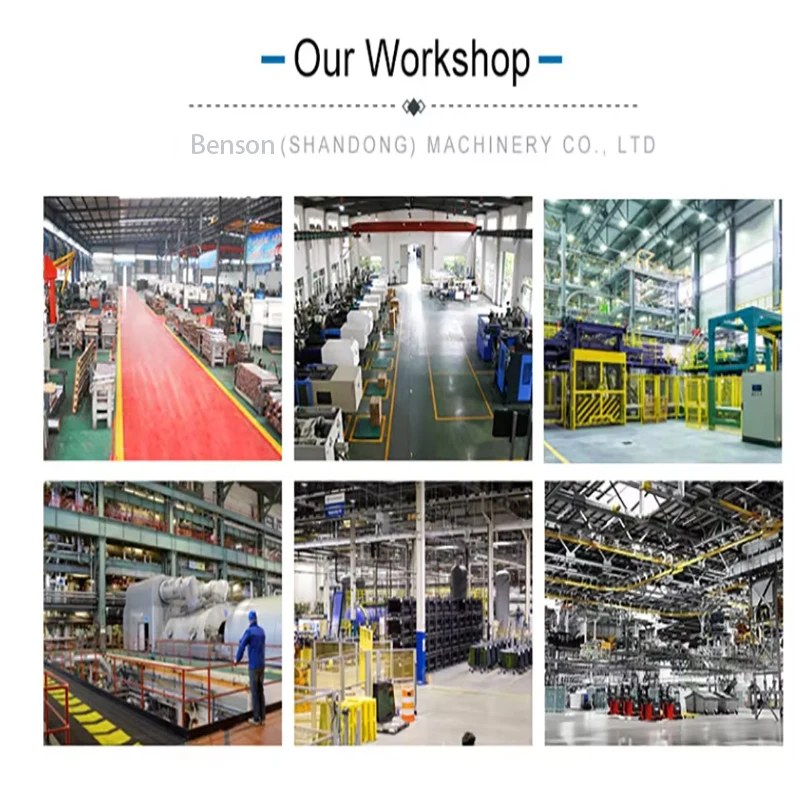

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry