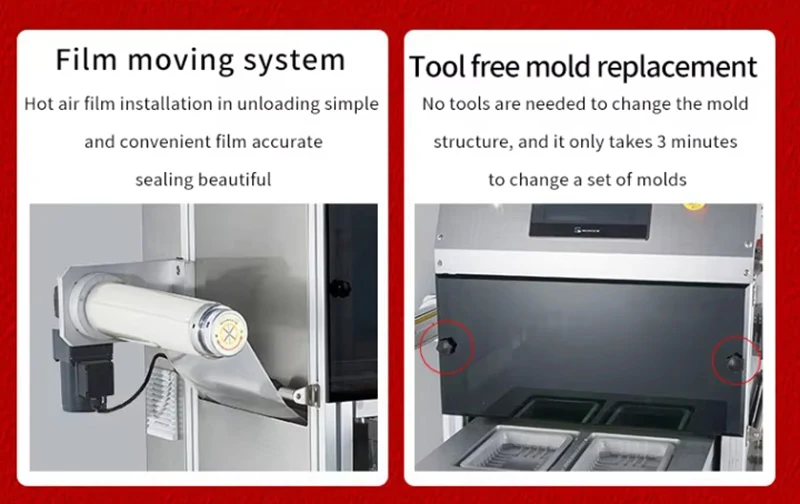

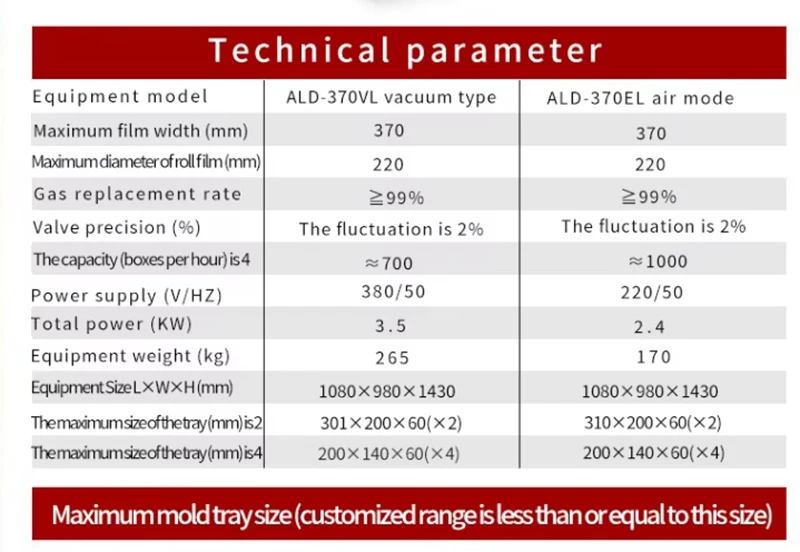

The "fully automatic fresh-keeping and sealing machine for fast food boxes" is a highly intelligent packaging device that integrates functions such as automated conveying, precise positioning, efficient sealing, and fresh-keeping treatment. Through the coordinated operation of sensors and robotic arms, the equipment can automatically complete a series of processes such as feeding fast food boxes, cutting sealing films, hot-pressing sealing, vacuuming, or filling with fresh-keeping

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

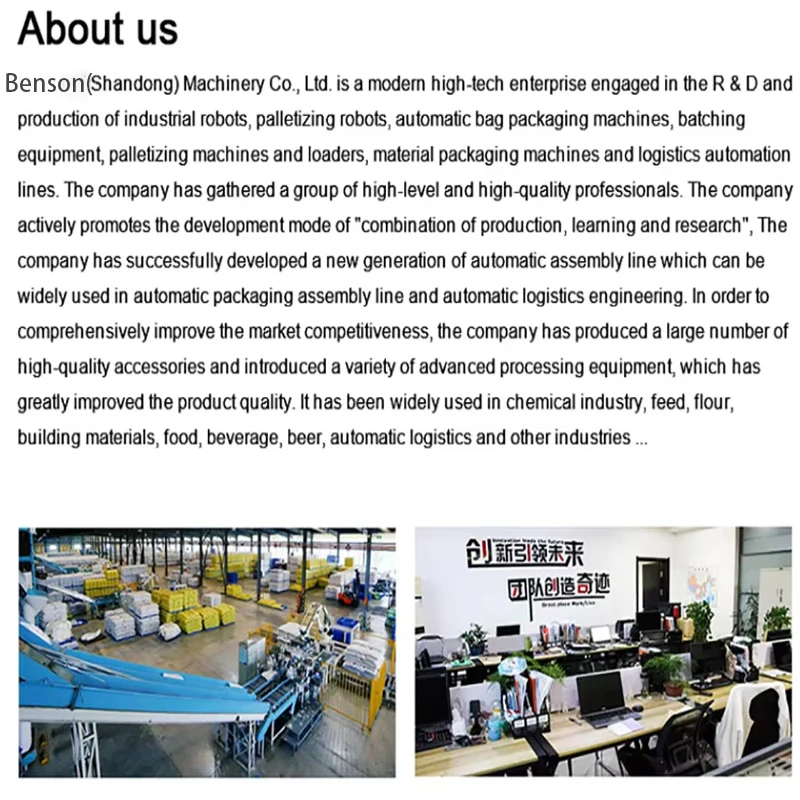

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

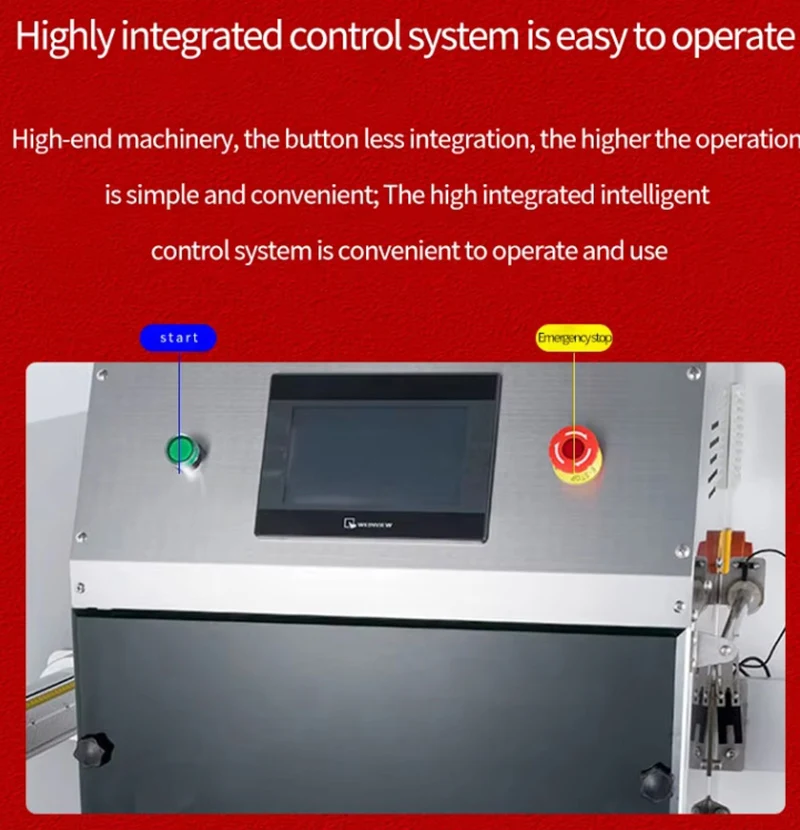

Fully automatic fresh-keeping and sealing machine for fast food boxesAdvantages

1. High-efficiency automation: It can process 30-60 fast food boxes per minute, significantly reducing labor costs and time consumption, and meeting the needs of large-scale production.

2. Excellent fresh-keeping effect: It supports vacuum sealing or filling with inert gas, effectively isolating oxygen and bacteria, extending the shelf life of food, and maintaining the fresh taste and nutritional components of food.

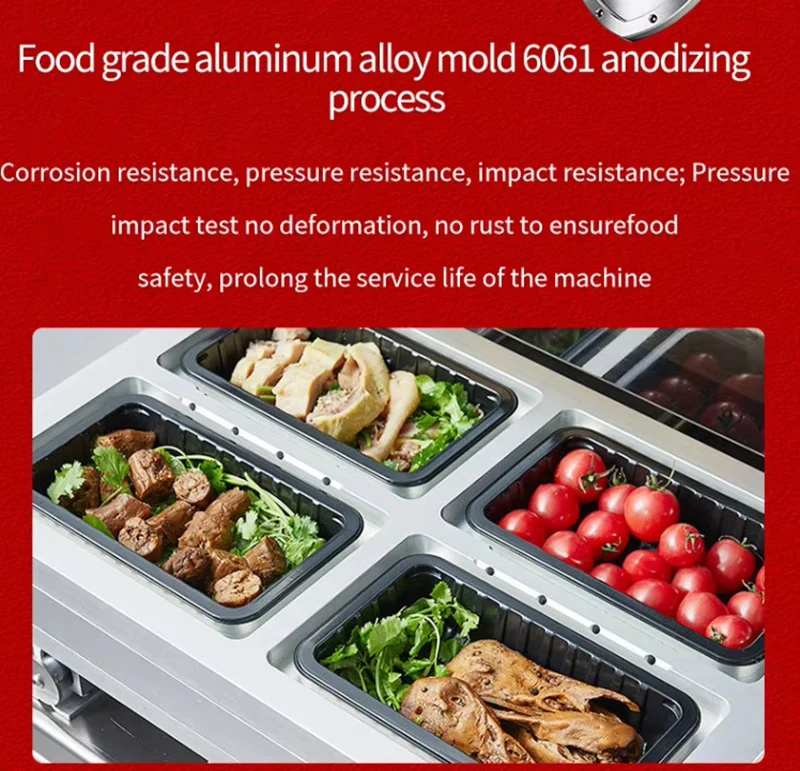

3. Precise and stable: It adopts an intelligent temperature control and pressure control system to ensure tight sealing without leakage, avoiding the leakage of soup or the entry of air, and improving the packaging quality.

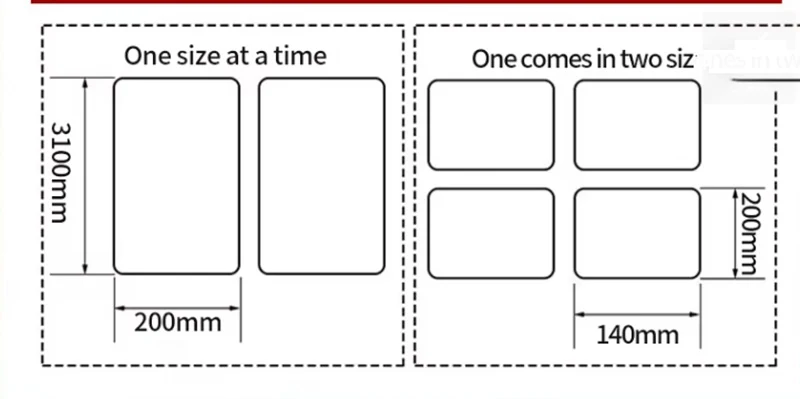

4. Strong compatibility: It is suitable for fast food boxes of various specifications and materials (such as PP, PET, paper, etc.), and can flexibly adjust the sealing parameters to meet the needs of different customers.

5. Safe and environmentally friendly: It is equipped with an automatic detection and alarm function to prevent malfunctions such as overheating and jamming of boxes; it uses environmentally friendly packaging materials, which is in line with the concept of sustainable development.

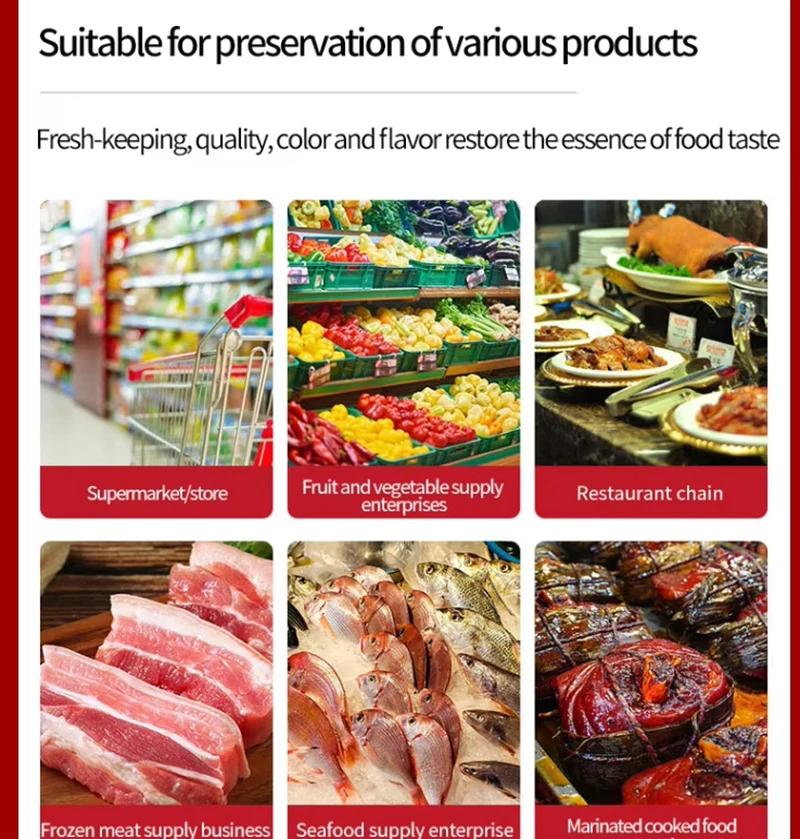

Fully automatic fresh-keeping and sealing machine for fast food boxesApplications

1. The catering and takeout industry: It is used for batch packaging of meals for chain restaurants and takeout platforms to ensure that the food remains fresh and does not spill during transportation.

2. Food processing enterprises: It is used for the fresh-keeping packaging of pre-packaged foods and ready-to-eat meals, extending the shelf life and enhancing the product competitiveness.

3. Supermarkets and convenience stores: It is used for packaging fresh salads, cooked foods, and semi-finished dishes to meet consumers' needs for convenient and fresh foods.

4. Central kitchens: It cooperates with assembly line operations to achieve efficient and standardized meal packaging, supporting group meal delivery and centralized supply.

5. Air and railway catering: It provides highly sealed, hygienic, and safe packaging for airline meal boxes and high-speed railway meals, adapting to harsh transportation environments.

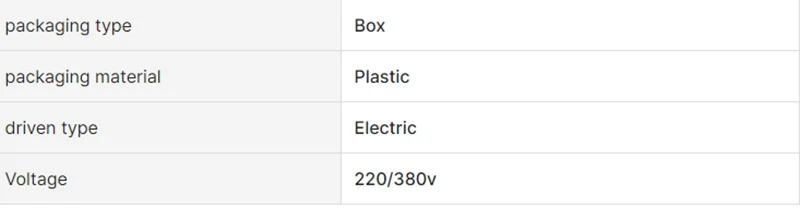

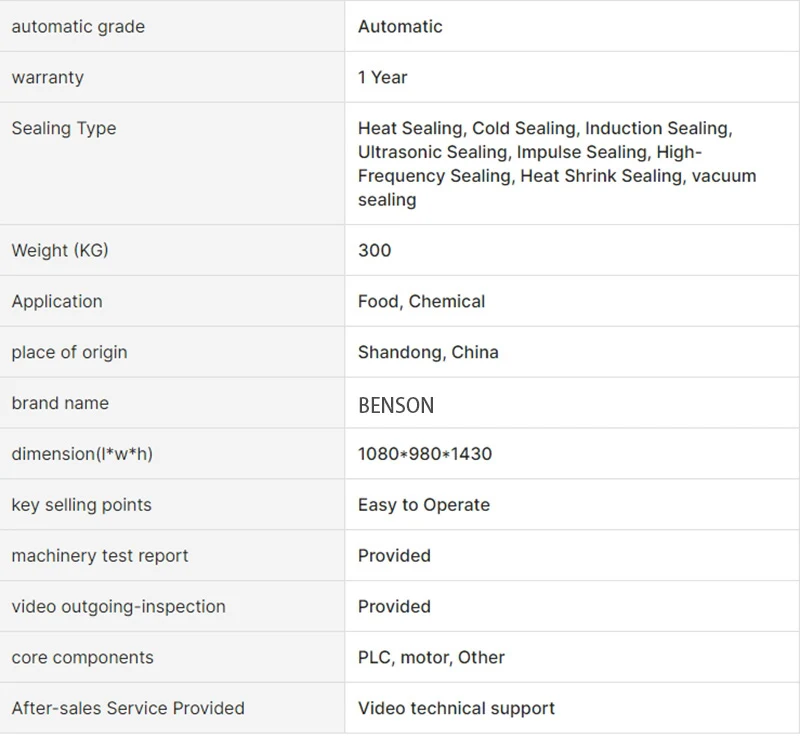

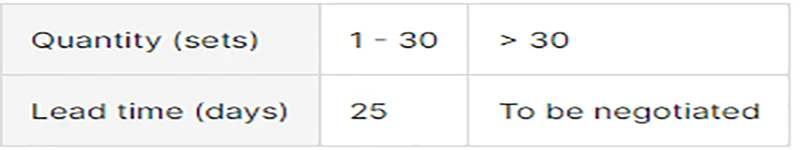

Products Description

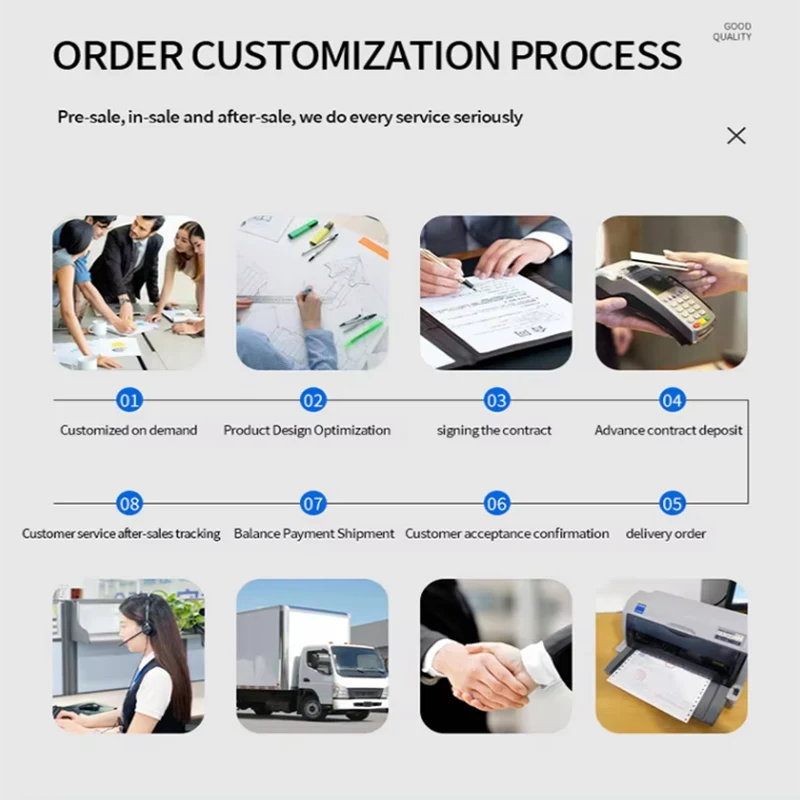

Product Inquiry