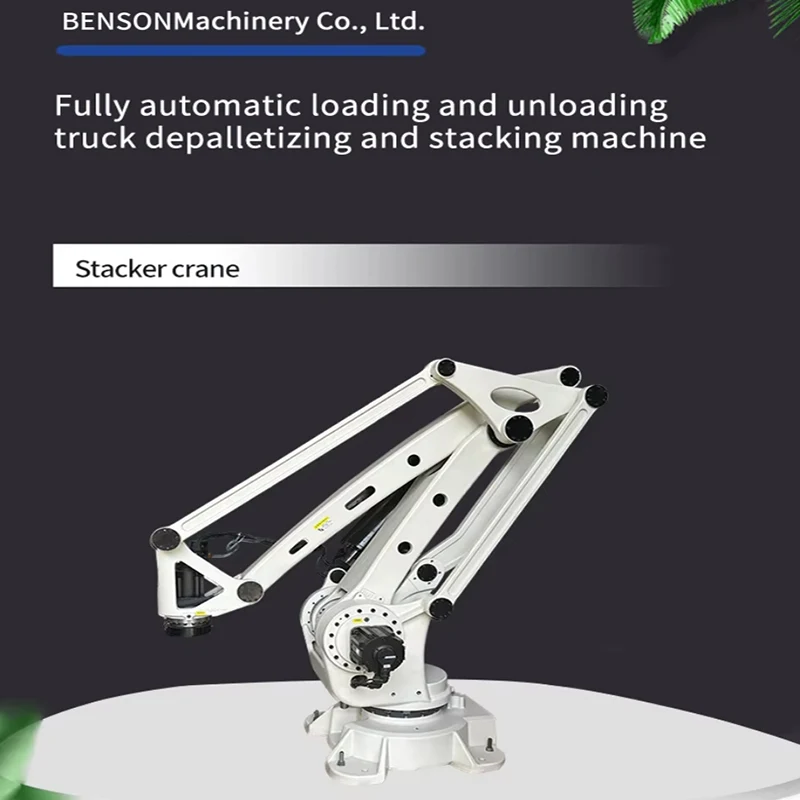

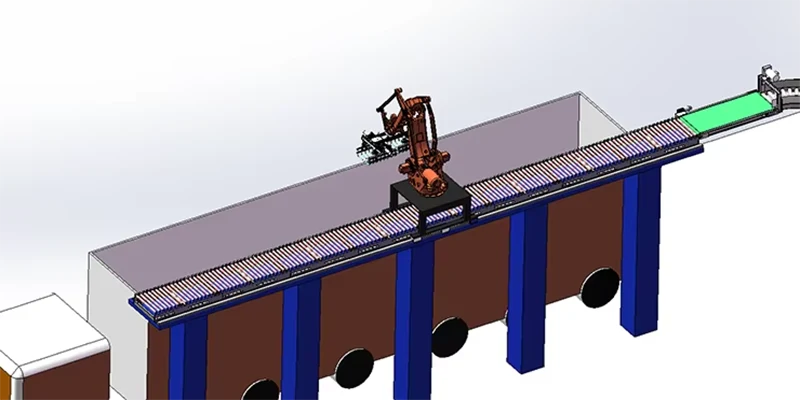

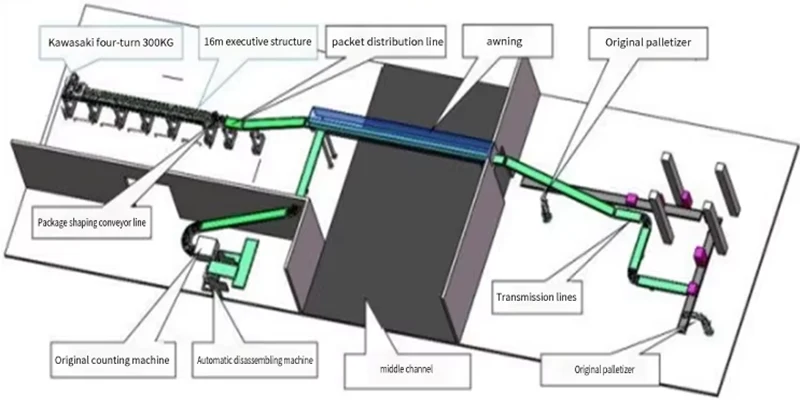

- The structure of the multi-joint electric robot palletizer is generally composed of a mechanical body (including multiple joint arms, bases, etc.), a servo motor (providing power for joint movement), a control system (responsible for command sending and motion control), an end effector (such as a gripper for grabbing materials) and a sensor (such as a position sensor, force sensor, etc., to assist in precise operation).

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

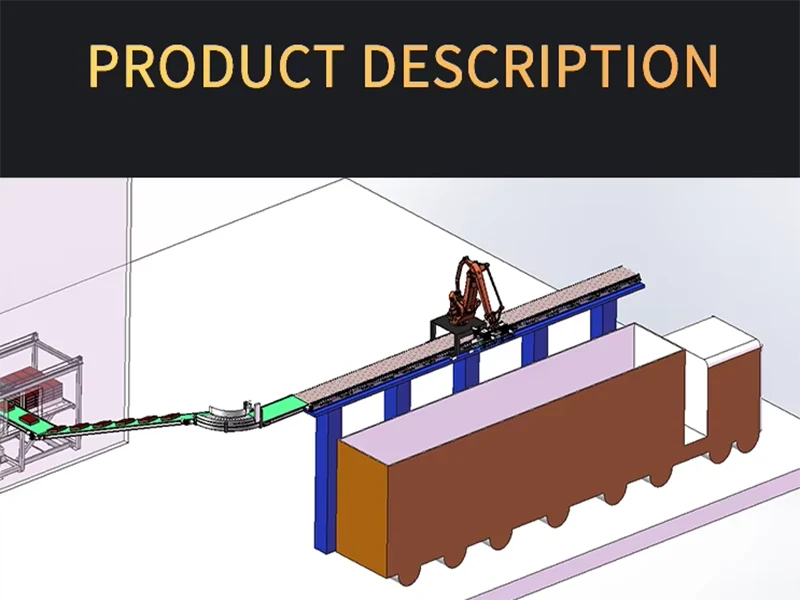

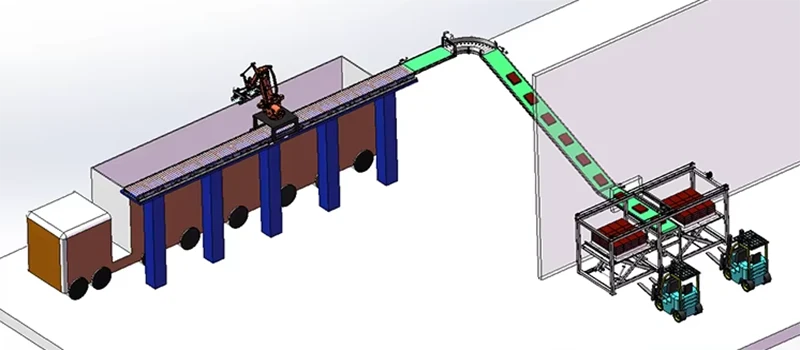

Products Description

- Working principle of fully automatic palletizing robot: send instructions through the control system, drive the servo motor to drive each joint to rotate, realize the multi-degree-of-freedom movement of the end effector in space, and complete the grabbing, handling and stacking of materials. At the same time, the sensor feedbacks information in real time to ensure the accuracy and safety of the operation. For example, when the packaged materials reach the designated palletizing area through the conveyor belt, the robot's control system coordinates the joint axes to move the clamp above the material. After receiving the material positioning signal, the clamp drops, and the servo motor accurately controls the clamp to clamp the material, and then transports it to the top of the palletizing position and places it accurately.

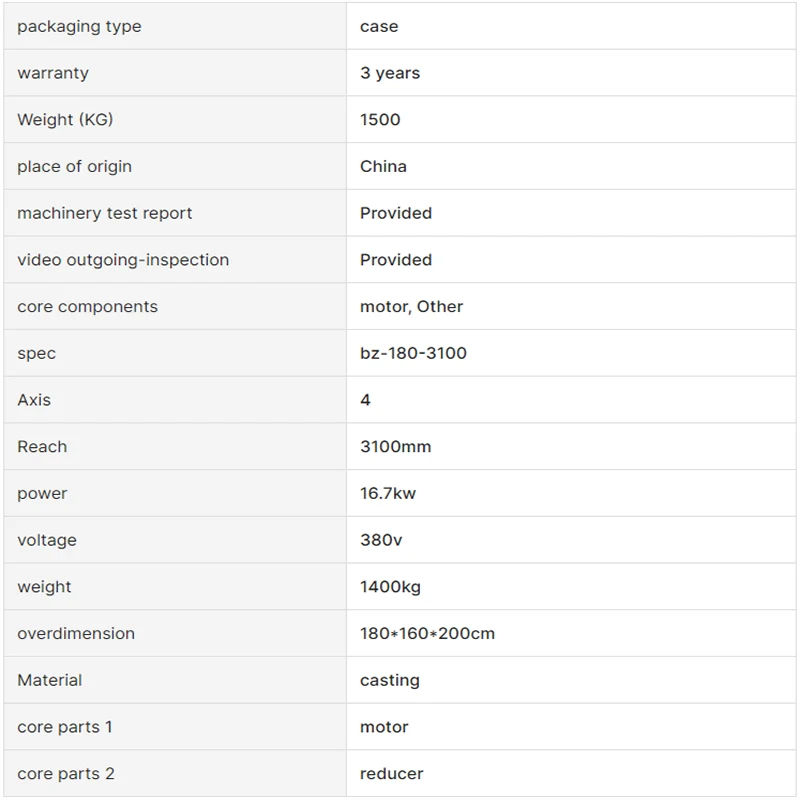

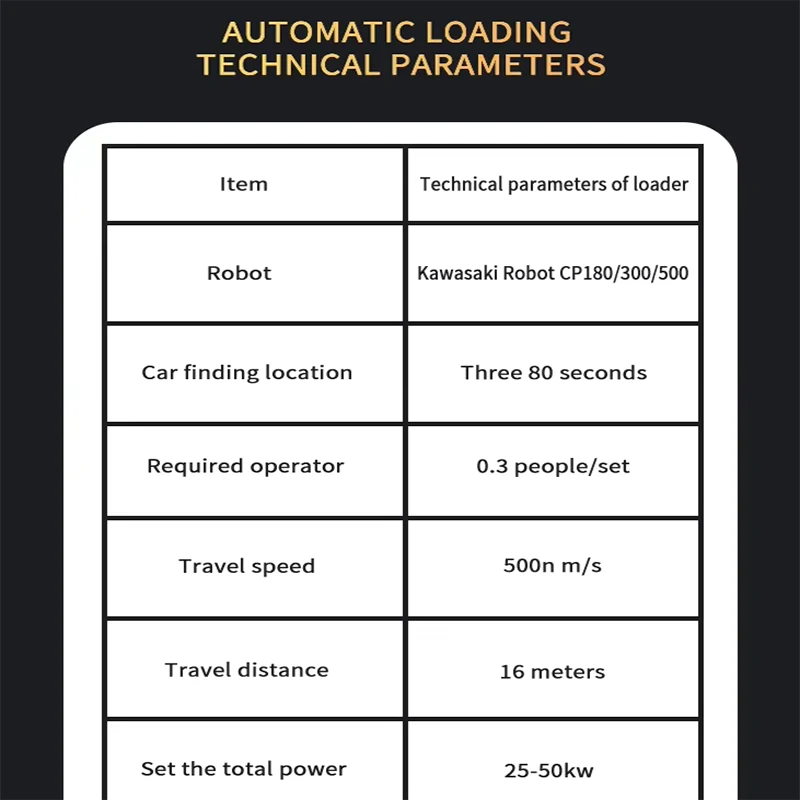

Technical parameters of fully automatic palletizing robot

- Load capacity: varies depending on the model, such as KW1180M-3200 can carry a load of 180kg; Huashu HSR-MD410 has a payload of 10kg; and some models have a load ranging from 5 to 30kg, which can meet the palletizing needs of materials of different weights.

- Number of joint axes: common ones are 4 axes and 6 axes. The more axes there are, the higher the flexibility of movement and the complexity of operation. For example, a 4-axis robot can achieve more flexible movements, and a 6-axis robot can achieve all-round movement and adapt to more complex palletizing tasks.

- Working radius: determines the robot's operating range, such as KW1180M-3200, the working radius can reach 3200mm; Huashu HSR-MD410 has a maximum working radius of 1510mm.

- Repeat positioning accuracy: reflects the accuracy of palletizing, such as Huashu HSR-MD410, the repeat positioning accuracy is ±0.08mm; some equipment can reach ±0.05mm, ±0.2mm, etc. High precision can ensure the neatness and tightness of the stacking shape and reduce product damage.

- Movement speed: includes joint rotation speed and end effector movement speed, such as a certain model J1 axis speed of 114°/sec, J2 axis speed of 108°/sec, etc. Fast speed can improve palletizing efficiency.

- Protection level: IP54 is common, which can prevent foreign objects from intruding and splashing water from intruding into the equipment, ensuring the stable operation of the equipment under certain conditions.

Product features of fully automatic palletizing robot

- Flexibility and versatility: The multi-joint design makes it flexible and has small inertia. It can grab workpieces close to the machine base and work around obstacles. It can adapt to a variety of product shapes, sizes and packaging forms. It can meet different palletizing needs through programming, and can also process different packaging materials at one workstation.

- Efficiency: It can operate continuously at high speed, is not affected by human fatigue, can greatly improve palletizing efficiency, and shorten production cycle. For example, the 200mm - 1700mm - 200mm gate type cycle beat of Huashu HSR - MD410 is 3.5s, and the punching beat can reach 16 times/min.

- Accuracy: It has high repeatability and positioning accuracy, which can ensure accurate material stacking, ensure the quality of the stacking shape, and reduce the defective rate.

- Stability and reliability: reasonable structural design, high-quality core components, stable operation, low failure rate, and long-term continuous work. Some complete machines use high-performance components to provide reliable performance guarantee for the equipment.

- Convenient operation and maintenance: usually equipped with graphic display touch screen, graphical programming interface or software, simple and easy to understand operation, easy fault diagnosis. Some adopt modular component structure, low maintenance difficulty, can quickly handle faults and resume production.

- Safety: equipped with a complete safety interlocking mechanism, equipped with light curtains, safety fences, emergency stop buttons and other safety devices. Some also have anti-collision functions, automatically stop when a collision is detected, to ensure the safety of operators and equipment.

Fully automatic palletizing robot application field

It is widely used in many industries such as food and beverage, medicine, chemical industry, building materials, grain and oil, feed, electronics, logistics and warehousing, etc. It can palletize various finished products such as cartons, bags, cans, bottles, etc., replacing traditional manual palletizing, and improving the production automation level and production efficiency of enterprises.

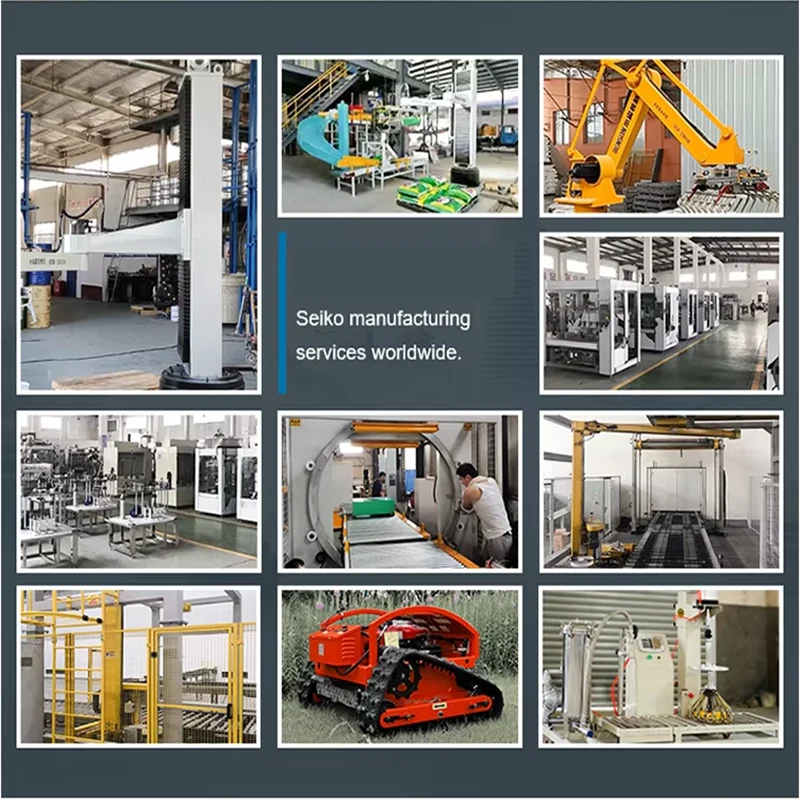

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

FAQ

Product Inquiry