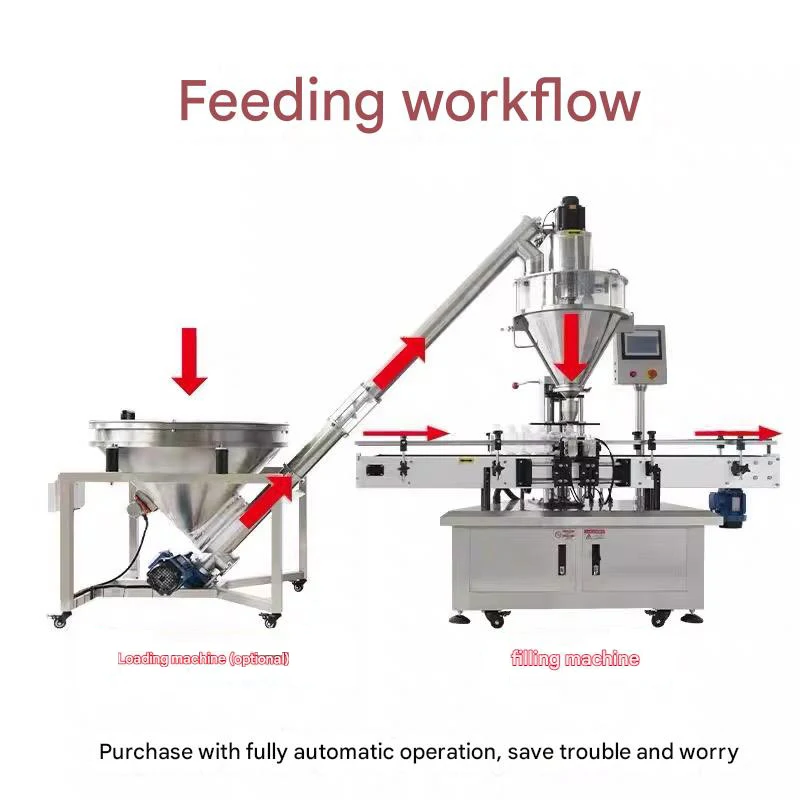

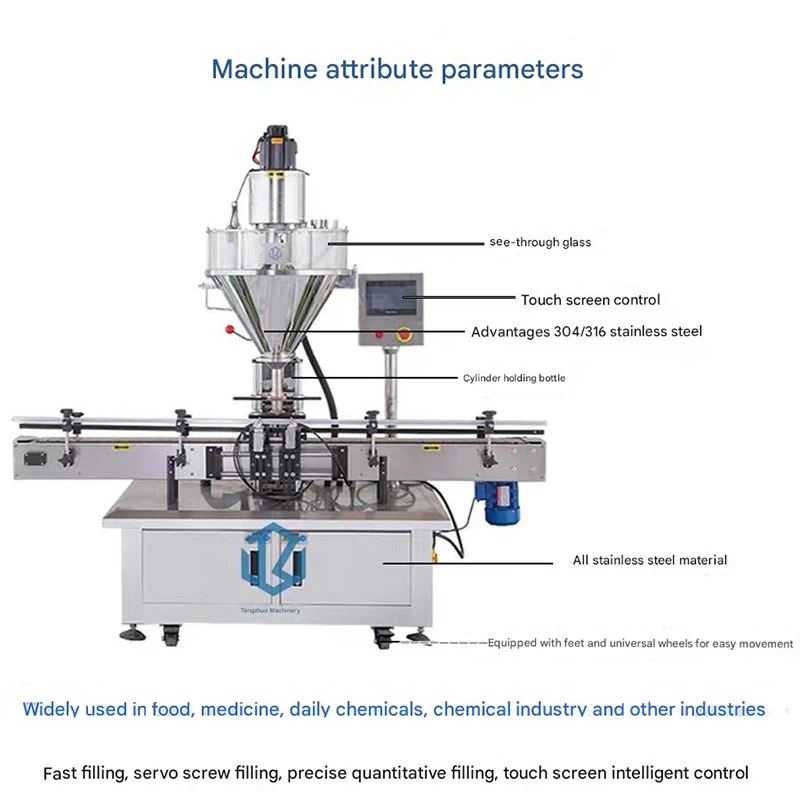

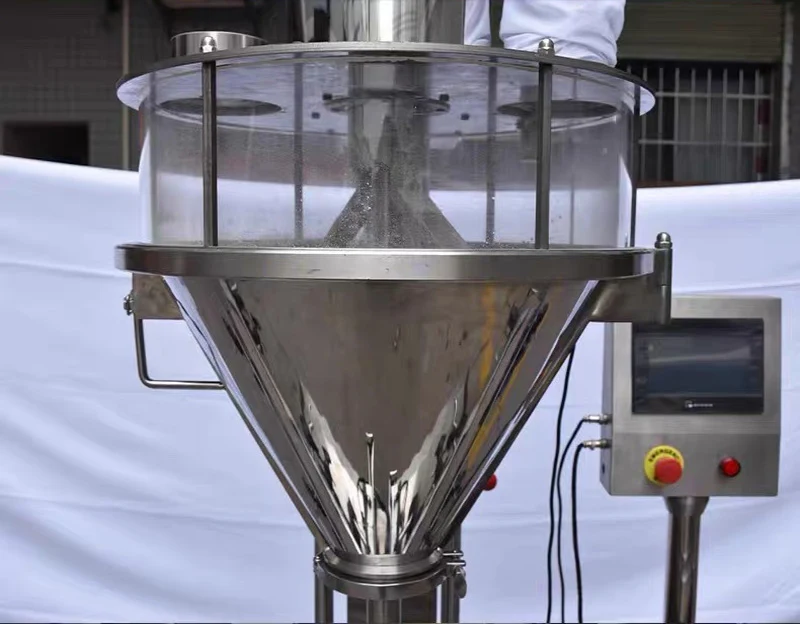

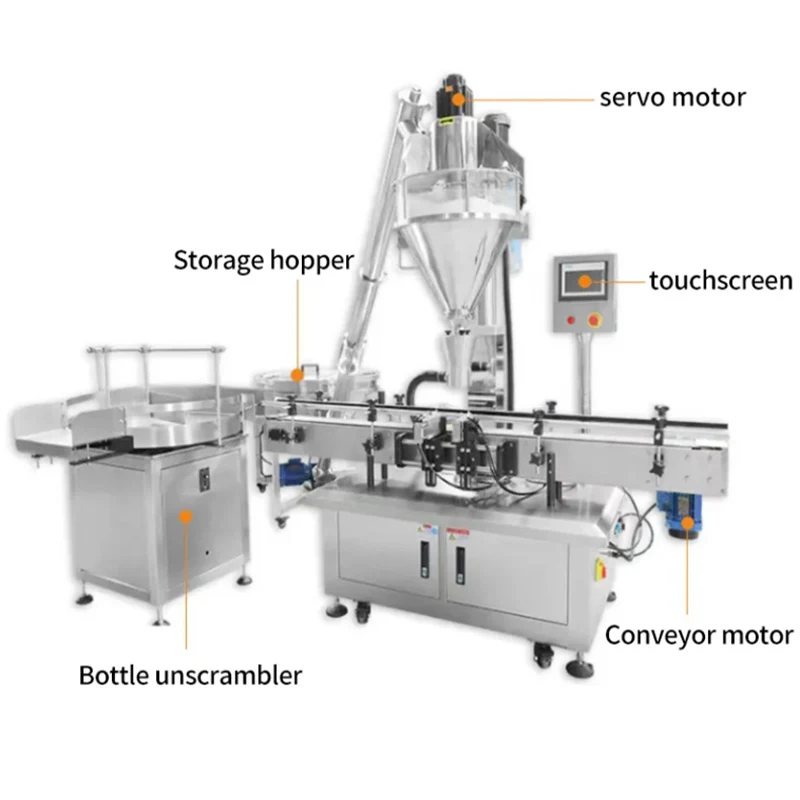

The full-automatic single-head powder bottle filling machine is an automated packaging device specially designed for powdery materials (such as food seasonings, pharmaceutical powders, chemical powders, etc.). Featuring a single filling head, it achieves precise quantitative filling of powders from the storage hopper into bottle containers. With a PLC control system at its core, the equipment integrates technologies such as servo motor drive, electronic weighing measurement, and photoelectric

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

During operation, empty bottles enter the station via a conveyor belt. Once detected by a photoelectric sensor, the filling head automatically dispenses materials according to preset weight or volume, and the filled bottles are output by the conveyor belt—requiring no manual intervention throughout. It is suitable for fine-scale production scenarios with medium-to-small capacity.

Full-automatic single-head powder bottle filling machineAdvantages

1. High-precision Quantitative Filling: Using an electronic weighing feedback system or screw metering technology, filling errors can be controlled within ±0.5%-1%, especially suitable for precise measurement of high-value powders (such as pharmaceuticals and premium seasonings) to reduce material waste.

2. Flexible Model Change: The single-head design supports quick replacement of filling heads and screws of different specifications (e.g., adapting to 50-500g bottle types). Parameters can be switched with one click via the touchscreen, completing specification adjustments within 10 minutes and compatible with various bottle types (round, square, special-shaped) and powder properties (good/poor fluidity).

3. Dust-proof and Explosion-proof Design: A fully enclosed filling chamber with a negative pressure dust removal device effectively suppresses powder spillage. Material-contact components are made of 304 stainless steel or food-grade plastic with mirror polishing, complying with GMP/FDA hygiene standards for high-cleanliness fields like food and pharmaceuticals.

4. Intelligent Fault Diagnosis: Equipped with functions such as automatic shutdown for missing bottles, blockage alarms, and weight anomaly prompts, it displays real-time operation status via the touchscreen, reducing manual monitoring costs and improving production stability.

5. Low Energy Consumption and High Efficiency: The single-head structure has low energy consumption (power: approximately 1.5-3kW), capable of filling 10-30 bottles per minute (depending on bottle type and powder properties), increasing efficiency by over 50% compared to traditional semi-automatic equipment. It is suitable for automated upgrades in small-to-medium batch production.

Full-automatic single-head powder bottle filling machineApplications

1. Food Industry:

- Condiments: Bottled powder seasonings like pepper, coffee powder, milk powder, and protein powder;

- Health Foods: Small-specification bottled production of meal replacement powders, probiotic powders, and nutritional powders.

2. Pharmaceutical Industry:

- Powder Medicines: Pharmaceutical-grade filling of Chinese herbal powders, western medicine granules, disinfectant powders, etc., supporting linkage with aluminum foil sealing.

3. Chemical/Cosmetic Industry:

- Cleaning Powders (laundry powder, dishwashing powder), cosmetic powders (talcum powder, facial mask powder), industrial additives, and other non-food powder filling.

4. Research/Laboratory Scenarios:

- Small-batch sample development, such as precise dispensing of new material powders and biological reagent powders.

Full-automatic single-head powder bottle filling machineFeatures

1. Compact Single-head Design: Small footprint (approximately 1.2×0.8 meters), suitable for small-to-medium enterprises with limited workshop space. It can operate alone or connect with downstream sealing and labeling equipment to form a simple production line.

2. User-friendly Interface: 7-10-inch color touchscreen supporting multi-language interfaces (Chinese/English/others), with intuitive parameter settings for quick operation by new employees.

3. Easy Cleaning and Maintenance: Core components like filling heads and screws can be quickly disassembled, combined with CIP (Clean-in-Place) interfaces to reduce cleaning time and meet hygiene requirements for high-frequency production.

4. Complete Safety Protection: Equipped with emergency stop buttons, protective barriers, and photoelectric safety light curtains to prevent accidental contact with moving parts, complying with CE safety certification standards.

Lead time

Product Inquiry