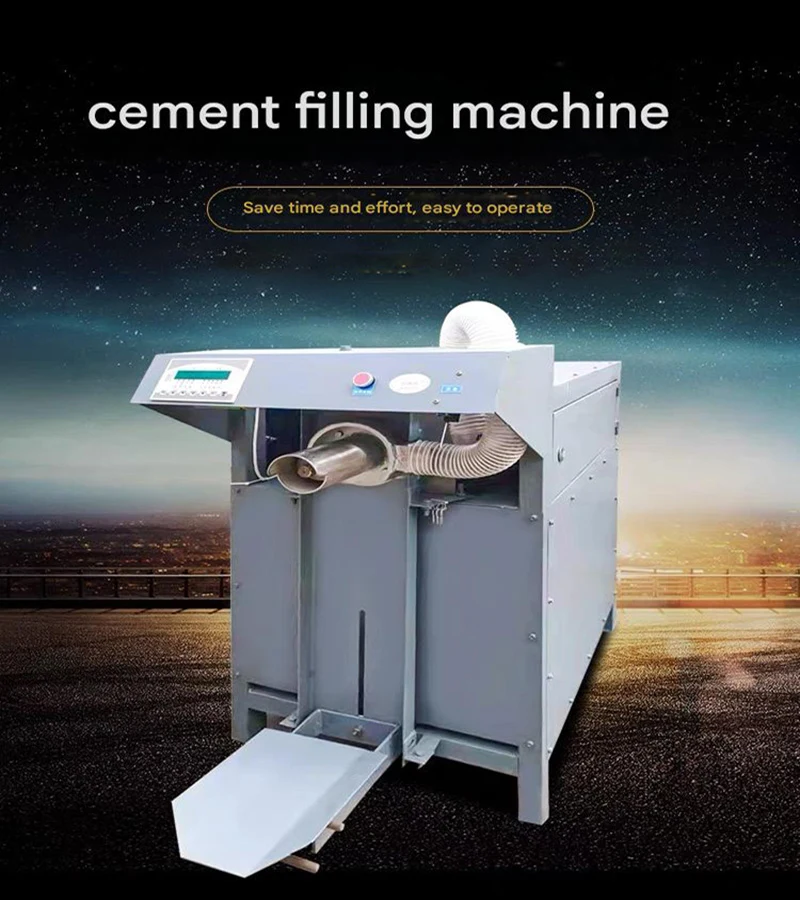

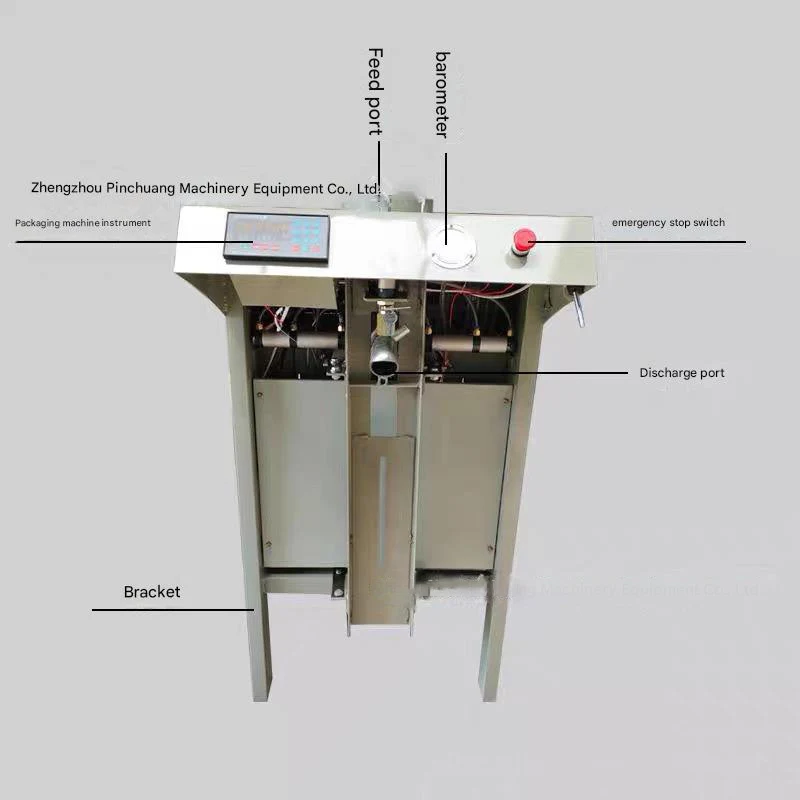

Electric dry powder material packaging machines are automated equipment designed for precise and efficient packaging of powdery substances (e.g., cement, flour, chemical powders). Driven by electric systems, they integrate functions like material feeding, metering, bagging, and sealing. These machines typically feature a hopper for material storage, a metering device for accurate dosing, and a sealing mechanism to ensure airtight packaging, suitable for dry powders in various industries.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

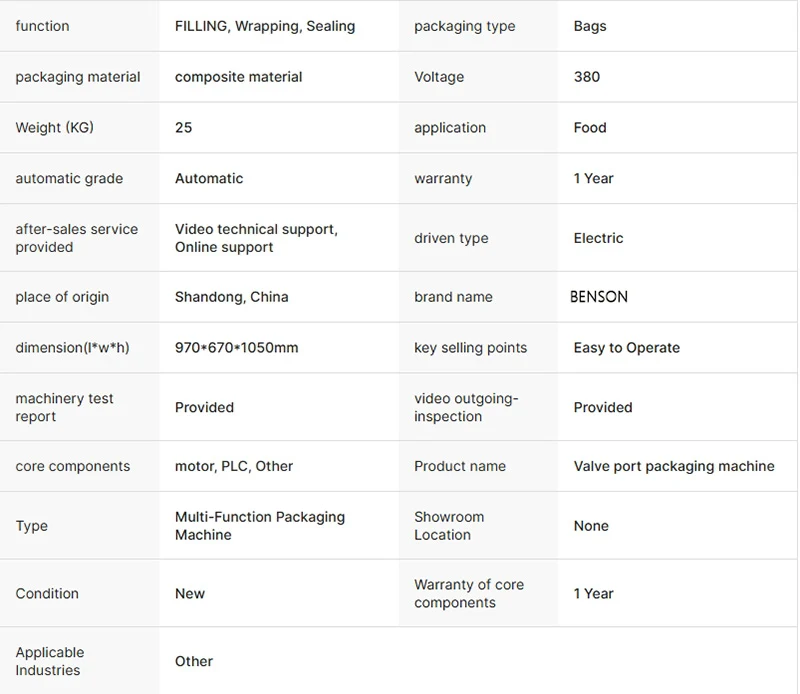

BensonElectric Dry Powder Material Packaging MachineAdvantages

1. High Precision: Electric control systems enable accurate metering, reducing material waste and ensuring consistent package weights.

2. Energy Efficiency: Electric-driven operation is more energy-saving than pneumatic systems, lowering long-term operational costs.

3. Automation: Full or semi-automated processes (feeding, measuring, sealing) minimize labor needs and improve production efficiency.

4. Adaptability: Suitable for different powder textures (fine/coarse) and packaging specifications (bags of various sizes).

BensonElectric Dry Powder Material Packaging MachineFeatures

1. Electric-Driven Design: Reliable motor and transmission systems ensure stable performance and low noise.

2. Intuitive Operation: Touchscreen interfaces and PLC control allow easy parameter adjustment (e.g., packaging weight, speed).

3. Dust Control: Closed hopper and dust suction ports reduce powder leakage, improving workshop hygiene.

4. Durable Construction: Main components (e.g., hopper, metering device) are made of stainless steel or wear-resistant materials for long service life.

BensonElectric Dry Powder Material Packaging MachineApplications

1. Building Materials: Packaging cement, dry mortar, lime, and wall putty in the construction industry.

2. Food Industry: Filling flour, sugar, powdered seasonings, and instant food ingredients into bags.

3. Chemical & Pharmaceutical Sectors: Packaging chemical powders (e.g., pigments, additives), pharmaceutical powders, and agricultural fertilizers.

4. Daily Products: Handling powdery detergents, cosmetics (e.g., face powder), and other household dry goods.

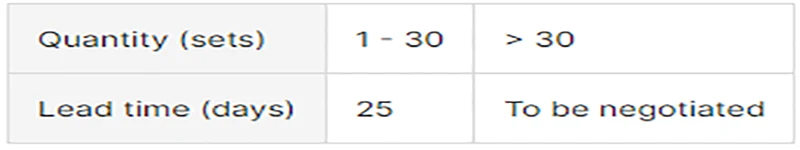

Key attributes

Products Description

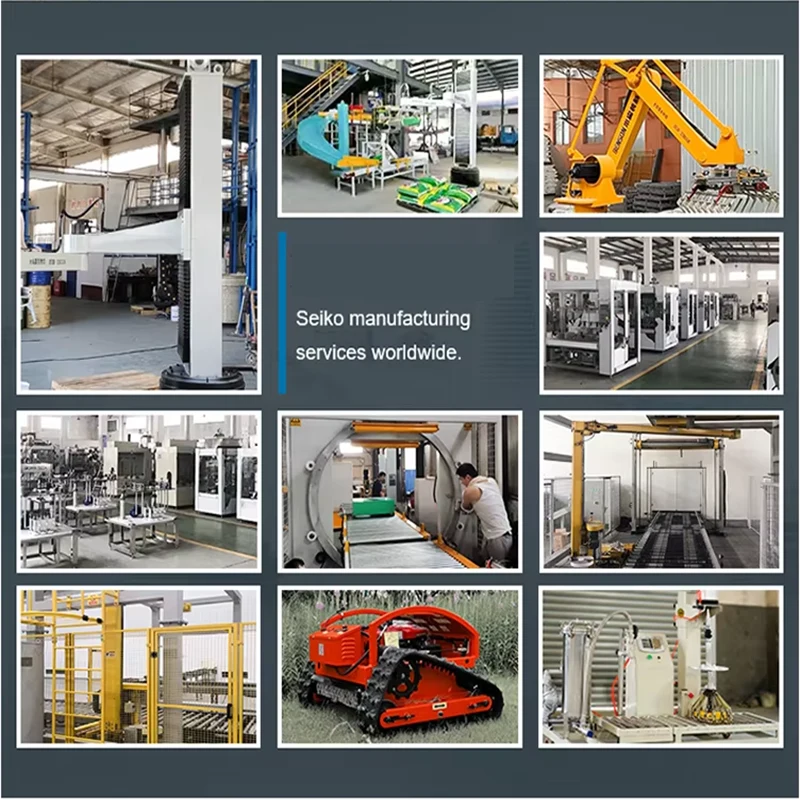

BENSON(Shandong) Machinery Co., Ltd. is a company engaged in winding machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bag feeding, large production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation A modern company that develops and produces production lines. high-tech enterprises. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "combination of production, education and research". The success of this research and development can be widely used in automated packaging routes, automated logistics engineering and other fields. A new generation of automated assembly line, the company has introduced various advanced processing equipment to comprehensively enhance market competitiveness, a large number of high-quality accessories, and product quality has been greatly improved. And other industries have been widely used, from product import to output, from electrical control to mechanical structure design, BENSON (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and equipment precision manufacturing, we have a complete after-sales service system. , To provide customers with high-quality technical support and after-sales service.

Product Inquiry