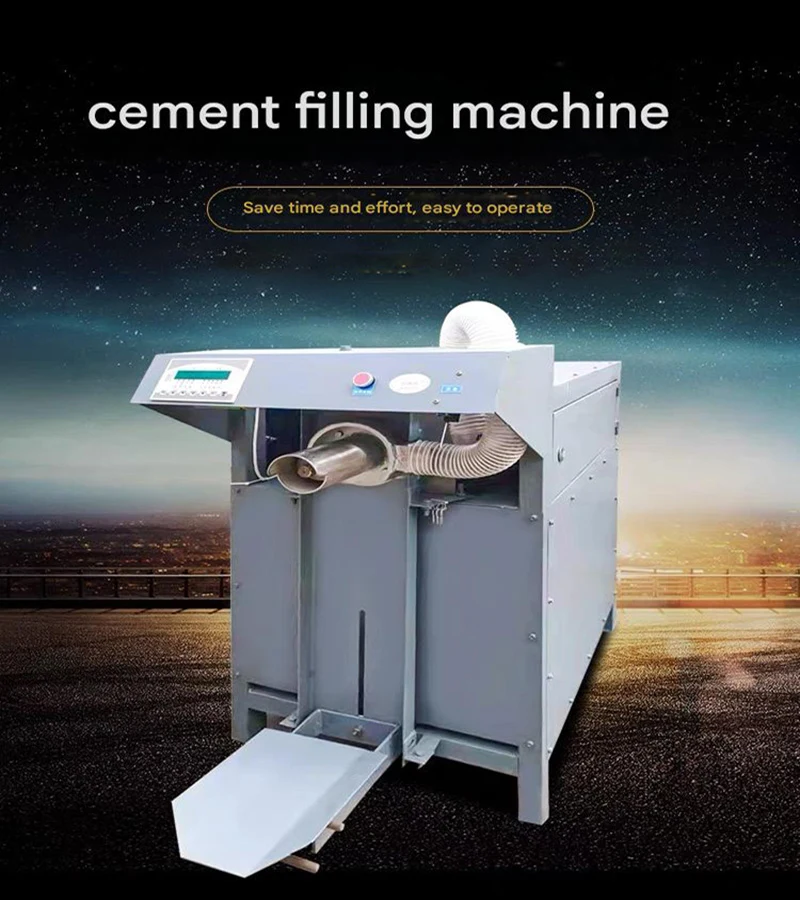

The electric impeller packaging machine is a mechanical device that uses an electric impeller as its core component to achieve material packaging. The equipment mainly consists of an electric drive system, impeller conveying mechanism, metering device, packaging forming mechanism, and electrical control system.During operation, the electric drive system drives the impeller to rotate at high speed. Using the centrifugal force or air flow generated by the impeller, powdery or granular materials

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

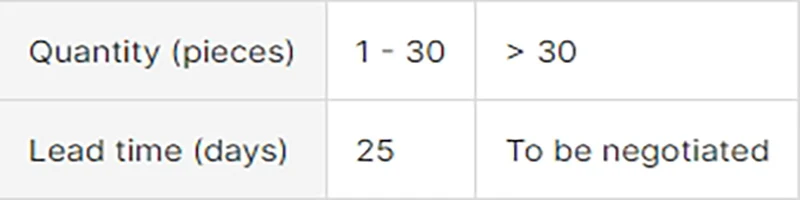

Lead time

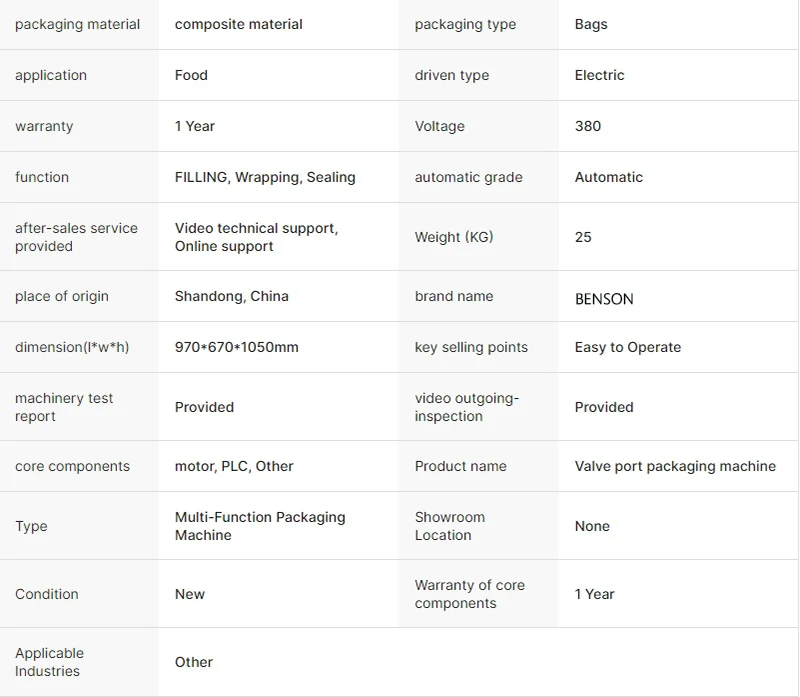

Product Introduction

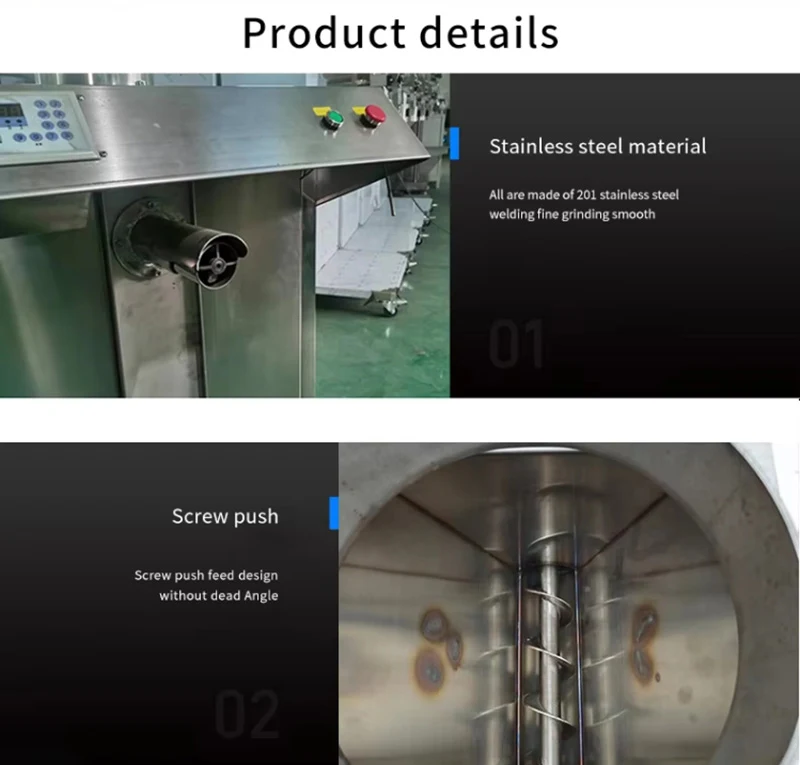

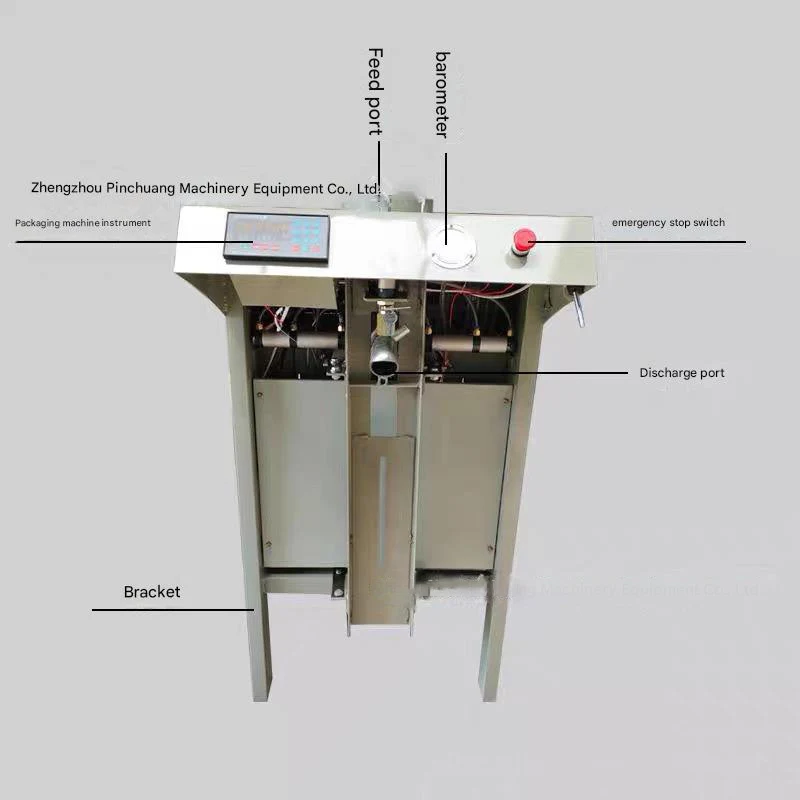

- The power drive system provides stable power for the entire equipment.

- Driven by a motor, the impeller conveying device transports materials from the storage bin to the packaging station.

- The intelligent metering module monitors and controls the packaging weight or volume of materials in real time.

- The packaging forming mechanism completes processes such as bagging and sealing.

- The automatic control system coordinates the entire packaging process for fully automated operation.

BensonElectric Impeller Packaging Machine Advantages

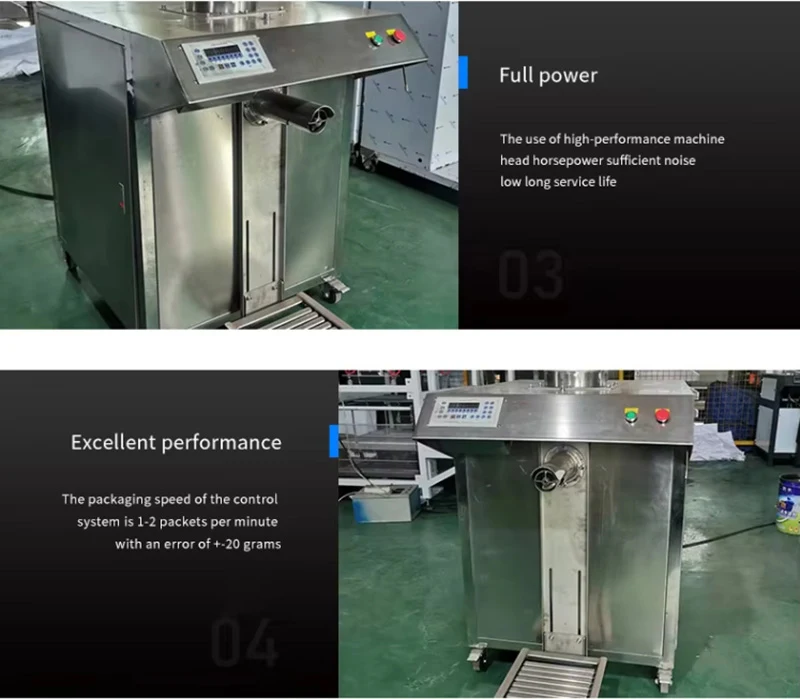

1. High Efficiency and Energy Saving: Compared with traditional packaging equipment, the electric impeller packaging machine adopts advanced motor drive technology and optimized impeller design, reducing energy consumption by 15%-20% during operation. It can complete 30-60 packaging cycles per minute, significantly improving production efficiency.

2. Precise Packaging: Equipped with high-precision sensors and an intelligent control system, it can limit material packaging errors within ±0.5%, ensuring uniform packaging specifications for each product and meeting high-standard quality requirements.

3. Low Maintenance Cost: The equipment features a compact structure, with key components made of wear-resistant and corrosion-resistant materials, ensuring a service life of 5-8 years under normal use. Its modular design facilitates component replacement and maintenance, reducing maintenance time by 30% and maintenance costs by 25%.

4. Stable and Reliable: After rigorous industrial testing and optimization, it can operate continuously and stably in complex environments such as high temperature, high humidity, and dust. The equipment has a low failure rate, with an average trouble-free operation time of over 8,000 hours.

BensonElectric Impeller Packaging MachineFeatures

1. Flexible Customization: It can flexibly adjust impeller speed, metering parameters, and packaging processes according to different material properties (such as particle size, density, and fluidity) and packaging requirements (such as packaging specifications and forms), adapting to multiple packaging scenarios.

2. Environmentally Friendly and Safe: The fully enclosed packaging structure effectively prevents material dust from spilling, reducing environmental pollution and health hazards to operators. It is also equipped with multiple safety protection devices, such as emergency stop buttons, overload protection, and leakage protection, to ensure safe equipment operation.

3. Intelligent Connectivity: It supports integration with factory ERP, MES, and other management systems to achieve real-time monitoring, analysis, and remote control of production data, facilitating production management and decision-making while helping enterprises achieve intelligent manufacturing.

4. Easy to Operate: With an intuitive touchscreen human-machine interface, the operation process is simple and easy to understand. Operators can master equipment operation after short-term training, reducing labor training costs.

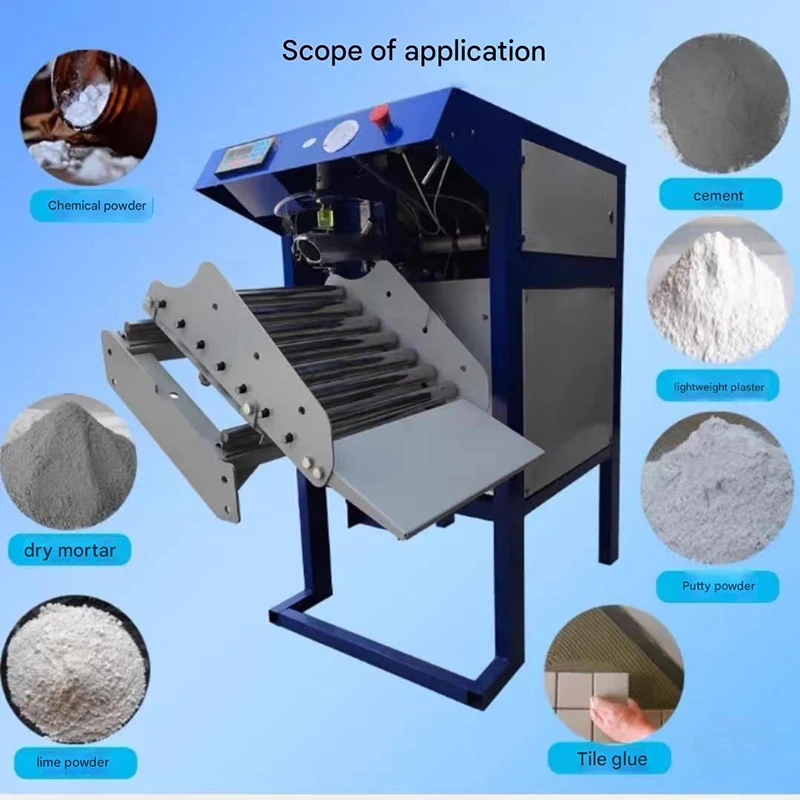

BensonElectric Impeller Packaging Machine Application Fields

1. Food Industry: Suitable for packaging powdery foods such as milk powder, coffee powder, seasonings, and starch, as well as granular foods such as candies, nuts, and grains, ensuring food hygiene safety and packaging quality.

2. Chemical Industry: Used for packaging various chemical raw materials, such as plastic particles, rubber additives, coating powders, pesticides, and fertilizers, meeting the high-precision and sealing requirements for chemical product packaging.

3. Pharmaceutical Industry: Capable of packaging pharmaceutical granules and powders, complying with the strict hygiene standards and production specifications of the pharmaceutical industry to ensure the safety and accuracy of drug packaging.

4. Building Materials Industry: Widely used in packaging building materials such as cement, dry mortar, putty powder, and gypsum powder, improving packaging efficiency and quality while reducing labor intensity.

5. Feed Industry: Used for packaging various feed granules and powders, meeting the large-scale and high-efficiency packaging needs of feed production enterprise.

Products Description

Product Inquiry