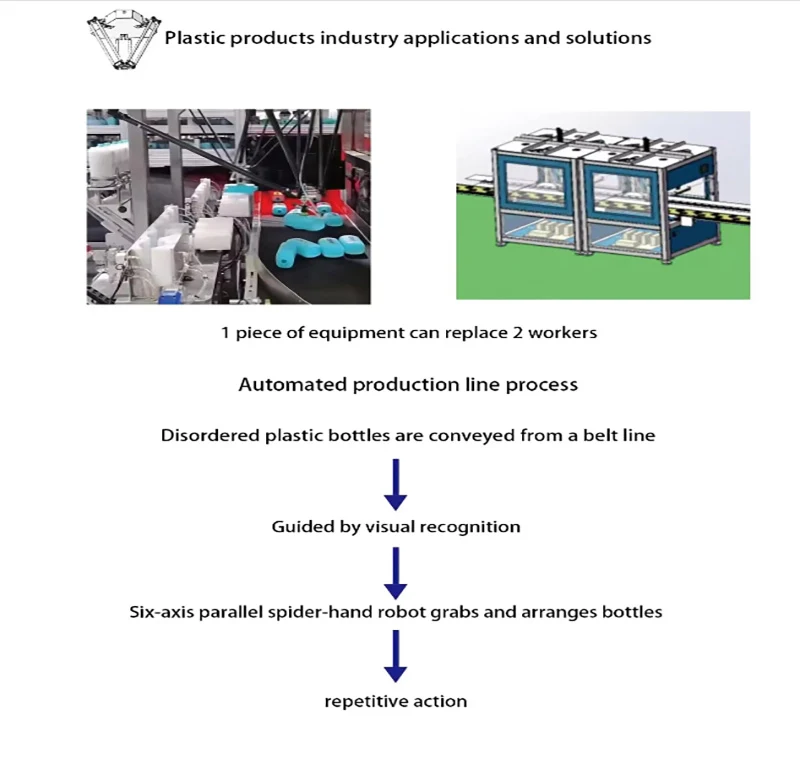

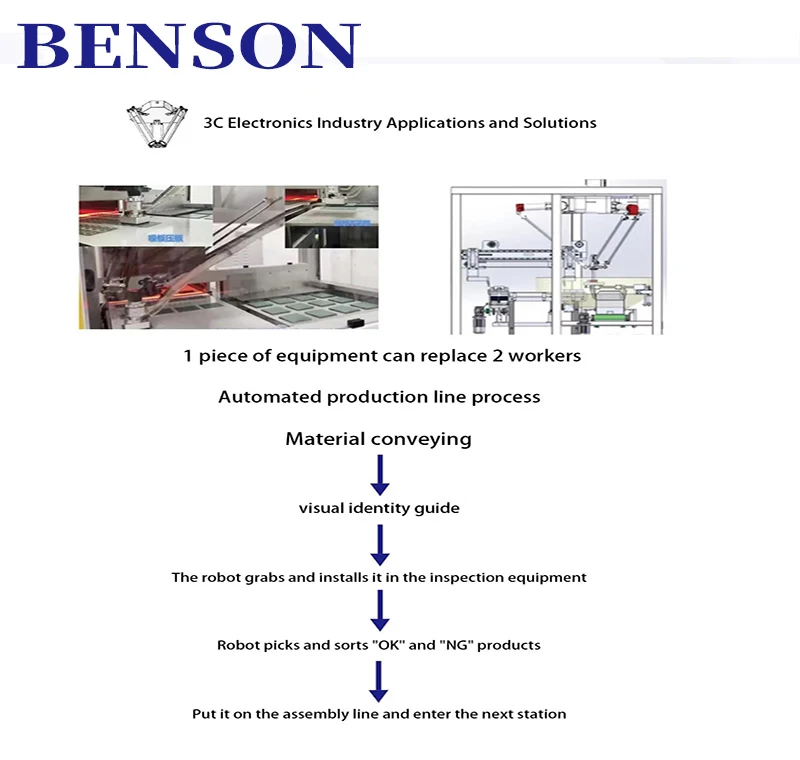

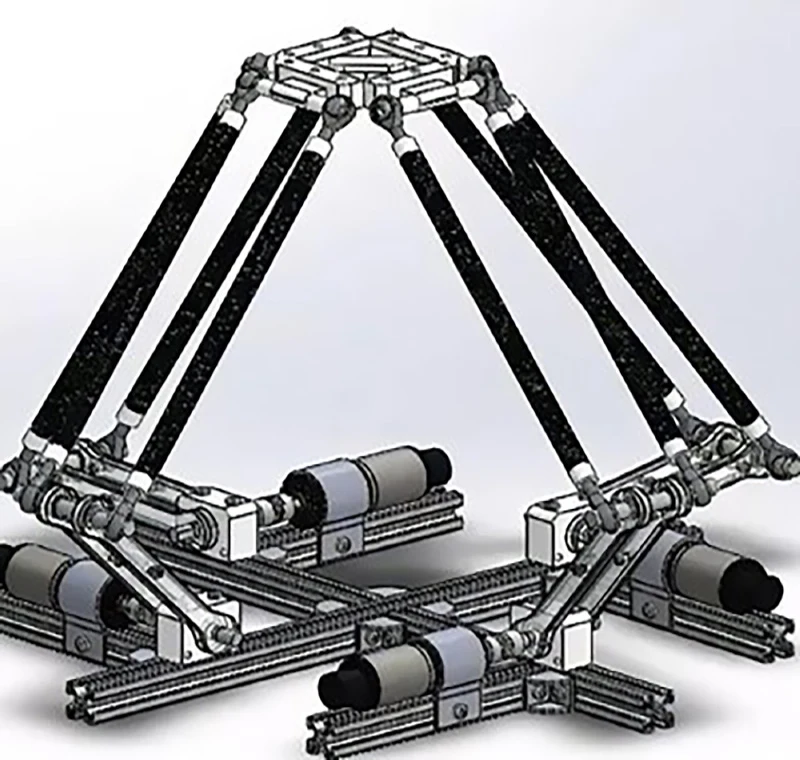

The industrial robot for grasping, packaging, and distribution is a highly automated intelligent device specifically designed for the material handling process in industrial production. It is equipped with advanced robotic arms and intelligent grasping devices, which can accurately identify and grasp various materials with different shapes and sizes. The robot's vision system enables it to quickly locate the target items, ensuring the accuracy of grasping. In the packaging process,

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Grab, Pack and Dispense Industrial Robot BENSONAdvantages:

Whether it is carton packaging, plastic bag sealing, or other forms of packaging, it can handle them with ease. After packaging, the robot can also accurately distribute the products to the corresponding positions or conveyor lines according to their different attributes and destinations, achieving a seamless connection of the entire production process.

1. Improve production efficiency: Compared with manual operations, industrial robots can work continuously without fatigue, quickly completing a large number of grasping, packaging, and distribution tasks, which greatly improves the production speed and shortens the product production cycle.

2. Ensure product quality: The robot has high operation precision and can strictly carry out packaging and distribution according to the set standards, reducing the product quality differences caused by human factors and ensuring the stability and consistency of product quality.

3. Reduce labor costs: It reduces the dependence on a large number of manual workers, lowering the labor costs and management costs of enterprises. Moreover, it avoids the production fluctuations caused by staff turnover.

4. Adapt to harsh environments: It can work in some environments that are harmful or dangerous to the human body, such as high-temperature, low-temperature, high-dust, and high-radiation environments, expanding the possibilities of production and ensuring the safety of workers.

5. Flexibility and scalability: Through simple programming and parameter adjustment, it can adapt to the grasping, packaging, and distribution needs of different products, with strong flexibility. At the same time, it can be easily integrated with other production equipment and systems to achieve the expansion and upgrading of production scale.

6. Data recording and analysis: It can record various data in the production process in real-time, such as working hours, product quantity, and fault information. Through the analysis of these data, enterprises can optimize the production process and improve the scientific nature of management decisions.

7. Precise positioning and operation: Advanced vision systems and sensor technologies enable the robot to achieve precise positioning and operation. Even in complex production environments, it can accurately grasp and place materials, reducing material damage and waste

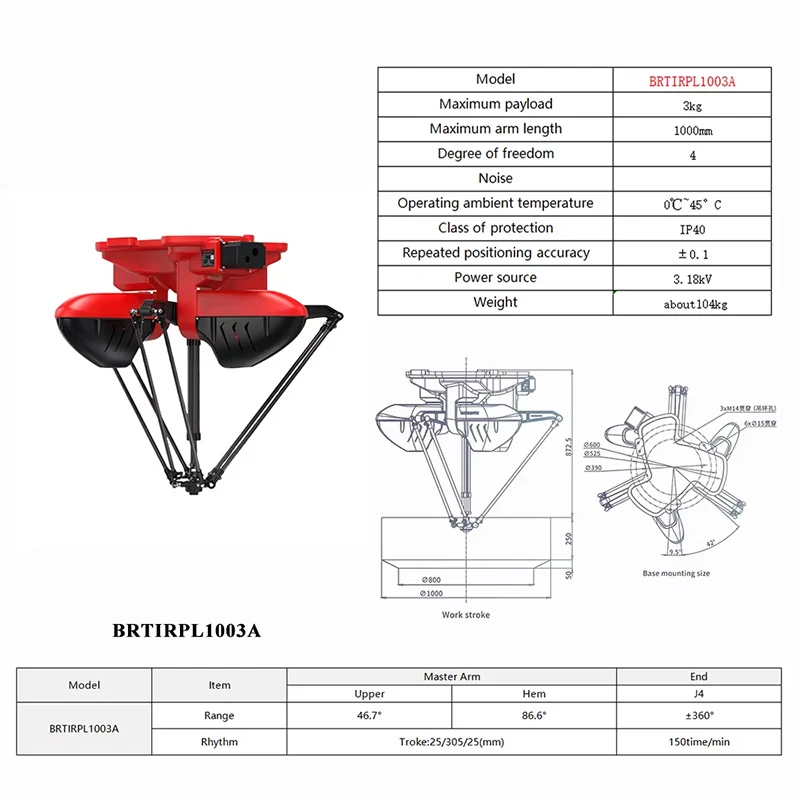

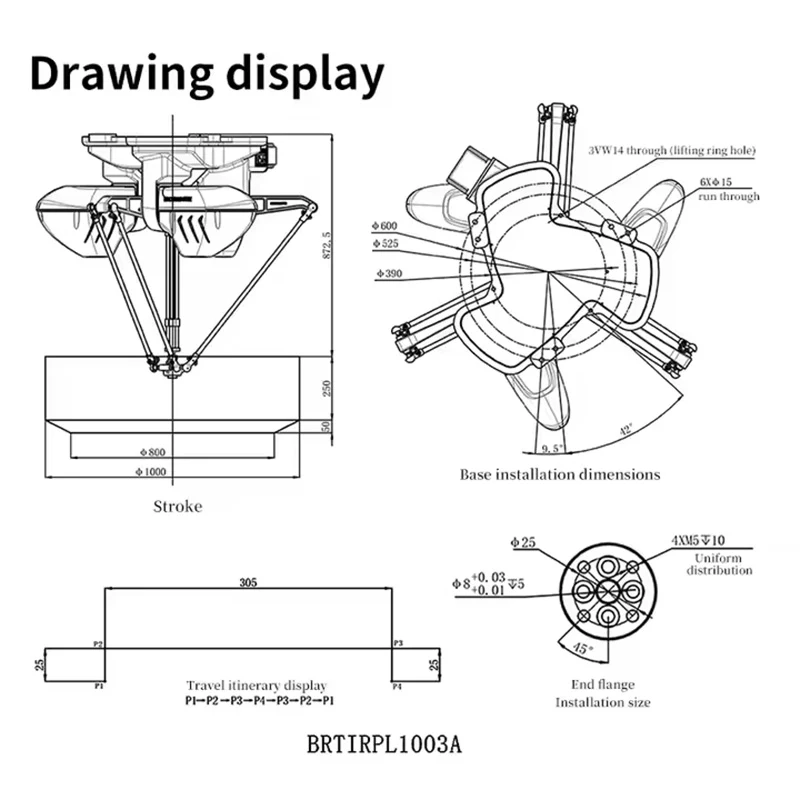

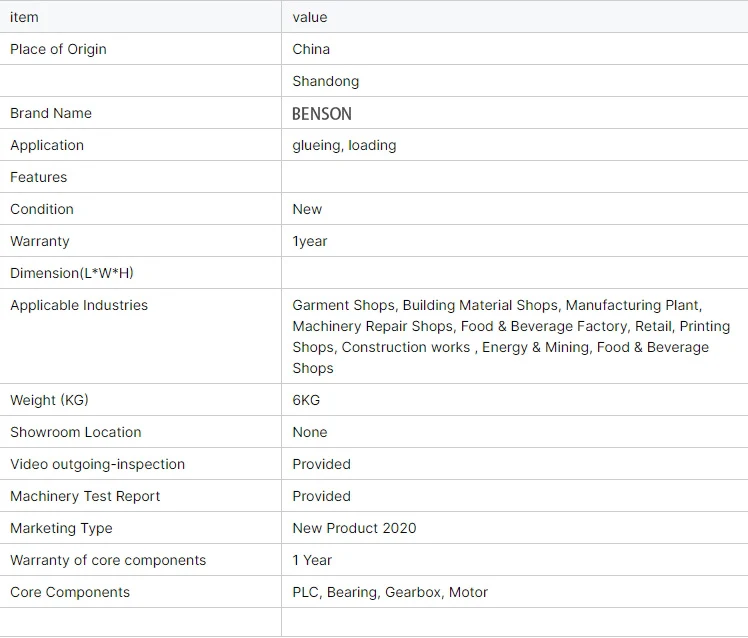

Product Description

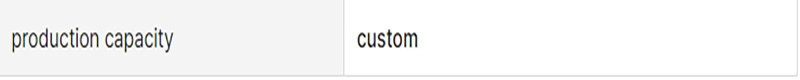

Specification

BENSON (Shandong) Machinery Co., Ltd. is a modernized company engaged in the R&D and production of industrial robots, palletizing robots, automatic bag feeding and packaging machines, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines, and logistics automation lines. high-tech enterprises. In terms of production, the company has brought together a group of high-level and high-quality professionals. The company actively promotes the development model of "combining production, learning and research". The successful research and development can be widely used in the fields of automated packaging routes, automated logistics engineering and other fields. A new generation of automated assembly lines, the company has introduced a variety of advanced processing equipment in order to comprehensively enhance market competitiveness, a large number of high-quality accessories, and the quality of products has been greatly improved. and other industries have been widely used, from product import to output, from electrical control to mechanical structure design, BENSON (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and equipment precision manufacturing, and we have a complete after-sales service system. , to provide customers with high-quality technical support and after-sales service.

Product Inquiry