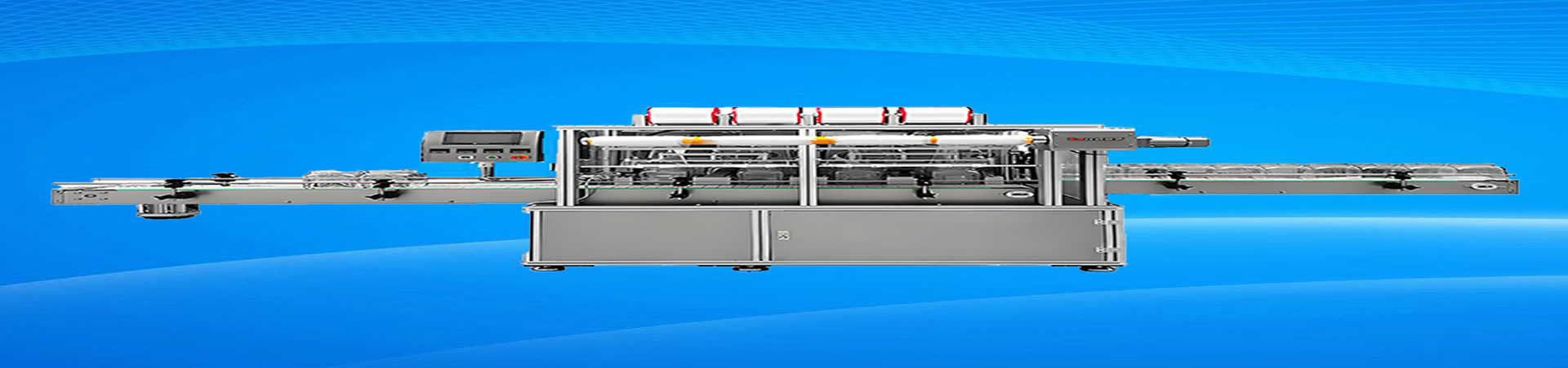

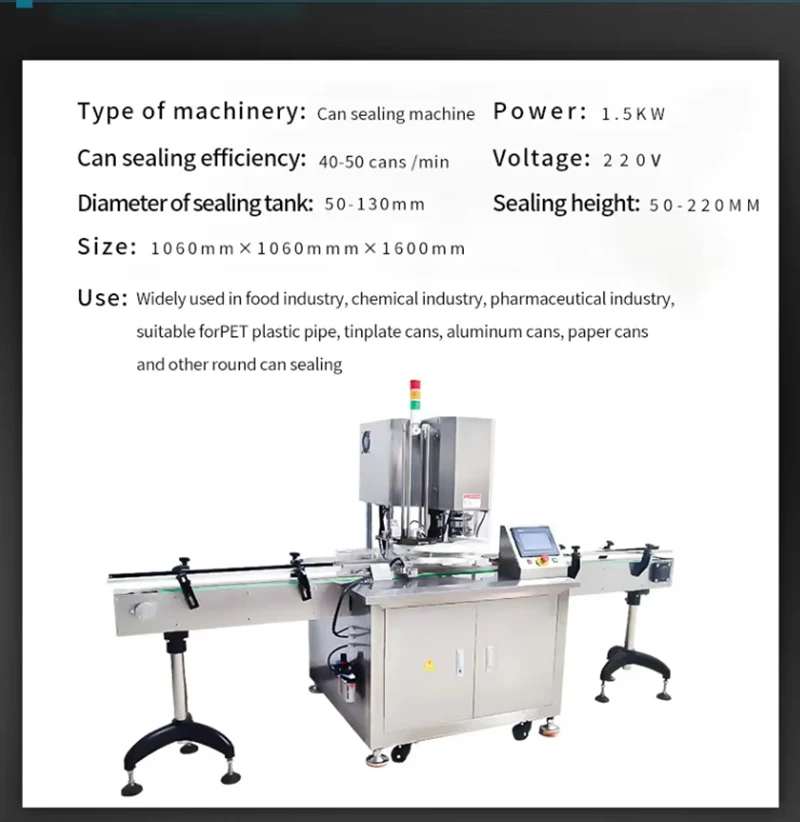

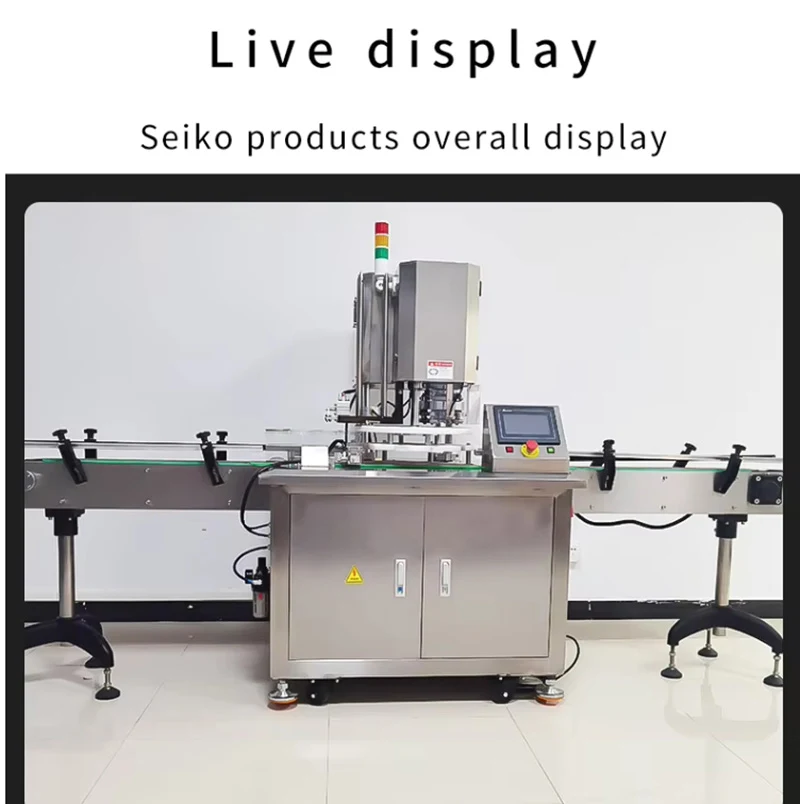

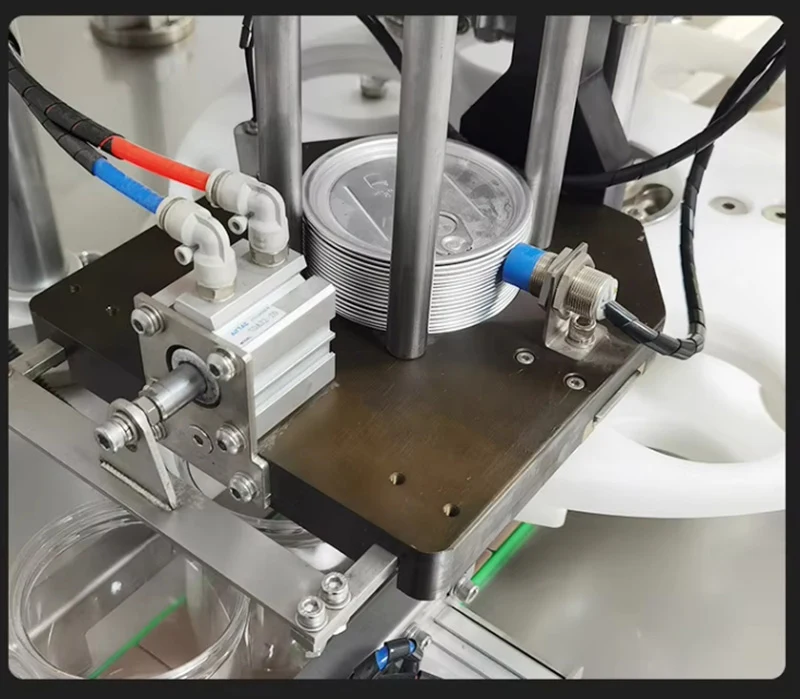

The fully automated electric beer can sealer is an advanced piece of industrial equipment designed specifically for the beer production industry. It integrates cutting-edge automation and electrical control technologies, enabling seamless and efficient can-sealing operations. This machine can automatically complete a series of processes, including can feeding, positioning, sealing, and outputting, minimizing human intervention. Its electric-driven system provides stable power, ensuring consisten

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Fully automated electric beer can sealerAdvantages

High Efficiency: It can seal a large number of beer cans per minute, significantly increasing production capacity compared to manual or semi-automatic seang methods. This high-speed operation helps breweries meet market demands quickly.

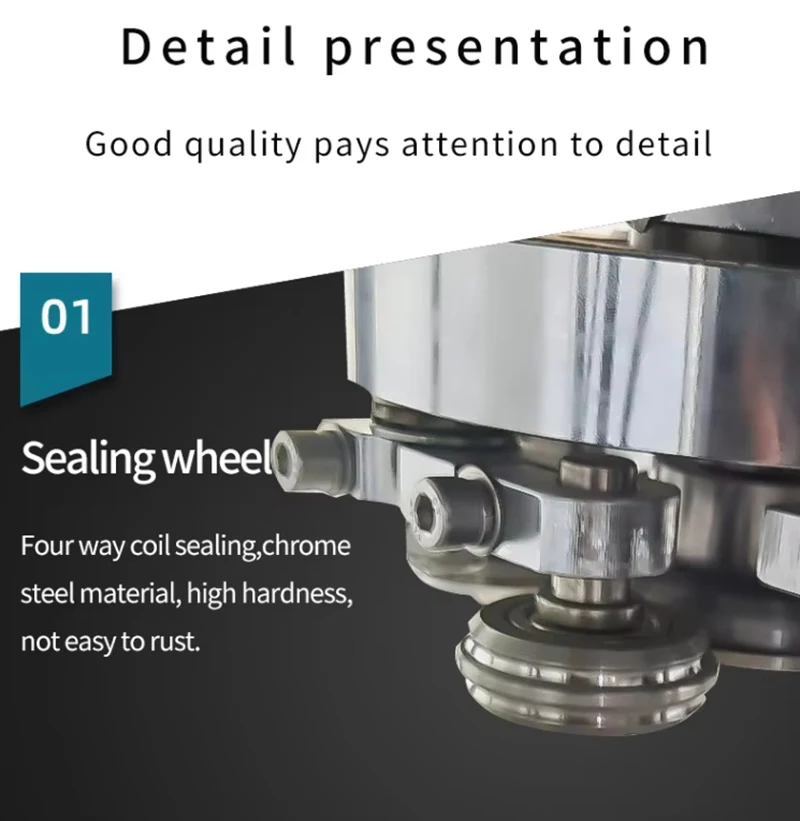

2. Consistent Quality: The automated process ensures uniform sealing quality for each can. It reduces the occurrence of sealing defects, such as leaks or improper seals, which helps maintain product integrity and prevent spoilage.

3. Cost Savings: By reducing the need for a large labor force, the machine cuts down on labor costs in the long run. Additionally, its high efficiency and low defect rate minimize material waste, further saving production costs.

4. Flexibility: It can adapt to different sizes and types of beer cans, providing flexibility for breweries that produce a variety of products. The machine's parameters can be easily adjusted to accommodate various can specifications.

5. Safety and Hygiene: The fully automated design reduces the risk of workplace injuries associated with manual can-sealing operations. Moreover, its materials and structure comply with food safety standards, ensuring that the sealing process does not contaminate the beer.

6. Data Monitoring and Management: Many advanced models are equipped with intelligent monitoring systems that can record production data, such as the number of sealed cans, sealing quality, and machine operating status. This data helps optimize production processes and perform predictive maintenance.

Fully automated electric beer can sealerApplications

1. Large-scale Breweries: In major beer production facilities, the fully automated electric beer can sealer is essential for high-volume canning lines. It enables continuous production, meeting the massive market demand for canned beer.

2. Craft Breweries: Even smaller craft breweries are increasingly adopting this technology to expand their production scale and improve product quality. The machine’s flexibility allows craft breweries to package different styles of beer in cans.

3. Co-packing Facilities: These facilities, which provide canning services for multiple beverage brands, rely on such automated sealers to handle various orders efficiently and maintain high-quality standards for their clients.

4. Research and Development Centers: In the beverage R&D field, the sealer is used for small-scale production of new beer formulations in cans, helping researchers test and optimize products before large-scale commercialization.

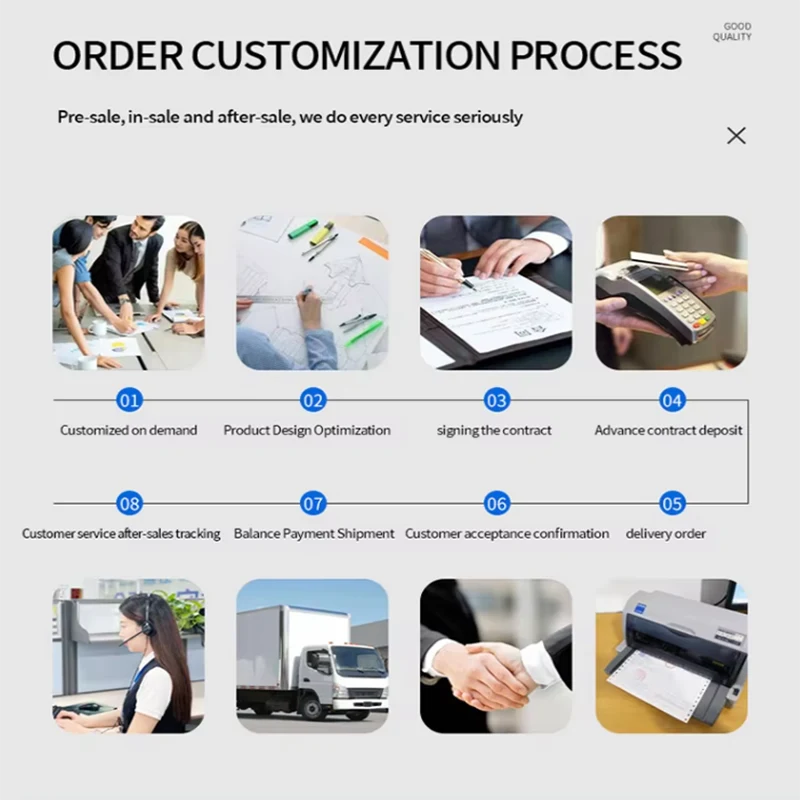

Product Inquiry