High-speed intelligent carton packing and filling machine features

- High degree of automation: PLC control and touch screen operation interface are adopted to realize a series of actions such as automatic unpacking, packing, filling, and sealing without manual intervention. It can also automatically shape and arrange the packaging materials and put them into the carton according to the preset quantity and method.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

High-speed intelligent carton packing and filling machine

- High production efficiency: equipped with high-speed distribution device and precise mechanical structure, it can realize high-speed grouping, can operate continuously and stably, and can process thousands of boxes per hour.

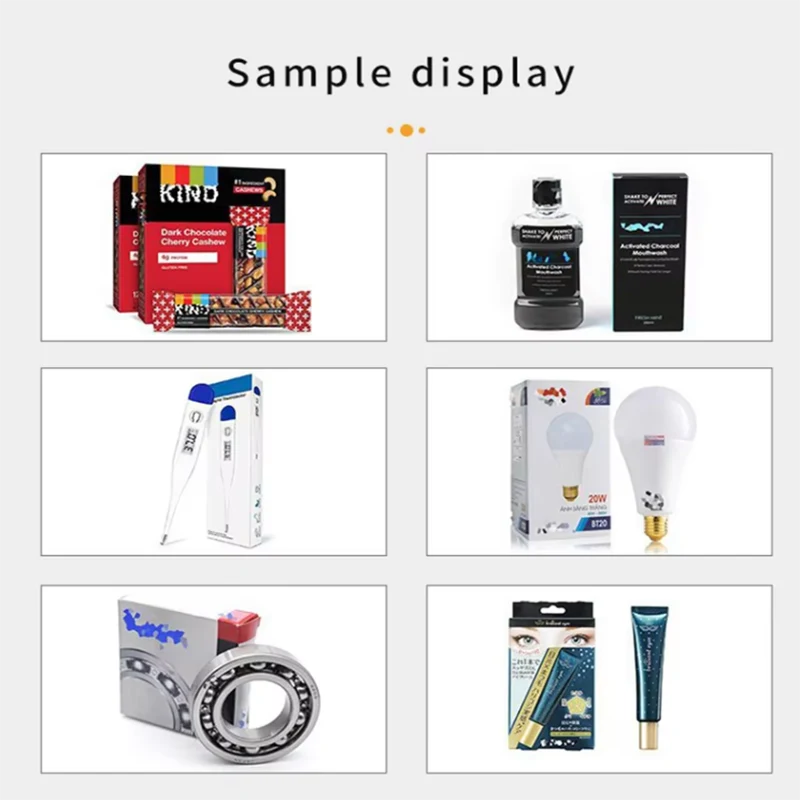

- Wide range of applications: It can pack various containers such as plastic flat bottles, round bottles, irregular bottles, glass bottles, square cans, paper cans, etc. It is also suitable for packaging boxes with partitions. It can also replace the gripper or adjust the parameters according to different products and packaging requirements. It is suitable for food, daily chemicals, medicine, beverages and other industries.

- Strong intelligence: equipped with intelligent recognition system, it can automatically adjust the carton size and packaging tightness according to the size, shape and weight of the items. Some also have Ethernet interface, which can be connected with upper management software to collect and analyze data.

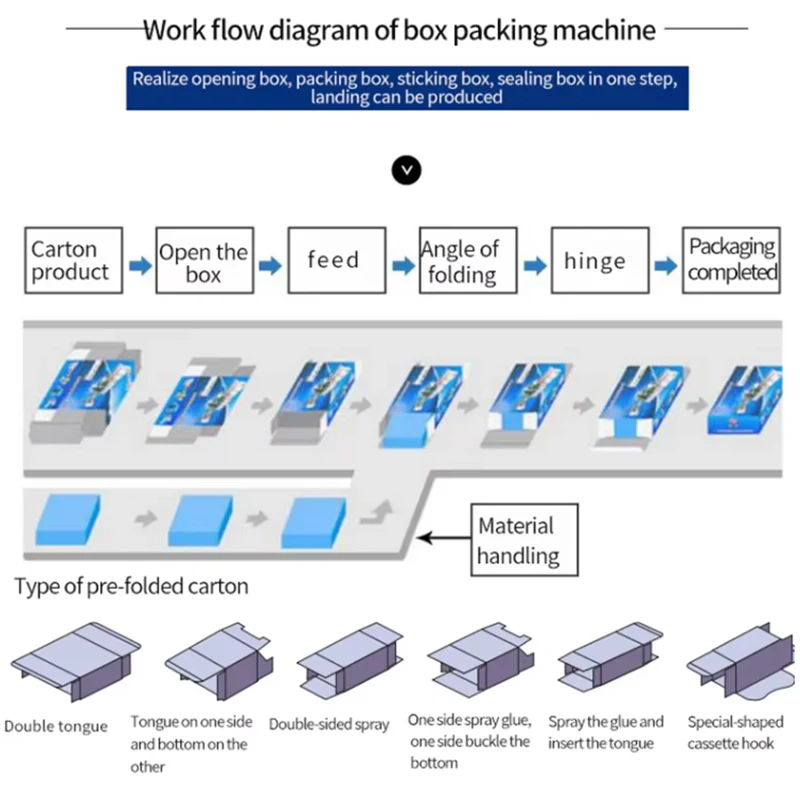

Working principle of high-speed intelligent carton packing and filling machine

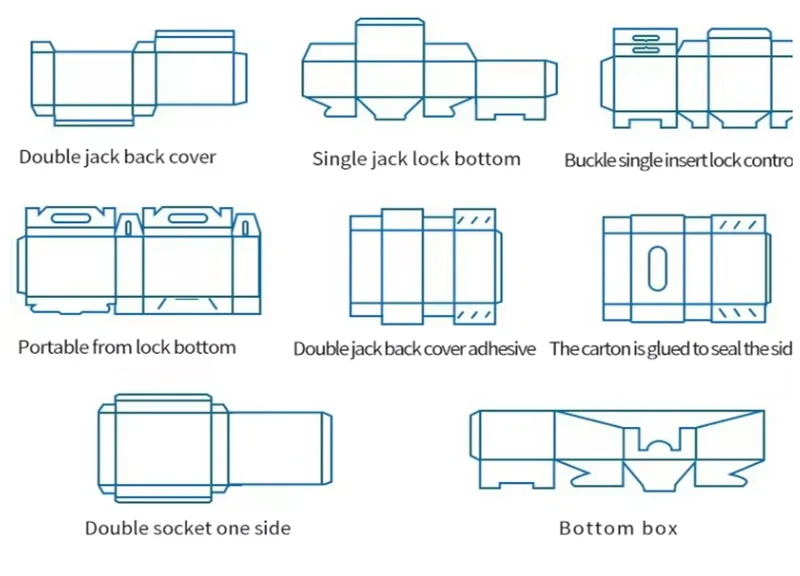

- Carton forming: grab the box board from the box blank rack, complete the box forming and bottom folding through a series of mechanical actions, and then transport the carton to the boxing area.

- Product sorting: Products are transported to the sorting area by conveyor belts and arranged and combined to meet the packing requirements.

- Product packing: When the carton arrives at the packing station, the box support station opens the upper large and small pages of the carton, and the main gripper sucks up or grabs the sorted products and puts them into the carton.

- Sealing: After the carton is filled with products, the certificate and the upper partition are placed according to the program settings, and then the top small page, large page, and upper and lower sealing tapes are completed in sequence during the conveying process.

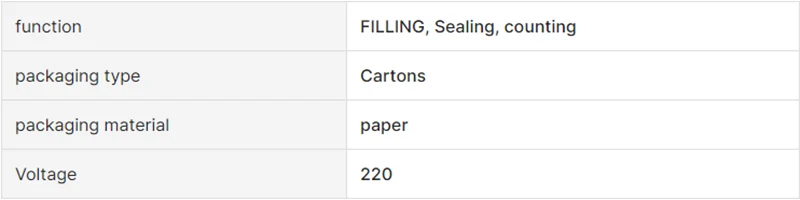

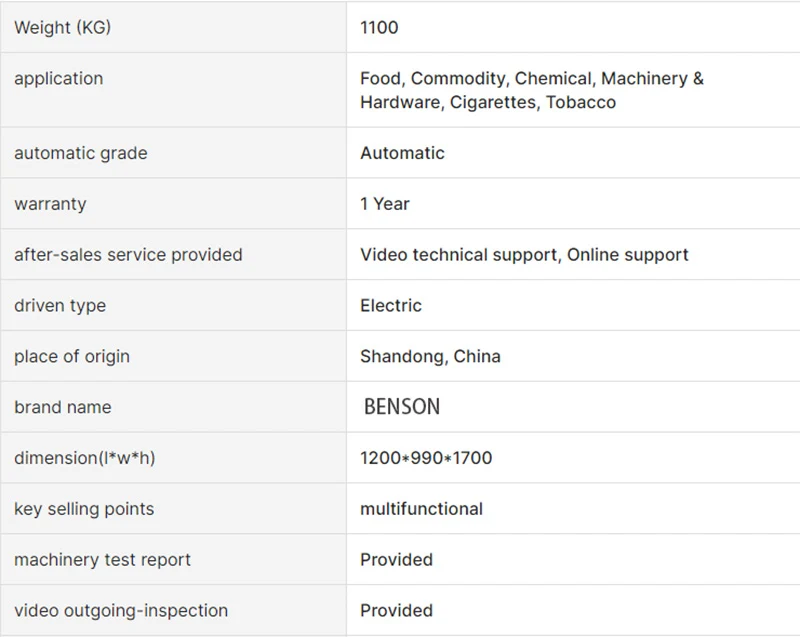

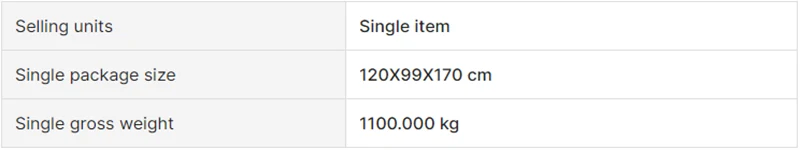

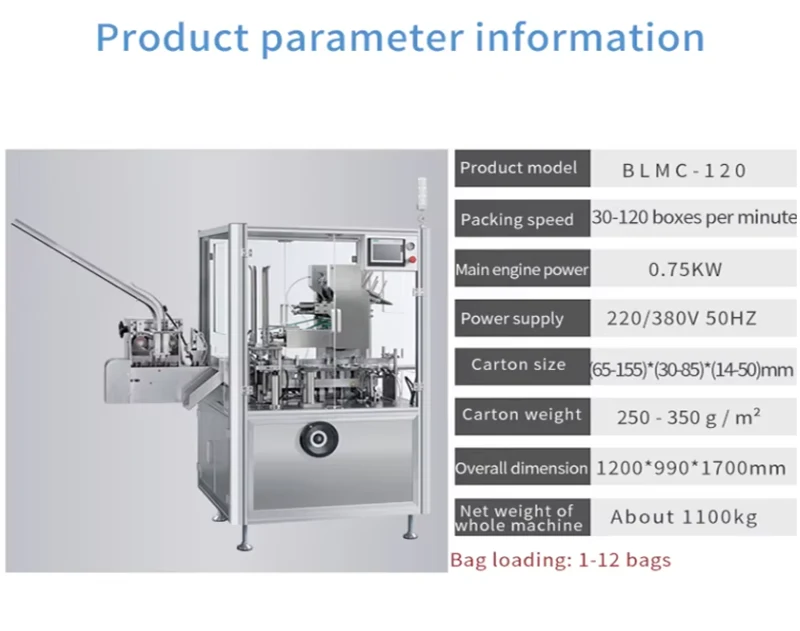

Technical parameters

- Production capacity: Usually up to hundreds of boxes per hour or even more, depending on the equipment model and product specifications.

- Carton size: Generally can adapt to a variety of size ranges, such as 200-510mm long, 150-400mm wide, 80-400mm high, etc.

- Power supply power: Commonly 220V or 380V, 50/60Hz, power ranging from several kilowatts to tens of kilowatts.

- Use air source: The air pressure is generally required to be around 0.4 - 0.6MPa.

Equipment composition

- Cartoning device: including box blank rack, lower carton assembly, etc., responsible for picking up, forming and bottom folding of cartons.

- Arrangement device: Arrange the products to meet the packing requirements.

- Filling device: composed of frame assembly, conveying and driving assembly, etc., to load the products into cartons.

- Sealing device: completes the folding, gluing, sealing and other actions on the top of the carton.

Products Description

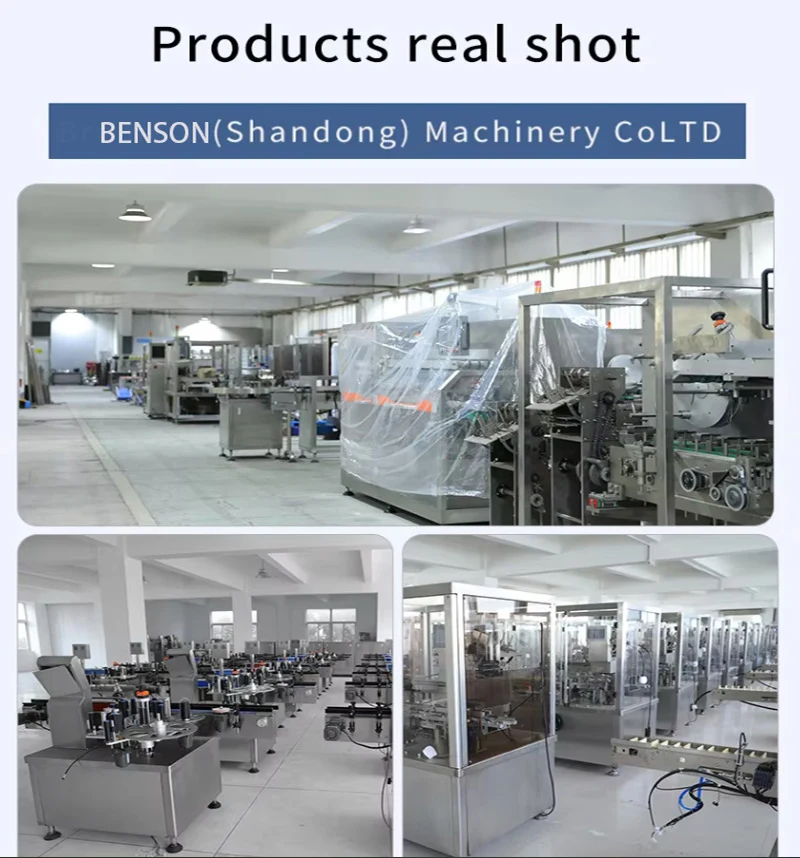

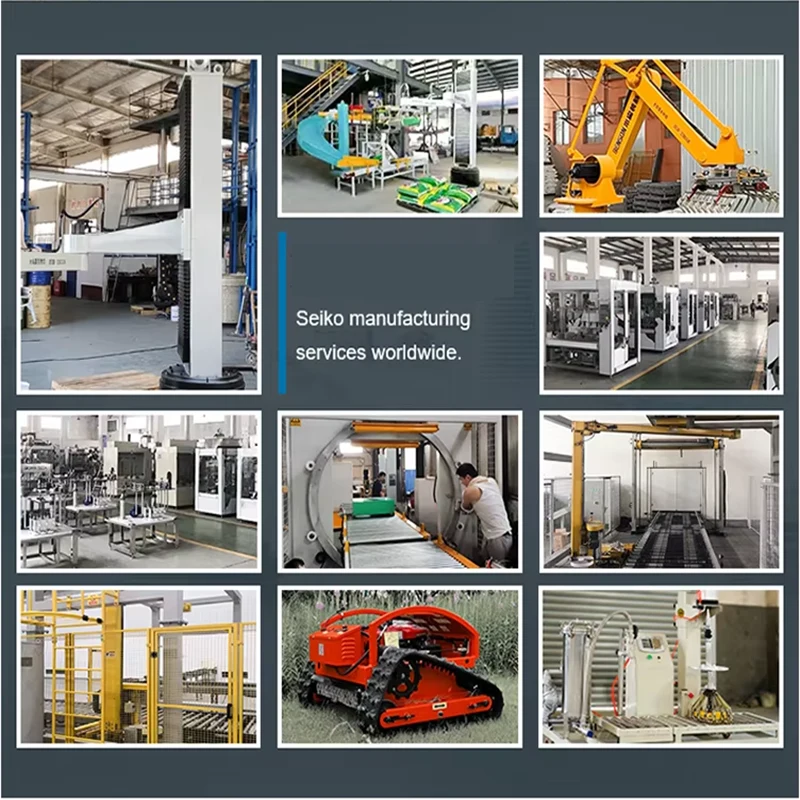

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

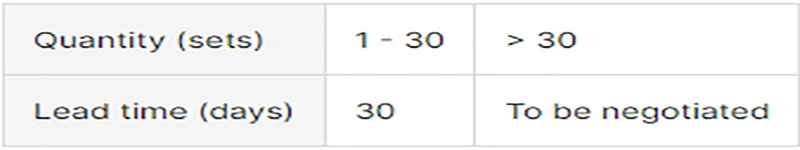

Product Inquiry