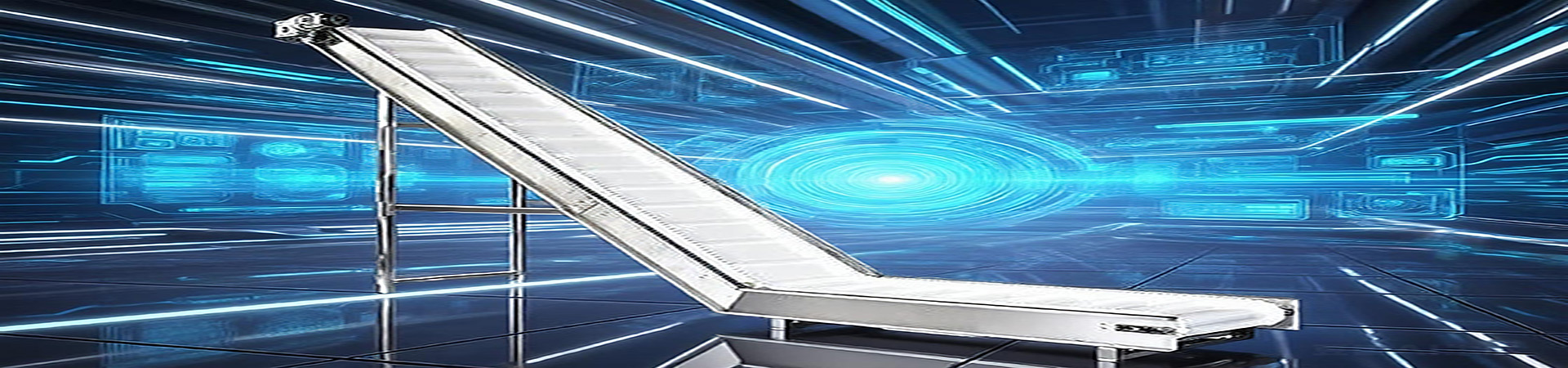

Z-type bucket elevator is a highly efficient vertical and inclined combined conveying equipment, named because of its "Z"-shaped running track. It breaks the limitations of traditional linear lifting, integrates horizontal conveying, inclined lifting and vertical lifting functions, and can achieve continuous and stable material transportation in a small space. It is widely used in grain, chemical, mining, building materials, food and other industries,

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Packaging and delivery

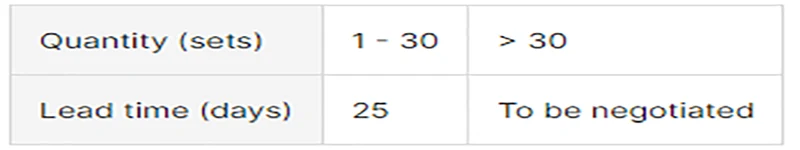

Lead time

Z-type bucket elevator structure

1. Bucket: Made of high-strength and wear-resistant materials, such as high-quality carbon steel, stainless steel, etc., it is designed into different shapes (such as deep bucket, shallow bucket, triangular bucket) according to the characteristics of the conveyed material to meet the loading needs of various materials such as powder, granular, and small blocks.

2. Traction component: It is composed of high-strength chain or belt, with good tensile strength and wear resistance, ensuring stable traction of the bucket to complete material transportation during long-term operation.

3. Drive device: Equipped with high-efficiency motor and reducer, it provides stable power through a reasonable transmission ratio to drive the entire system to operate. The variable frequency speed regulation function can be configured according to actual needs to achieve flexible adjustment of the conveying speed.

4. Guide rail and casing: The guide rail provides precise guidance for the hopper operation to ensure smooth operation; the fully enclosed casing effectively prevents material overflow and dust flying, which not only ensures a clean working environment, but also avoids material loss.

5. Inlet and outlet: The inlet is designed with a special guide device to allow the material to enter the hopper evenly; the outlet can flexibly adjust the position and angle according to the actual use scenario to achieve accurate material unloading.

Advantages of Z-type bucket elevator products

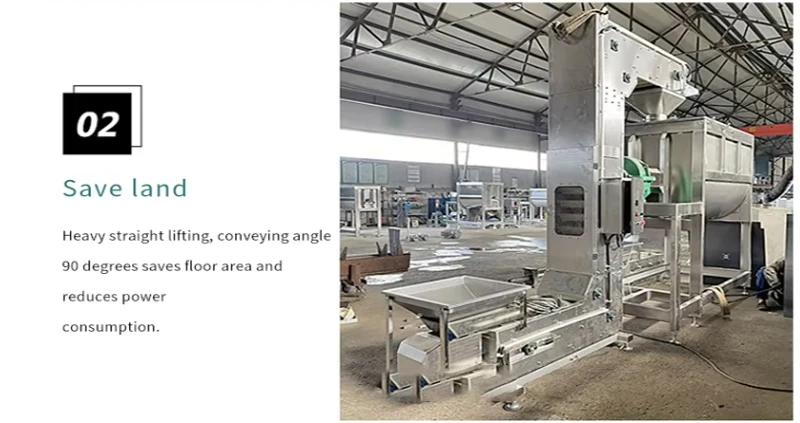

1. High space utilization: The unique Z-type design can realize the three-dimensional transportation of materials in a limited space, which is especially suitable for working environments with narrow sites and complex spatial layouts, effectively saving floor space.

2. High transportation efficiency: The transportation speed is fast, the transportation volume per unit time is large, and it can work continuously and uninterruptedly, greatly improving production efficiency and meeting the material transportation needs of large-scale production.

3. Strong adaptability: It can transport materials in various forms, has a certain adaptability to the physical properties of the materials (such as humidity and temperature), and can meet the personalized needs of different working conditions by adjusting parameters such as hopper type and transportation speed.

4. Stable and reliable operation: With high-quality components and advanced manufacturing technology, the equipment runs smoothly and has a low failure rate. At the same time, it is equipped with multiple safety protection devices, such as overload protection and deviation alarm, to ensure the safety of equipment and operators.

5. Easy maintenance: The modular design makes it easy to disassemble and replace the various parts of the equipment, and daily maintenance is convenient and quick, reducing maintenance costs and downtime.

6. Good environmental performance: The fully enclosed structure effectively controls dust from flying outward, reduces environmental pollution, and meets the requirements of modern environmental protection production; in addition, the operating noise is low and will not interfere with the surrounding environment.

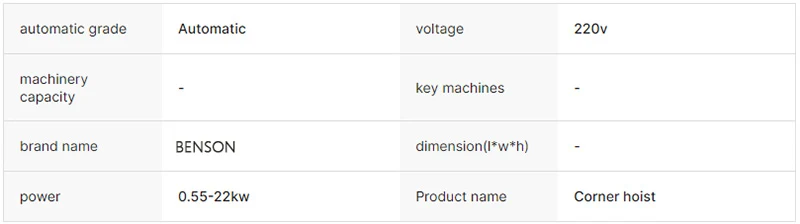

Technical parameters of Z-type bucket elevator

Item Parameter range

Conveying capacity 5 - 200 m³/h

Lifting height 3 - 30 m

Conveying speed 0.5 - 1.2 m/s

Bucket volume 0.01 - 0.5 m³

Motor power 2.2 - 37 kW

Applicable material particle size ≤50 mm (customizable)

Working temperature -20℃ - 80℃ (customizable for special working conditions)

Application fields of Z-type bucket elevator

Grain industry: used for lifting, conveying, storage and transportation of raw grains such as wheat, rice and corn, and can be used in conjunction with cleaning equipment, drying equipment, processing equipment, etc.

Chemical industry: realize the transportation of powdered and granular chemical raw materials (such as fertilizers, resins, pigments), meet the material handling needs in the chemical production process, and ensure production continuity.

Mining industry: suitable for lifting and transporting materials such as ore and mineral powder, playing an important role in ore dressing plants, mining sites and other places, helping to improve mining efficiency.

Building materials industry: used for conveying building materials such as cement, sand, gravel, coal powder, etc., connecting with crushers, mixers, packaging machines and other equipment to ensure the smooth operation of building materials production lines.

Food industry: Made of food-grade materials, in line with hygiene standards, it can safely convey food raw materials such as grains, candies, nuts, etc., and is widely used in food processing companies.

Customized service

We can provide a full range of customized solutions according to the specific needs of customers, including:

1. Customize the appropriate hopper material, shape and specifications according to the characteristics of the conveyed materials and the on-site working conditions.

2. Design exclusive Z-type conveying routes and equipment sizes based on spatial layout and conveying requirements.

3. Provide a variety of control methods and safety protection devices to meet the operation requirements of different usage scenarios.

4. Equipped with an automated control system to achieve linkage operation with other equipment and improve the level of production automation.

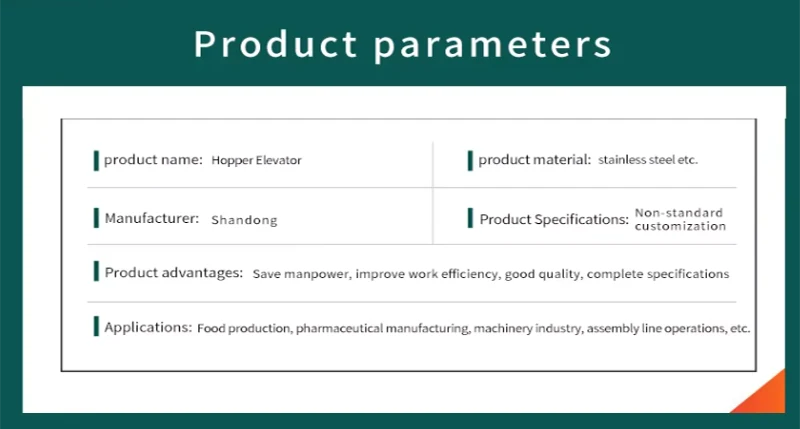

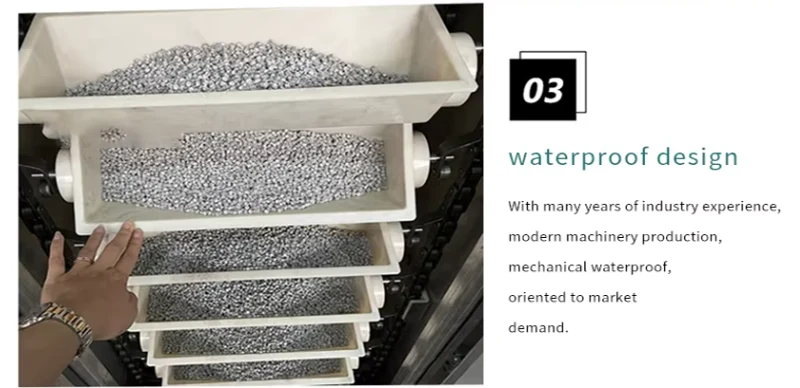

Products Description

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry