The automatic sand filling function of the electric dry powder filling machine uses an electrically driven precise mechanism to automatically, continuously, and stably fill powdery sand materials into packaging containers. The precise sealing and packaging function relies on advanced technologies such as heat sealing and pressure sealing, accurately controlling parameters like temperature, pressure, and time according to the characteristics of packaging materials, ensuring tight closure

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

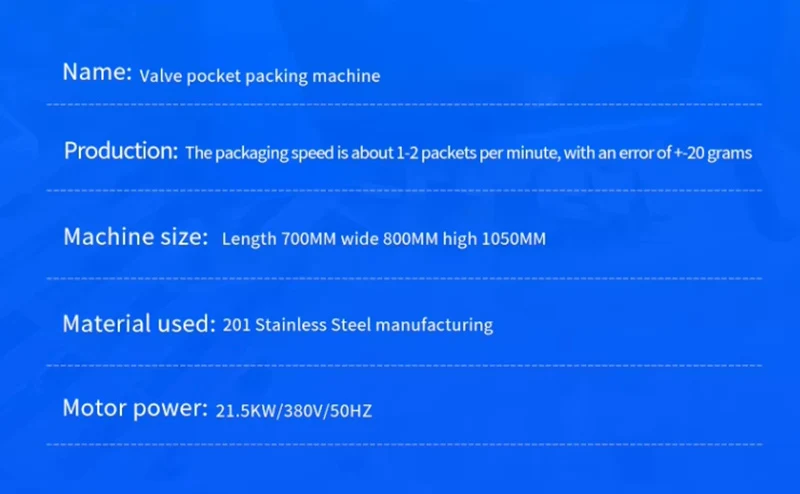

Electric dry powder filling machineAdvantages

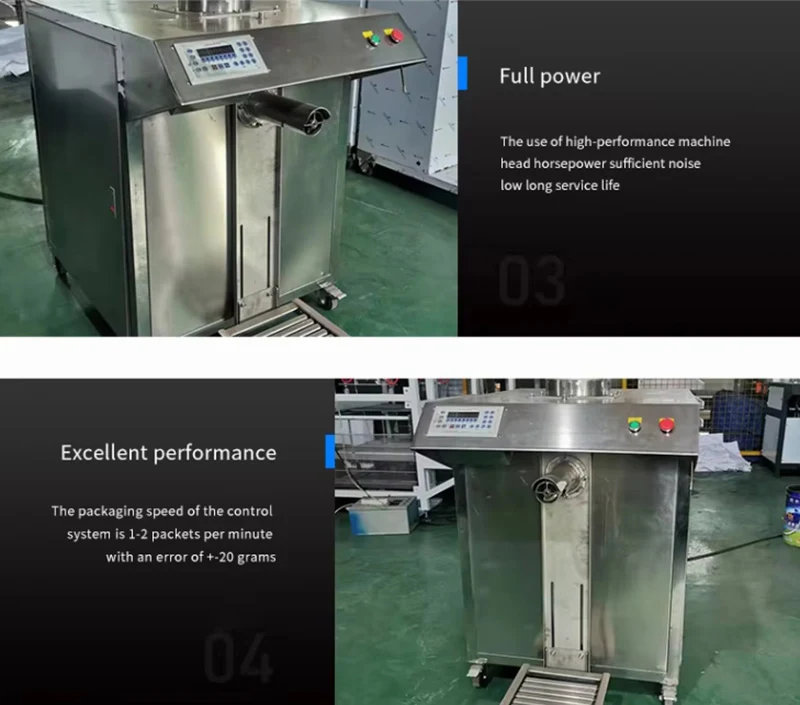

- High Efficiency Production: Automatic sand filling significantly reduces manual filling time and labor input. Combined with precise sealing and packaging, fully automated operation significantly improves filling and packaging speed to meet large-scale production needs.

- Accurate Metering: It can precisely control the filling volume of sand materials with small metering errors, ensuring consistent weight for each package, reducing material waste, and improving product quality stability.

- Reliable Sealing: Precise sealing and packaging form a good sealing effect, effectively preventing moisture, dust, and leakage, extending product shelf life, and enhancing quality safety during storage and transportation.

- Strong Adaptability: It can be adjusted for dry powder sand materials with different particle sizes and flow properties, as well as diversified shapes and specifications of packaging containers, adapting to multiple packaging materials.

Electric dry powder filling machineApplications

- Building Materials Industry: Used for packaging dry powder building materials such as dry mortar, cement, and gypsum powder to meet the packaging needs of materials in construction processes like masonry, plastering, and painting.

- Chemical Industry: Suitable for packaging dry powder chemical raw materials, such as filling and sealing of certain powdery coatings, pigments, and additives.

- Food Industry: Applied in packaging dry powder food products, such as quantitative filling and sealing of milk powder, protein powder, and seasoning powders.

- Pharmaceutical Industry: Used for packaging pharmaceutical powders, such as filling and sealing of certain granular and powder medications to ensure drug quality and safety.

Electric dry powder filling machineCharacteristics

- High Automation Level: Equipped with an intelligent control system, it can achieve automatic feeding, metering, filling, and sealing operations, with simple operation, reduced manual intervention, and fewer human errors.

- High-Precision Sensing Technology: Uses high-precision weighing sensors, photoelectric sensors, etc., to monitor the filling process in real time, ensuring accurate metering of sand filling and packaging sealing quality.

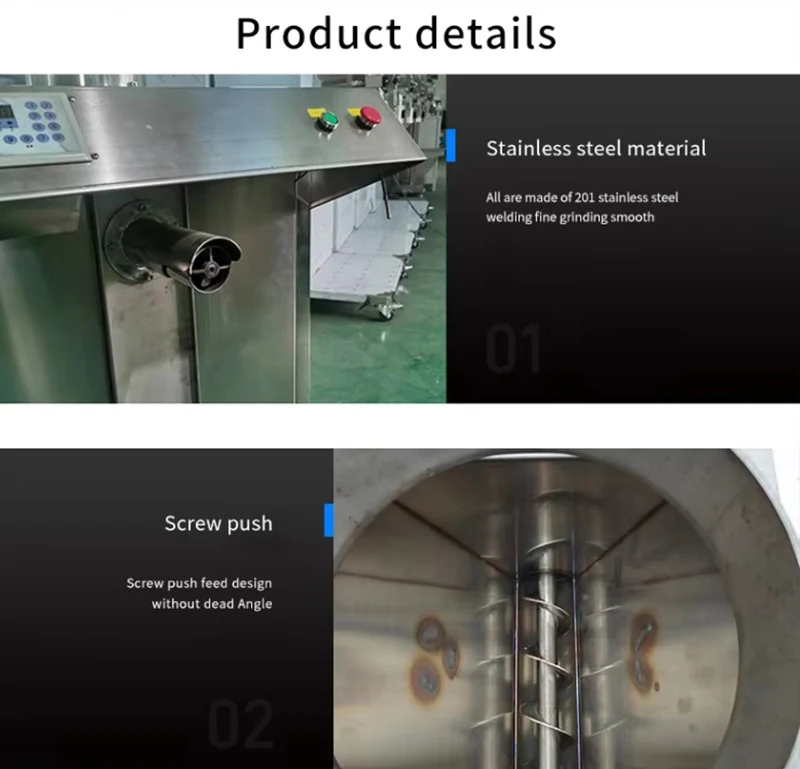

- Reasonable Structural Design: The mechanical structure is compact and stable, and parts in contact with materials often use corrosion-resistant and easy-to-clean stainless steel, facilitating daily maintenance and cleaning.

- Safety Protection Features: Equipped with multiple safety protection devices, such as emergency stop buttons, protective barriers, and leakage protection, to ensure the personal safety of operators and stable equipment operation.

Product Inquiry