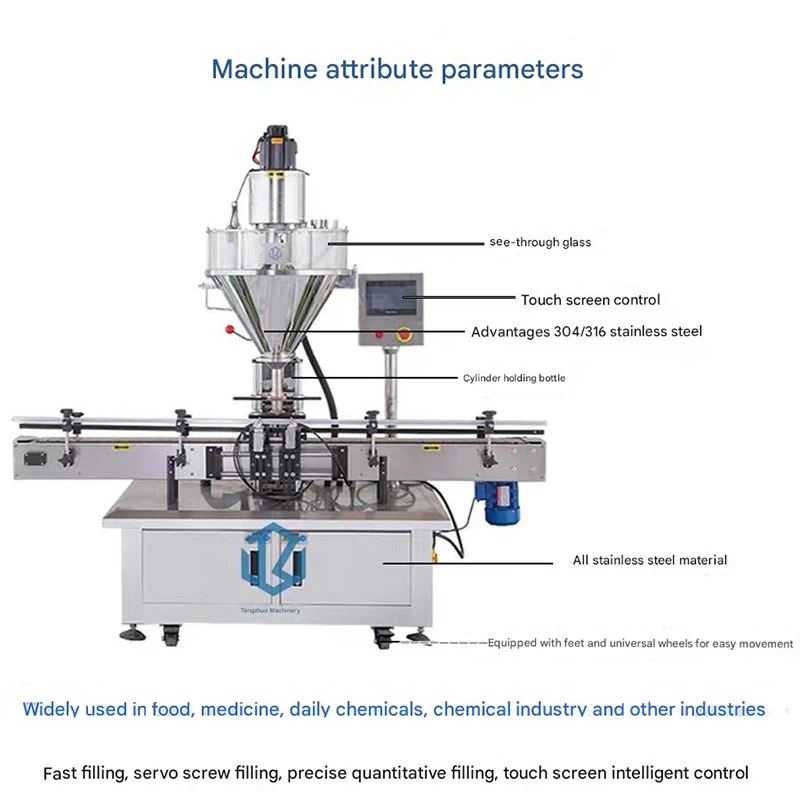

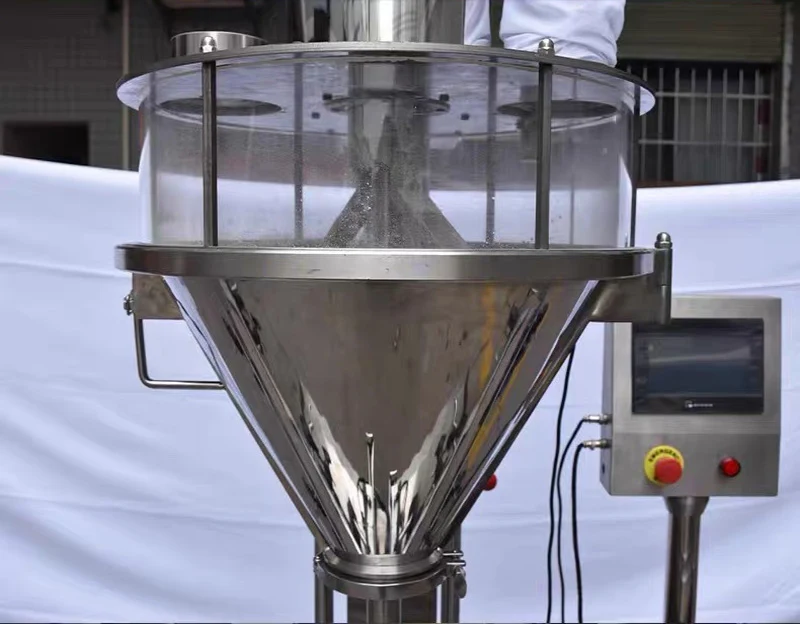

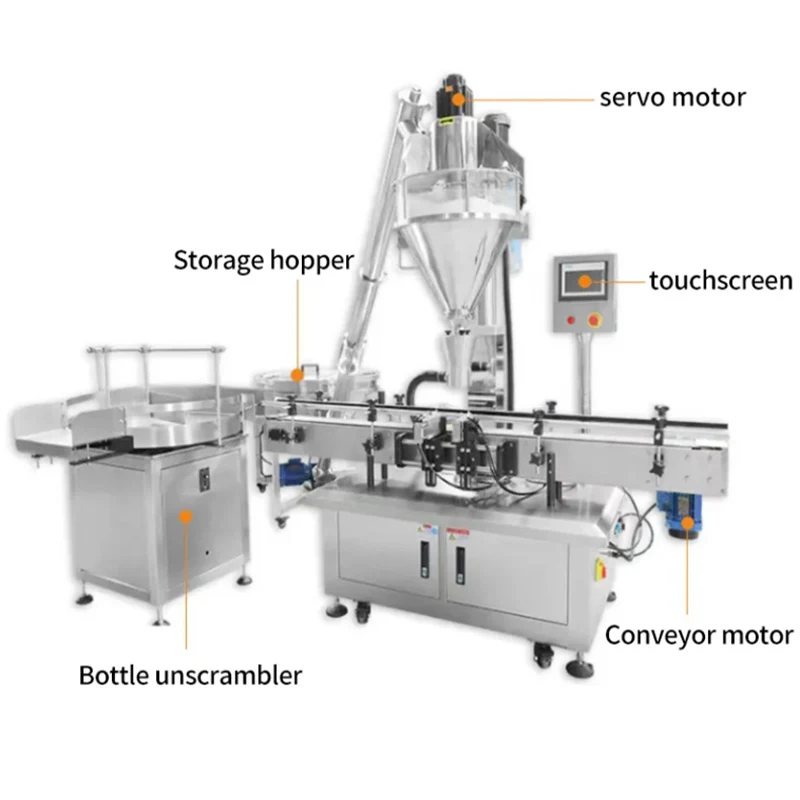

The full - automatic powder filling machine plastic packaging assembly line is an integrated production system designed for the efficient and continuous processing of powder products. It combines multiple automated processes, including powder metering and filling, plastic bag feeding, sealing, coding, and product conveying. The powder filling machine precisely measures and dispenses powder into plastic packaging materials, such as bags or containers. Meanwhile, the plastic packaging system

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

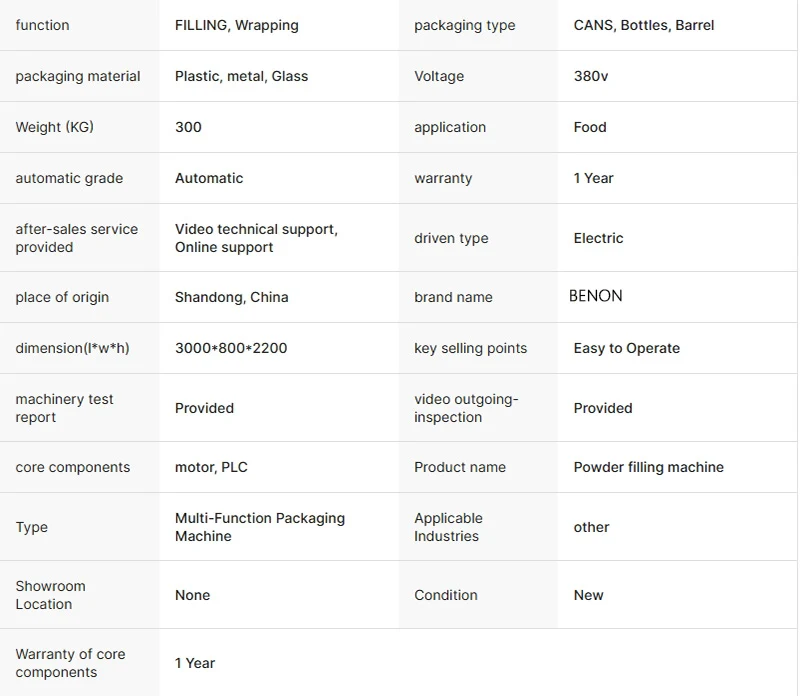

Full-automatic Powder Filling MachineAdvantages

1. High Efficiency:By integrating multiple processes into one continuous line, it significantly reduces manual intervention and production time, greatly increasing the output per unit time compared to traditional single - machine operations.

2. Accuracy and Consistency:The powder filling machine uses advanced metering technology, ensuring accurate powder dosing for each package, which minimizes product weight variations and improves product quality consistency.

3. Cost - saving:Automation reduces the need for a large number of laborers, lowering long - term labor costs. Additionally, accurate filling and reliable sealing reduce material waste, contributing to overall cost savings.

4. Flexibility:It can be easily adjusted to handle different types of powder products and various packaging specifications, such as different bag sizes and shapes, to meet diverse market demands.

5. Hygiene and Safety:The fully enclosed production environment reduces the risk of powder contamination, meeting strict hygiene requirements, especially for products in the food and pharmaceutical industries. Automatic safety features also protect operators from potential hazards during operation.

Full-automatic Powder Filling MachineApplications

1. Food Industry:Used for packaging various powdered food products, such as milk powder, coffee powder, seasoning powder, flour, and instant drink mixes. It ensures the freshness and hygiene of food products while meeting high - volume production needs.

2. Pharmaceutical Industry:Ideal for filling and packaging pharmaceutical powders, like powdered drugs, nutritional supplements, and medical powders. The high precision and hygiene standards of the assembly line are crucial for maintaining the quality and efficacy of pharmaceutical products.

3. Chemical Industry:Applied to pac

kage chemical powders, including pigments, dyes, fertilizers, and various industrial powders. It can handle potentially hazardous chemical powders safely and efficiently.

4. Cosmetics Industry:Used to fill and package cosmetic powders, such as face powder, eye shadow powder, and bath salts, ensuring accurate dosing and elegant packaging for high - end cosmetic products.

Full-automatic Powder Filling MachineFeatures

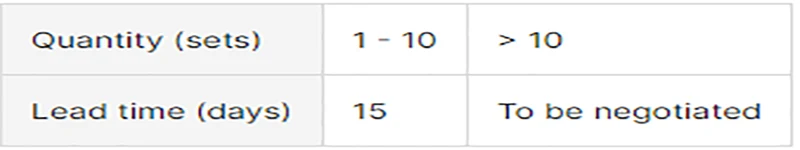

1. Intelligent Control:Equipped with a PLC (Programmable Logic Controller) or advanced computer control system, operators can easily set parameters, monitor production status, and troubleshoot problems through a user - friendly touch - screen interface

2. High - speed Operation:The assembly line is designed for high - speed production, capable of handling a large number of packages per minute, which meets the mass - production requirements of modern enterprises.

3. Self - diagnosis and Alarm Function:It has built - in sensors and diagnostic systems that can detect malfunctions, such as blockages in the powder feeding system, sealing failures, or abnormal temperature, and immediately trigger alarms to notify operators for timely maintenance.

4. Easy Maintenance and Cleaning:The modular design of the equipment allows for quick disassembly and replacement of components, facilitating regular maintenance. Smooth surfaces and detachable parts make it easy to clean, ensuring compliance with hygiene regulations.

5. Energy - efficient Design:Adopts energy - saving technologies, such as variable - frequency drives for motors, to optimize energy consumption during operation, reducing the overall energy footprint of the production process.

Lead time

Products Description

Product Inquiry