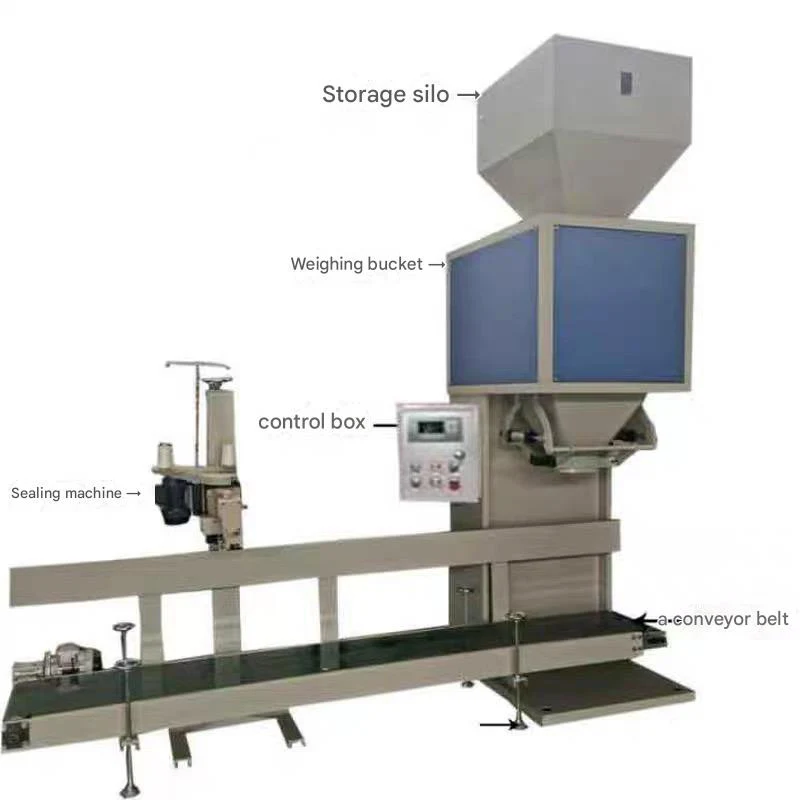

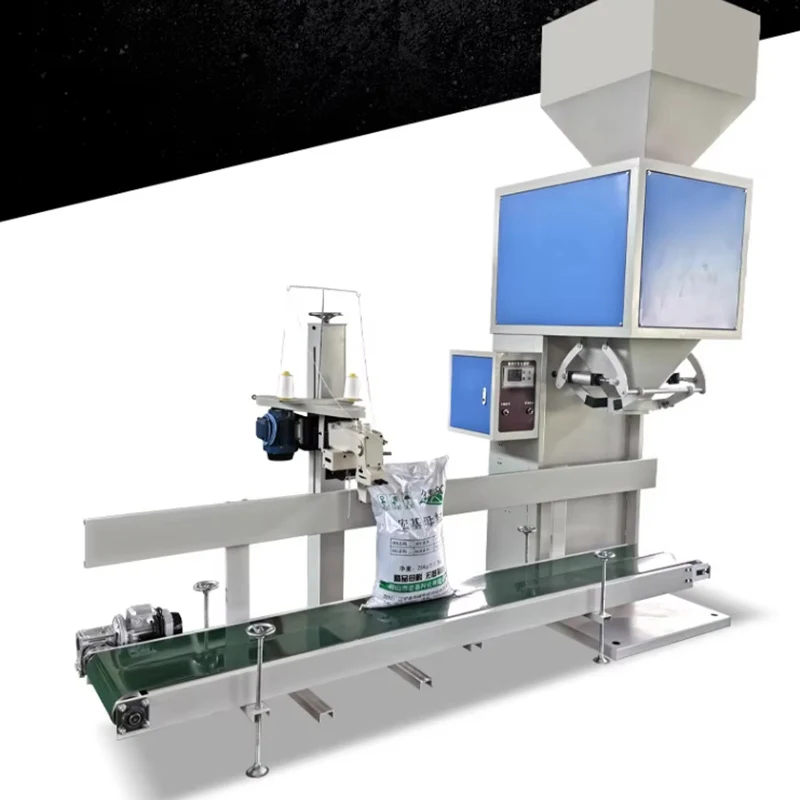

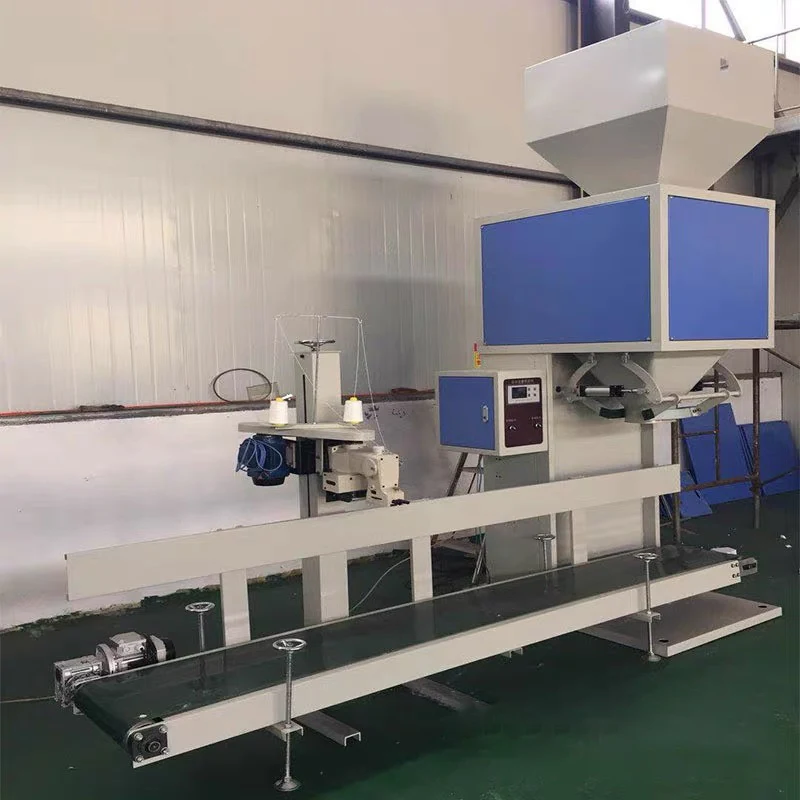

The granular quantitative packaging machine is a highly automated industrial equipment specialized in accurately measuring granular materials (such as grains, seeds, fertilizers, candies, plastic granules, etc.) according to preset weights or quantities, and completing packaging processes such as filling and sealing. The equipment typically integrates a weighing system, control system, conveying device, and packaging actuators, enabling fully automated operations from material handling

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

BensonGranule Quantitative Packaging MachineAdvantages

1. High-precision measurement: Using advanced weighing sensors and intelligent control systems, packaging errors can be controlled within minimal ranges, ensuring consistent weight per bag, reducing material waste, and cost loss.

2. Efficient production: The equipment operates at high speed, enabling continuous and large-scale production, significantly improving enterprises' production efficiency to meet rapid market supply demands.

3. Flexible customization: Supports multiple packaging specifications and material types. Packaging weight and bag types (such as three-side sealing, back sealing, stand-up pouches, etc.) can be adjusted according to actual needs, adapting to diverse requirements across industries and customers.

4. Labor savings: Automated operations greatly reduce manual intervention, lowering labor costs while minimizing human operation errors and improving the stability of packaging quality.

5. Safety and environmental protection: The closed packaging process effectively avoids material dust and pollution, complying with hygiene standards in food, pharmaceutical, and other industries to ensure production environment safety and product quality.

BensonGranule Quantitative Packaging MachineFeatures

- Intelligent control: Equipped with a PLC control system and touchscreen human-machine interface, featuring simple operation, flexible parameter settings, and functions such as one-button startup, fault self-diagnosis, and data statistics.

- Modular design: Functional components (such as weighing modules and sealing modules) are independently detachable, facilitating maintenance, upgrades, and replacements while reducing equipment maintenance costs.

- Strong compatibility: Can seamlessly integrate with other equipment in the production line (such as elevators and palletizing robots) to build a complete automated packaging production line.

- High durability: Made of high-quality stainless steel or high-strength engineering plastics, resistant to corrosion and wear, suitable for complex industrial environments, and extending equipment service life.

BensonGranule Quantitative Packaging MachineApplications

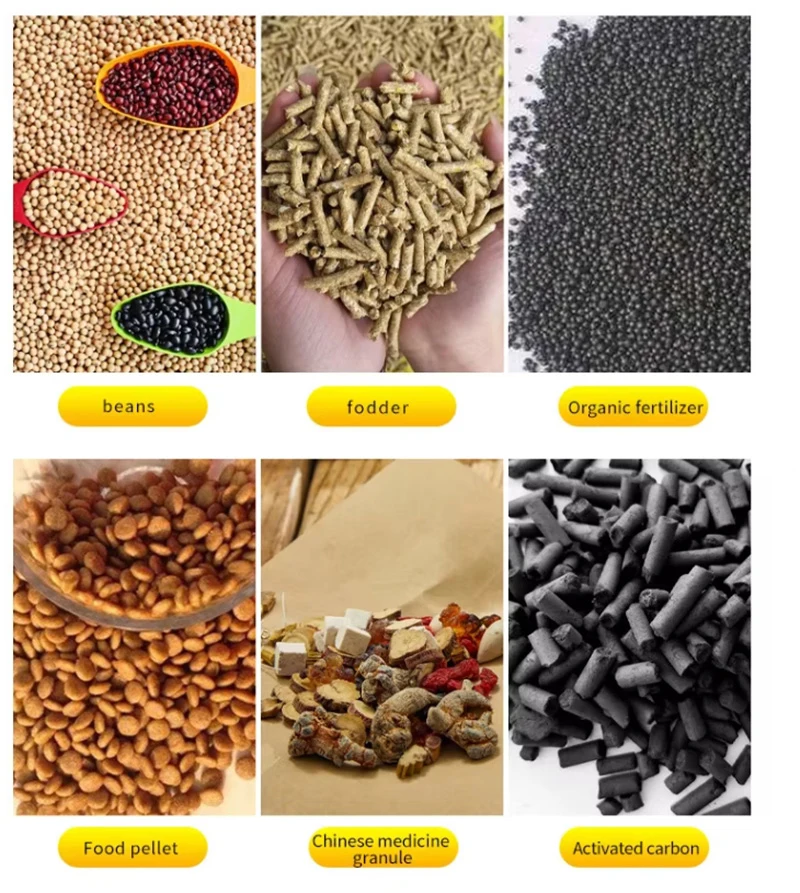

1. Food industry: Used for quantitative packaging of granular foods such as rice, beans, nuts, candies, and pet food.

2. Pharmaceutical industry: Suitable for precise measurement and packaging of medicinal granules and health product granules, meeting GMP standard requirements.

3. Chemical industry: Used for packaging chemical raw materials such as fertilizers, plastic granules, rubber granules, and pigments to prevent material leakage and pollution.

4. Agricultural sector: Packaging granular products such as seeds, feed, and organic fertilizers to facilitate standardized supply of agricultural production materials.

5. Building materials industry: Large-scale packaging of building materials such as cement granules and dry mortar to improve warehousing and transportation efficiency.

Products Description

Product Inquiry