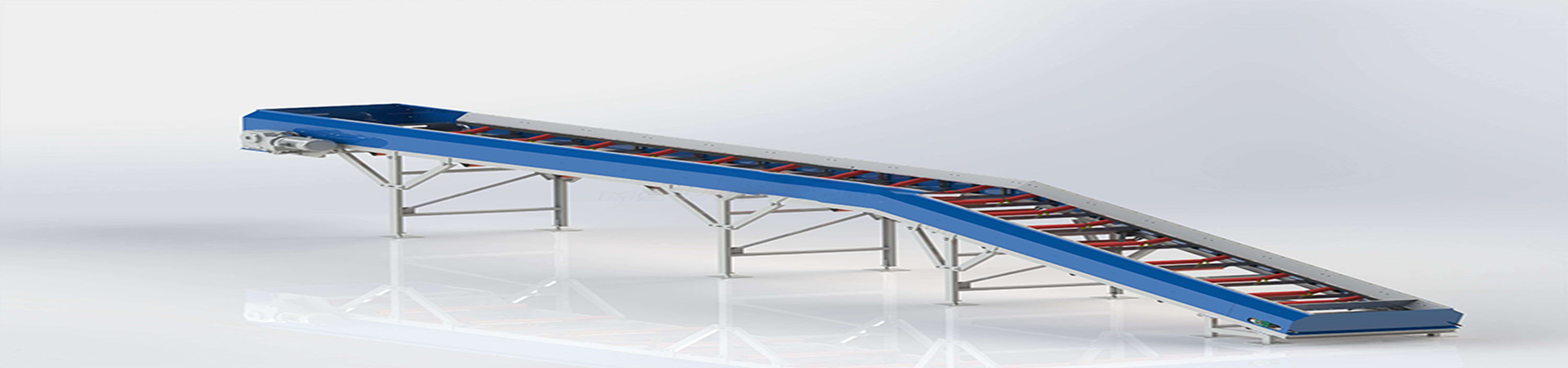

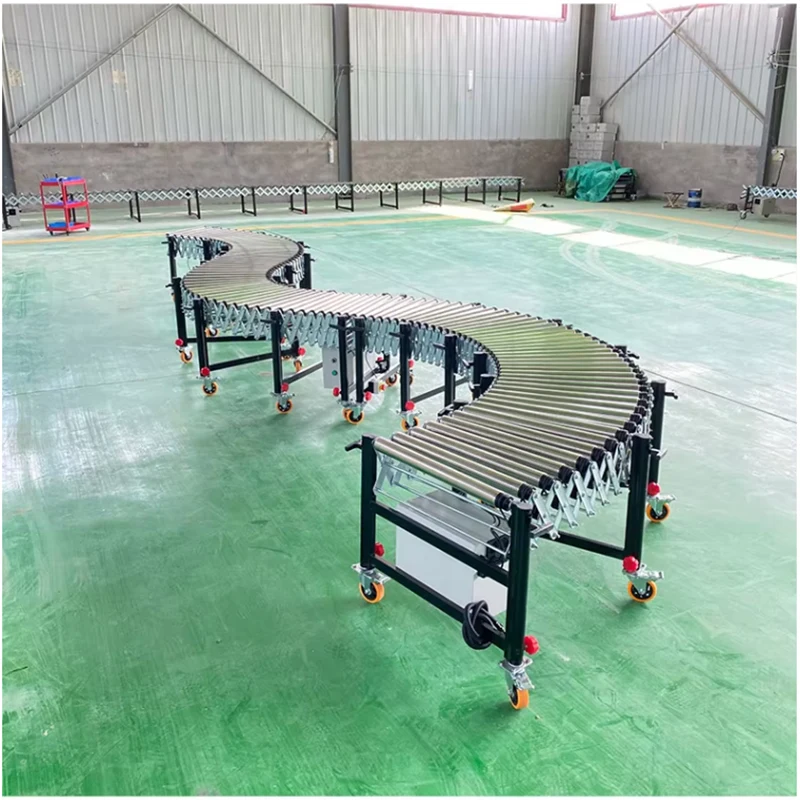

Vegetable Roller Conveyor High Quality Construction: Designed with premium materials to ensure durability and long-lasting performance, the powered roller conveyor is ideal for heavy-duty industrial applications.

Customizable Sizes: The machine can be customized to the exact requirements of the customer and can be seamlessly integrated into a variety of production lines and assembly systems.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Free replacement parts

Free replacement parts

Get free replacement parts service and online technical support for 1 year after purchase. Additional shipping fees may apply. Additional shipping fees may apply.

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

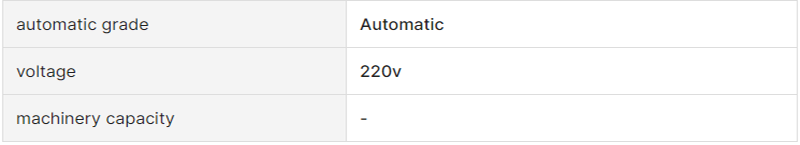

Key attributes

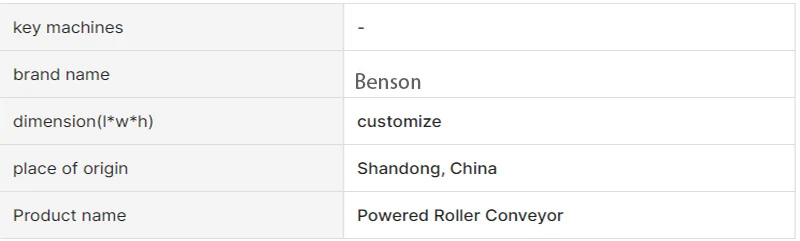

Industry-specific attributes

Other attributes

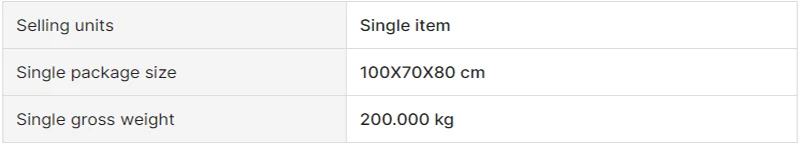

Packaging and delivery

Lead time

Product descriptions from the supplier

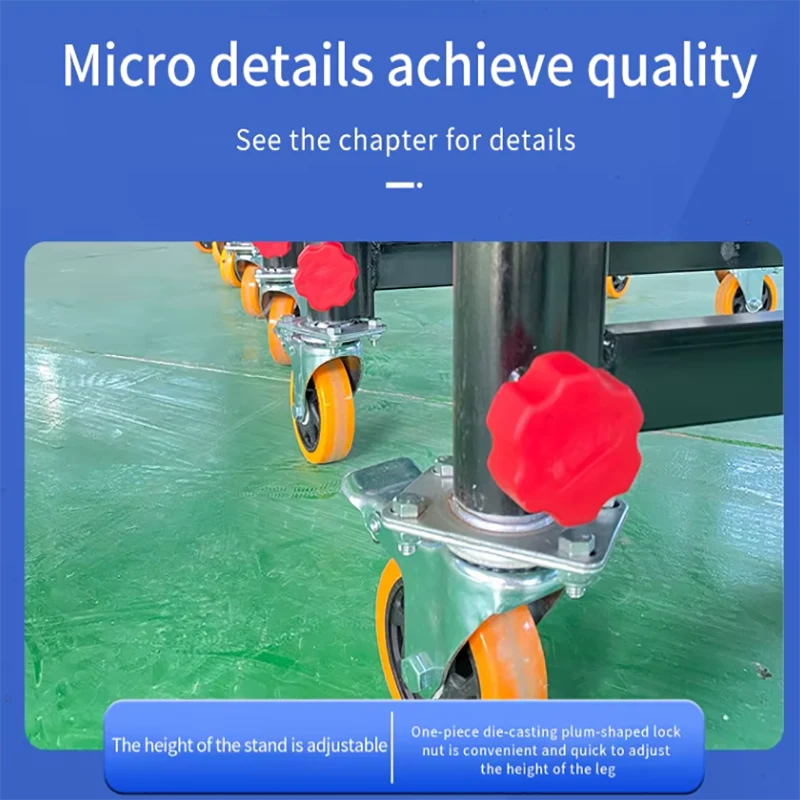

Bread roller conveyor structure

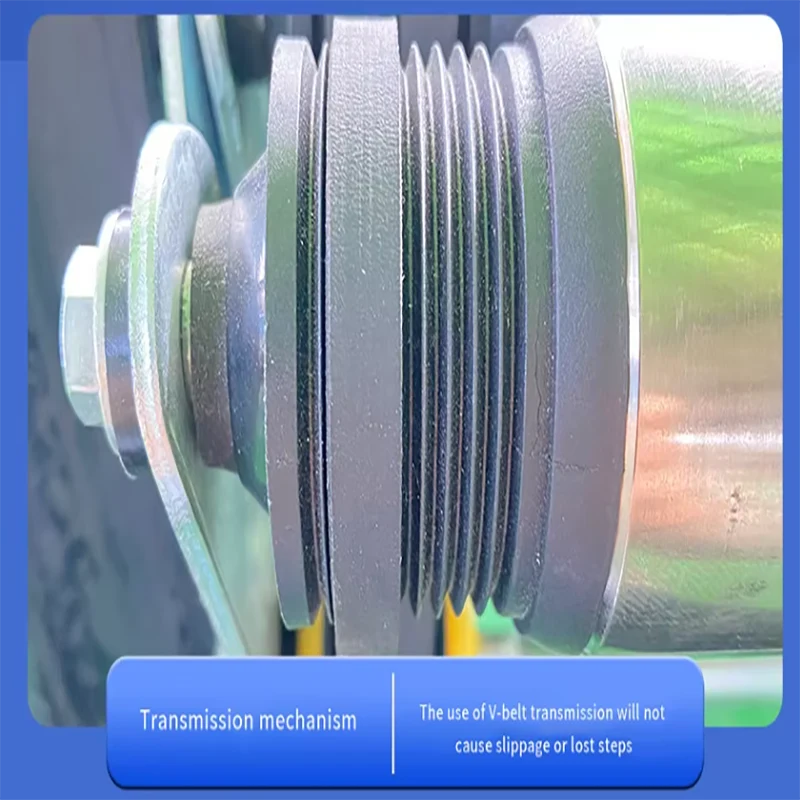

- Drive device: It adopts reduction motor drive or electric roller drive to provide power for the conveyor. Frequency conversion speed regulation or stepless speed change can be selected to achieve precise control of the conveying speed.

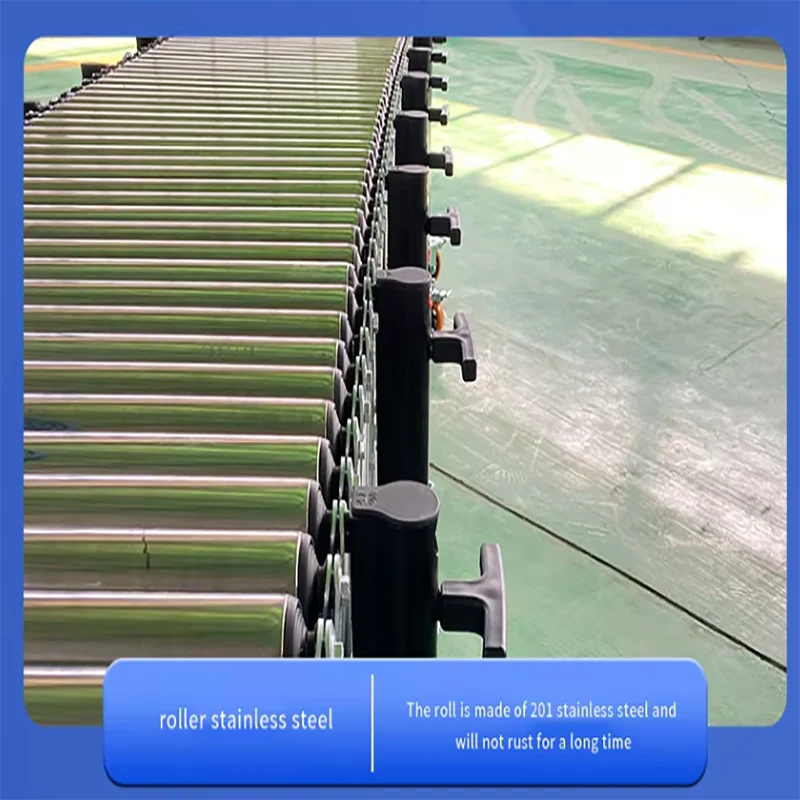

- Roller: It includes driving roller and driven roller, which are mostly made of metal materials with smooth surface to ensure smooth food conveying. The straight roller diameter has various specifications such as 38, 50, 60, 76, 89mm, etc.

- Conveyor belt: The material is usually food-grade materials such as PU, PVC, silicone, etc., which are non-toxic, odorless, wear-resistant, corrosion-resistant, easy to clean, etc., and can meet the conveying needs of different foods.

- Frame: It is mainly made of carbon steel, stainless steel or aluminum profiles, with sufficient strength and stability, and can adapt to different working environments and conveying requirements.

Working principle of roller conveyor

The friction generated by the rotation of the roller drives the food-grade conveyor belt to move, thereby pushing the material to be transported upward or downward along the inclined direction. The driven roller and the tensioning device work together to ensure that the conveyor belt maintains proper tension and stability, ensuring a smooth conveying process.

Product features of roller conveyor

- Food-grade safety standards: Made of materials that meet food hygiene standards, it ensures that the food will not be contaminated during the conveying process, ensuring food safety.

- Smooth conveying: The combination of the roller and the conveyor belt prevents relative movement between the material and the conveyor belt, which can avoid damage to the conveyed food, especially suitable for fragile and deformable foods.

- Adjustable tilt angle: The tilt angle can be adjusted according to the actual working scene and process requirements to achieve efficient vertical or near-vertical conveying in a limited space, saving space.

- Automatic control function: Equipped with an advanced control system, it can realize automated operations such as automatic start and stop, speed adjustment, fault alarm, etc., to improve production efficiency and management level.

- Easy to clean and maintain: The surface of the conveyor belt and the roller is smooth, and it is not easy to adhere to food residues. The equipment structure is reasonably designed, which is easy to disassemble and clean, reducing sanitary dead corners and meeting the hygiene requirements of the food industry.

Optional accessories for roller conveyors

- Protective devices: such as guardrails on both sides of the conveyor belt to prevent materials from falling and ensure the safety of operators.

- Cleaning devices: such as automatic spray cleaning systems, which clean the conveyor belt and rollers during transportation or after shutdown to keep the equipment clean.

- Material detection devices: such as photoelectric sensors, which can detect the location, quantity and other information of materials to achieve automatic material tracking and control.

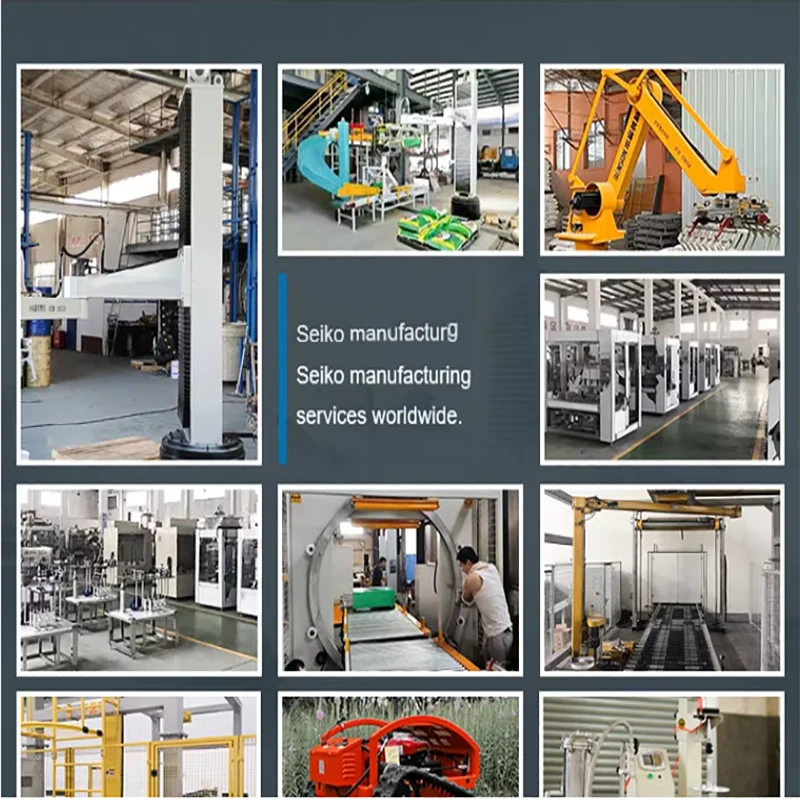

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizing loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research", and the success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been used, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in many industries at home and abroad. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry