A powder packaging and filling machine is specialized automated equipment designed for accurately measuring, filling, and packaging various powdered materials. It integrates functions of powder metering, conveying, filling, and sealing. Typically, it consists of a feeding system, a precise metering device, a filling mechanism, a packaging material handling unit, and a control system. The feeding system transports the powder to the metering device, which accurately measures the specified amount

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

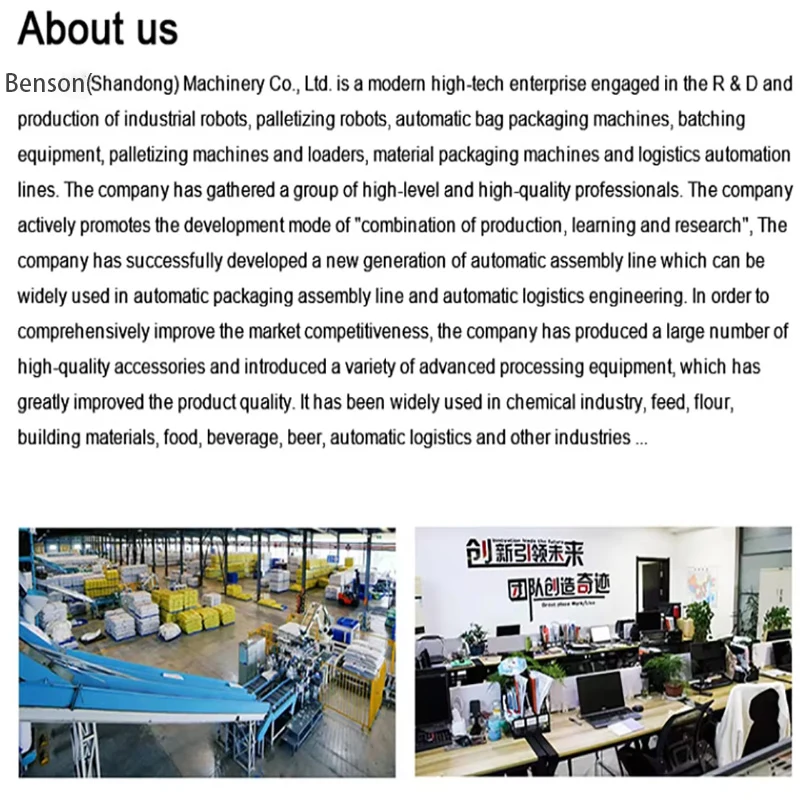

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Powder packaging and filling machineAdvantages

1. High Precision:Equipped with advanced metering technology, it can achieve high - accuracy filling, reducing the error rate of powder dosage to ensure product consistency and meet strict quality control requirements. For example, in pharmaceutical powder packaging, the accurate dosage is crucial for the efficacy and safety of drugs.

2. High Efficiency:Automated operation significantly improves production efficiency, capable of continuously working for a long time, and greatly increasing the output of powder packaging compared with manual operations. It can complete a large number of packaging tasks in a short time, which is suitable for mass - production scenarios in industries.

3. Cost - saving:By reducing labor costs and minimizing powder waste through accurate metering, it helps enterprises save production costs in the long run. The reduced need for manual labor also decreases the probability of human - related errors and product loss.

4. Flexibility:It can be adjusted to handle different types of powders with varying physical properties, such as fine - grained, coarse - grained, free - flowing, or cohesive powders. Moreover, it can adapt to different packaging sizes and materials, including plastic bags, paper bags, glass bottles, etc.

Powder packaging and filling machineApplications

1. Food Industry:Used for packaging powdered food products like milk powder, coffee powder, flour, seasoning powder, etc. It ensures the hygiene and accurate dosage of food products, extending their shelf life with proper sealing.

2. Pharmaceutical Industry:Vital for packaging pharmaceutical powders, such as raw materials for tablets, capsules, and various medicinal powders. Strict hygiene standards and high - precision filling requirements in the pharmaceutical industry can be well - met by this machine.

3. Chemical Industry:Applies to the packaging of chemical powders, including pesticides, fertilizers, pigments, and various industrial chemical powders. It helps in safely and accurately packaging potentially hazardous or valuable chemical substances.

4. Cosmetics Industry:Used to package cosmetic powders like face powder, eye shadow powder, etc. It can meet the aesthetic and quality requirements of cosmetic products, ensuring the packaging is both beautiful and functional.

Powder packaging and filling machineCharacteristics

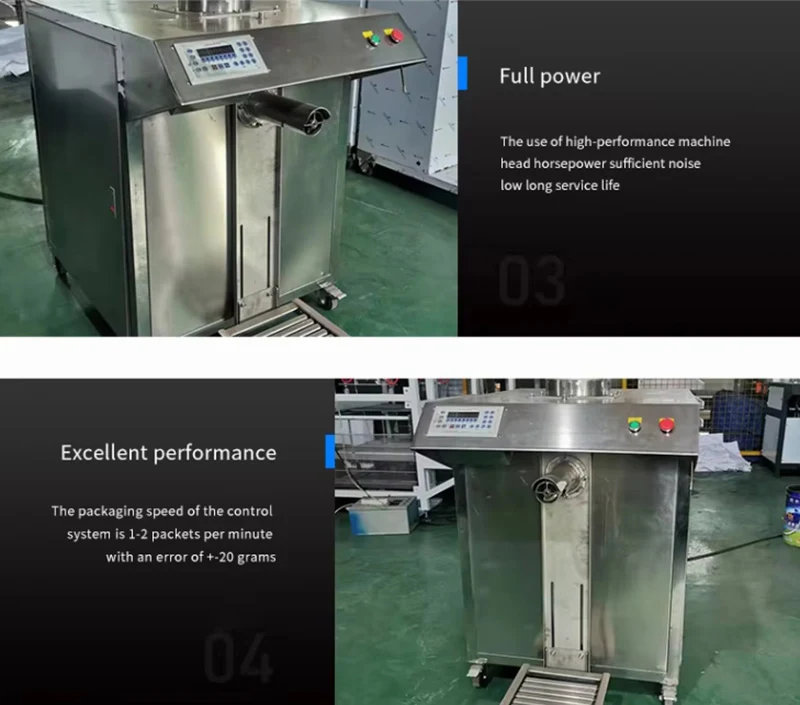

1. Intelligent Control:Most powder packaging and filling machines are equipped with intelligent control systems. Operators can set parameters such as filling volume, packaging speed, and sealing temperature through a touch - screen interface. The system can also monitor the operation status in real - time, display fault information, and facilitate maintenance and troubleshooting.

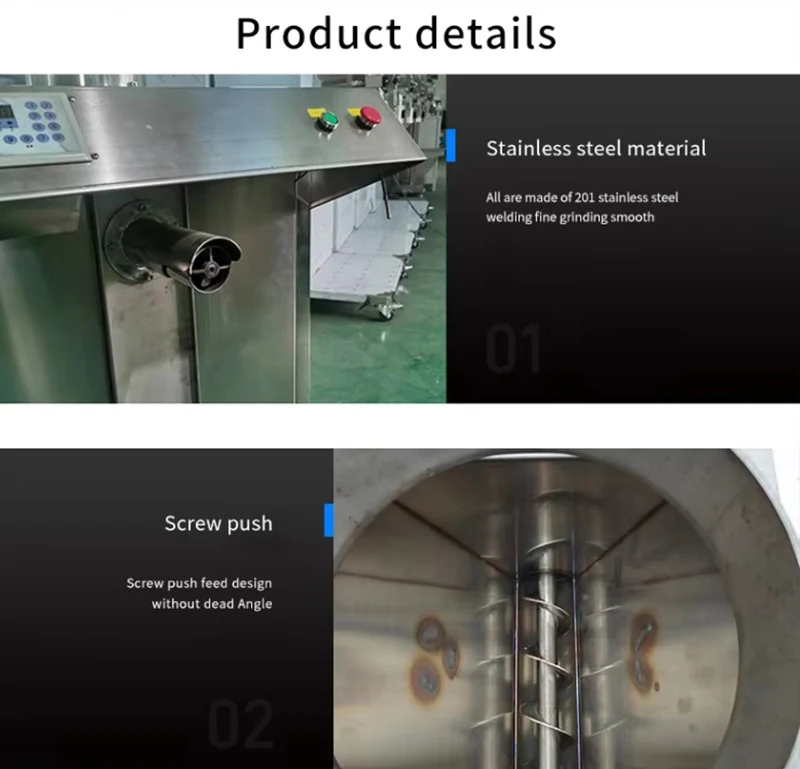

2. Hygienic Design:In consideration of the hygiene requirements of products in industries like food and pharmaceuticals, the machine's contact parts with powders are usually made of high - quality, corrosion - resistant, and non - toxic materials. It is also designed for easy disassembly and cleaning, reducing the risk of product contamination.

3. Stable Structure:With a robust mechanical structure, the machine can maintain stable operation during high - speed production, reducing vibration and noise. Its durable components ensure a long service life and reliable performance.

4. Safety Features:It is equipped with multiple safety devices, such as emergency stop buttons, safety guards to prevent operators from accidental contact with moving parts, and sensors to detect abnormal situations and automatically stop the machine to ensure operator safety and equipment protection.

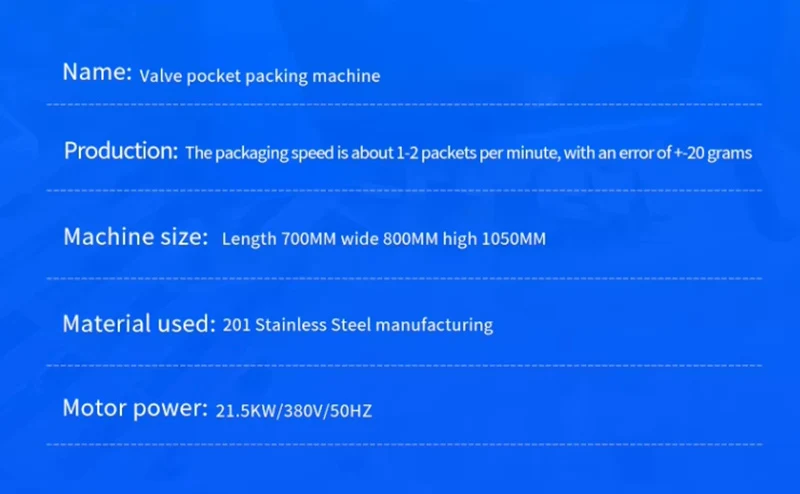

Products Description

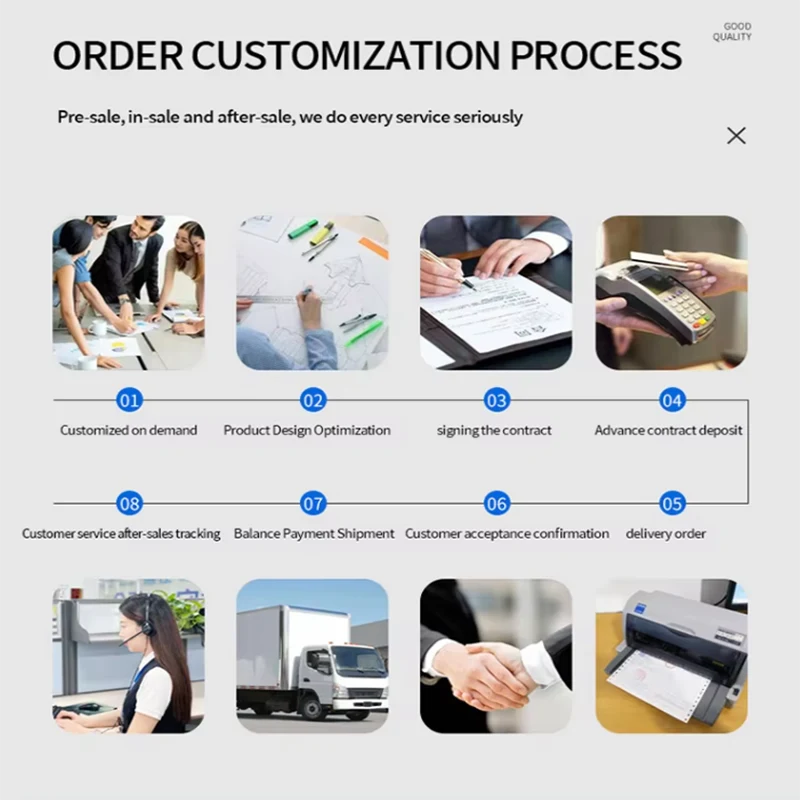

Product Inquiry