The high-precision high-level palletizer adopts advanced servo drive and intelligent control system, with a positioning accuracy of ±5mm. It can achieve stable high-level palletizing at a height of 3 - 5 meters, efficiently handle 25 - 50kg bagged and boxed materials, with a processing capacity of 300 - 600 bags per hour, and support 24-hour continuous operation. Through intelligent path planning and vision correction technology, the equipment ensures neat and standardized stacking,

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

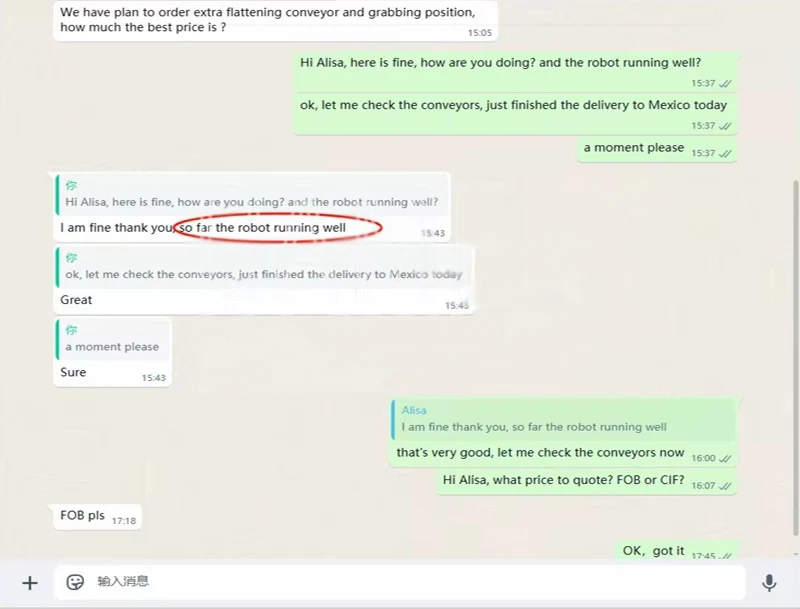

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

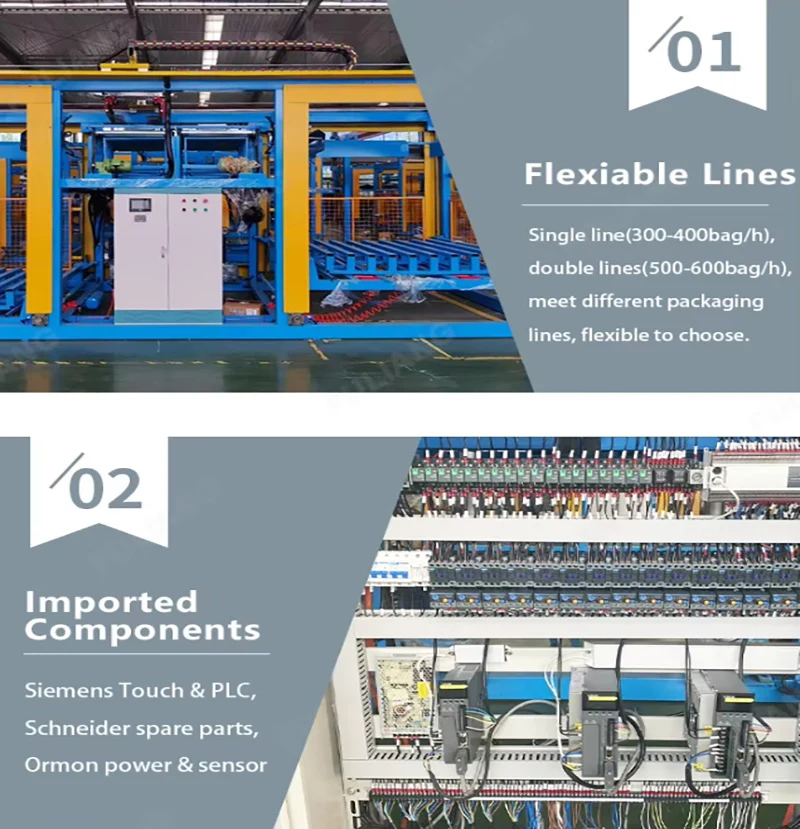

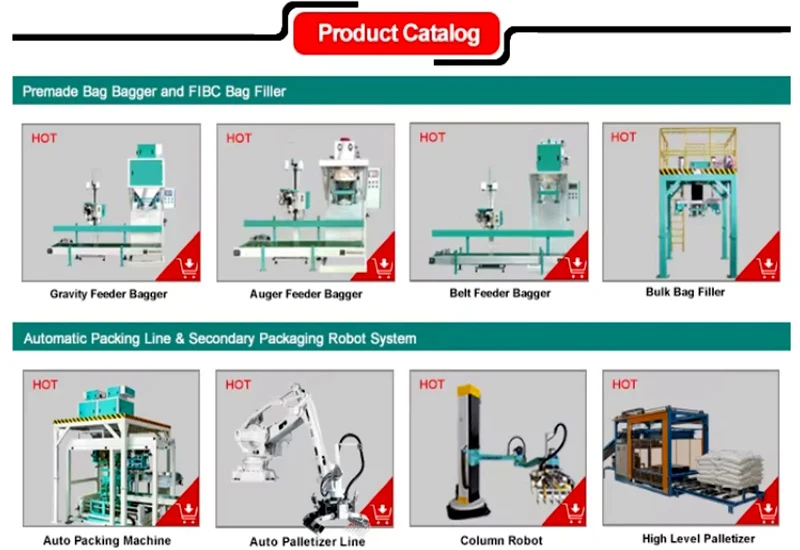

Products Description

High-precision high-level palletizer

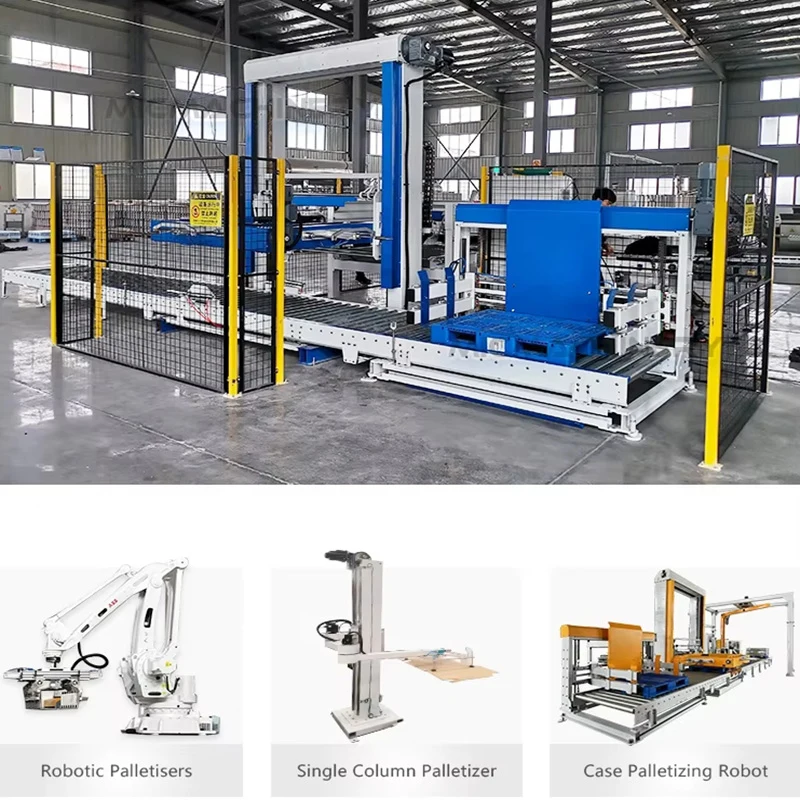

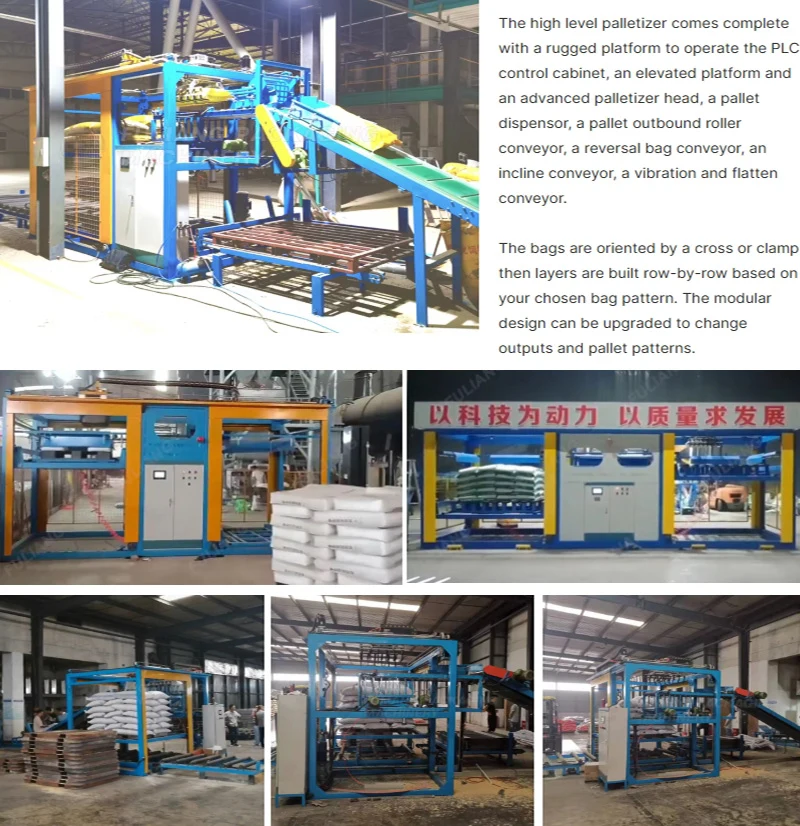

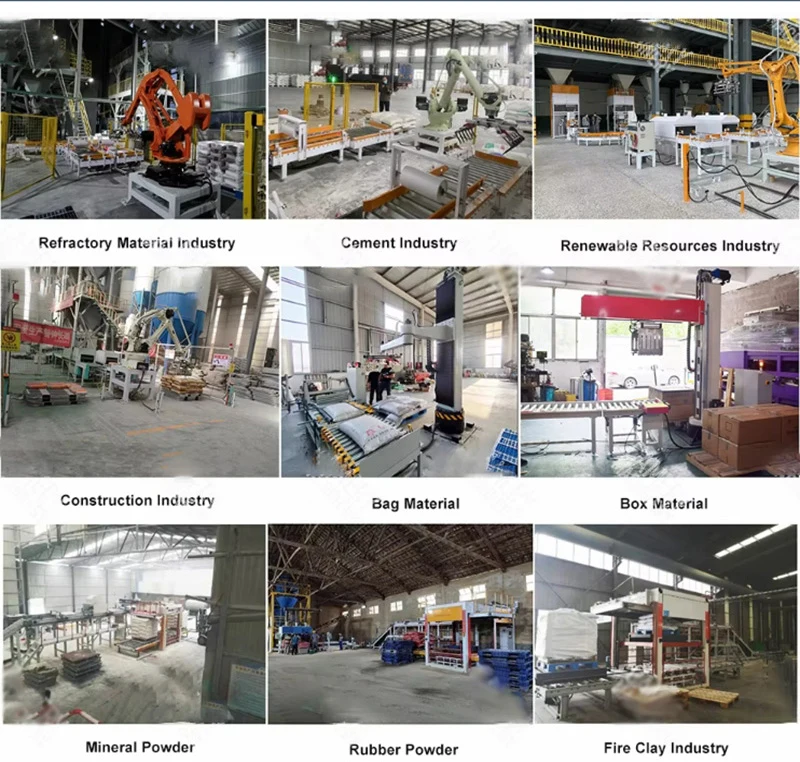

This high-precision high-level palletizer integrates advanced servo drive and intelligent control systems. With an ultra-high positioning accuracy of ±5mm, it can accurately complete stable palletizing operations at a height of 3 - 5 meters. It can efficiently handle bagged and boxed materials weighing 25 - 50kg, with a processing capacity of 300 - 600 bags per hour, and supports 7×24-hour continuous operation. Through intelligent path planning algorithms and vision correction technology, it ensures that the stacks are neatly arranged and effectively reduces material losses. High-precision high-level palletizer, Its low-power consumption design and modular structure not only significantly reduce operating costs and improve the utilization rate of storage space, but also can quickly adapt to different specifications of products in various industries such as rice, cement, and feed, enabling enterprises to achieve efficient and stable automated production upgrades.

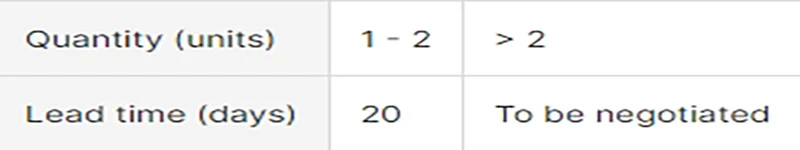

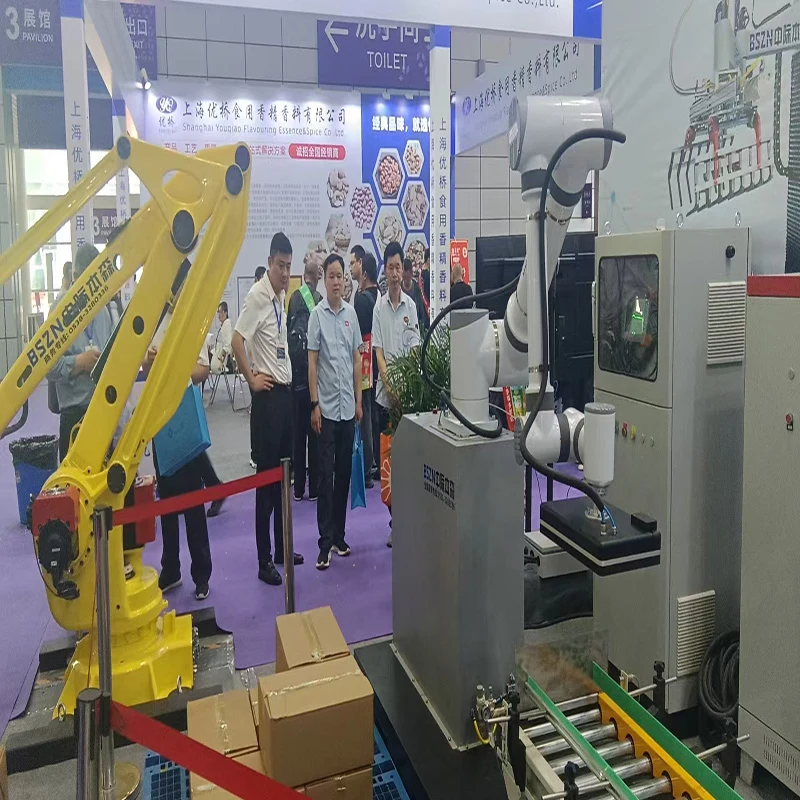

Benson Robotic palletizer cells offer wide layout flexibility and are engineered from experience.Automatic palletizing equipment is an investment that benefits countless industries. The increased efficiency, safety, and productivity of robotic palletizing helps businesses of every size and sector improve their supply chain processes and reach greater heights as a company.

Working process of high-precision high-level palletizer:

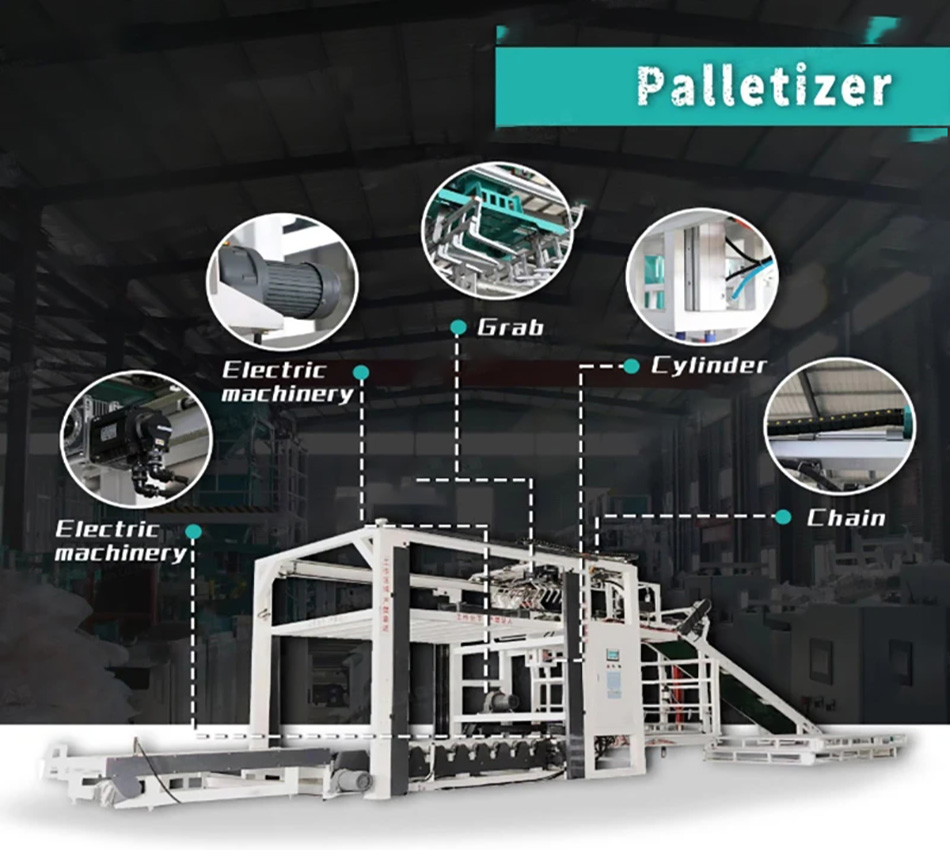

1. Material Conveying and PretreatmentMaterials are conveyed to the front end of the palletizer via belt conveyors or chain plate conveyors. The shaping machine extrudes or vibrates and levels bagged and boxed materials to ensure that the materials have a regular shape. At the same time, the weight detection equipment weighs and inspects the materials, and rejects unqualified products.

2. Visual Recognition and Positioning

high-precision high-level palletizervisual inspection system installed above or on the side of the equipment scans the materials, identifies the size, position, and orientation information of the materials, and transmits the data to the PLC control system. The control system calculates the precise position and posture for material grasping according to the preset palletizing program.

3. Mechanical Grasping and HandlingThe servo - driven robotic arm accurately moves above the materials according to the instructions of the control system, and grabs the materials through gripping devices such as vacuum suction cups and grippers. The robotic arm transports the materials to the designated pallet position along the planned path.

4. Palletizing OperationThe high-precision high-level palletizer robotic arm accurately places the materials on the pallet. After completing one layer of palletizing, the pallet conveying system automatically descends a distance equal to the height of one material to prepare for the next layer of palletizing. Through intelligent path - planning algorithms, various stacking methods such as cross - stacking and tic - tac - toe stacking can be achieved.

5. Pallet Replacement and OutputWhen a pallet is completed with palletizing, the pallet conveying system transports the full - stacked pallet to the discharge port, and at the same time, transports the empty pallet to the palletizing station. The fully - stacked materials are transported away by forklifts or AGV cars and enter the subsequent warehousing or transportation links.

6. System Monitoring and FeedbackDuring the entire working process, the PLC control system monitors the running status of the equipment in real - time. The sensors detect parameters such as the position of the robotic arm, gripping force, and pallet height in real - time and feedback the data to the control system to ensure the high - precision and stability of the palletizing process. Once an abnormality occurs, the system immediately alarms and stops, waiting for manual handling. The

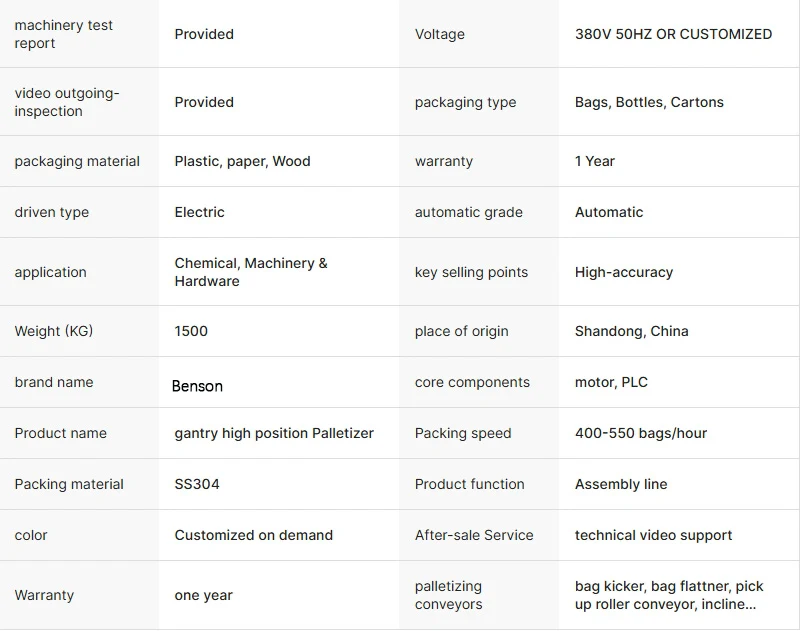

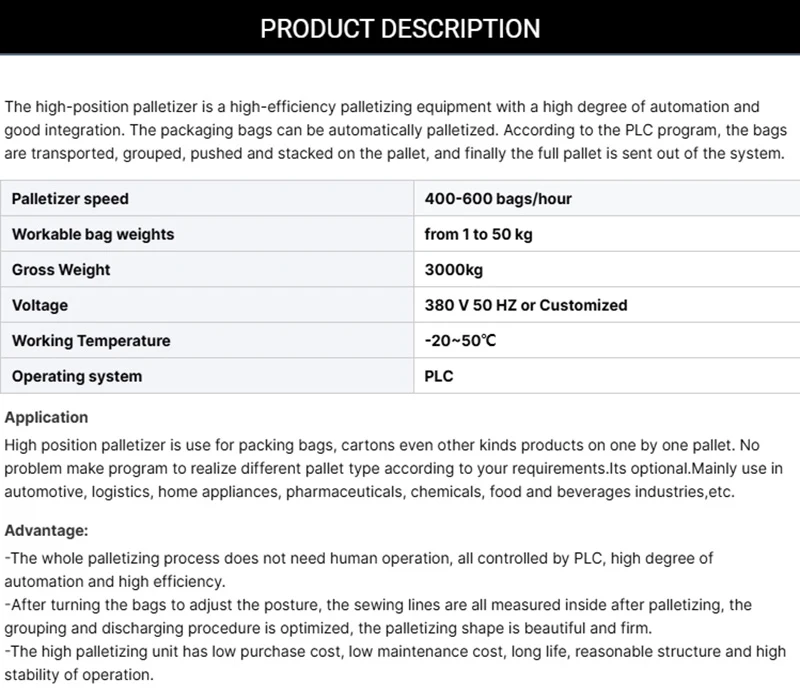

Specification

Main advantages of high-precision high-level palletizer:

1. Ultra-high precision and stabilityAccurate positioning: high-precision high-level palletizerThe servo drive system and intelligent control technology are adopted, with a positioning accuracy of ±5mm. This ensures that the materials are neatly aligned layer by layer when stacked at a height of 3 - 5 meters, avoiding collapses or losses caused by errors in traditional machinery. Dynamic deviation correction: Integrating vision detection and path planning algorithms, it can identify the position and posture of materials in real time, dynamically adjust the grasping and placement paths, adapt to the size fluctuations of materials, and guarantee the consistency of stacking.

3. Intelligent flexibility and multi-scenario adaptabilityModular and flexible design: Using a standardized modular structure, the grasping devices (such as vacuum suction cups, grippers) and palletizing programs can be quickly switched to adapt to different specifications of products (bagged, boxed, barreled) in various industries such as rice, cement, feed, and chemicals. Intelligent path planning: It supports multiple stacking patterns such as five-flower stacks, cross-shaped stacks, and multi-layer staggered stacks. Automatic switching can be achieved through preset programs to meet the requirements of different industries for stacking strength and aesthetics.

4. Low energy consumption and cost-effective maintenanceEnergy-saving design: Compared with traditional pneumatic/hydraulic systems, the energy consumption of servo motor drives is reduced by 40% - 60%. Long-term operation can significantly reduce electricity costs. Convenient maintenance: The modular structure reduces the wear and tear of components. Key components (such as robotic arms, sensors) support online monitoring and quick replacement. The maintenance cost is reduced by more than 50%, and the downtime is greatly shortened.

5. Safe, reliable, and intelligent managementhigh-precision high-level palletizerFull-process monitoring: The PLC control system monitors the running status of the equipment in real time. Sensors feedback parameters such as the position of the robotic arm, grasping force, and pallet height in real time. In case of abnormalities, it will automatically alarm and stop to avoid equipment failures and material damage. Unmanned operation: It reduces human contact with high-frequency repetitive labor, reduces the risk of work-related injuries. At the same time, it can be connected to the factory MES system through a data interface to achieve digital management of the production process.

6. Industry adaptability and return on investmentWide applicability: It is compatible with 25 - 50kg materials, covering multiple fields such as food, building materials, chemicals, and logistics. It is especially suitable for scenarios with high standardization and high palletizing intensity (such as loading bagged cement, storing boxed feed).Quick return on investment: Compared with traditional manual palletizing or low-end equipment, it can reduce labor costs by more than 80% and increase efficiency by 3 - 5 times. Usually, the equipment investment can be recovered within 1 - 2 years.High processing efficiency: It can handle 300 - 600 bags of 25 - 50kg bagged/boxed materials per hour, and supports 7×24-hour continuous operation. This significantly improves the palletizing efficiency at the end of the production line and reduces labor dependence. Advantages of high-position operation: The 3 - 5-meter stacking height effectively utilizes the vertical space of the warehouse, reduces the floor area, and is especially suitable for high-shelf storage scenarios, increasing the space utilization rate by more than 30%.intelligent control system, saving time, labor and manpower, truly realizing automation for enterprises

Customer Sites

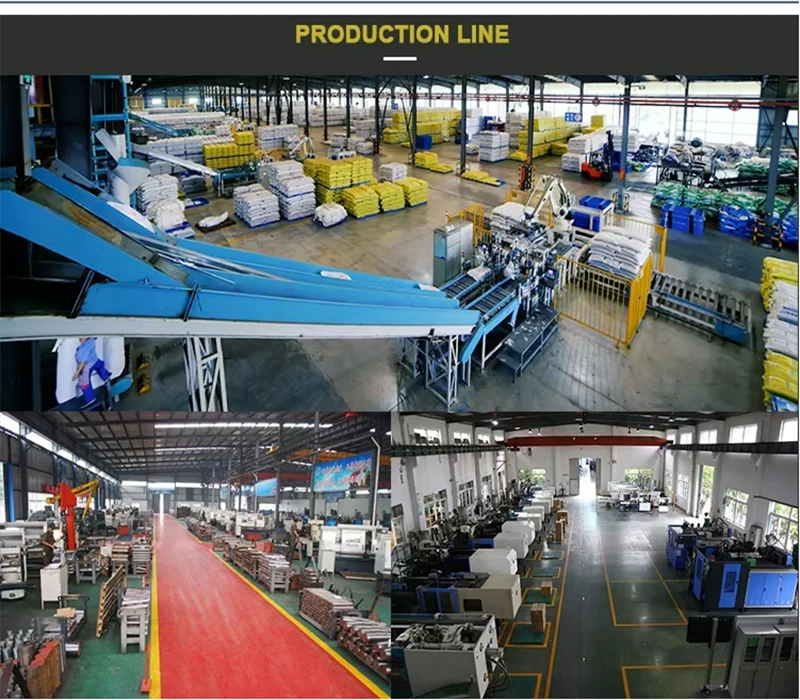

Company Profile

Benson Intelligent Equipment (Shandong) Co., Ltd.was founded in 2013, including self-researching and development, design, production and sales.

Benson machinery is committed to the design, production and sales of automatic packaging machine, intelligent palletizing machine, wrapping machine etc. Our products are widely used in food, chemical industry, building materials, feed, warehousing and other industries.Benson has 10 senior technical engineers, more than 20 production workers and 10 senior sales,exporting countries including United States,Mexico, Australia, Russia. Saudi Arabia, Singapore, South Africa etc., all over the world, provided professional solution with efficient and intelligent products to each customer, got the high recognization and compliment from every serviced domestic and foreign client.

Benson machinery advocates innovation, professional, efficient, pragmatic business philosophy, to achieve mutual benefit and win-win, continue to provide our customers with high-end products and quality service.

Exhibition

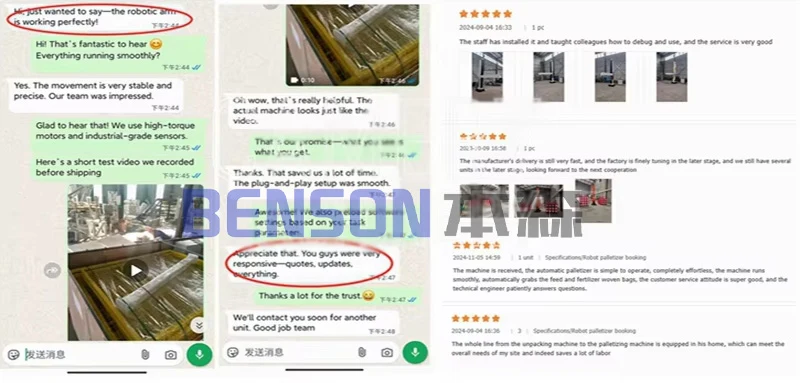

1. Are you factory or trading company?We are the factory, we doing this line for more than 10 years.

2. Can you provide after-sales service for installation?Yes. Before the equipment is shipped, we will install and debug it in the factory to ensure that all components are running stably. After that, the whole set of equipment will be packed in wooden boxes/containers. After receiving the equipment, there is no need for a lot of installation and debugging. At the same time, we will provide corresponding pictures/videos/manuals, and provide telephone consultation online, so that you can ask questions at any time.

If you need to send engineers to the local area to install, debug and train employees, we can also provide you with it. We will provide manuals and detailed videos to help customers install the machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room fees and a daily subsidy of US$150.

3. How long is the warranty on your palletizer robot?We provide a one-year warranty. If there is any problem with the equipment during the warranty period, we will replace it free of charge. If the warranty period expires, we will provide damaged spare parts at cost price. At the same time, our palletizers use brand components such as Schneider and AirTac, which have more stable performance and longer service life. Please rest assured to buy, we are worthy of your trust.

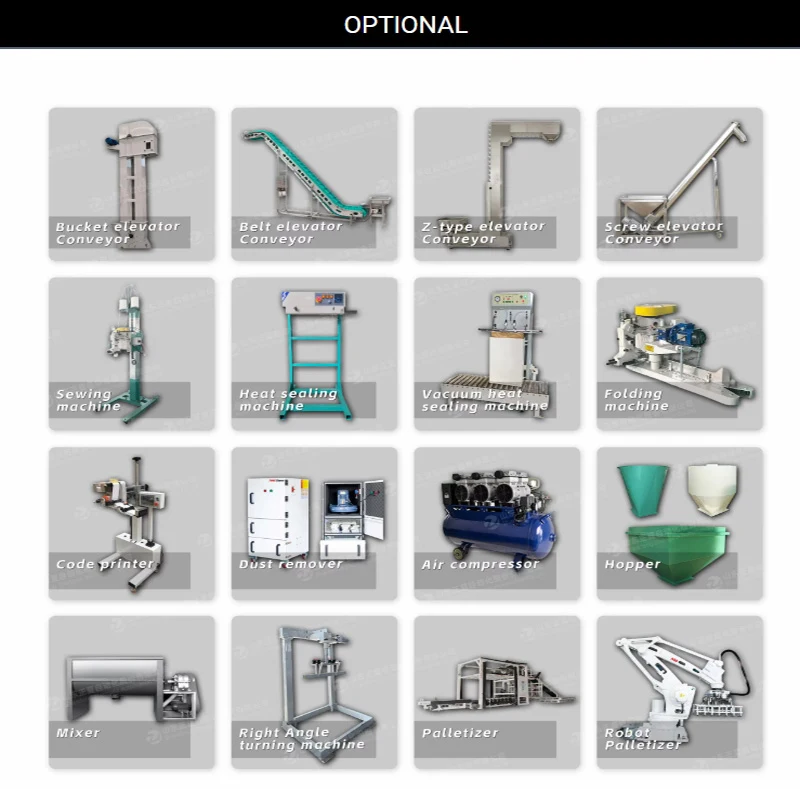

4. Are there any requirements for pallet size and stacking height?It supports a variety of pallet sizes, and the maximum stacking height can reach 1.8 meters to meet different shipping needs.5. Is there a complete solution with a conveyor line?We can provide a complete line: belt conveyor, automatic bag sorting, steering, bag pressing, palletizing, and integrated delivery.

Product Inquiry