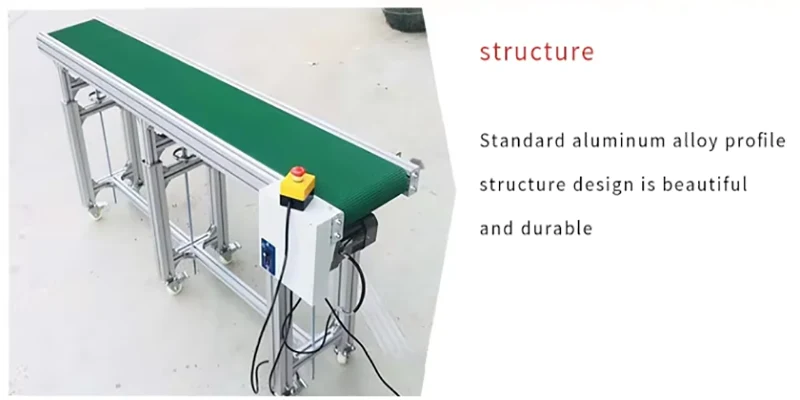

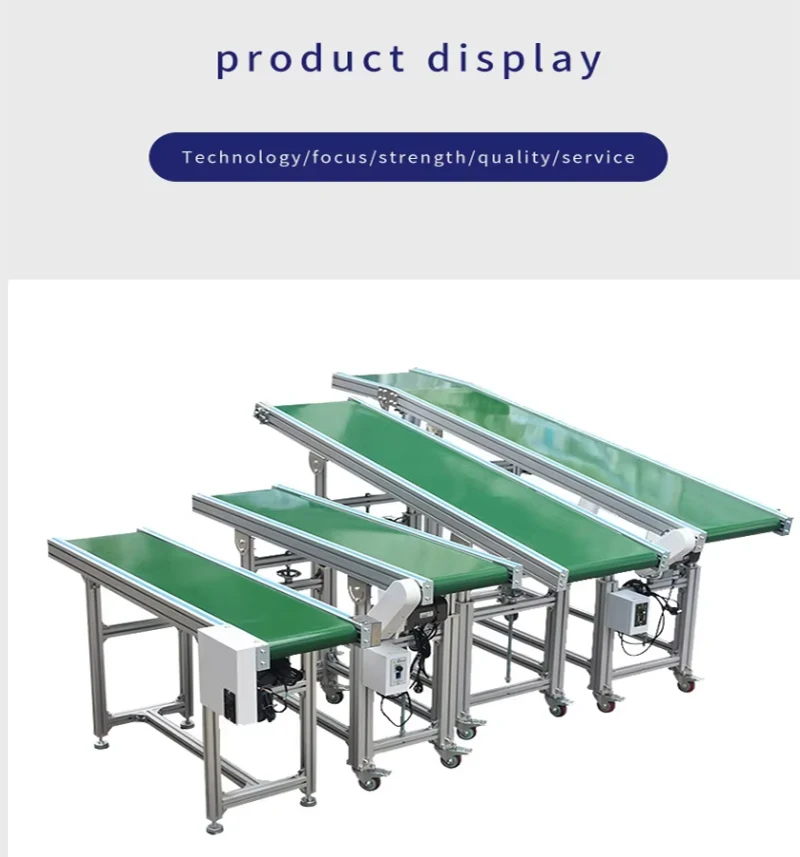

The fully automatic belt conveyor relies on the friction between the driving roller and the conveyor belt to drive the conveyor belt to rotate. The material is fed from the feeding end and falls on the rotating conveyor belt. The material is transported to the discharge end by the friction of the conveyor belt. By adding strips, jigs, skirts, etc. to the belt, large-angle or climbing conveying can also be achieved.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

Get free replacement parts service and online technical support for 1 year after purchase. Additional shipping fees may apply. Additional shipping fees may apply.

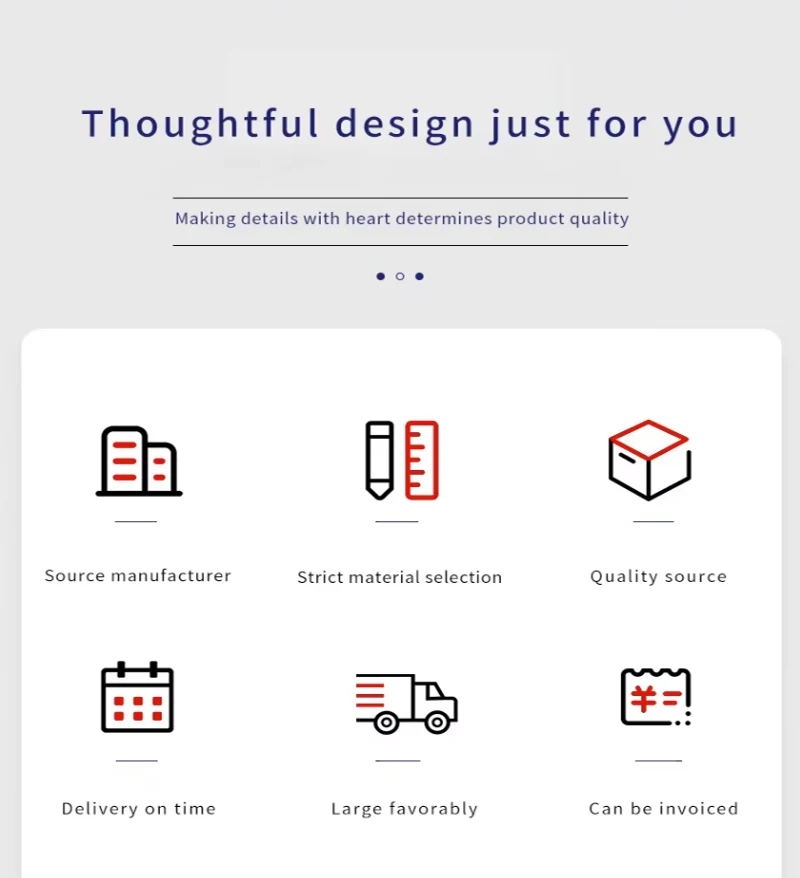

Structural composition of fully automatic belt conveyor

- Conveyor belt: It is a key component for conveying materials. It is generally made of materials such as rubber, plastic or fabric, and has the characteristics of wear resistance, oil resistance, and corrosion resistance.

- Belt roller: It is divided into drive roller and redirection roller. The drive roller is driven by the motor through the reducer, and relies on the friction between the conveyor belt to drag the conveyor belt to rotate; the redirection roller is used to change the movement direction of the conveyor belt.

- Tensioning device: Common forms include weight tensioning, spiral tensioning, hydraulic tensioning, etc. Its function is to keep the conveyor belt in proper tension and prevent the conveyor belt from slipping or running off.

- Transmission device: It includes motors, reducers, couplings, etc., which transmit the power of the motor to the drive roller to drive the conveyor belt.

Performance characteristics of fully automatic belt conveyor

- Strong conveying capacity: Different bandwidths, belt speeds and conveying angles can be designed according to different application scenarios and needs. The conveying capacity is generally 30-3000t/h, which can meet material conveying tasks of various sizes.

- Smooth operation: Using a continuous conveyor belt as the conveying medium, the vibration and noise are small during operation, which can ensure the smooth conveying of materials and reduce the damage and spillage of materials.

- High degree of automation: It can be linked with other production equipment to realize automatic conveying, batching, packaging and other operations of materials, improve the automation level of the production process, reduce manual intervention and reduce labor intensity.

- Simple maintenance: The structure is relatively simple, and the installation and disassembly of each component are relatively convenient. Daily maintenance mainly includes checking the wear of the conveyor belt, the rotation flexibility of the roller, the working status of the tensioning device, etc., and the maintenance cost is low.

Application field

- Mining industry: It is used for the conveying link in the mining, transportation and processing of bulk materials such as ore and coal, and can realize the material transportation between different locations such as underground to the ground, from the ore dressing plant to the smelter.

- Metallurgical industry: In steel mills, non-ferrous metal smelters and other places, it is used to transport raw materials and finished products such as iron ore, coke, sintered ore, pelletized ore, as well as waste slag, dust and other wastes.

- Chemical industry: It can transport various chemical raw materials, finished products and semi-finished products, such as fertilizers, plastic particles, soda ash, caustic soda, etc., to meet the material transfer and distribution needs in the chemical production process.

- Food industry: In food processing plants, it is used to transport food raw materials and finished products such as fruits, vegetables, meat, fish, bread, biscuits, and packaging materials, etc., in accordance with food hygiene standards.

Key points for selecting fully automatic belt conveyors

- Conveying material characteristics: including material particle size, shape, density, humidity, viscosity, etc., according to the material characteristics, select the appropriate conveyor belt type, bandwidth, belt speed and other parameters.

- Conveying volume requirements: According to the production scale and process requirements, determine the required conveying volume, so as to select the appropriate conveyor model and specifications to ensure that it can meet production needs.

- Conveying distance and height: Consider the conveying distance and lifting height of the conveyor, and select the appropriate drive mode, tensioning mode and support structure to ensure the operating efficiency and stability of the conveyor.

Products Description

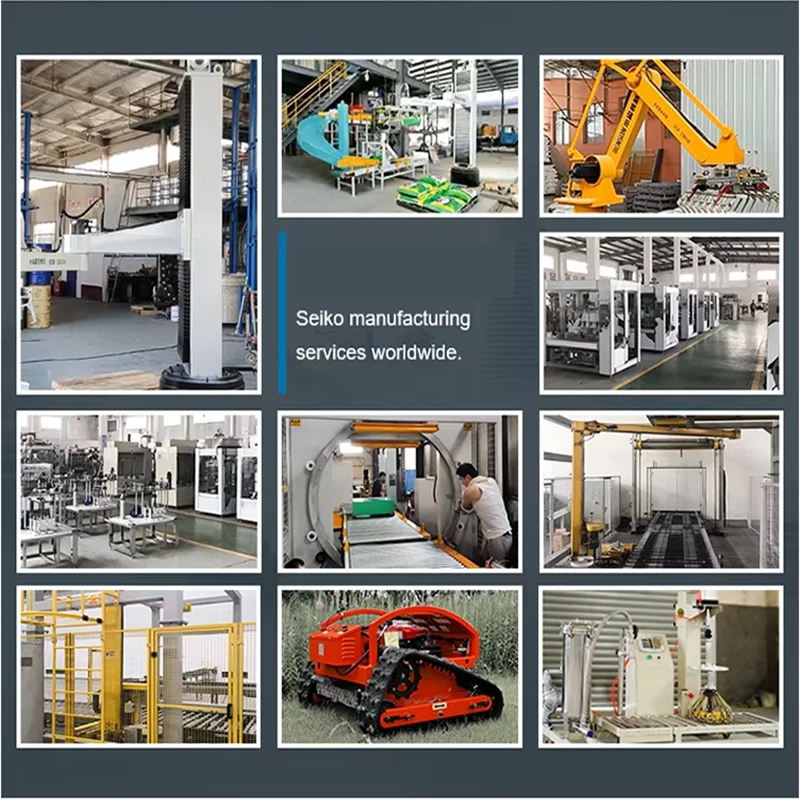

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry