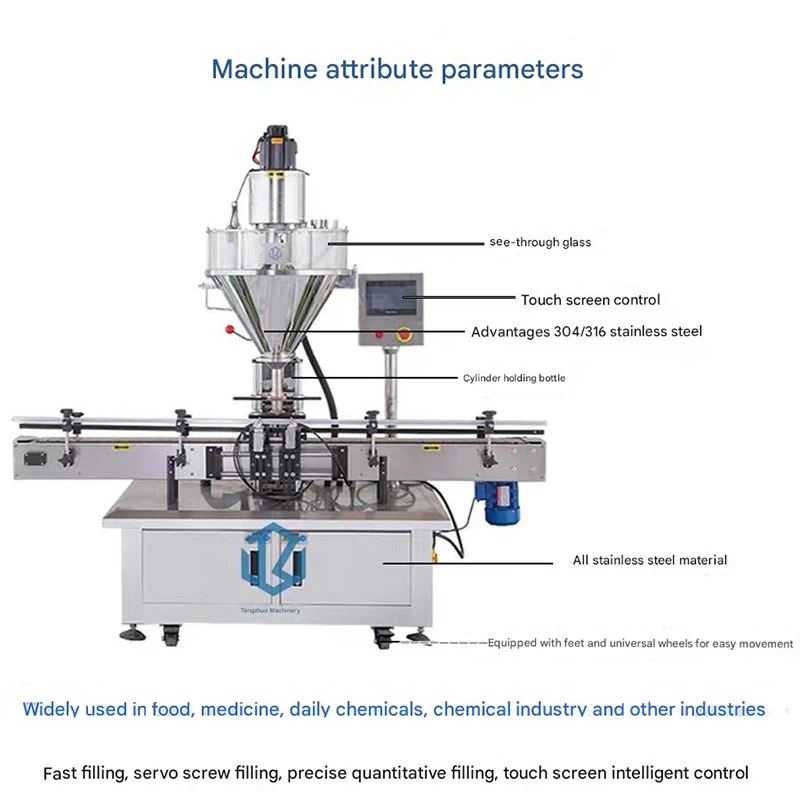

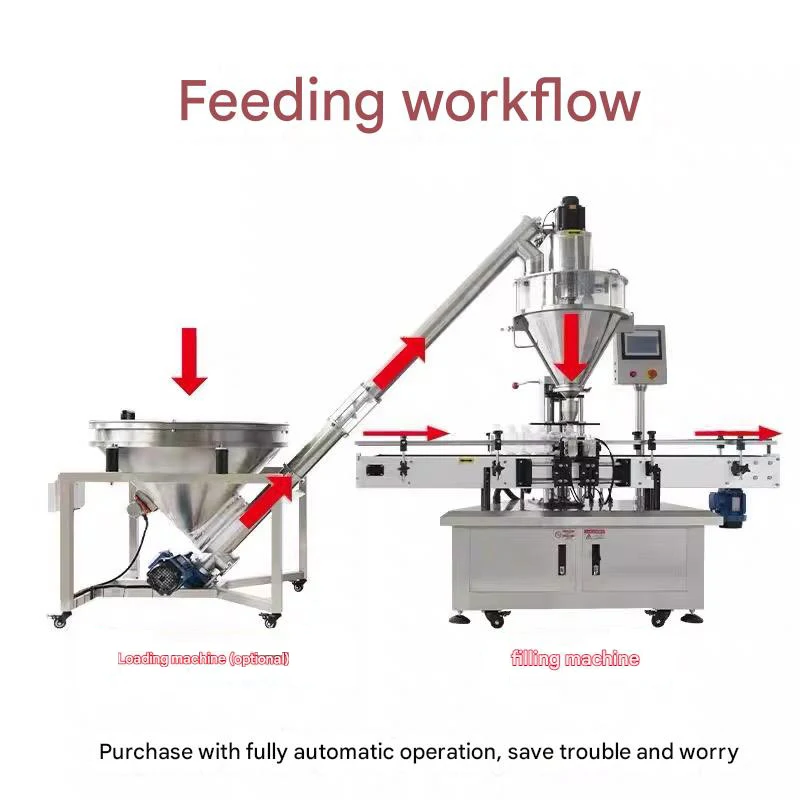

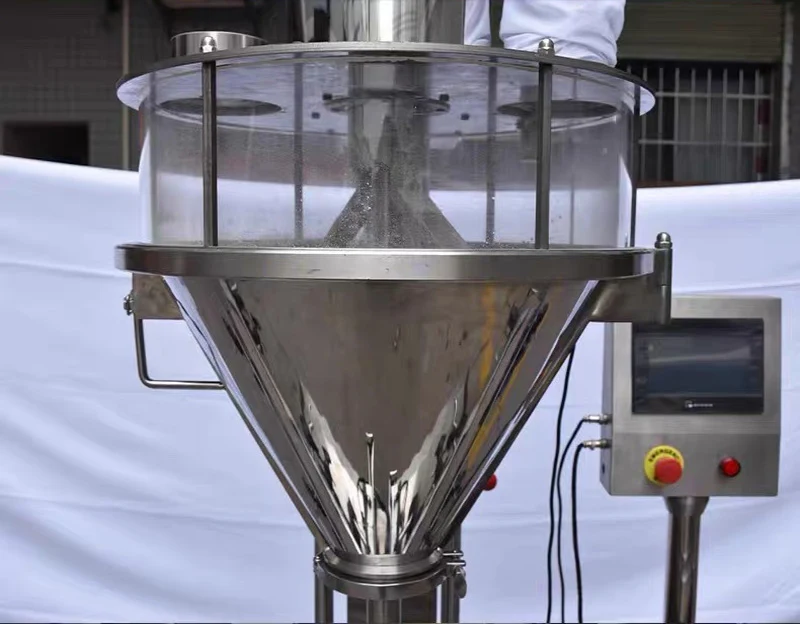

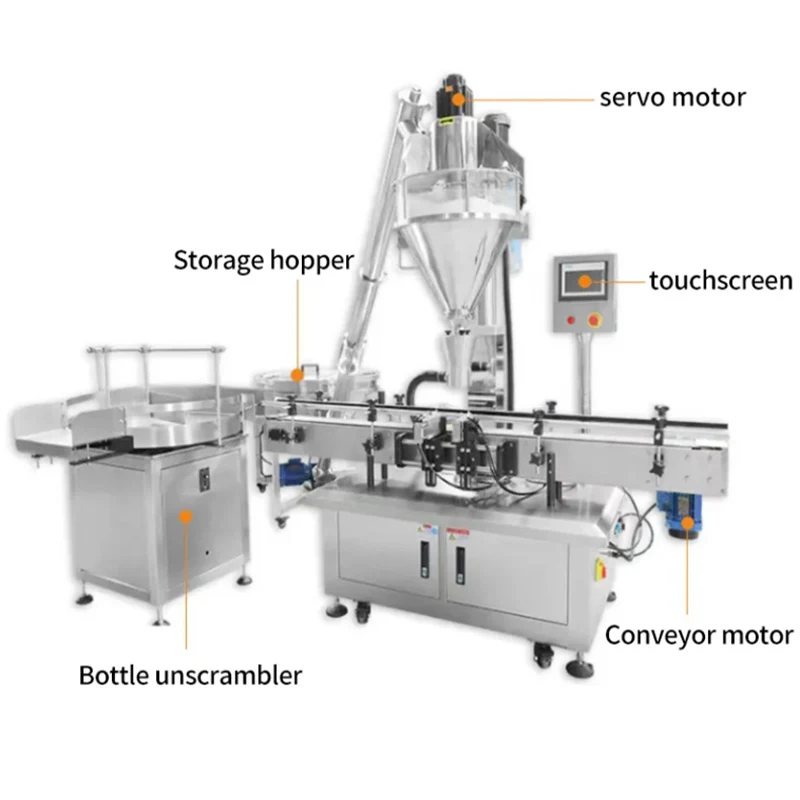

The full-automatic food-grade plastic packaging and filling machine is a highly intelligent industrial device specialized in integrated production of filling and plastic packaging for food products. With a PLC control system at its core, it integrates advanced technologies such as sensing detection, mechanical transmission, and pneumatic control, enabling automatic completion of a series of operations including transportation, positioning, filling, sealing, and counting of plastic packaging

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Full-automatic food-grade plastic packaging and filling machineAdvantages

1. High Efficiency: With automated continuous operation capability, it can complete dozens or even hundreds of filling and packaging operations per minute. Compared with traditional manual or semi-automatic equipment, its production capacity is increased by several times, meeting large-scale production needs and effectively reducing unit production costs.

2. Precise Measurement: Equipped with high-precision metering pumps, flow meters, and other devices, the filling volume error can be controlled within a minimal range, ensuring accurate and consistent capacity for each product, complying with strict quality standards and regulatory requirements, and reducing material waste.

3. Hygiene and Safety: Components in contact with food are made of food-grade stainless steel, non-toxic plastics, and other materials, with smooth surfaces for easy cleaning to effectively prevent food contamination. The equipment also features complete cleaning and disinfection functions, such as CIP (Clean-in-Place) and SIP (Sterilize-in-Place) systems, to ensure a hygienic production environment.

4. Flexibility and Versatility: It supports various plastic packaging forms, such as plastic bottles, cans, and boxes. By quickly replacing molds and adjusting parameters, it can adapt to different specifications and shapes of packaging containers, as well as filling and packaging various types of food, including liquids (e.g., beverages, cooking oil), pastes (e.g., jam, condiments), and granular products (e.g., candies, grains).

5. Stability and Reliability: Using high-quality components and mature mechanical structure design, it has strong anti-interference capability and durability, with low failure rates and long maintenance cycles, enabling stable long-term operation and reducing downtime and maintenance costs.

Full-automatic food-grade plastic packaging and filling machineApplications

1. Beverage Industry: Suitable for filling and packaging various liquid beverages (e.g., carbonated drinks, juices, dairy products, alcoholic beverages) in plastic bottles, such as common PET bottled cola and mineral water.

2. Condiment Industry: Used for filling and packaging seasonings (e.g., soy sauce, vinegar, cooking wine, cooking oil, ketchup, salad dressing) in plastic bottles or cans, meeting the diverse needs of household and catering markets.

3. Food Processing Industry: Capable of filling and packaging jams, honey, canned foods (e.g., fruit cans in plastic boxes), frozen foods (e.g., dumplings in plastic trays), etc., extending food shelf life and facilitating storage and transportation.

4. Snack Food Industry: Achieves filling and sealing of granular and flaky snack foods (e.g., potato chips, nuts, biscuits) in plastic bags or boxes, providing good sealing and preservation conditions for products.

Full-automatic food-grade plastic packaging and filling machineFeatures

1. Intelligent Control: Equipped with a touchscreen human-machine interface for simple and intuitive operation. Operators can easily set parameters such as filling volume, packaging speed, and production batches. The equipment also has automatic fault diagnosis and alarm functions to quickly locate problems and prompt maintenance, reducing operation difficulty and professional requirements for operators.

2. Energy Saving and Environmental Protection: Using energy-efficient motors, optimized pneumatic systems, and intelligent control systems, it reduces energy consumption while ensuring high-efficiency production. Additionally, it operates with low noise, complies with environmental standards, and minimizes impact on the production environment and surrounding residents.

3. Modular Design: The whole machine adopts a modular structure, with relatively independent functional units for easy installation, debugging, maintenance, and upgrading. When a component fails, the corresponding module can be quickly replaced to shorten downtime for repairs. It also facilitates functional expansion and personalized customization according to production needs.

4. Safety Protection: Multiple safety protection devices are installed, such as emergency stop buttons, safety light curtains, and protective barriers, which effectively prevent accidental injuries to operators during equipment operation and ensure production safety

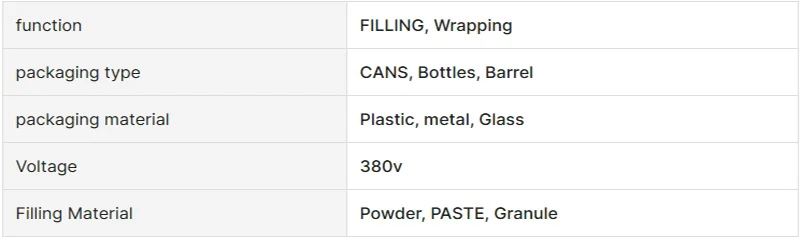

Key attributes

Industry-specific attributes

Products Description

Product Inquiry