Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

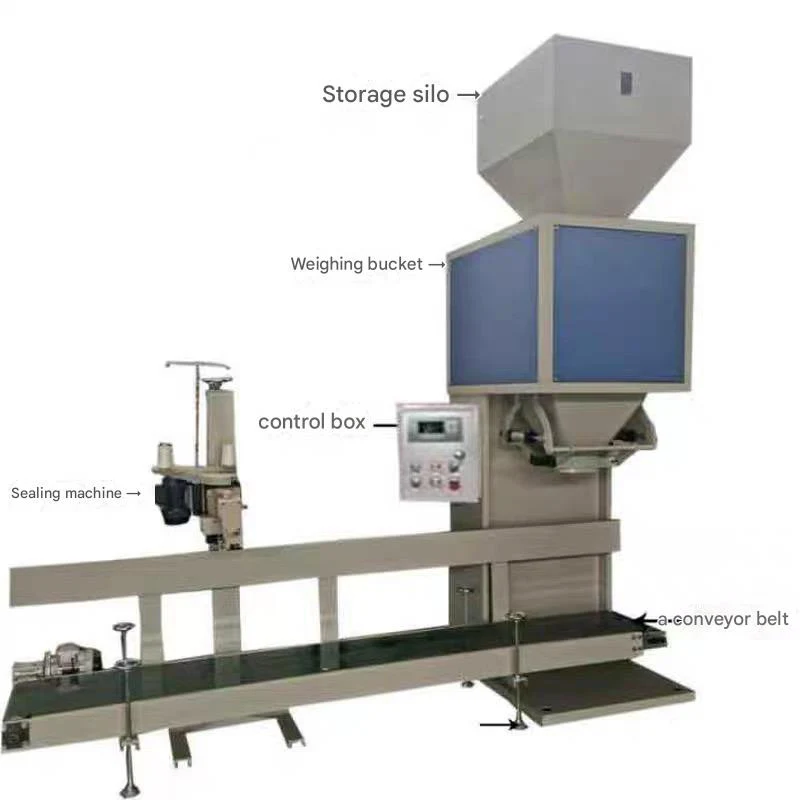

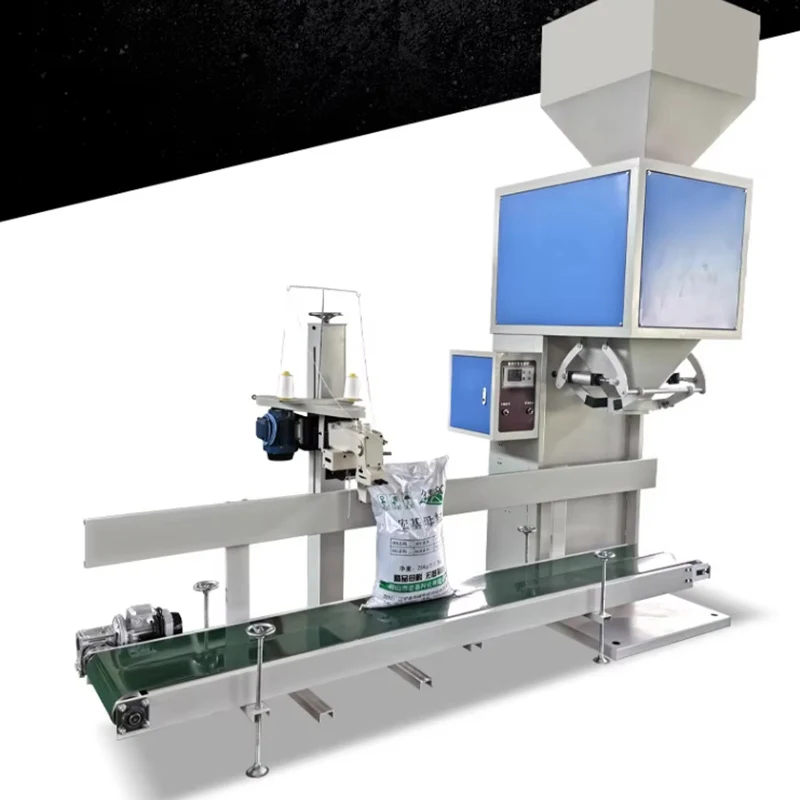

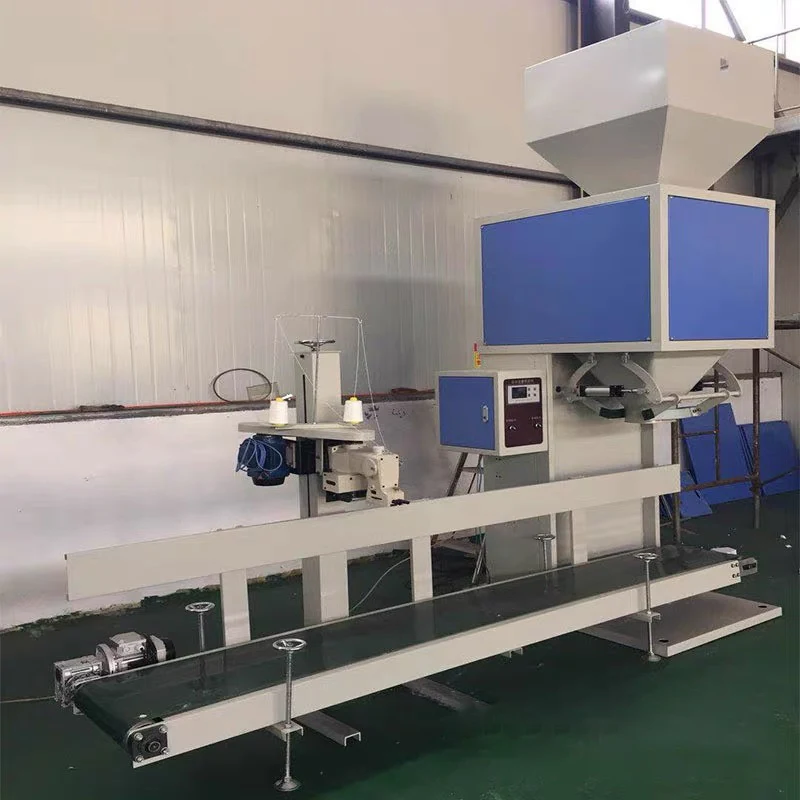

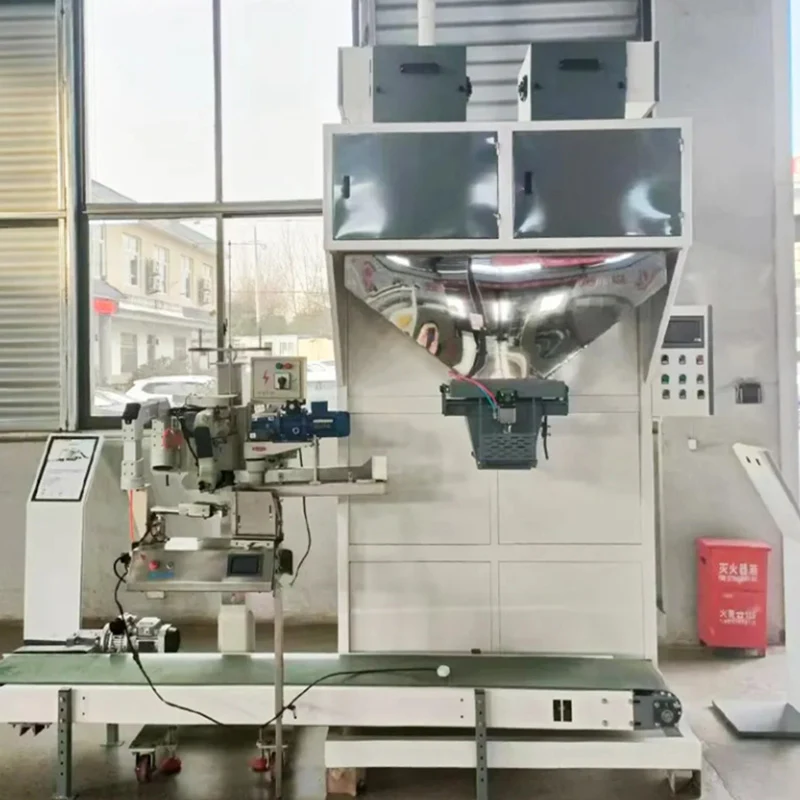

- Weighing and Metering System: Equipped with high - precision load cells, it can accurately measure the weight of urea granules. According to the preset packaging weight, the system automatically controls the start and stop of feeding to ensure that the weight of each bag of urea meets the standard, with the error controlled within a very small range.

- Bagging System: After weighing is completed, it fills a pre - prepared packaging bag with a fixed quantity of urea granules. The bagging process is fast and stable, effectively preventing the spillage and loss of urea granules.

- Sealing System: After bagging, it seals the packaging bag. Common sealing methods include heat sealing and stitching. Heat sealing makes the plastic at the sealing part of the packaging bag melt and bond through heating; stitching uses sewing thread to sew the packaging bag, ensuring the packaging's tightness and preventing urea granules from getting damp or leaking.

- Electrical Control System: It is the "brain" of the entire bagging machine. It coordinates the operation of each system. Operators can set parameters such as packaging weight and packaging speed through the operation interface, monitor the equipment's operating status in real - time, and receive timely alarms and fault information when a failure occurs.

Benson Advantages of Fertilizer Urea Granule Bagging Machine

1. High - precision Measurement: By adopting advanced weighing technology and high - precision load cells, it can achieve accurate quantitative packaging. The weight error of each bag of urea is extremely small, ensuring the stability of product quality, meeting the strict requirements of the market for product weight standards, and reducing customer complaints and returns due to inaccurate weights.

2. Efficient Production: Compared with manual bagging, the fertilizer urea granule bagging machine has higher production efficiency. It can complete the bagging of a large number of urea granules in a short time, greatly improving the production capacity of enterprises. It meets the rapid supply demand for fertilizers during the peak agricultural production season, helping enterprises seize market opportunities and increase economic benefits.

3. Labor Cost Reduction: The automated bagging process reduces the dependence on manual labor and lowers the intensity of manual operation. Enterprises do not need to hire a large number of bagging workers, saving labor costs. At the same time, it also reduces product quality problems caused by non - standard manual operations, improving the efficiency of production management.

4. Simple Operation: The equipment is equipped with a user - friendly operation interface. Operators can master the operation method proficiently after simple training. They can conveniently set packaging parameters through the operation interface, monitor the equipment's operating status in real - time, and the equipment has a self - diagnosis function for faults, which can quickly locate the fault point, facilitating maintenance personnel to carry out maintenance and repairs in a timely manner, reducing the difficulty and cost of equipment maintenance.

Benson Features of Fertilizer Urea Granule Bagging Machine

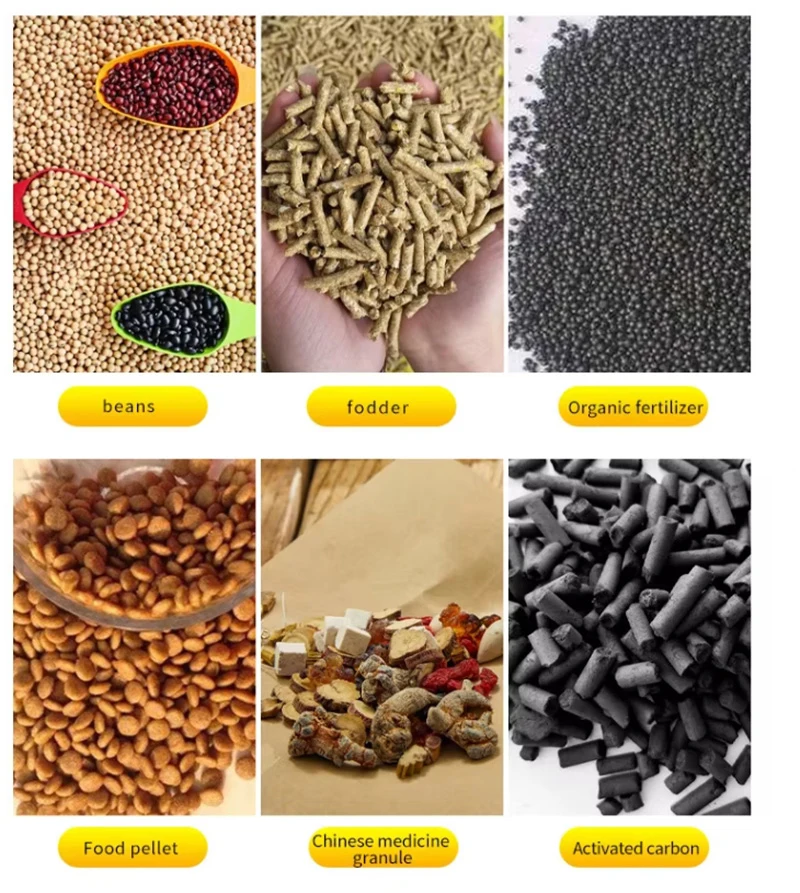

1. Strong Adaptability: It can adapt to urea granules of different specifications and characteristics. Whether it is differences in particle size, humidity, or fluidity, it can ensure normal bagging work by adjusting the equipment's parameters and feeding methods. At the same time, it can also be compatible with a variety of packaging bags of different materials and sizes, meeting the diverse packaging needs of enterprises.

2. High Stability: It uses high - quality mechanical components and electrical elements. After strict quality inspection and debugging, the equipment has a sturdy and durable structure, with good anti - interference ability and stability. During long - term continuous operation, it can maintain stable performance, reducing downtime due to failures and improving the utilization rate and production efficiency of the equipment.

3. Environmental Protection and Energy Conservation: In the design and manufacturing process, requirements for environmental protection and energy conservation are fully considered. The equipment generates less dust during operation and is equipped with corresponding dust removal devices, reducing pollution to the working environment. Meanwhile, the optimized electrical control system and mechanical structure reduce the energy consumption of the equipment, which is in line with the concept of sustainable development.

4. Scalability: In order to meet the changes in the future development and production needs of enterprises, the fertilizer urea granule bagging machine has certain scalability. For example, functions such as automatic labeling and coding can be added as needed to further improve the product packaging process and enhance the added value and market competitiveness of products.

Benson Applications of Fertilizer Urea Granule Bagging Machine

1. Fertilizer Production Enterprises: It is a key piece of equipment on the production line of fertilizer production enterprises, used for quantitatively packaging the produced urea granules for easy storage, transportation, and sales. Whether it is large - scale state - owned fertilizer enterprises or small - and medium - sized private fertilizer manufacturers, this kind of bagging machine is widely used to improve production efficiency and product quality.

2. Agricultural Input Dealers: Some large - scale agricultural input dealers also use fertilizer urea granule bagging machines when repackaging urea. By repackaging large - packaged urea into small packages suitable for farmers to purchase, it meets the needs of different customers, and at the same time improves the sales flexibility and market coverage of products.

3. Agricultural Cooperatives and Large - scale Growers: With the development of large - scale and modern agriculture, some agricultural cooperatives and large - scale growers, in order to reduce procurement costs, directly purchase bulk urea and then use the bagging machine to package it according to their own needs. This not only ensures the quality and accurate dosage of fertilizers but also improves the management efficiency of agricultural production.

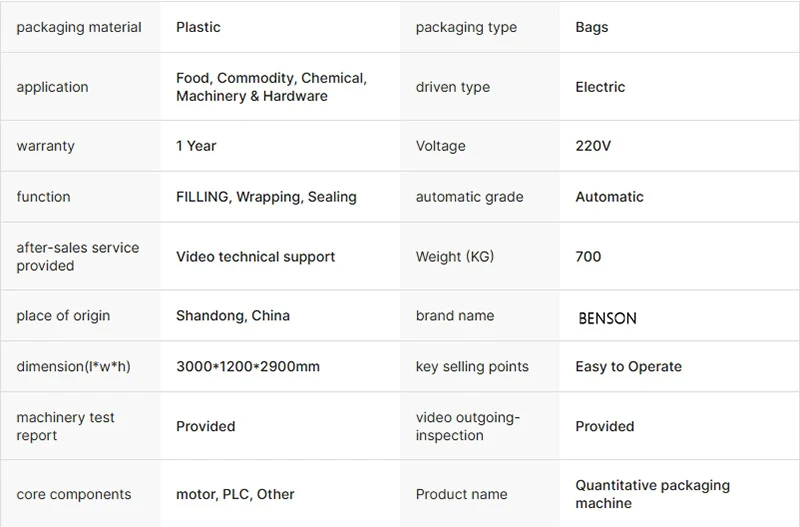

Key attributes

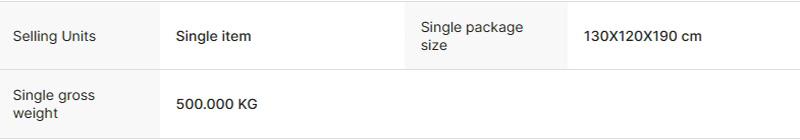

Packaging and delivery

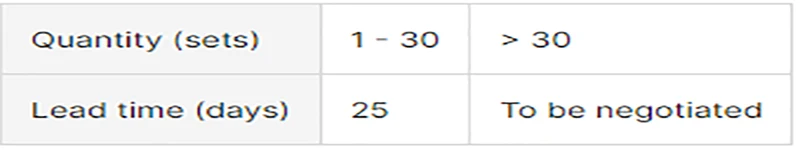

Lead time

Products Description

Title goes here.

can ship it within 7 days. Customized types are welcome, and the delivery time is about 20-25 working days. Q2: How long is the

product warranty period? A2: The product warranty period is 12 months. Q3: Can you help me pack other goods together into the

container? A3: Yes, of course. If most of the products are purchased from us, and other products are also purchased from other

suppliers, you can ask other suppliers to send the products to our factory (Tai'an City, Shandong Province). We help you pack all

your products into one container. Arrange everything. Q4: After the machine is finished, how to check the quality of the machine?

A4: We have made video calls with customers in seminars for on-site inspection on zoom, Microsoft, Teamviewer, whatspp, skype and

wechat.

Product Inquiry