In modern industrial automation production and logistics transportation system, electric roller conveyor has become the core equipment in the field of material transmission with its integrated and intelligent conveying advantages. It realizes the integration of power and transmission with innovative design, and is widely used in multiple industry scenarios, significantly improving production and transportation efficiency.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

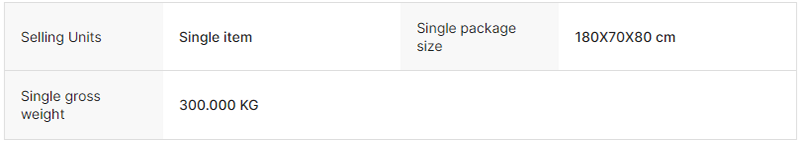

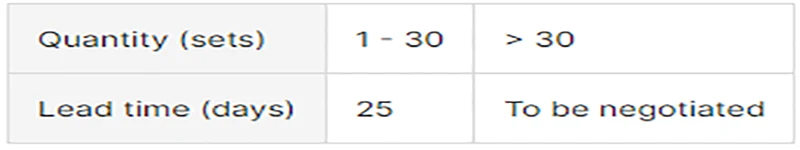

Packaging and delivery

Lead time

BensonElectric roller conveyor: intelligent and efficient conveying solution

Modular conveying unit of Bensonelectric roller conveyor

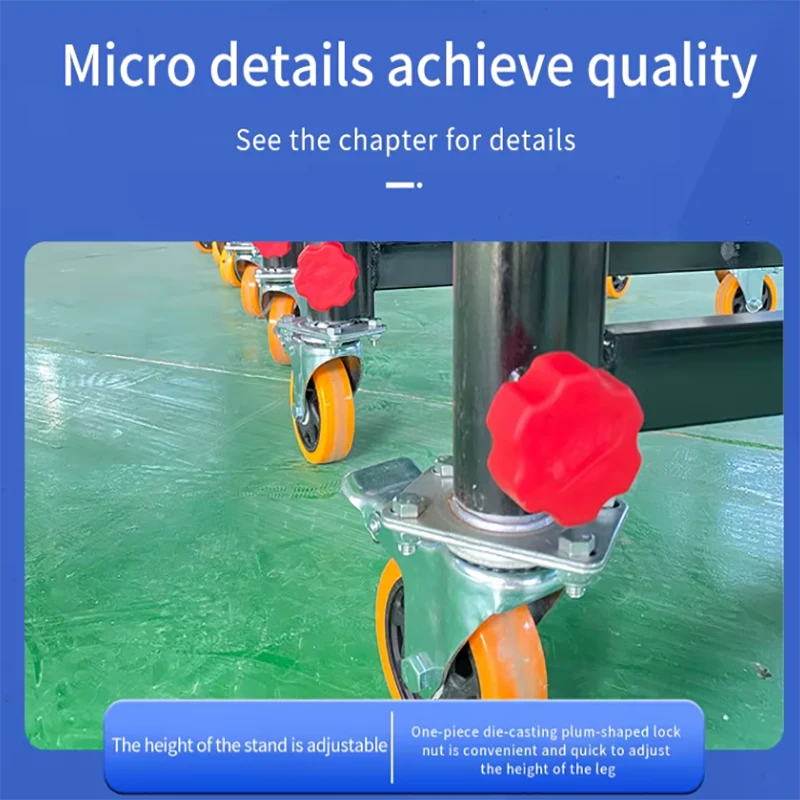

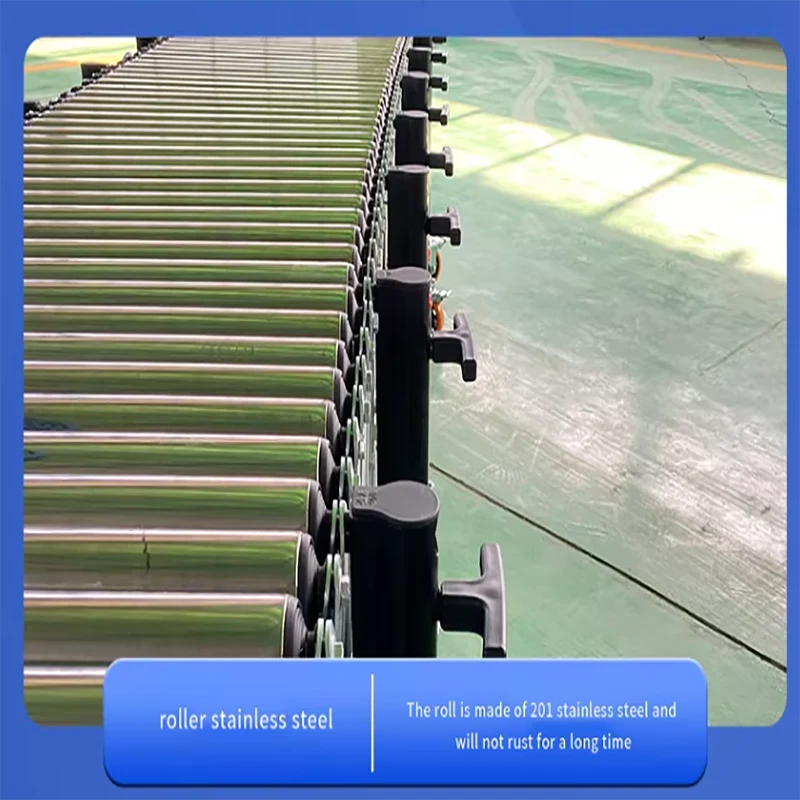

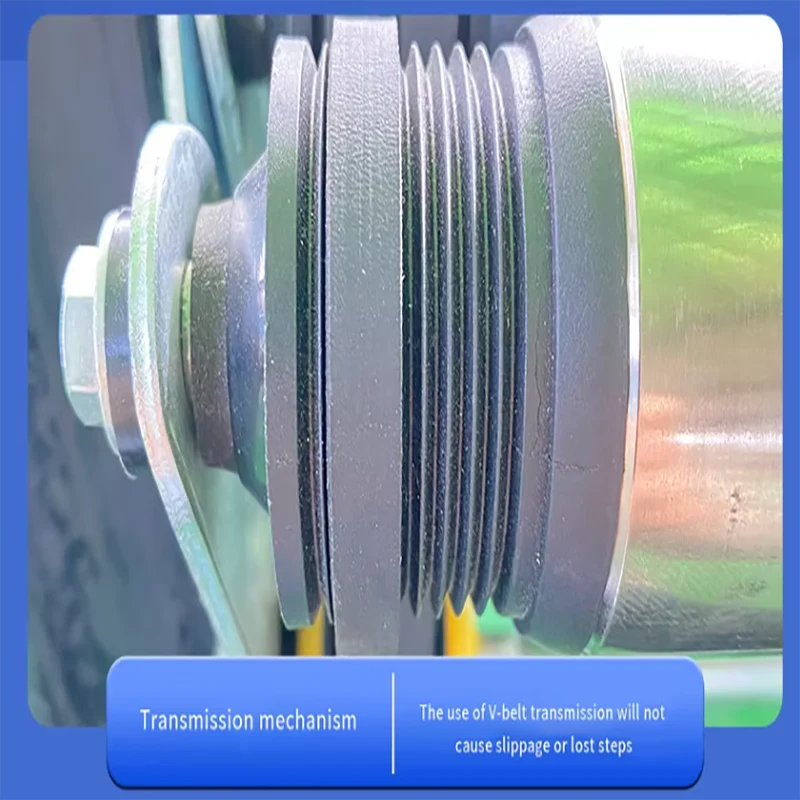

It consists of modules such as electric roller, conveyor belt, frame, tensioning device, etc. The electric roller is used as the driving source to drive the conveyor belt to circulate and carry materials to complete horizontal, inclined or turning conveying; the frame is made of high-strength steel or aluminum alloy to ensure the stability of the structure; the tensioning device can automatically adjust the tightness of the conveyor belt to ensure smooth operation.

Intelligent control configuration of Bensonelectric roller conveyor

It supports functions such as variable frequency speed regulation and PLC programming control. Users can flexibly adjust the conveying speed and start and stop according to actual needs; it is equipped with sensors such as photoelectric sensing and weight detection to realize intelligent operations such as automatic sorting, counting, and anti-deviation, meeting the automation needs of complex working conditions.

Core advantages of Bensonelectric roller conveyor

1. Compact structure and space optimization: The electric roller has a built-in drive design, which does not require additional power equipment space. It is suitable for space-constrained scenes such as narrow workshops and dense warehousing, saving more than 30% of the installation area.

2. High efficiency and energy saving, reducing costs: integrated transmission reduces energy loss, saving 20%-30% energy compared to traditional conveying equipment; no external transmission parts reduce maintenance frequency, extend equipment life, and reduce comprehensive operation and maintenance costs by 40%.

3. Safe, stable, low-noise operation: fully enclosed electric roller design prevents the motor from contacting the outside world, with a protection level of IP54 or above, suitable for harsh environments such as humidity and dust; operating noise is less than 65 decibels to ensure a comfortable working environment.

4. Flexible customization and strong adaptability: supports a variety of conveyor belt materials (rubber, PVC, PU, food-grade materials, etc.) and width customization; can combine a variety of conveying forms such as straight lines, curves, and climbing to meet the personalized needs of different industries.

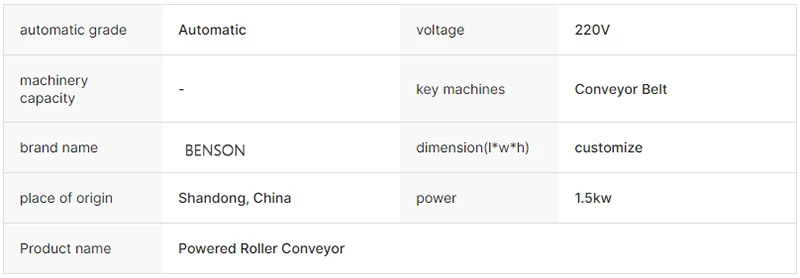

Technical parameters ofBenson electric roller conveyor

Item Parameter range

Conveying speed 0.1-3m/s (adjustable by frequency conversion)

Maximum conveying weight 50-500kg/m² (customizable)

Electric roller power 0.75-15kW

Applicable ambient temperature -20℃-60℃ (customizable for special working conditions)

Protection level IP54/IP65

Conveying length 1-100m (modular splicing)

Multiple application fields ofBenson electric roller conveyor

1. Logistics warehousing: used in express sorting centers and smart warehouses to achieve high-speed sorting and transfer of parcels and pallets; with automatic scanning system, it can complete automatic classification and transportation of goods.

2. Food processing: using food-grade conveyor belts and stainless steel racks to meet the continuous transportation needs of biscuits, candies, fruits and vegetables, etc., in line with GMP hygiene standards to prevent cross contamination.

3. Electronics and electrical appliances: Precision design ensures low vibration and low static electricity, suitable for electronic product assembly lines, and realizes accurate transmission and positioning of mobile phone and computer parts.

4. Packaging industry: Linked with packaging machines and palletizers, it completes automatic transportation and stacking of products after packaging, and improves the automation level of packaging production lines.

5. Automobile manufacturing: The large load-bearing design is suitable for automobile parts and vehicle transportation, and supports customization of heavy-duty rollers and high-strength conveyor belts to ensure efficient operation of production lines.

Customized services

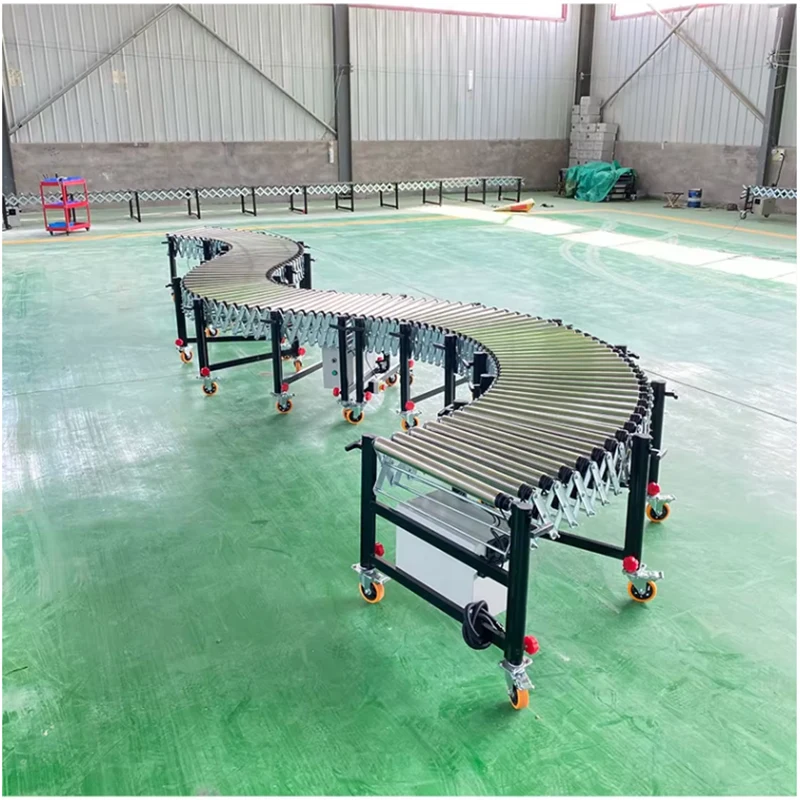

- Scenario adaptation: According to the customer's factory layout, material characteristics, and transportation requirements, we provide a variety of conveying scheme designs such as straight lines, S-types, and Z-types.

- Functional upgrade: Optional functional modules such as explosion-proof electric rollers, anti-static conveyor belts, automatic sorting systems, and weighing and metering modules.

- Full-cycle service: Provide one-stop services such as equipment installation and commissioning, operation training, regular maintenance, and emergency repairs to ensure stable operation of equipment.

With its high efficiency, intelligence and flexibility, electric roller conveyors are becoming a key driver for modern industrial automation upgrades, helping companies reduce costs, increase efficiency and optimize production processes.

Products Description

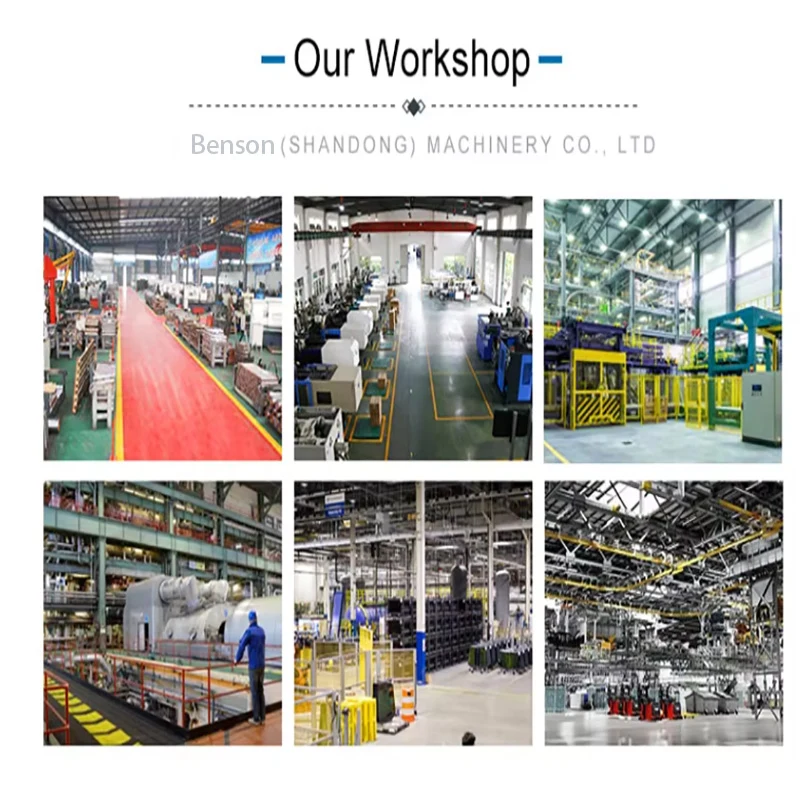

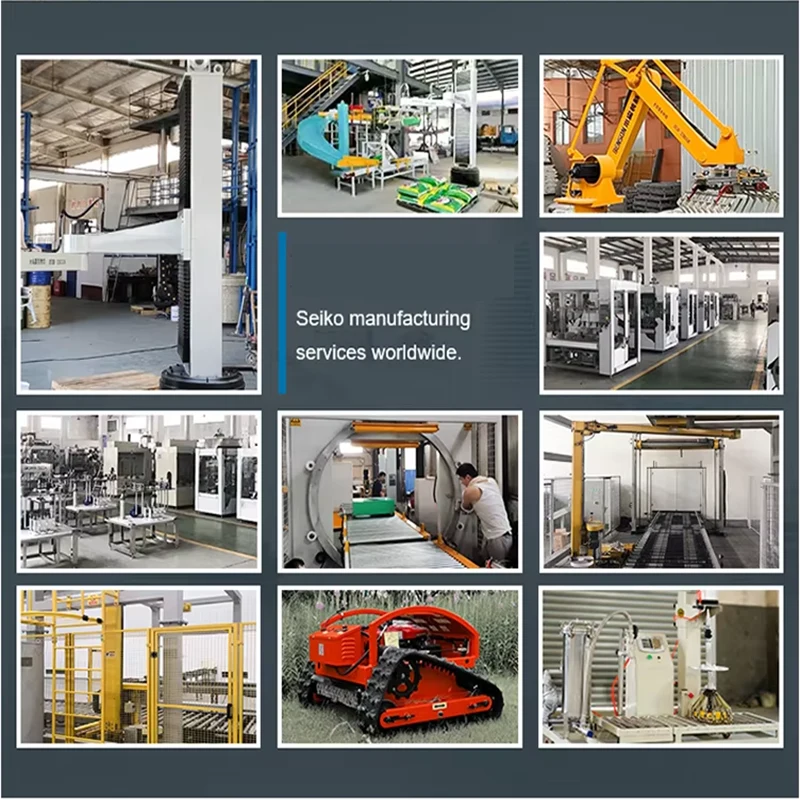

Company Profile

Benson (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Benson (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry