The high-precision semi-automatic filling machine for cosmetic powder and fragrance is a device specifically designed for the filling of cosmetic powder and fragrance. This equipment combines manual operation with automated control. After the operator places the empty containers in the designated positions, the equipment can automatically carry out high-precision filling of powder and fragrance. It adopts advanced metering technology and can accurately control the filling volume, being suitable

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

The equipment has a compact structure, is easy to operate, and convenient for maintenance and cleaning, which can meet the needs of cosmetic production enterprises of different sca

Semi-automatic filling machine for high-precision cosmetic powder and fragranceAdvantages

1. High-precision metering: By using advanced metering devices, it can achieve precise control of the filling volume with high filling accuracy, meeting the strict quality requirements of the cosmetics industry for products and reducing raw material waste.

2. Semi-automatic operation: It not only reduces the errors and labor intensity of manual filling but also has certain flexibility. Operators can flexibly adjust the filling parameters according to the actual production situation, making it suitable for small-batch and multi-variety cosmetic production.

3. Wide applicability: It can handle different types of cosmetic powders and fragrances, such as delicate loose powder and fragrances with special particles, and is adaptable to various packaging specifications and container types.

4. Hygiene and safety: The components in contact with cosmetics are all made of materials that meet the hygiene standards of food and cosmetics, are easy to clean, prevent product contamination, and ensure product quality and safety.

5. High cost-effectiveness: Compared with fully automated equipment, semi-automated equipment has a lower investment cost. At the same time, it can improve production efficiency, reduce the production cost per unit product, and enhance the economic benefits of the enterprise.

Semi-automatic filling machine for high-precision cosmetic powder and fragranceApplications

1. Cosmetic production enterprises: It is suitable for various cosmetic manufacturers. Whether large enterprises carry out large-scale production or small enterprises carry out small-batch customized production, this equipment can be used to fill products such as loose powder, setting powder, and scented powder.

2. Fragrance processing enterprises: It can be used in the filling process of fragrance production, such as the filling of perfume raw materials and solid fragrances, meeting the requirements of the fragrance industry for precision and hygiene.

3. Laboratories and research institutions: It can be used as a tool for research and development and small-batch production, helping researchers develop and test new products, precisely controlling the filling volume, and ensuring the accuracy of experimental data.

Semi-automatic filling machine for high-precision cosmetic powder and fragranceFeatures

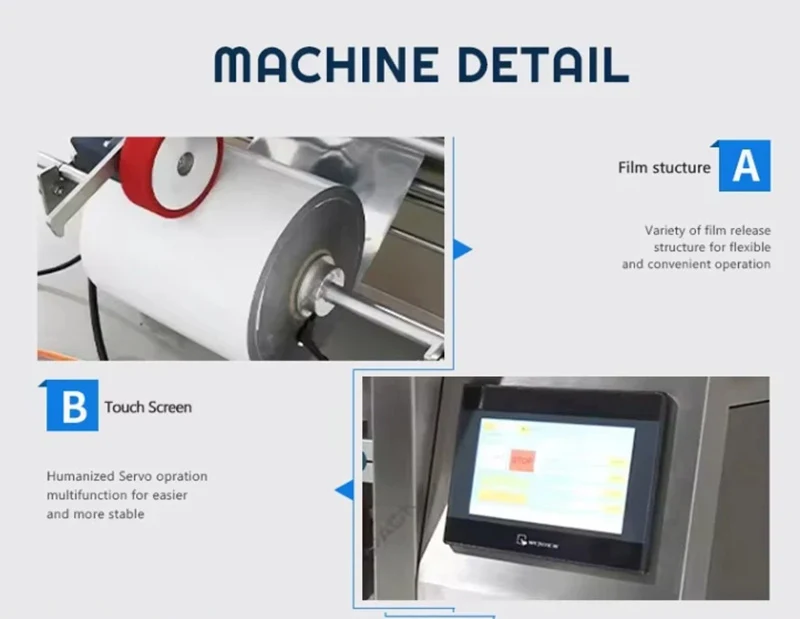

1. Intelligent control: Equipped with an advanced control system, it can achieve precise setting and adjustment of parameters such as the filling volume and filling speed. The operation interface is simple and easy to understand, making it convenient for operators to quickly master.

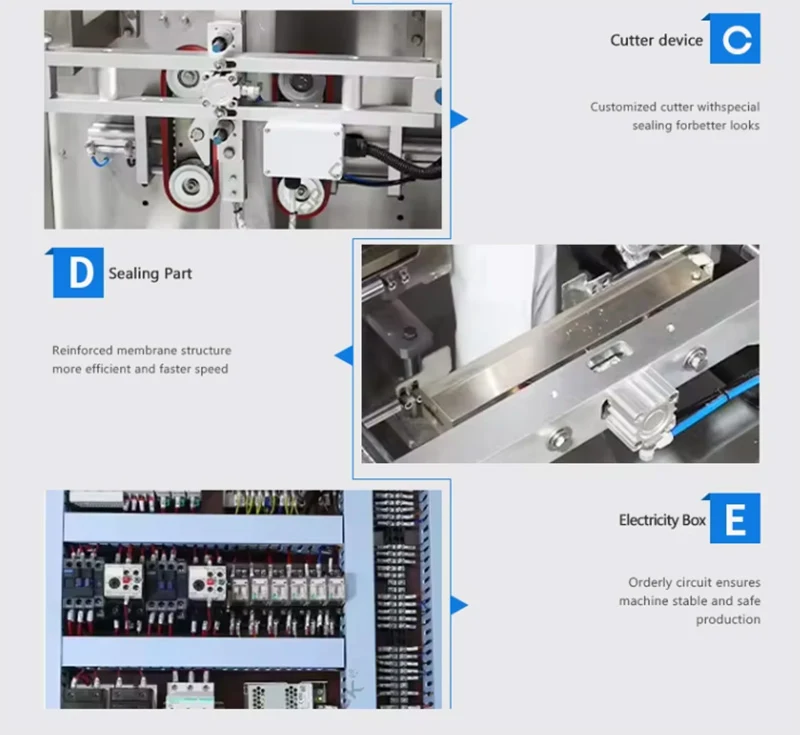

2. Modular design: The equipment adopts a modular structure, which is convenient for maintenance and upgrading. Different modules can be flexibly combined according to actual needs, improving the versatility and adaptability of the equipment.

3. Dust-proof and leak-proof design: Aiming at the characteristics of cosmetic powder and fragrance being prone to flying and leakage, the equipment has good sealing performance and dust-proof devices, keeping the working environment clean and avoiding product losses.

4. Quality detection function: It has a built-in simple quality detection system that can monitor the product quality in the filling process in real time, promptly detect and eliminate unqualified products, and ensure the stability of product quality.

5. Scalability: According to production needs, it can be integrated with other equipment (such as capping machines, labeling machines, etc.) to form a complete production line, improving the degree of production automation and production efficiency.

Product Inquiry