In the field of daily necessities production, the efficiency and accuracy of the filling process directly affect product quality and corporate benefits. With its excellent performance, the fully automatic multifunctional daily necessities filling machine has become the core equipment for the daily chemical industry to achieve automated and intelligent production, providing strong support for enterprises to reduce costs and increase efficiency and enhance market competitiveness.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Core functions and advantages of multifunctional filling machine

Multifunctional compatibility to meet diverse needs

It can be widely used in the filling of various liquid, paste, and emulsion daily necessities such as shampoo, shower gel, laundry detergent, hand soap, skin care products, and cosmetics, and supports fast switching of products of different specifications (from 50ml sample to 5L family pack) and different bottle types (round, square, special-shaped bottles, etc.). Through modular design, the filling head can be replaced and the conveying track can be adjusted to adapt to different product characteristics. One machine can be used for multiple purposes, effectively reducing equipment procurement and maintenance costs.

Intelligent and precise, worry-free quality

Precise measurement: It adopts a variety of measurement methods such as piston type, flow meter type, and weighing type, which can be flexibly selected according to product characteristics to ensure that each filling meets the set standards and avoid material waste.

Anti-drip design: The filling head is equipped with a vacuum suction device, which automatically sucks back the residual liquid after filling, eliminates dripping and drawing, keeps the production line clean, and improves the appearance quality of the product.

Fault self-checking: It has an intelligent fault diagnosis system to monitor the operation status of the equipment in real time. Once an abnormality occurs (such as lack of bottles, bottle jams, filling volume deviation, etc.), it will immediately alarm and automatically shut down, which is convenient for quick troubleshooting and maintenance.

Sanitary and safe, in line with industry standards

The whole machine is made of 304 stainless steel and food-grade engineering plastics, which is corrosion-resistant, easy to clean, and meets GMP production standards; the parts that contact the materials are made of non-toxic and harmless materials to ensure that the products are safe and pollution-free, meeting the needs of industries such as daily chemicals and medicines that have extremely high hygiene requirements. At the same time, the equipment has a strict protective structure and is equipped with safety light curtains and emergency stop buttons to ensure the personal safety of operators.

Flexible adaptation and personalized customization

Support customized solutions based on the actual production needs of the enterprise. Whether it is adjusting the number of filling heads to increase production capacity, adding special function modules (such as nitrogen filling, anti-foam filling, etc.), or connecting to the company's existing production lines for seamless integration, it can respond quickly and create a filling system that meets business needs for the company.

Application scenarios

- Personal care products: suitable for filling shampoo, conditioner, shower gel, facial cleanser and other products.

- Household cleaning products: can complete the efficient filling of large-volume packaging such as laundry detergent, dishwashing liquid, glass cleaner, etc.

- Cosmetics: accurately meet the filling needs of skin care products and makeup products such as essence, lotion, face cream, hand cream, etc.

After-sales service guarantee

We provide a full range of after-sales services, including equipment installation and commissioning, operation training, regular maintenance and 24-hour online technical support. The professional after-sales team responds quickly to ensure the stable operation of the equipment and escort the production of the enterprise.

Choosing our fully automatic multi-functional daily necessities filling machine is to choose an efficient, precise and intelligent production experience, helping enterprises to stand out in the competition in the daily chemical market and achieve high-quality development! Fully automatic multi-functional daily necessities filling machine-efficient, precise and intelligent filling solution

In the field of daily necessities production, the efficiency and precision of the filling link directly affect product quality and corporate benefits. With its excellent performance, the fully automatic multifunctional daily necessities filling machine has become the core equipment for the daily chemical industry to achieve automated and intelligent production, providing strong support for enterprises to reduce costs, increase efficiency and enhance market competitiveness.

Products Description

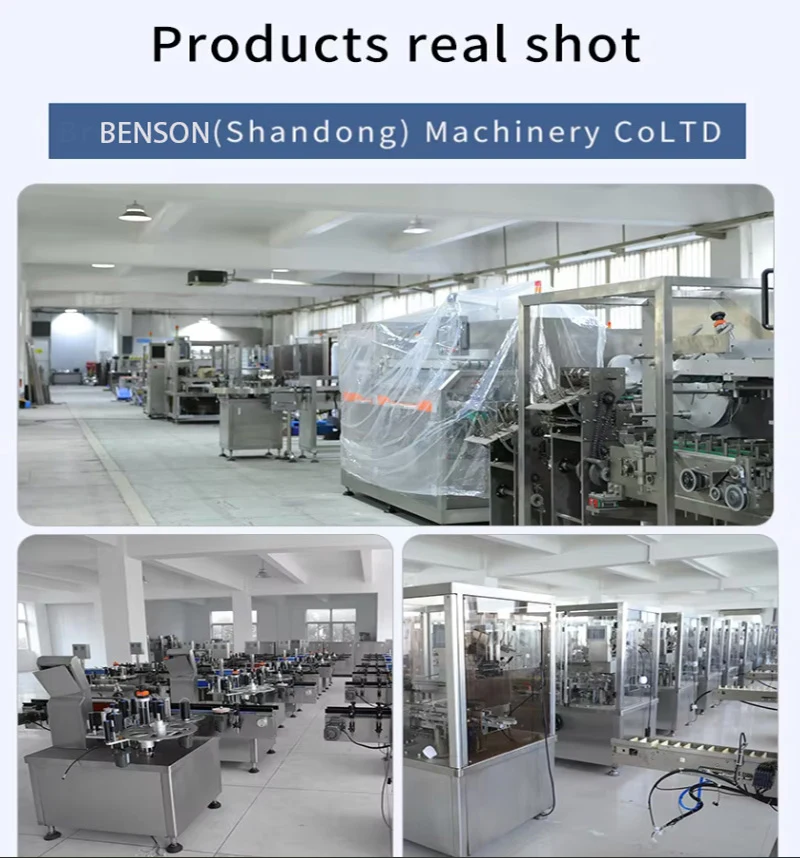

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry