The fully automatic coffee and milk filling machine is an integrated intelligent device designed for liquid beverages such as coffee and milk, enabling fully automated processes from empty bottle/can loading to filling, sealing, and labeling (optional). The equipment uses servo motor drive or pneumatic control systems, equipped with high-precision flowmeters, load cells, or positive displacement metering pumps to ensure precise quantitative filling of liquid materials such as coffee beverages

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

- Aseptic filling valve: Prevents microbial contamination, suitable for pasteurized or sterilized beverages;

- Bottle/can positioning device: Achieves precise container alignment through conveyor belts and bottle clamping mechanisms;

- CIP/SIP cleaning system: Supports in-line cleaning (CIP) and sterilization (SIP), complying with food hygiene standards.

Fully automatic coffee and milk filling machine Advantages

1. High Efficiency and Automation

- Production capacity 3,000–10,000 bottles/hour (model-dependent), with over 50% efficiency improvement compared to traditional semi-automatic equipment;

- Fully unmanned operation reduces manual intervention, labor costs, and human errors.

2. High Precision and Stability

- Filling error controlled within ±1–3 ml (depending on liquid viscosity), ensuring consistent bottle volume;

- Anti-drip filling heads and pressure compensation technology prevent foam overflow or liquid residue.

3. Multi-Functional Adaptability

- Compatible various packaging formats (glass bottles, PET bottles, aluminum cans, cartons) and container sizes (300ml–2L);

- Handles multiple liquid materials including pure milk, flavored milk, coffee beverages, and milk-based drinks, adapting to different viscosities (e.g., thick shakes).

4. Hygiene and Safety

- Material-contact components use 316L stainless steel or food-grade silicone, compliant with FDA/CE certifications;

- Aseptic filling modules support cold or hot filling, preserving nutritional components (e.g., active substances in fresh milk);

- Equipped with safety light curtains and emergency stop devices to ensure operator safety.

5. Flexible Changeover

- Modular design enables 15–30-minute quick changeovers, with one-touch product specification switching via touchscreen;

- Supports customized needs (e.g., multi-head synchronous filling for multi-flavor beverages).

Fully automatic coffee and milk filling machine Applications

1. Dairy Industry

- Suitable for filling pasteurized milk, sterilized milk, yogurt, and milk drinks, commonly used in production lines of dairy enterprises like Mengniu and Yili.

2. Coffee Beverage Industry

- Fills ready-to-drink (RTD) coffee, cold brew coffee, café lattes, etc., adapting to canning needs of brands like Suntory and Nestlé.

3. Plant-Based Beverages

- Supports filling of soy milk, oat milk, almond milk, and other plant-based milks to meet the growing health beverage market demand.

4. Other Liquid Foods

- Extendable to fruit juices, tea drinks, functional beverages, etc., suitable for beverage enterprises like Uni-President and Master Kong.

Fully automatic coffee and milk filling machineFeatures

1. Intelligent Control System

- Equipped with PLC + touchscreen HMI for real-time monitoring of production data (e.g., output, pass rate, energy consumption);

- Supports OEE (Overall Equipment Effectiveness) analysis and fault self-diagnosis, automatically generating maintenance reminders.

2. Energy-Saving Design

- Servo motors provide on-demand power, saving over 30% energy compared to traditional pneumatic systems;

- Frequency-controlled conveyor belts and low-power sensors reduce standby energy consumption.

3. High-Precision Metering Technology

- Volumetric metering: Suitable for low-viscosity liquids (e.g., pure milk), using piston or rotor pumps for dosing;

- Weighing metering: Ideal for high-viscosity or particulate-containing beverages (e.g., coffee shakes), adjusting filling volume via dynamic weighing feedback.

4. Aseptic Filling Solutions

- Cold filling: Directly fills pasteurized beverages in aseptic environments, preserving taste and nutrition;

- Hot filling: Simultaneously sterilizes containers and materials (e.g., above 85°C), suitable for long-shelf-life products.

5. Easy Maintenance

- Quick-release filling heads and pipeline designs facilitate manual cleaning or CIP system integration;

- Open-frame structure provides ample maintenance access, reducing downtime.

Conclusion: The fully automatic coffee and milk filling machine, characterized by high efficiency, precision, and hygiene, serves as a core device for large-scale production in the beverage industry, particularly suited for enterprises with high demands for capacity, product consistency, and food safety. Its intelligent and modular design also offers upgrade potential for future flexible production (e.g., small-batch customized beverages).

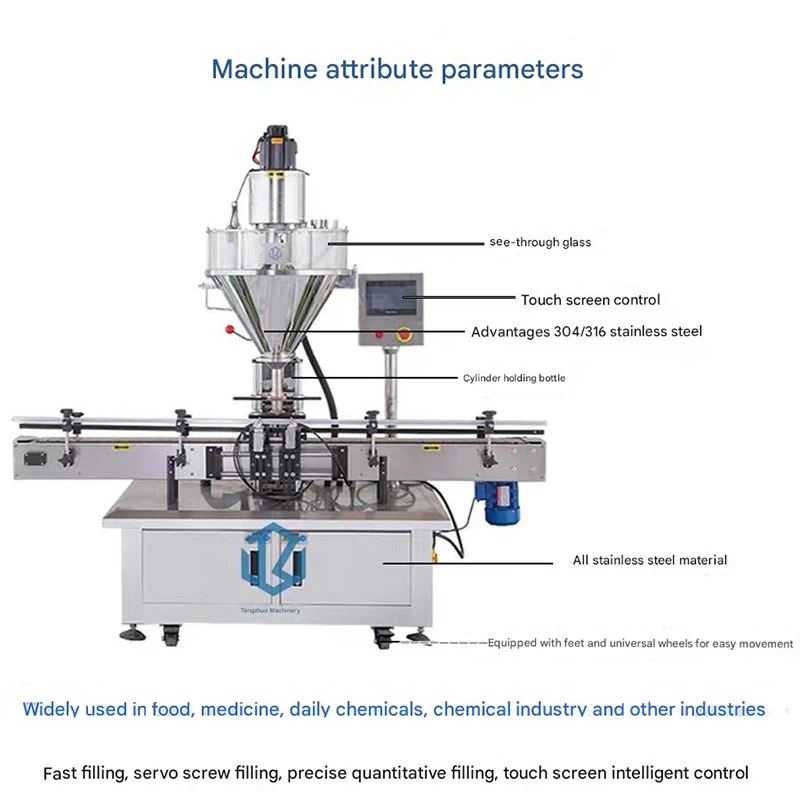

Products Description

Product Inquiry