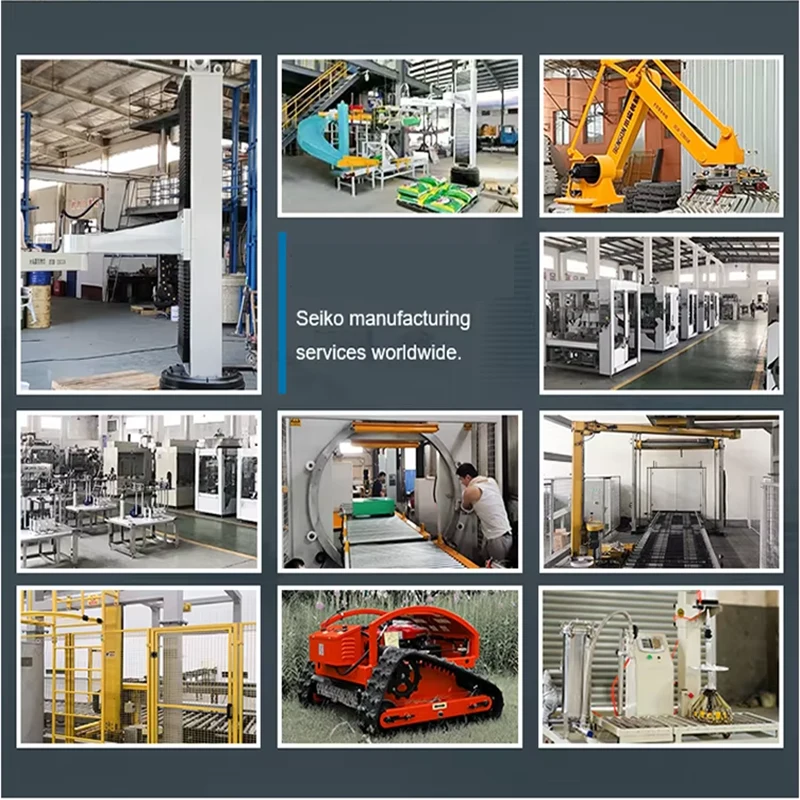

Description: The electric high-frequency turntable welding machine is a mechanical device that uses electric drive and high-frequency welding technology. It is equipped with a rotatable turntable working platform, which can realize the continuous rotation of workpieces, making it convenient to carry out welding operations on multiple workpieces or different parts of the same workpiece. It is suitable for various industries that require precision welding, such as electronics, electrical appliance

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

.Electric high-frequency turntable welding machine

-. Cost savings: On the one hand, efficient production and high-quality welding reduce the defective product rate and lower the production cost. On the other hand, automated operation reduces the demand for manpower, and in the long run, it can save labor costs.

-. Small heat-affected zone: The heat generated by high-frequency welding is concentrated in the welding area, and the thermal influence on the surrounding area is small, which is conducive to protecting the performance of the workpiece and is suitable for welding temperature-sensitive materials.

-. Small floor space: It has a compact structure, and the turntable design makes rational use of space. In a limited production site, the equipment can be effectively arranged, improving the space utilization rate.

Electric high-frequency turntable welding machine

1. Efficient production: The electric high-frequency turntable welding machine can achieve continuous welding. The turntable can quickly transport workpieces, shortening the auxiliary time and greatly improving the production efficiency. For example, in the welding of electronic components, it can quickly complete the welding of multiple components, meeting the needs of large-scale production.

2. High welding quality: The high-frequency welding technology can precisely control the welding temperature and time, making the welding points firm and beautiful, and reducing problems such as poor soldering and missed soldering. In the welding of automotive parts, for instance, it can ensure the welding strength and improve the reliability of the products.

3. Strong flexibility: According to the shape, size and welding requirements of different workpieces, the welding parameters such as frequency and power can be adjusted to adapt to a variety of welding scenarios. Moreover, the rotation angle and speed of the turntable can also be flexibly adjusted to meet the needs of different welding processes.

4. High degree of automation: The electric system and control system of the equipment can achieve automated operation, reducing manual intervention and labor intensity. Operators only need to perform simple parameter settings and monitoring to complete complex welding tasks.

5. Cost savings: On the one hand, efficient production and high-quality welding reduce the defective product rate and lower the production cost. On the other hand, automated operation reduces the demand for manpower, and in the long run, it can save labor costs.

6. Small heat-affected zone: The heat generated by high-frequency welding is concentrated in the welding area, and the thermal influence on the surrounding area is small, which is conducive to protecting the performance of the workpiece and is suitable for welding temperature-sensitive materials.

7. Small floor space: It has a compact structure, and the turntable design makes rational use of space. In a limited production site, the equipment can be effectively arranged, improving the space utilization rate.

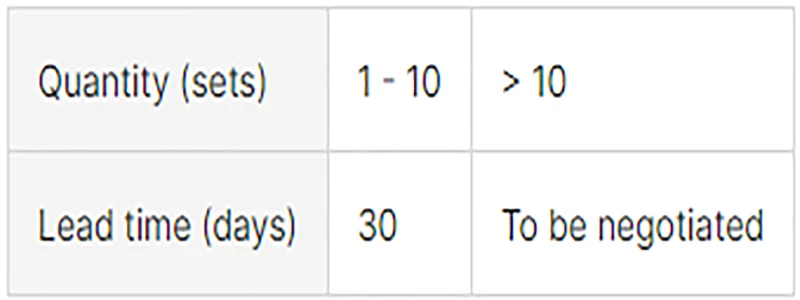

Lead time

Products Description

Product Inquiry