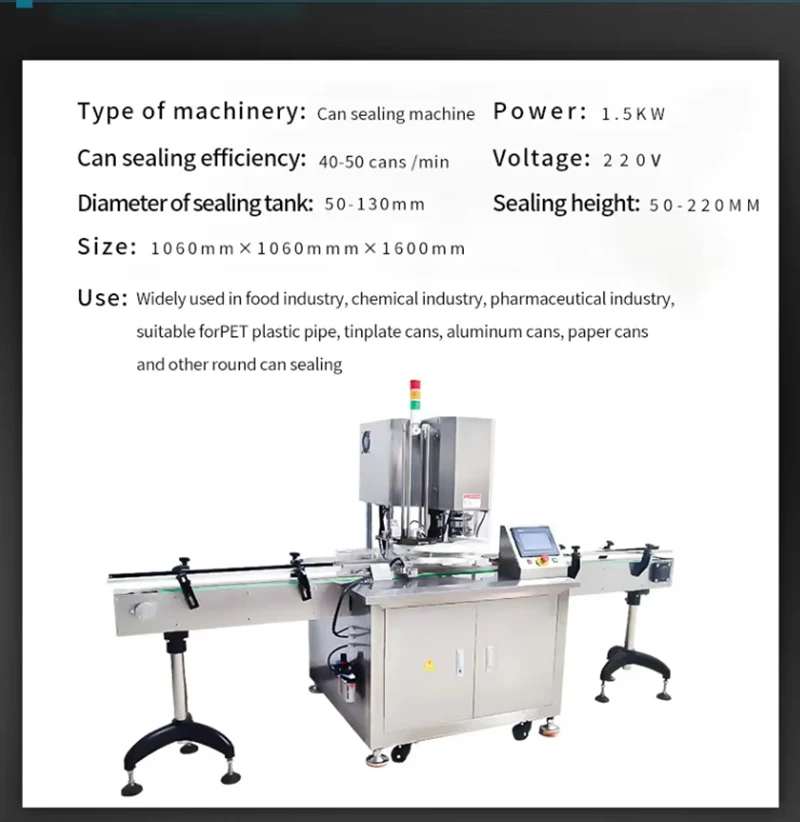

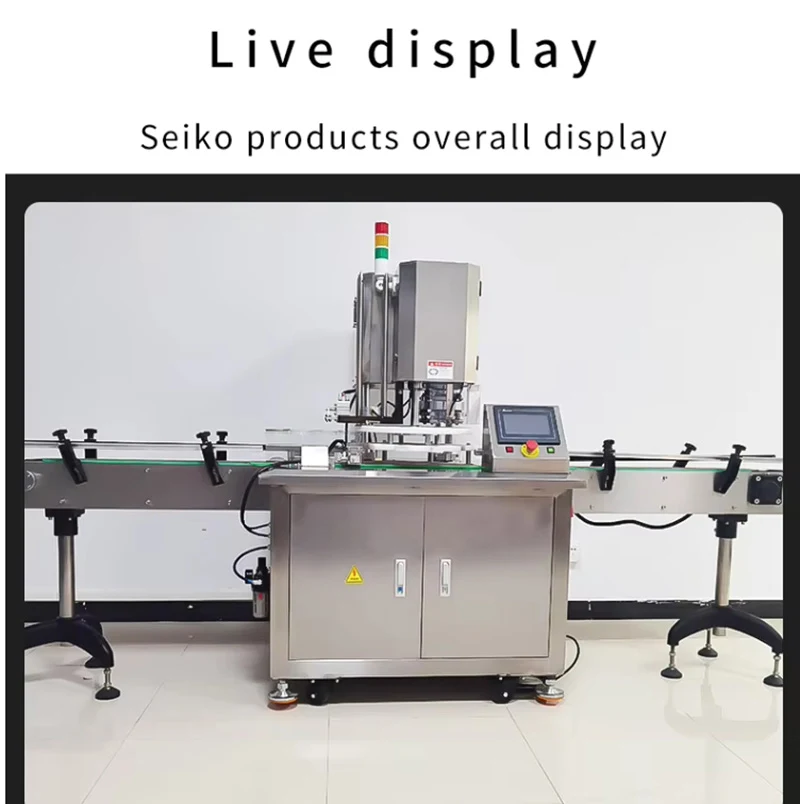

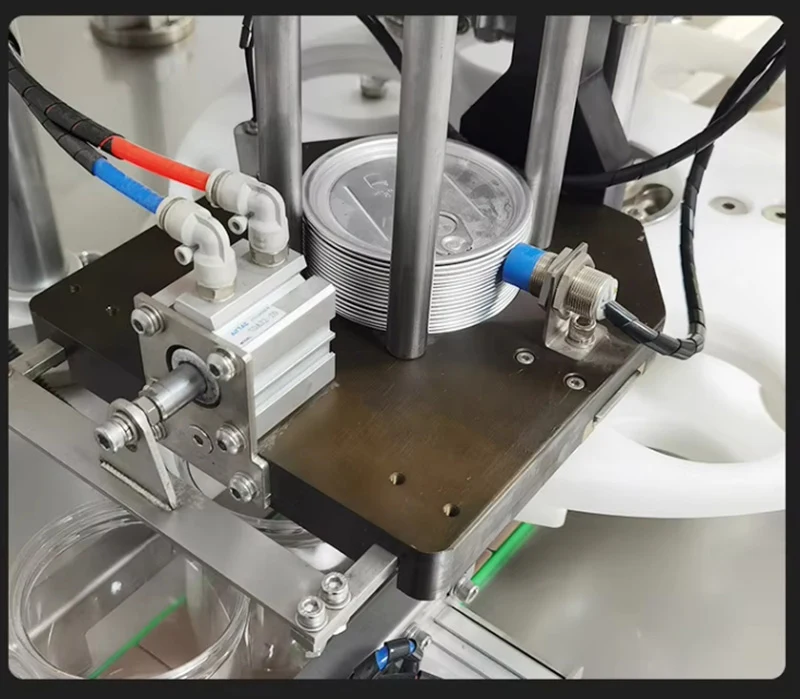

The fully automatic chemicals paper and glass packaging sealing machine is an advanced device specifically designed for chemical packaging, integrating automated control and precise sealing technology. This equipment is capable of handling two types of packaging materials, paper and glass, and is equipped with a series of functions such as automatic feeding, filling, and sealing. Its sealing system adopts advanced heating or bonding technology,

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

The control system of the equipment is equipped with an intelligent operation interface, allowing operators to easily set packaging parameters such as sealing temperature, pressure, speed, etc., to meet the requirements of different types of chemicals and packaging. In addition, the equipment is also equipped with safety protection devices, such as emergency stop buttons and light curtain protection, to ensure the safety of operators.

Fully Automatic Chemicals Paper and Glass Packaging Sealing MachineRemarkable Advantages

1. High-efficiency automation: It realizes fully automated operations from the transportation of packaging materials, the filling of chemicals to sealing, greatly improving production efficiency, reducing labor operation costs, and meeting the needs of large-scale production.

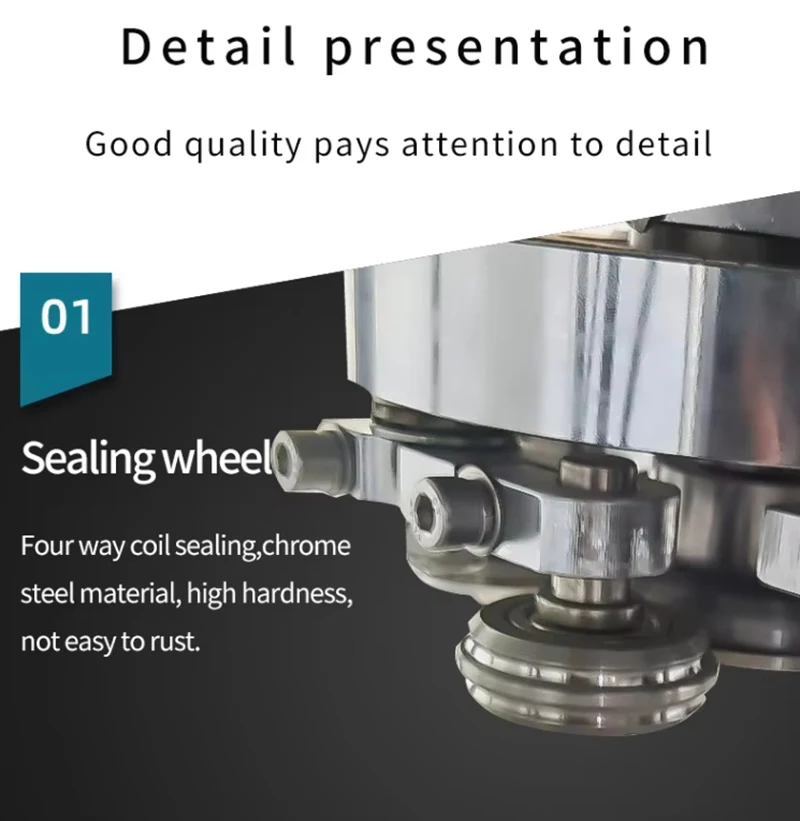

2. Precise sealing: By using advanced sealing technology, it can accurately control the quality of the seal, ensure the tightness of the packaging, effectively prevent the leakage of chemicals, and guarantee the safety of products.

3. Versatility: It can handle two different packaging materials, paper and glass, and is suitable for the packaging of various types of chemicals, meeting the needs of different customers.

4. Safety and reliability: It is equipped with a complete set of safety protection devices, which can effectively prevent operators from being injured during the operation of the equipment. At the same time, the stability and reliability of the equipment are also guaranteed, reducing the occurrence of equipment failures.

5. Easy operation: The intelligent operation interface is simply and intuitively designed. Operators can skillfully operate the equipment after simple training, reducing the operation difficulty and improving work efficiency.

Fully Automatic Chemicals Paper and Glass Packaging Sealing MachineApplication Fields

1. Chemical industry: Used for the packaging of various chemicals, such as acids, alkalis, organic solvents, etc., to ensure the safety of chemicals during storage and transportation.

2. Pharmaceutical industry: Suitable for the packaging of drugs, especially those with high requirements for tightness, such as injections and oral liquids, to ensure the quality and stability of drugs.

3. Food industry: Can be used for the packaging of food additives, seasonings, etc., to ensure that food is not contaminated during storage and transportation and to extend the shelf life of food.

4. Scientific research field: In scientific research experiments, it is used for the small-batch packaging of chemicals to meet the requirements of researchers for packaging quality and safety.

5. Environmental protection industry: Used for the packaging of treated chemical waste to prevent the leakage of waste from polluting the environment and ensure the safe treatment and transportation of waste.

Products Description

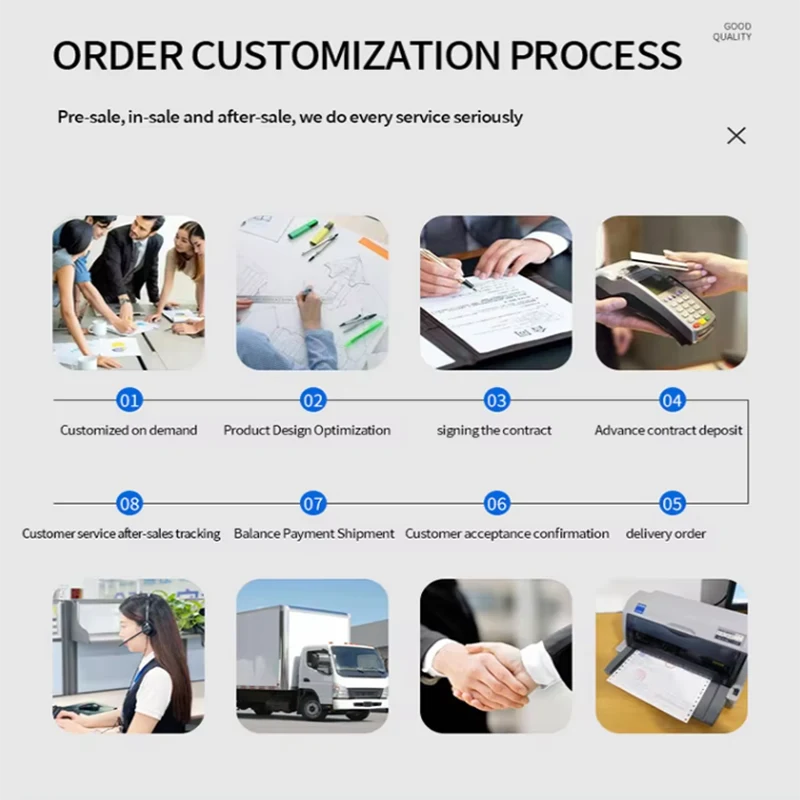

Product Inquiry