The electric dry powder sand filler and filling machine is a specialized automated equipment designed for efficiently and accurately filling dry powder sand into various containers. It integrates electric-driven technology, enabling automated material conveying, metering, and filling processes. The machine can handle different specifications of dry powder sand, and its operation is controlled through an intelligent system, ensuring stable performance and high filling precision.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Electric Dry Powder Sand Filler and Filling MachineAdvantages

1. High Efficiency:With its automated operation, it can significantly increase the filling speed compared to manual work, greatly improving production efficiency and reducing labor costs.

2. Precise Filling:Equipped with advanced metering devices, it can achieve accurate filling of dry powder sand, minimizing material waste and ensuring consistent product quality.

3. Flexibility:It can adapt to various container sizes and shapes, meeting the diverse needs of different production scenarios.

4. Energy - Saving:The electric - driven system is energy - efficient, reducing power consumption while maintaining high - performance operation.

5. Reliable and Durable:Constructed from high - quality materials and components, the machine has a long service life and is less prone to breakdowns, ensuring continuous and stable production.

Electric Dry Powder Sand Filler and Filling MachineApplications

1. Construction Industry:Used for filling dry powder sand in the production of building materials such as mortar bags, precast concrete products, and insulation materials.

2. Manufacturing of Abrasives:Applies to the filling of abrasive - grade dry powder sand into packages for sandblasting, polishing, and other abrasive applications.

3. Foundry Industry:Can fill dry powder sand into molds for casting processes, ensuring the correct amount of sand is used for each mold.

4. Landscaping and Gardening:Used to package dry powder sand for gardening projects like paving, leveling, and decorative purposes.

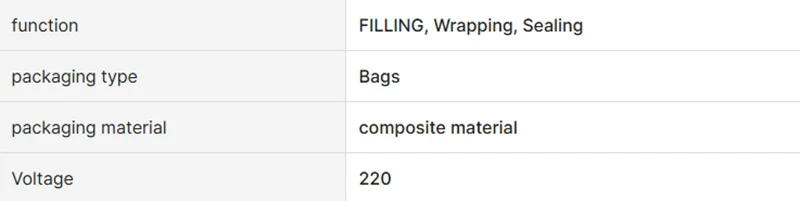

Electric Dry Powder Sand Filler and Filling MachineFeatures

1. Automated Operation:The entire filling process, from material feeding to container filling, is automated, reducing human intervention and the risk of errors.

2. Intelligent Control:Controlled by a programmable logic controller (PLC) or other intelligent control systems, allowing for easy adjustment of filling parameters such as filling volume and speed.

3. Dust - Proof Design:To prevent dust from dry powder sand from spreading during the filling process, the machine is designed with dust - proof structures, creating a cleaner working environment and protecting operators' health.

4. Easy Maintenance:With a modular design, components are easy to disassemble and replace, facilitating regular maintenance and reducing downtime.

5. Safety Protection:Equipped with various safety devices such as emergency stop buttons and safety interlocks to ensure the safety of operators during operation.

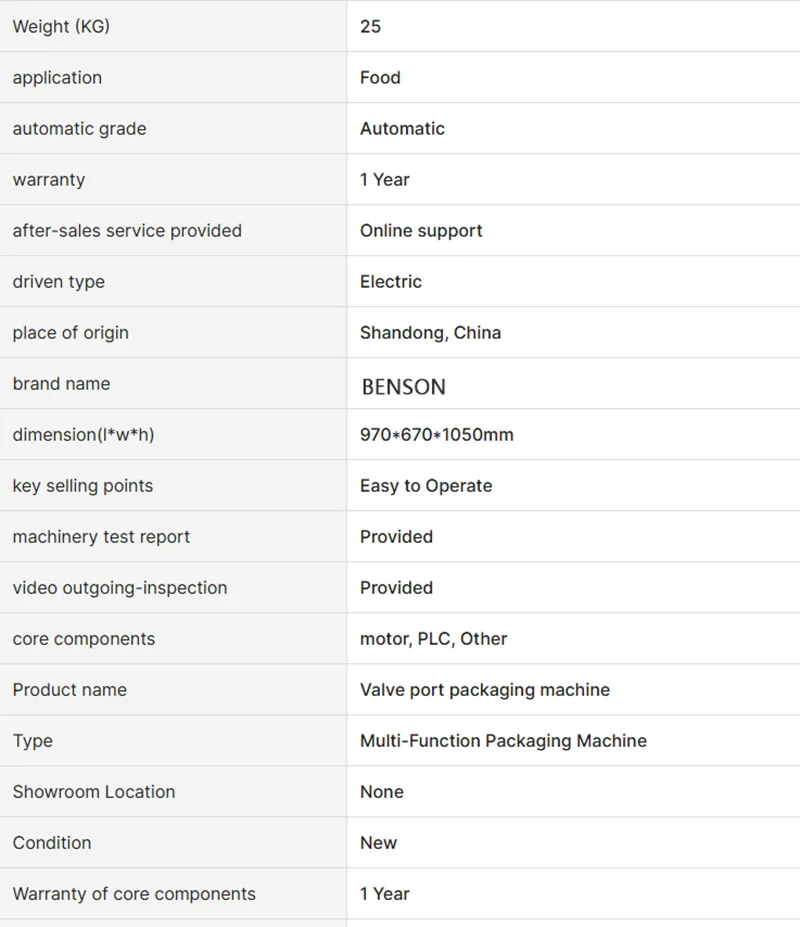

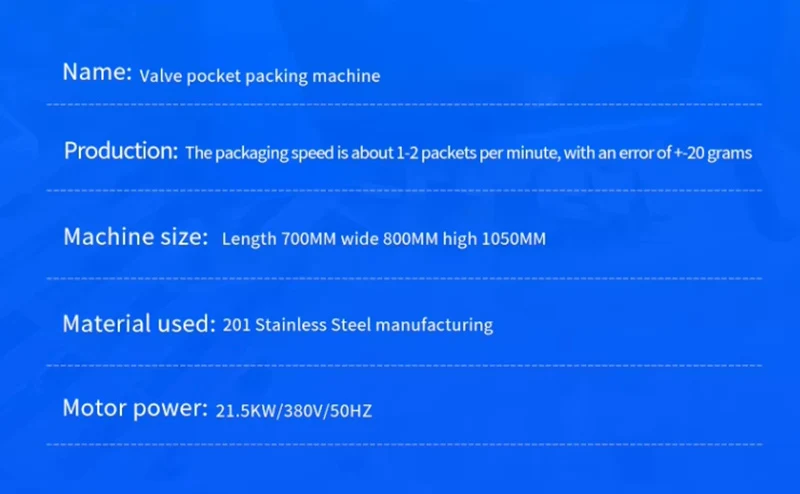

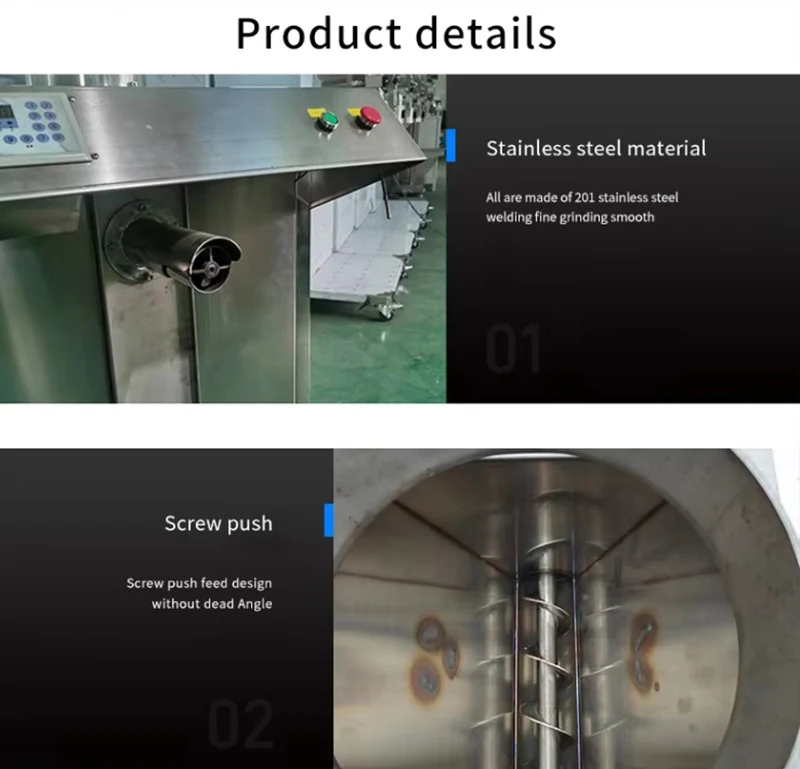

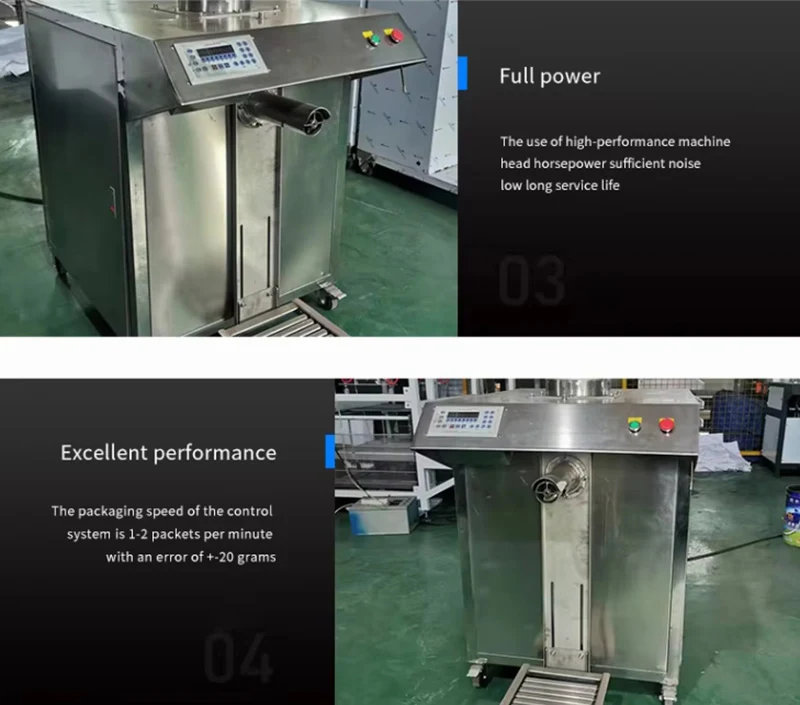

Products Description

Product Inquiry