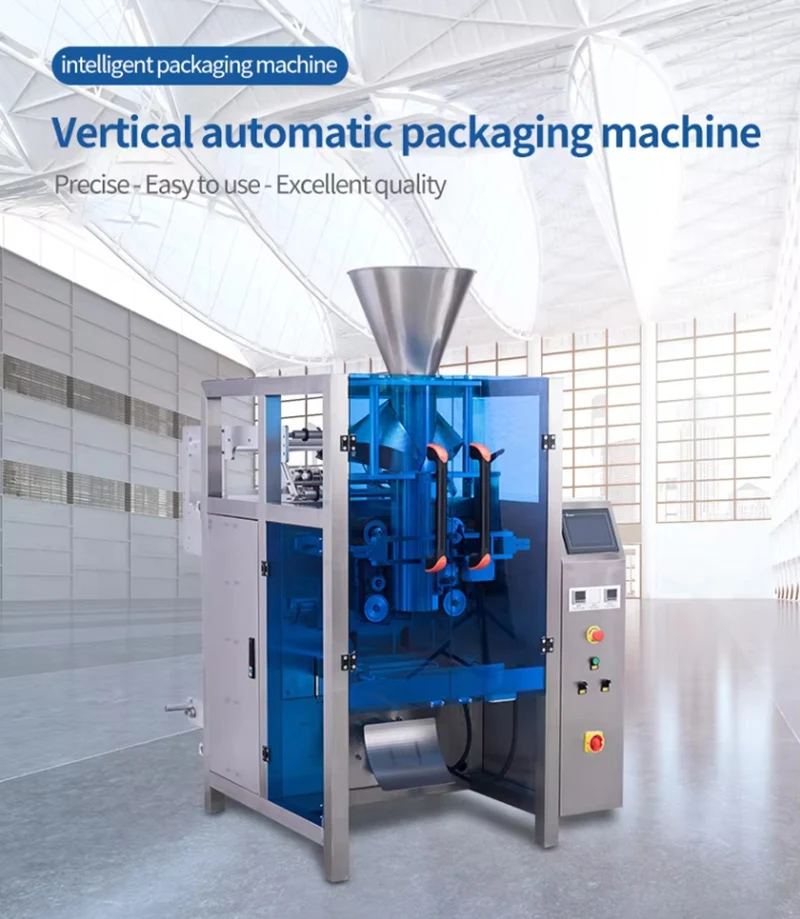

The full-automatic weighing vertical packaging machine is an automated packaging equipment that integrates weighing and metering, bag making, filling, sealing, printing, and sorting. Its working principle is as follows: precise weighing of solid materials such as granules, powders, and lumps is carried out through weighing sensors and metering devices. The vertical bag-making system then forms plastic films or composite films into packaging bags. After the materials are filled by the feeding

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Full-automatic Weighing Vertical Packaging MachineAdvantages

1. High-precision weighing: Using multiple sets of weighing sensors and intelligent algorithms, the metering accuracy can reach ±0.1% to ±1%, meeting the strict requirements of the food and pharmaceutical industries for quantitative packaging.

2. Efficient production: The packaging speed can reach 20–60 bags per minute (depending on material characteristics and specifications), increasing efficiency by 5–8 times compared to traditional manual packaging, suitable for large-scale continuous operations.

3. Multi-functional integration: The machine completes the entire process of weighing, bag making, filling, sealing, and date printing (optional), reducing equipment floor space and manual intervention costs.

4. Flexible model changeover: By adjusting parameters or replacing a small number of components (such as metering cups and sealing molds), it can quickly switch between different materials (e.g., rice, milk powder, nuts) and packaging specifications (50g–10kg).

5. Low loss and environmental protection: The closed feeding system reduces material spillage, and the waste recycling device minimizes packaging material waste. Energy-saving motors can be optionally configured to reduce energy consumption.

Full-automatic Weighing Vertical Packaging MachineCharacteristics

1. Compact vertical structure: The vertical bag-making design occupies less space, suitable for workshops with limited space, and facilitates docking with upstream production lines (such as elevators and silos).

2. Intelligent control interface: The touchscreen operation interface supports storage of multiple groups of parameters (such as weighing values and bag lengths for different products), real-time display of production data (output, failure rate), and has a fault self-diagnosis function.

3. Hygienic and safe design: Material-contact components are made of food-grade stainless steel (e.g., 304 material) for easy cleaning. The sealing device is equipped with anti-scald protection, and an emergency stop button ensures operational safety.

4. Compatibility with multiple packaging materials: Suitable for various materials such as polyethylene (PE), polypropylene (PP), and aluminum foil composite films, supporting multiple bag types such as three-side sealing, back sealing, and stand-up pouches.

Full-automatic Weighing Vertical Packaging MachineApplication Fields

1. Food industry:

- Granules: Rice, beans, nuts, pet food;

- Powders: Flour, milk powder, seasonings;

- Lumps: Candies, chocolates, frozen foods.

2. Pharmaceutical industry:

- Packaging of pharmaceutical granules (such as traditional Chinese medicine decoction pieces), health product powders, and tablets, complying with GMP cleanliness standards.

3. Chemical industry:

- Quantitative packaging of chemical raw materials (e.g., plastic granules, pigment powders), fertilizers, and pesticides. Explosion-proof components can be optionally configured for flammable and explosive materials.

4. Daily necessities industry:

- High-speed packaging of daily products such as washing powder, detergent powder, wet wipes, and tissue paper, adapting to large-family packs and small retail packs.

5. Other industries:

- Automation packaging of solid materials such as building materials (e.g., putty powder, coating powder), seeds, and activated carbon.

Product Description

Product Inquiry