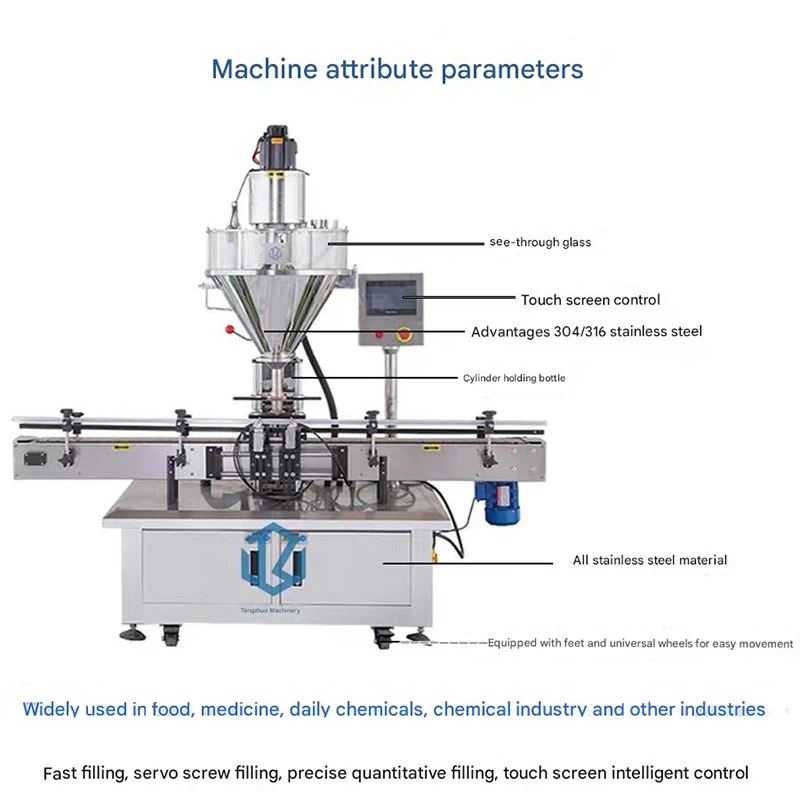

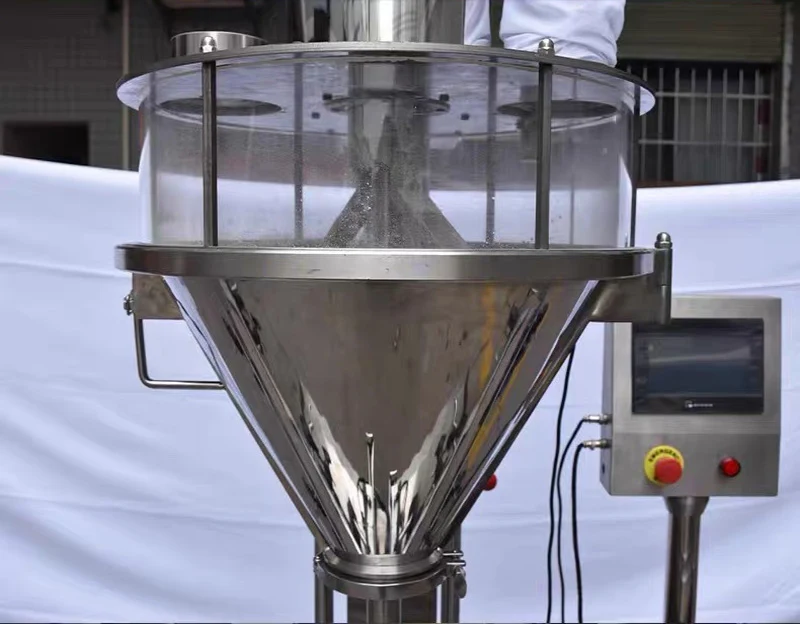

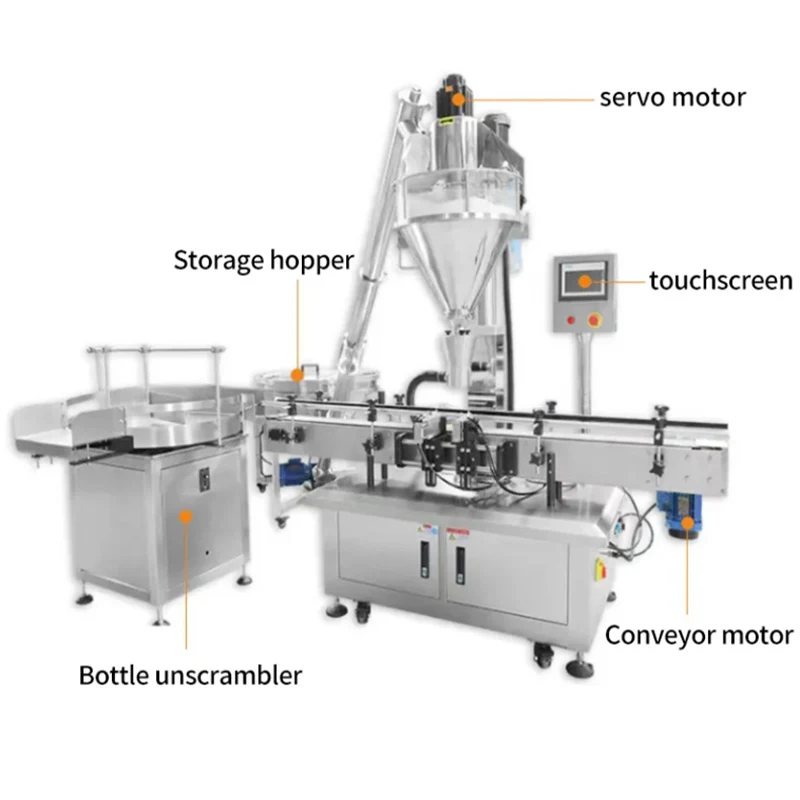

The full-automatic plastic packaging powder filling machine is an advanced industrial equipment designed to precisely measure and fill various types of powders into plastic packaging containers. It integrates automatic feeding, metering, filling, and sealing processes, reducing manual intervention and significantly improving production efficiency. The machine is highly adaptable to different powder properties, such as fineness, fluidity, and density, and can be adjusted to meet various packaging

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

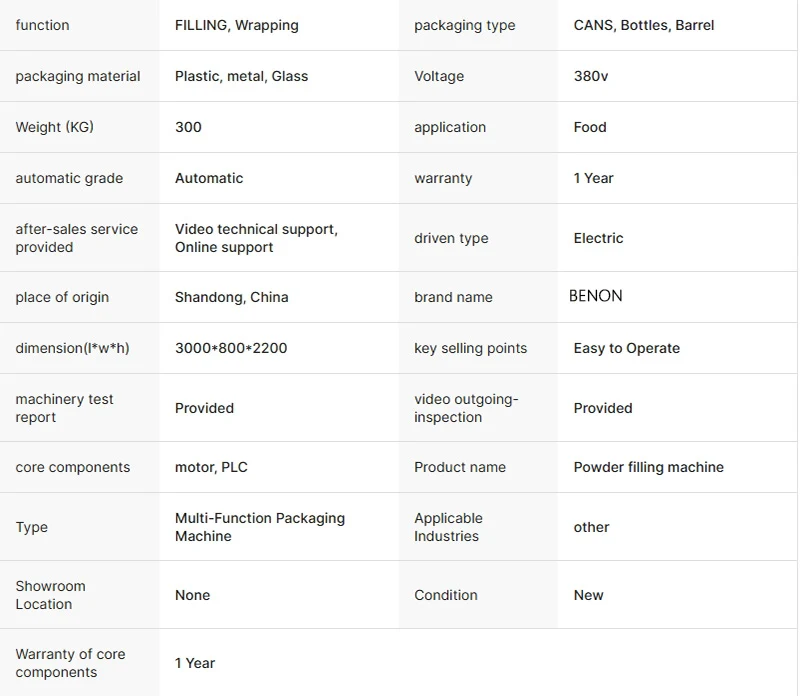

Full-automatic plastic packaging powder filling machineAdvantages

1. High Efficiency:With its automated operation, it can complete a large number of filling tasks in a short time, far exceeding the output of manual or semi-automatic filling methods, which is conducive to mass production.

2. Accurate Filling:Equipped with precise metering systems, it can achieve high-precision filling, minimizing errors in filling volume, ensuring product consistency, and reducing material waste.

3. Cost - saving:Automation reduces the demand for labor, cuts down on labor costs in the long run. Meanwhile, accurate filling and reduced material waste also contribute to cost savings.

4. Versatility:Capable of handling a wide range of powder products, from food powders like milk powder, flour, to industrial powders such as chemicals, pharmaceuticals, and building materials.

5. Enhanced Hygiene:In the case of food and pharmaceutical applications, the closed filling process minimizes the contact between the powder and the external environment, reducing the risk of contamination and ensuring product safety and hygiene.

Full-automatic plastic packaging powder filling machineApplications

1. Food Industry:Used for filling powdered food products, including infant formula, coffee powder, seasoning powder, and powdered beverages.

2. Pharmaceutical Industry:Ideal for filling pharmaceutical powders, such as raw materials for tablets, capsules, and health supplements, ensuring accurate dosing and product quality.

3. Chemical Industry:Applied to fill chemical powders, like pesticides, fertilizers, dyes, and other industrial chemicals, meeting strict production requirements.

4. Cosmetics Industry:Suitable for filling cosmetic powders, such as face powder, eyeshadow powder, ensuring consistent product quality and accurate packaging volume.

5. Building Materials Industry:Can be used to fill building material powders, like cement powder, dry mortar powder, improving the efficiency of construction material production.

Full-automatic plastic packaging powder filling machineFeatures

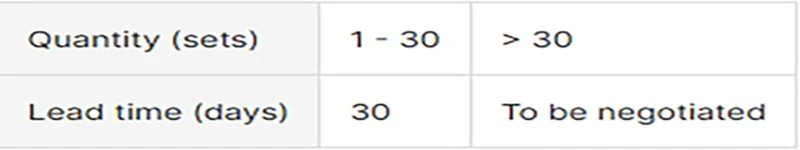

1. Intelligent Control:It is equipped with a PLC control system and a touch - screen interface, enabling easy operation, parameter adjustment, and real-time monitoring of the filling process. Operators can quickly set filling volume, speed, and other parameters according to production needs.

2. Flexible Adjustment:The machine can be easily adjusted to accommodate different sizes and shapes of plastic packaging containers, as well as various filling volumes, providing great flexibility for different production requirements.

3. Reliable and Durable:Made of high-quality materials and components, it has good wear resistance and corrosion resistance, ensuring long-term stable operation and reducing maintenance frequency.

4. Safety Design:With safety protection devices, such as emergency stop buttons, safety interlocks, and overpressure protection, it can effectively prevent accidents during operation, ensuring the safety of operators and equipment.

5. Easy to Clean and Maintain:The structure of the machine is designed to be easy to disassemble and clean, which helps to avoid cross-contamination between different products. Regular maintenance is simple, reducing downtime and improving overall production efficiency.

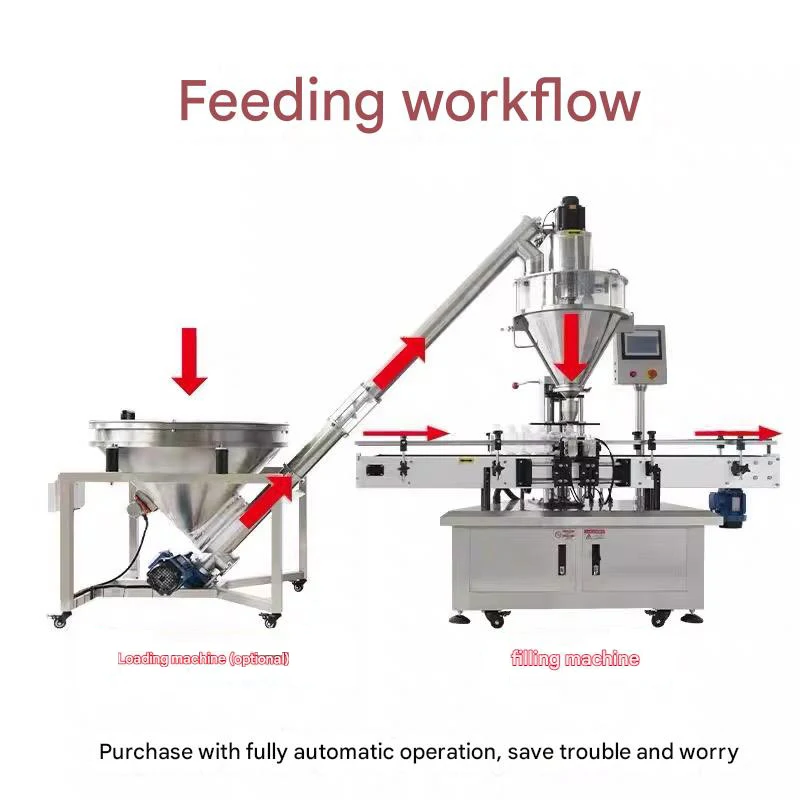

Lead time

Products Description

Product Inquiry