In the field of automated packaging and palletising, various professional robots showcase their strengths: the fully automatic nut bagging articulated robot precisely manages the bagging process of nuts, ensuring that the specifications of each bag of products are consistent; Kawasaki packaging and palletising robots achieve seamless integration between packaging and palletising, significantly enhancing production efficiency with their efficient and stable performance; the Benson grain packaging

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

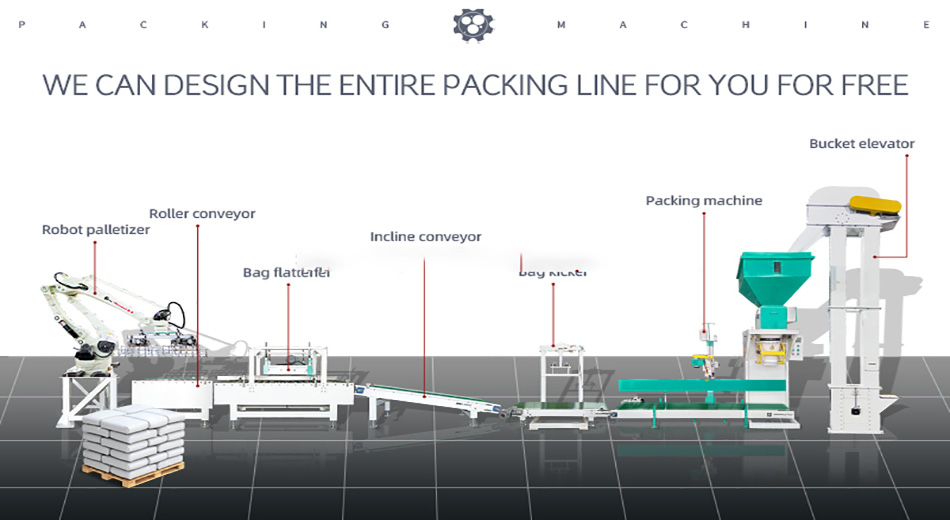

Product descriptions from the supplier

Video Description

Key attributes

| machinery test report | Provided | Voltage | 220/380V OR CUSTOMIZED |

| video outgoing-inspection | Provided | packaging type | Cartons, CANS, Bags, Film, case |

| packaging material | plastic, Paper, Metal, Wood | warranty | 1 Year |

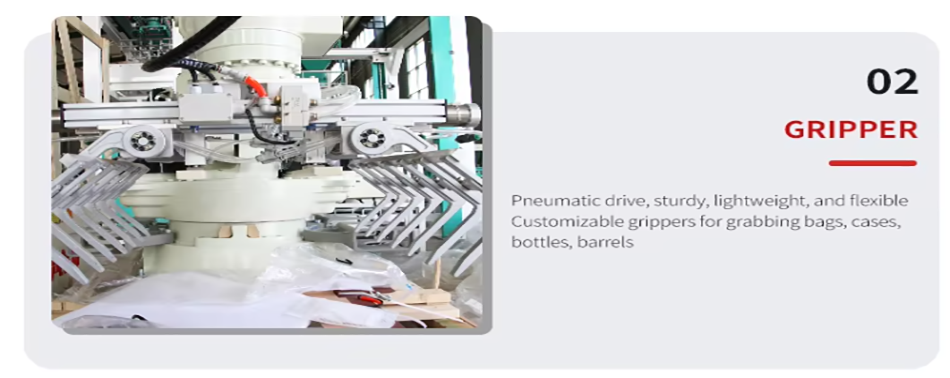

| driven type | Pneumatic | automatic grade | Automatic |

| application | Food, Chemical, Machinery & Hardware | key selling points | Easy to Operate |

| Weight (KG) | 1800 | place of origin | Shandong, China |

| brand name | BENSON | dimension(l*w*h) | 2200x3200x3700 |

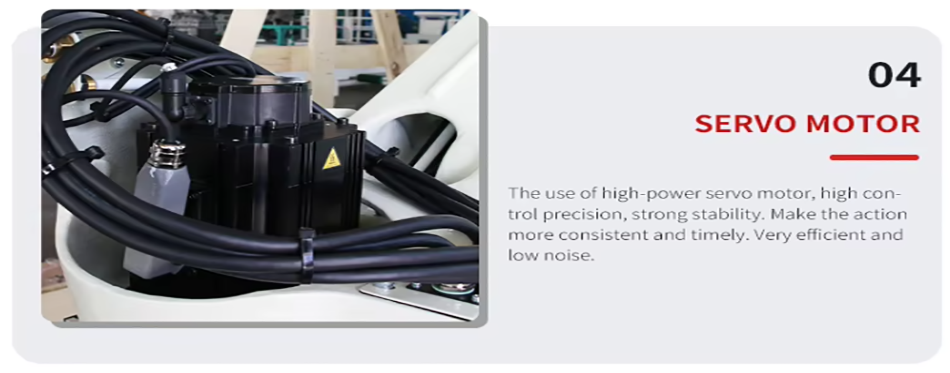

| core components | motor, Pump, PLC, Other | Product name | Robot Palletizer |

| Speed | 600-1000pcs/hour | Type | Palletizing Line |

| Packaging Type | Cartons, Bottles, Bags, case | Automatic Grade | Automatic |

| Voltage | 220/380V OR CUSTOMIZED | After-sales Service Provided | Provided |

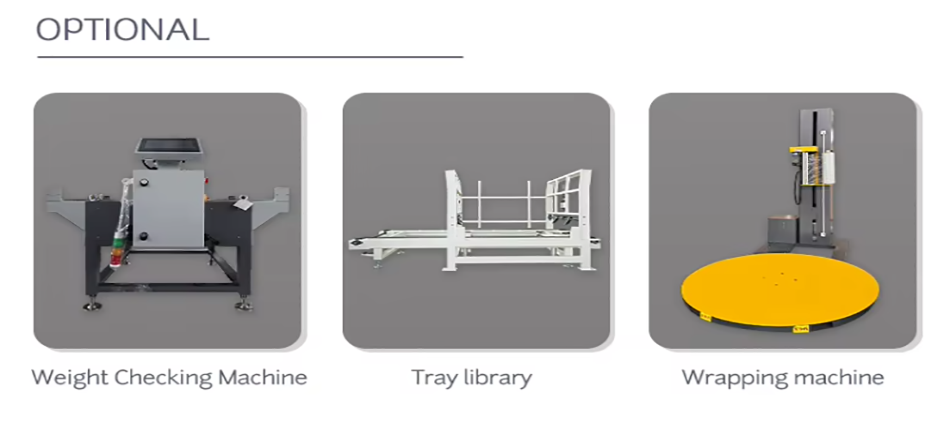

PRODUCT DETAILS

MACHINE COMPONENTS

COMPANY PROFILE

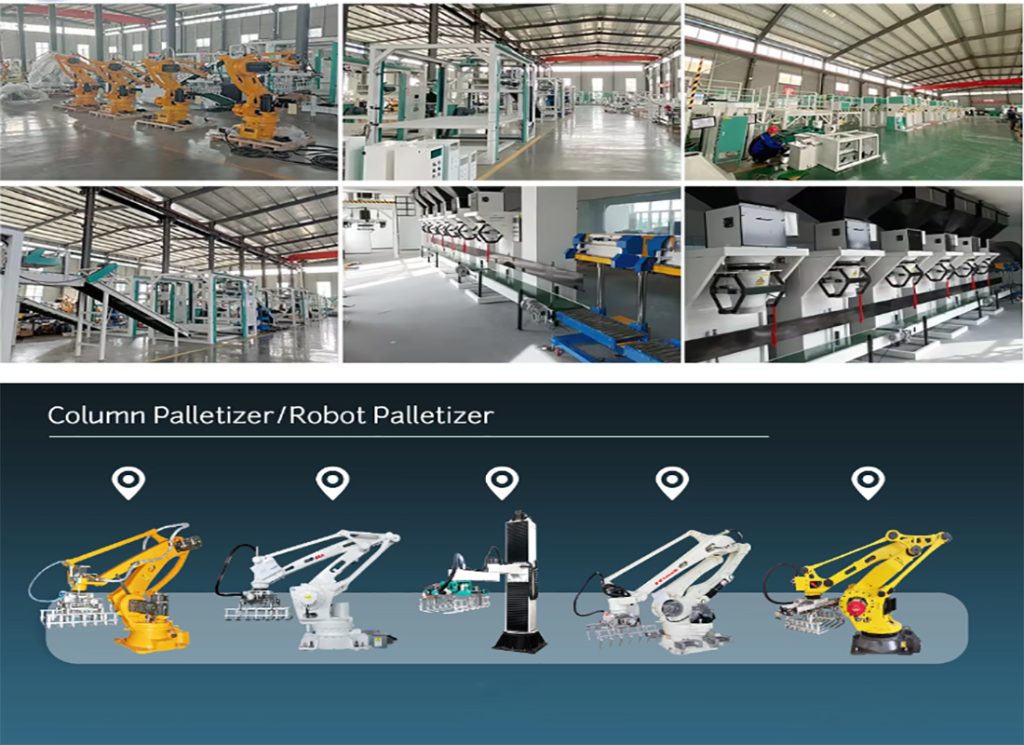

BENSON Intelligent Equipment (Shandong) Co., Ltd. is a modern high-tech enterprise, focusing on the research and development of industrial robots, palletizing robots, palletizers, high-position palletizers, fully automatic bagging packaging machines, packaging machines, batching equipment, depalletizers, loaders, logistics automation lines and other projects. The company has brought together a group of high-level and high-quality professionals. The company actively promotes the development model of “production, learning and research” and has successfully developed a new generation of automated production lines that can be widely used in automated packaging and automated logistics engineering. Its capabilities and various technical indicators are at a high level. In order to comprehensively improve its market competitiveness, the company has selected a large number of high-quality accessories from the United States, Japan, Europe and other countries, and introduced various advanced processing equipment to greatly improve the quality of its products. It has been widely used in chemical, feed, flour, building materials, food, beverages, beer, automated logistics and other industries. From product import to output, from electrical control to mechanical structure design, BENSON Intelligent Equipment (Shandong) Co., Ltd. can fully provide system technical solutions and precision manufacturing of equipment. At the same time, we have a complete after-sales service system to provide you with high-quality technical support and after-sales service.

PACKAGING & DELIVERY

Production workshop

FAQ

Q1: Are you factory or trading company?

A1: We are the factory, we doing this line for more than 5 years.

Q2: How to choose suitable packaging machine?

A2: Need to provide your material pictures and requirements, such as packaging speed, packaging weight, bag type and bag size.

Q3: How to ensure the quality of the machine?

A3: We usually delivery the machine after successful inspection in our factory. We have our own quality control department,beforethe delivery we have to running the machine for three days without problem. You can send us your materials and we will make video as long as you want. Or you can arrange a third-party inspection agency.

Q4: How to install the equipment?

A4: We will provide manuals and detailed videos to help customer install machine.

Product Inquiry