Description)

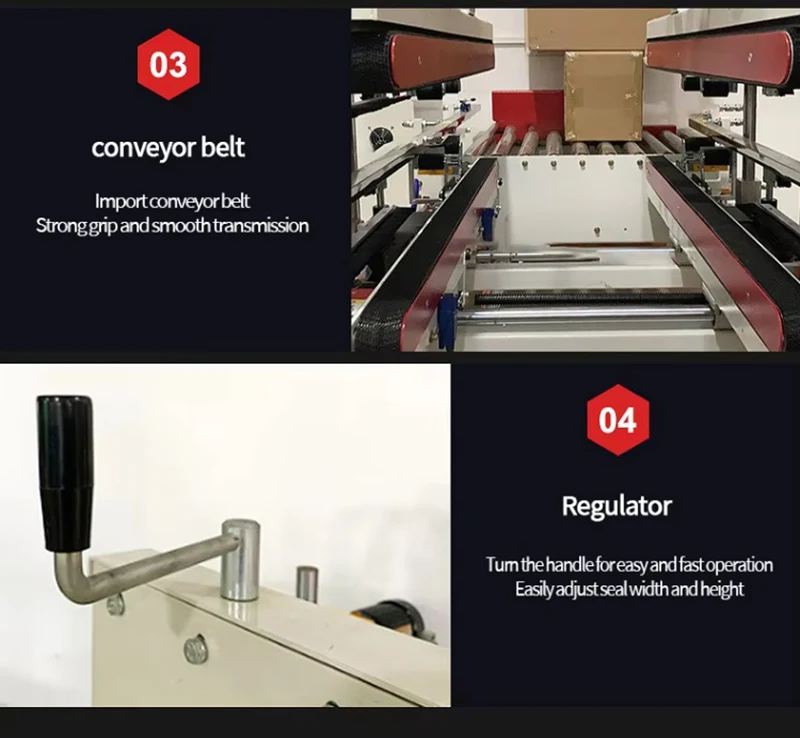

The fully automatic tic-tac-toe packaging machine is an advanced packaging equipment that automatically arranges and secures items with strapping materials in a tic-tac-toe pattern. Leveraging intelligent control systems, sensors, and mechanical arms, it streamlines the packaging process. After items are placed on the designated platform, the machine automatically detects their size and position, precisely adjusting the strapping route to form a robust tic-tac-toe structure.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Fully automatic tic-tac-toe packaging machineAdvantages

1. High Efficiency: Significantly reduces packaging time compared to manual operations. It can complete multiple packaging tasks in a short period, meeting the high-volume production demands of enterprises.

2. Superior Stability: The tic-tac-toe strapping pattern distributes pressure evenly, providing excellent stability and effectively preventing items from shifting, deforming, or getting damaged during handling, transportation, and storage.

3. Accuracy and Consistency: Thanks to its automated control system, the machine ensures consistent strapping tension and pattern for each package, eliminating the variability associated with manual work.

4. Labor Savings: Minimizes the need for a large number of packaging workers, reducing labor costs and the risk of repetitive-strain injuries in the workplace.

5. Adaptability: Capable of handling a wide range of item sizes, shapes, and weights. It can be easily adjusted or programmed to accommodate different packaging requirements.

6. Enhanced Safety: With safety sensors and protective devices, it reduces the risk of accidents during operation, ensuring the safety of both operators and equipment.

Fully automatic tic-tac-toe packaging machine

1. Logistics and Warehousing: Ideal for securing palletized goods, boxes, and crates, ensuring safe transportation and storage of various commodities in the logistics industry.

2. Manufacturing Industry: Used for packaging finished products in factories, such as electronic appliances, machinery parts, furniture, and building materials, improving production line efficiency.

3. E-commerce: Helps in efficiently packing and shipping large quantities of parcels, ensuring items reach customers intact, especially for bulky or irregularly shaped products.

4. Agriculture and Forestry: Applicable for packaging agricultural products like bales of hay, lumber, and other forestry products, facilitating their transportation and distribution.

5. Recycling Industry: Useful for捆扎(strapping)bundles of recycled materials, such as paper, plastic, and metal, for easier handling and transportation to recycling facilities.

Product Inquiry