Multifunctional fully automatic vertical sealing machine for efficient and continuous operation: It adopts an advanced transmission system, the sealing speed can reach [X] m/min, and can be infinitely adjusted within [speed range] according to production needs, to achieve continuous and uninterrupted sealing work, greatly improve production efficiency, and meet the rhythm of large-scale production.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Performance characteristics of multifunctional fully automatic vertical sealing machine

Precise temperature control system: equipped with intelligent digital display temperature controller, the temperature control range is [0 - maximum temperature] ℃, which can accurately control the heating temperature to ensure uniform heating at the sealing point. Whether the packaging material is a single-layer film or a composite film, it can achieve stable and firm sealing to avoid poor sealing caused by temperature deviation.

Flexible height adjustment: The height of the conveyor table can be easily adjusted between [minimum height - maximum height] mm to meet the sealing requirements of packaging containers of different sizes. Whether it is a small packaging bag or a large packaging barrel, it can be easily handled and easy to operate. You only need to operate the adjustment handle to quickly complete the height adjustment.

Powerful load-bearing capacity: Equipped with a high-power conveying motor, it can also smoothly convey heavy packaging filled with materials, ensuring the smooth progress of the sealing process and reducing production interruptions caused by insufficient load.

Multifunctional integration: Some models can be equipped with vacuum and inflation functions according to customer needs to achieve diversified packaging effects such as vacuum sealing and nitrogen filling for freshness preservation, meet the special requirements of different products for the packaging environment, extend the shelf life of products, and increase product added value. At the same time, a printing device can be installed to print product information, production date, batch, etc. while sealing, so as to improve packaging efficiency and standardization in one step.

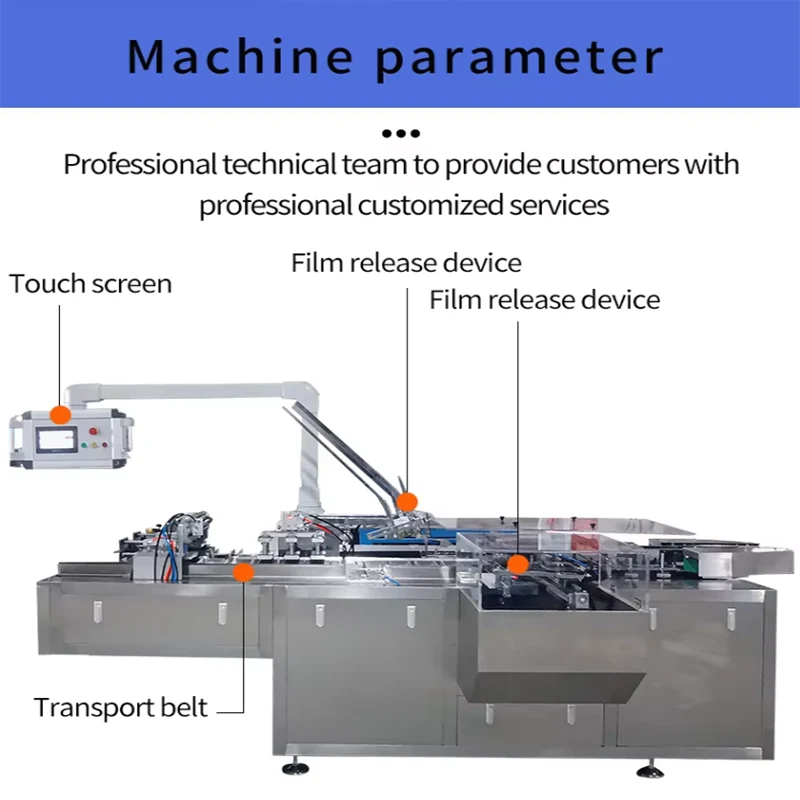

Structural composition and working principle of fully automatic vertical sealing machine

Structural composition: The sealing machine is mainly composed of a sturdy and durable frame, a precise and stable speed reduction transmission mechanism, an efficient and fast heating and heat dissipation mechanism, a clear and beautiful sealing and printing mechanism, a smooth and smooth conveying device, and an intelligent and reliable electrical and electronic control system. All components work together to ensure stable operation of the equipment.

Working principle: After the power is turned on, each mechanism starts in turn. The electric heating element heats up quickly, and the upper and lower heating blocks quickly heat up to the set temperature. The temperature control system monitors and accurately controls the temperature in real time. The embossing wheel starts to rotate, and the cooling system is turned on as needed. The conveyor belt runs at the set speed under the control of the speed regulating device. When the package containing the items is placed on the conveyor belt, the sealing part of the bag mouth is automatically introduced between the two running sealing belts and enters the heating zone. The heat of the heating block is transferred to the bag mouth through the sealing belt, so that the film is heated and softened; then it enters the cooling zone, the surface temperature of the film drops, and then it is rolled by the knurling wheel (or printing wheel) to make the upper and lower plastic films of the sealing part tightly bonded, and a mesh pattern (or printed logo) is pressed out. Finally, the guide rubber belt and the conveyor belt send the sealed packaging bag out of the machine to complete the entire sealing process.

Scope of application of fully automatic vertical sealing machine

Applicable to the packaging of various heat-sealed materials, such as plastic film bags, composite bags, aluminum-plastic bags, kraft paper bags, etc. In the food industry, it can be used for packaging and sealing of snacks, dry goods, condiments, liquid sauces, etc.; in the pharmaceutical industry, it is suitable for packaging of medicines, health products, medical devices, etc.; in the daily chemical industry, it can meet the packaging needs of products such as shampoo, shower gel, skin care products, etc.; in addition, it is also widely used in product packaging and sealing operations in other industries such as electronics, hardware, and toys.

After-sales guarantee

Warranty service: A one-year warranty period is provided from the date of purchase. During the warranty period, if the equipment fails due to quality problems, we will provide free repair services and replace parts, so that you have no worries.

Technical support: We have a professional technical team to provide you with technical consultation and remote guidance at any time. If you encounter any problems during the use of the equipment, just a phone call or email, we will respond quickly to solve your problems.

Maintenance service: Outside the warranty period, we will continue to provide you with high-quality maintenance services, charging only reasonable parts cost and maintenance labor fees. Regularly visit customers to understand the use of the equipment, provide you with equipment maintenance suggestions, and extend the service life of the equipment.

Products Description

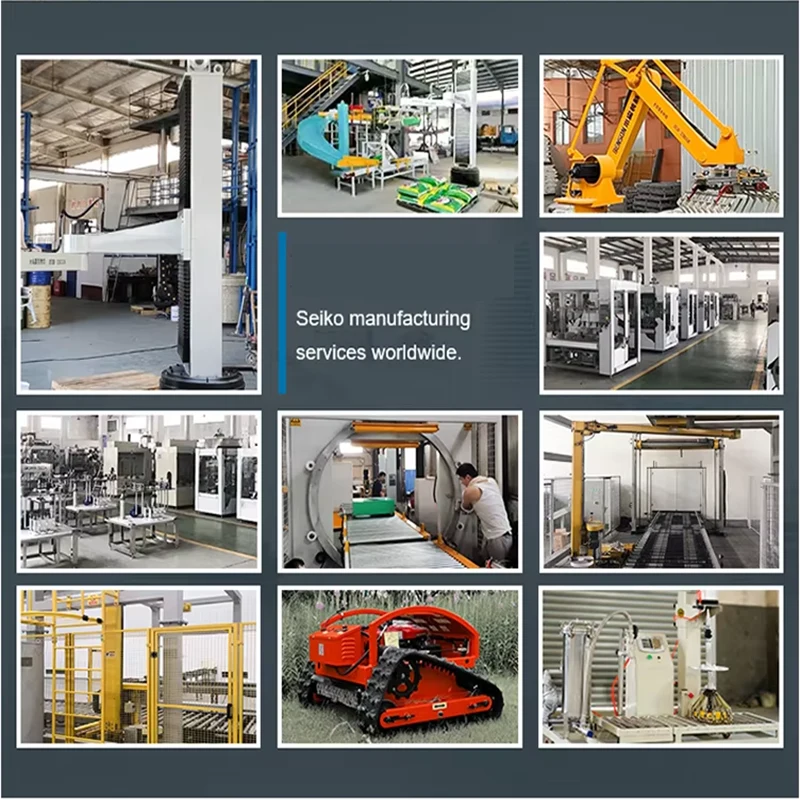

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry