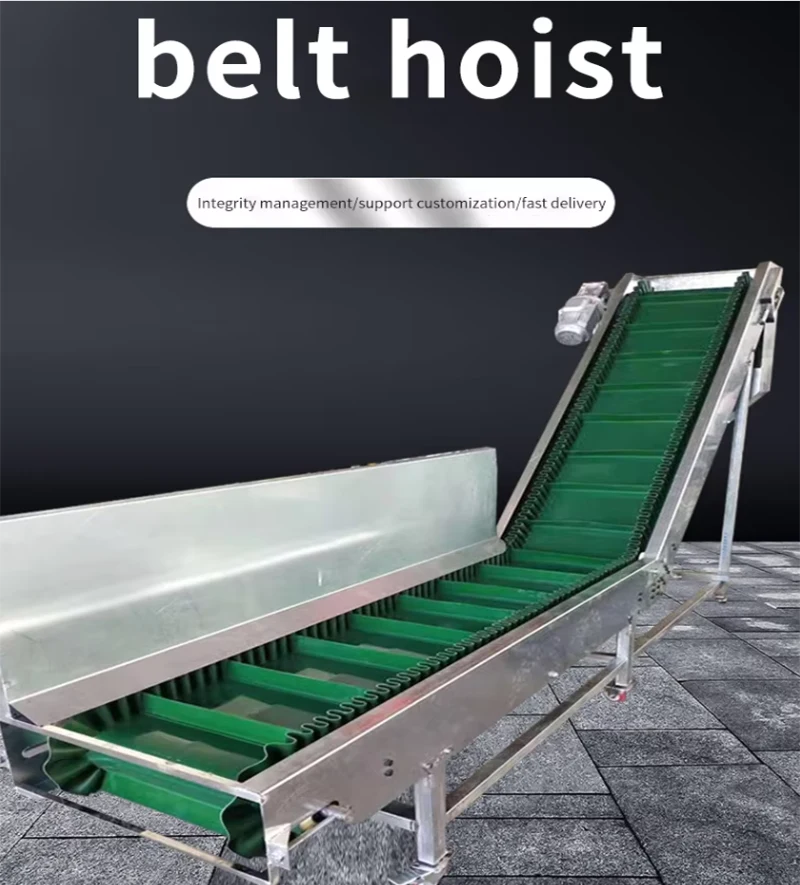

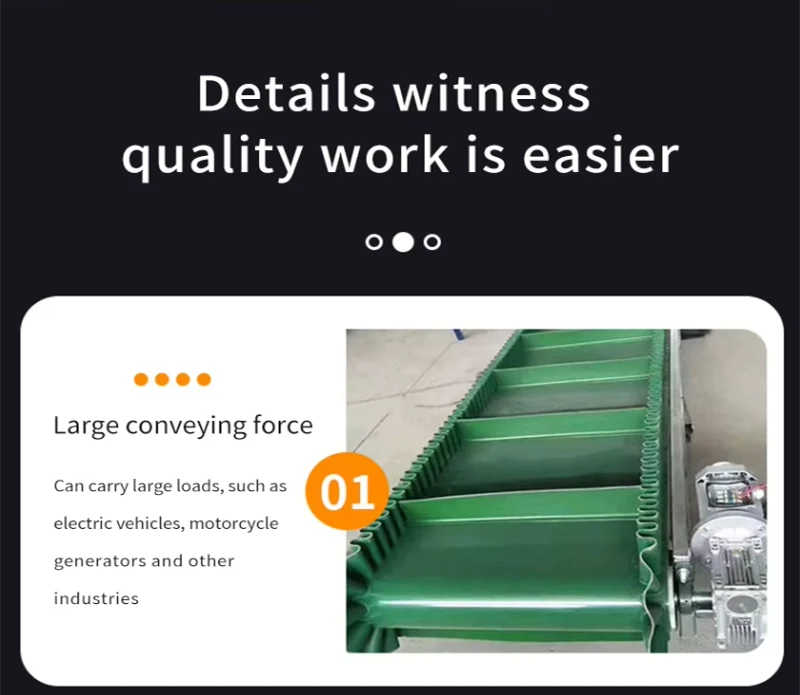

The new skirt conveyor adopts a high-strength skirt structure. The skirts are closely arranged to form a continuous conveying surface, which can effectively prevent materials from scattering and sliding during the conveying process. Even irregular materials such as powder, granular, and block, or special materials with a certain viscosity, can be stably conveyed. With a large inclination design, it can easily complete the vertical and inclined material lifting.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

Get free replacement parts service and online technical support for 1 year after purchase. Additional shipping fees may apply. Additional shipping fees may apply.

New skirt conveyor with innovative technology

- Intelligent drive system: equipped with variable frequency speed regulation technology, users can flexibly adjust the conveying speed according to actual production needs to ensure that the conveying rhythm is perfectly matched with the production line. At the same time, the system has overload protection and fault warning functions. Once an abnormality occurs, it can automatically stop and feedback fault information to reduce the risk of equipment damage and ensure production safety.

- Wear-resistant and corrosion-resistant materials: The skirt is made of high-strength alloy material or food-grade stainless steel (optional), and the surface is treated with special processes to significantly enhance the corrosion resistance. Whether in harsh environments such as humidity, acid and alkali, or in high-sanitation industries such as food and medicine, it can operate stably for a long time.

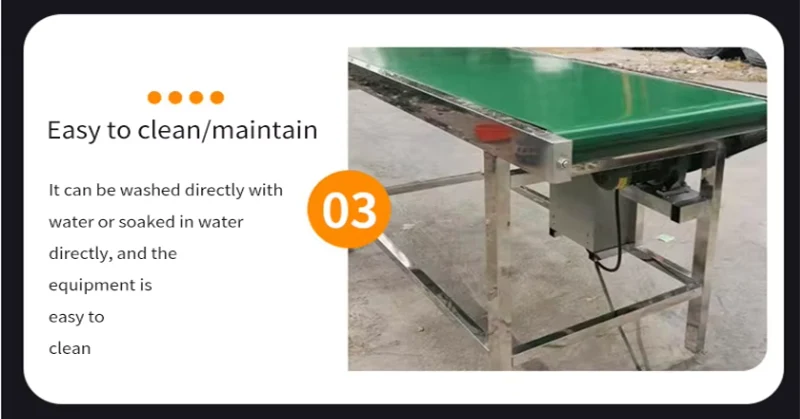

Flexible customized design of new skirt conveyor

Support highly customized services, and can customize the length, width, conveying angle, drive mode and other parameters of the conveyor according to the user's plant layout, material characteristics, and conveying volume requirements. Whether it is local transportation of small production lines or long-distance and large-volume transportation of large logistics centers, it can provide precise adaptation solutions to achieve seamless connection with existing production systems.

Wide range of applications

- Food and beverage industry: used for packaging and conveying finished products such as biscuits, candies, and bottled beverages. Food-grade materials ensure hygiene and safety and avoid material contamination.

- Chemical industry: competent for conveying powdered chemical raw materials and granular chemicals. The anti-corrosion performance effectively resists chemical erosion and ensures stable operation of the equipment.

- Mining and metallurgical industry: cope with the continuous conveying of heavy and highly abrasive materials such as ores and mineral powders. The high-strength structure ensures long-term reliable operation under heavy load conditions.

- Logistics and warehousing industry: realize the sorting, stacking and conveying of goods, and cooperate with automation equipment to improve the intelligence level and operation efficiency of warehousing and logistics.

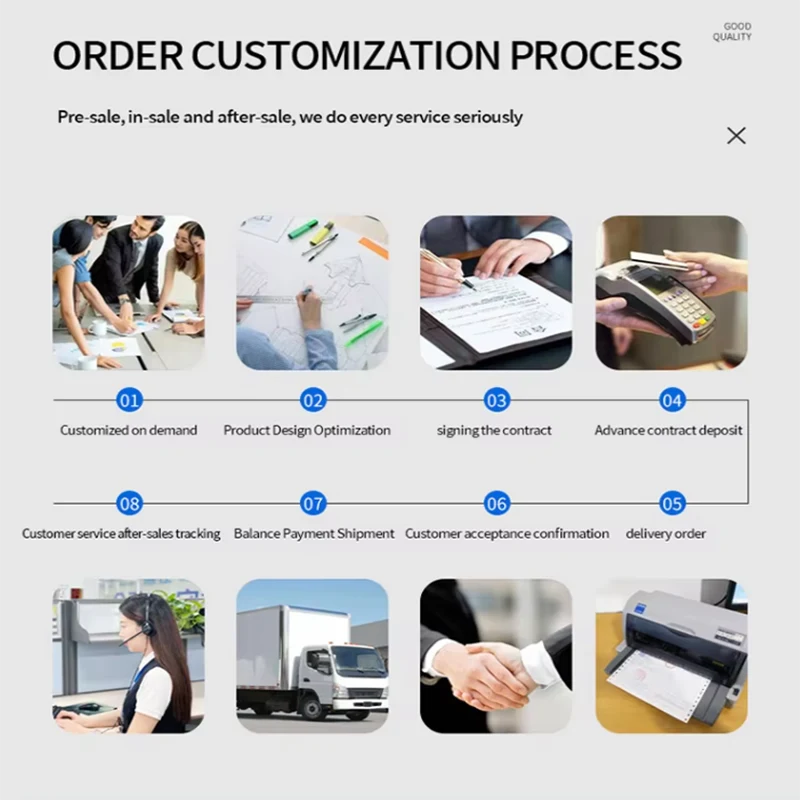

Intimate service system

We provide one-stop service from equipment selection, solution design, installation and commissioning to after-sales maintenance. The professional technical team responds to customer needs at any time, and regularly provides equipment inspection and maintenance guidance to ensure that the new skirt conveyor always maintains the best operating state. With many years of industry experience and high-quality service, it has won unanimous praise from customers.

Choosing our new skirt conveyor means choosing efficiency, stability and peace of mind! Contact us now to get exclusive conveying solutions and start a new journey of intelligent production!

Products Description

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry