Performance characteristics

Flexible extension: The bottle belt conveyor can be freely extended in the length direction, and the conveying length can be controlled at any time according to the operation requirements. Generally, it can penetrate about 10 meters into the carriage.

High loading and unloading efficiency: In the case of continuous transportation, the loading and unloading efficiency can reach about 20-30 pieces of goods per minute, about 1,200 bags of grain.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

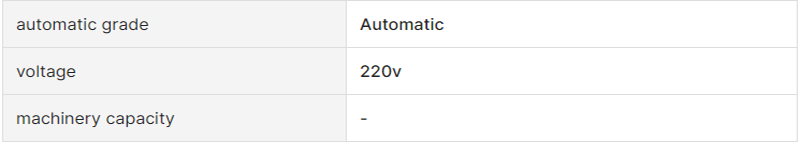

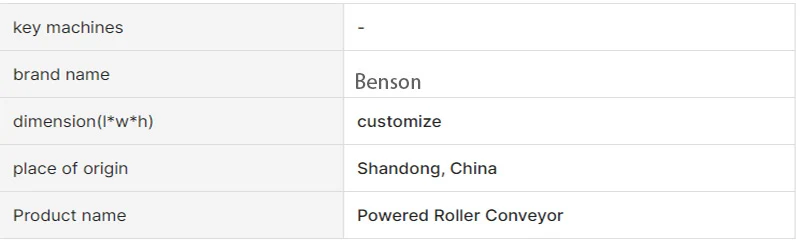

Other attributes

Packaging and delivery

Supply Ability

Product descriptions from the supplier

Product Description

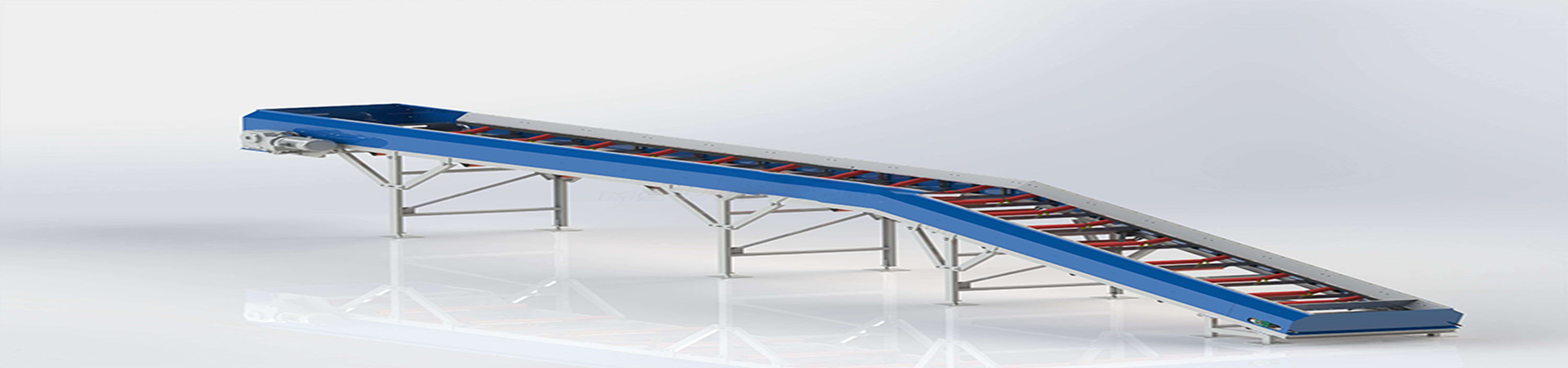

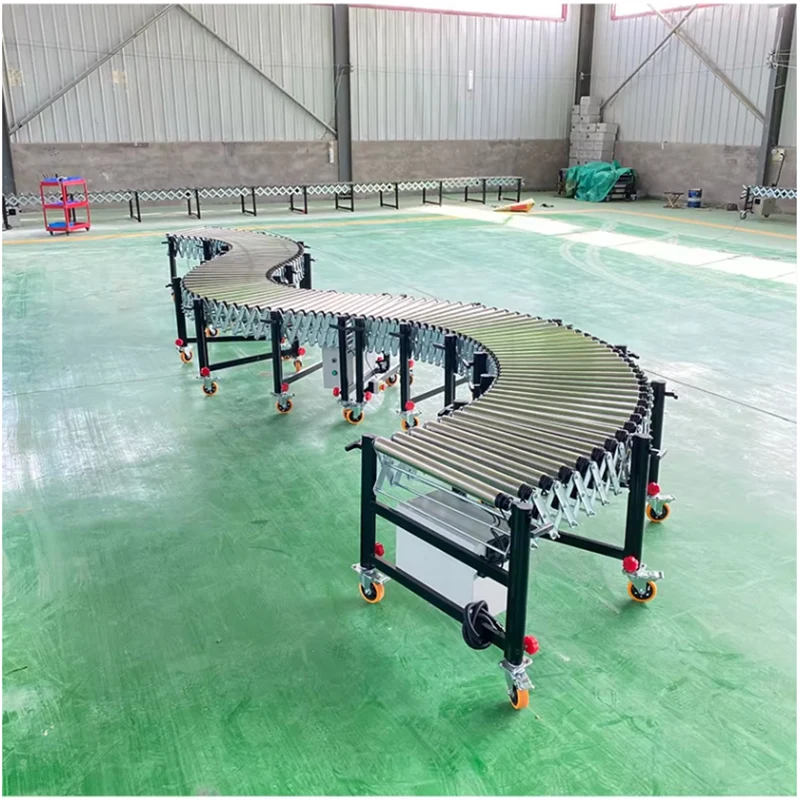

Structural composition of bottled belt conveyor

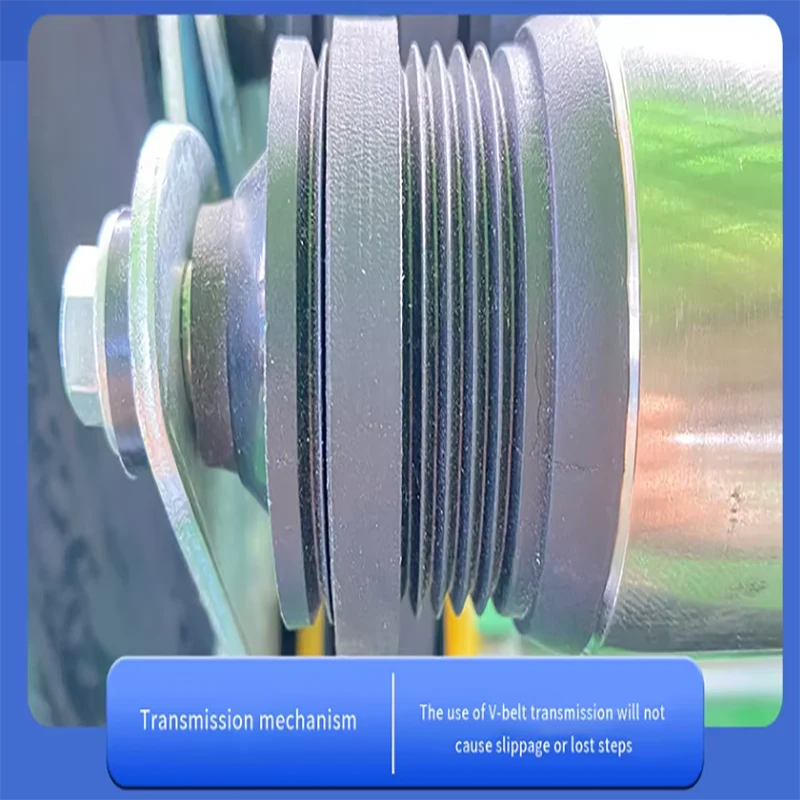

- Driving device: Generally driven by an electric motor through a reducer, the conveyor belt is driven to operate and realize horizontal transportation of goods.

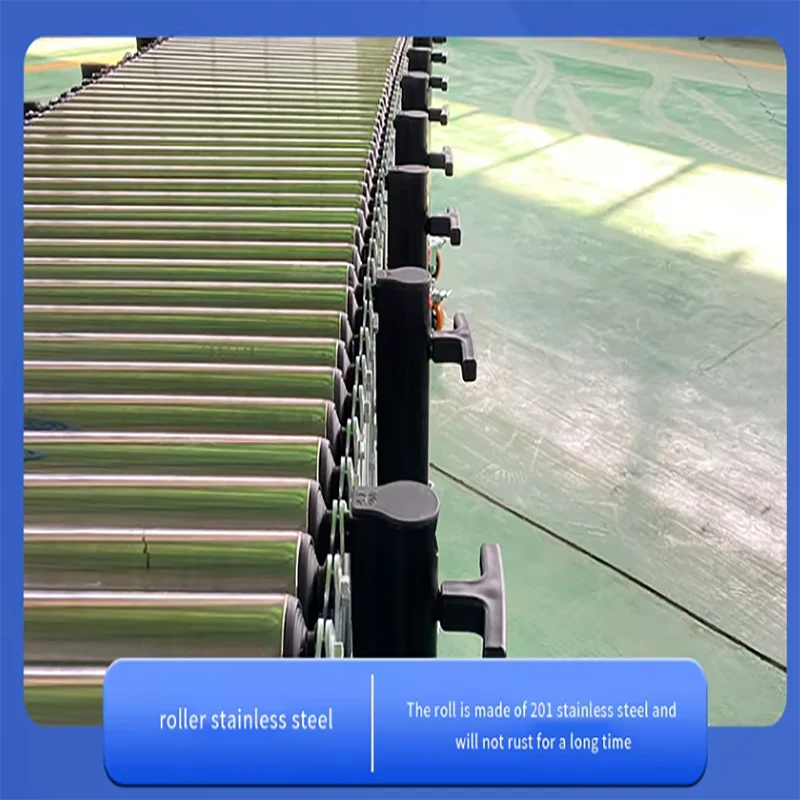

- Conveyor belt: Select belts with heat resistance, flame retardancy, wear resistance, tear resistance and other characteristics to adapt to long-term elongation and contraction and the transportation of various goods.

- Telescopic mechanism: Through the control of hydraulic or electric system, the telescopic function of the conveyor belt is realized, usually composed of fixed section, movable frame, synchronous telescopic thrust mechanism, etc.

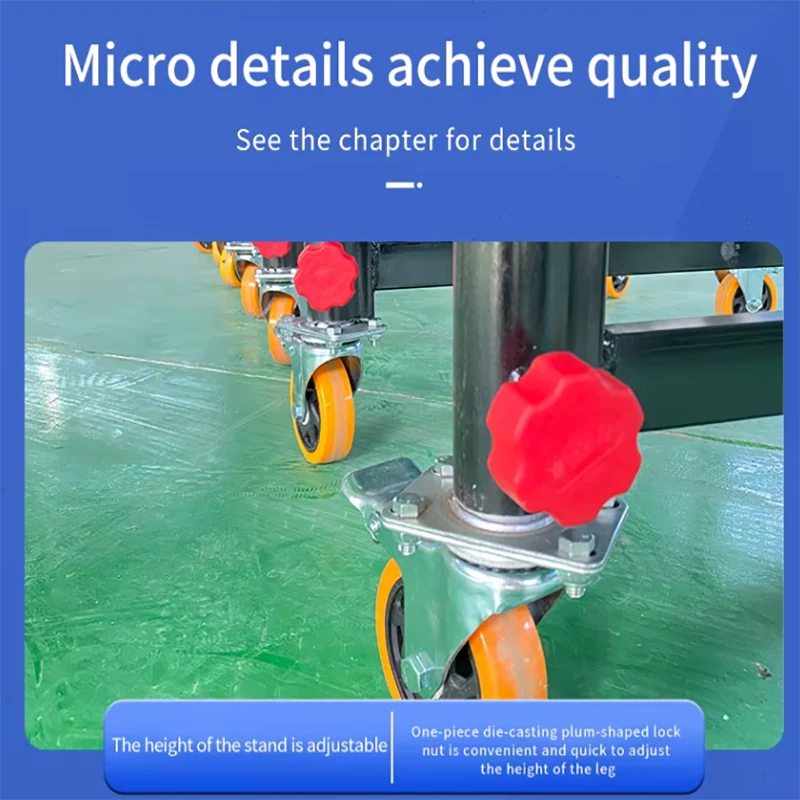

- Bracket: Used to support the structure of the entire conveyor to ensure its stability and reliability. Some brackets are also equipped with walking devices and steering wheel steering functions.

- Control system: Including electrical control system, which can realize the control of conveyor start, stop, forward and reverse, telescopic, lifting and lowering operations, and some are also equipped with wireless remote control function.

Technical parameters of bottled belt conveyor

- Weight of conveyed goods: Mainly suitable for bagged goods of about 10-60 kg, and can also be used for finished goods and bulk materials with a single weight of less than 100 kg.

- Power supply: usually 380V three-phase (-7% ~ +7%) 50Hz.

- Working environment temperature: generally -40℃ ~ +45℃.

- Working environment humidity: 20% ~ 99%RH.

Application areas

- Logistics express: used for rapid loading and unloading and sorting of goods to improve logistics distribution efficiency.

- Port terminal: realize efficient transfer of goods between container trucks and cargo ships.

- Warehouse storage: facilitate the entry and exit of goods and reduce manual handling costs.

- Chemical, grain and other industries: can be used for loading and unloading and transportation of chemical raw materials, bagged grain, etc.

Precautions

- Regular maintenance: Regularly inspect and maintain the equipment to ensure the normal operation of each component, such as checking the wear of the conveyor belt, the oil level and pressure of the hydraulic system, etc.

- Safe operation: The operator should be familiar with the operating procedures of the equipment and strictly abide by safety regulations during the operation to avoid accidents.

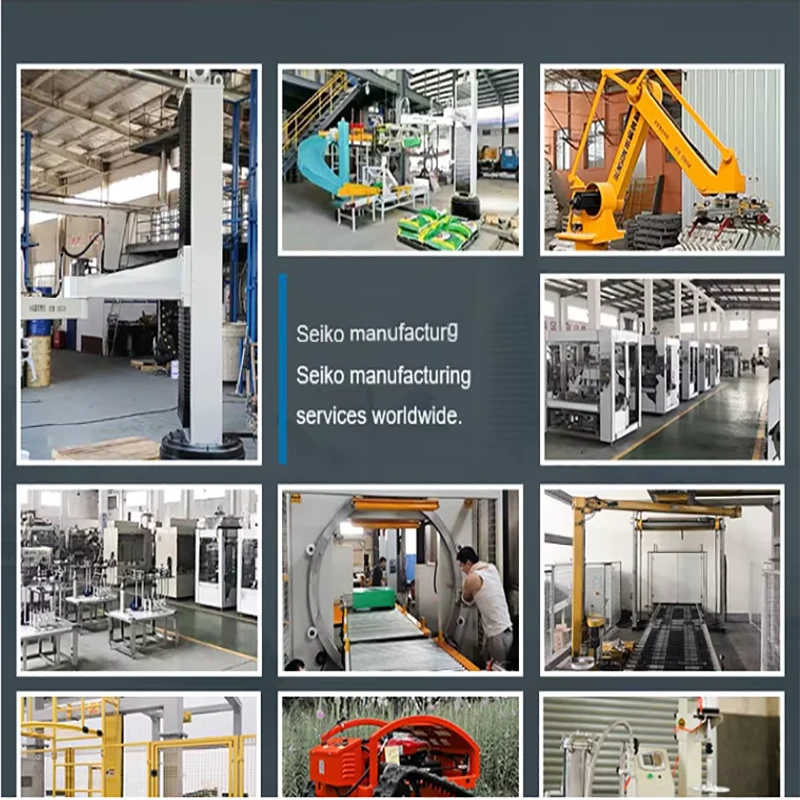

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research", and the success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. The products of Bomei (Shandong) Machinery Co., Ltd. have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry