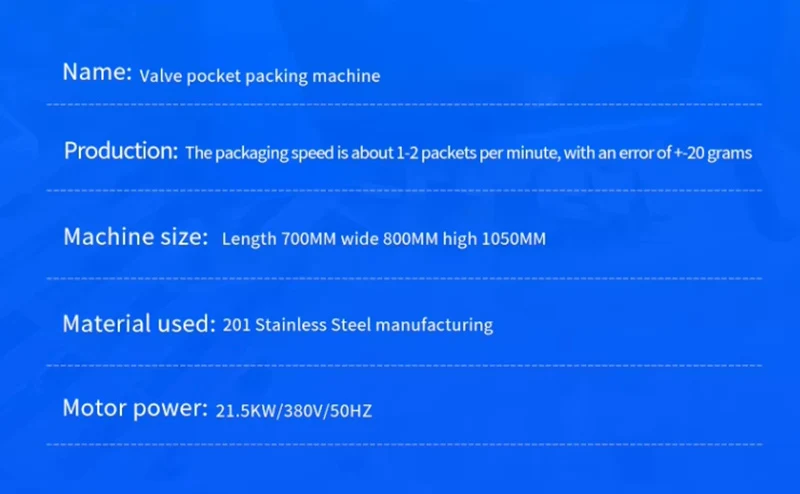

The electric dry mortar packaging machine is specially designed for dry mortar products such as tile adhesives, degreasing coating materials, and valve port sealing fillers. It achieves precise metering, filling, and sealing of materials through an electric drive system. The equipment can adapt to dry mortars with different viscosities and particle sizes (such as tile adhesives, interface agents, sealing fillers, etc.). By adjusting the filling speed and packaging specifications through

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Electric dry mortar packaging machineAdvantages

1. Professional Adaptability: Optimizes filling paths and metering accuracy for the flow characteristics of special dry mortars like tile adhesives and degreasing coatings, avoiding material adhesion or stratification to ensure stable performance of packaged materials.

2. Reliable Sealing: The valve port sealing and filling process uses multi-stage pressure control combined with customized sealing molds to achieve seamless sealing between packaging bags and valve interfaces, suitable for packaging sealing fillers requiring high airtightness.

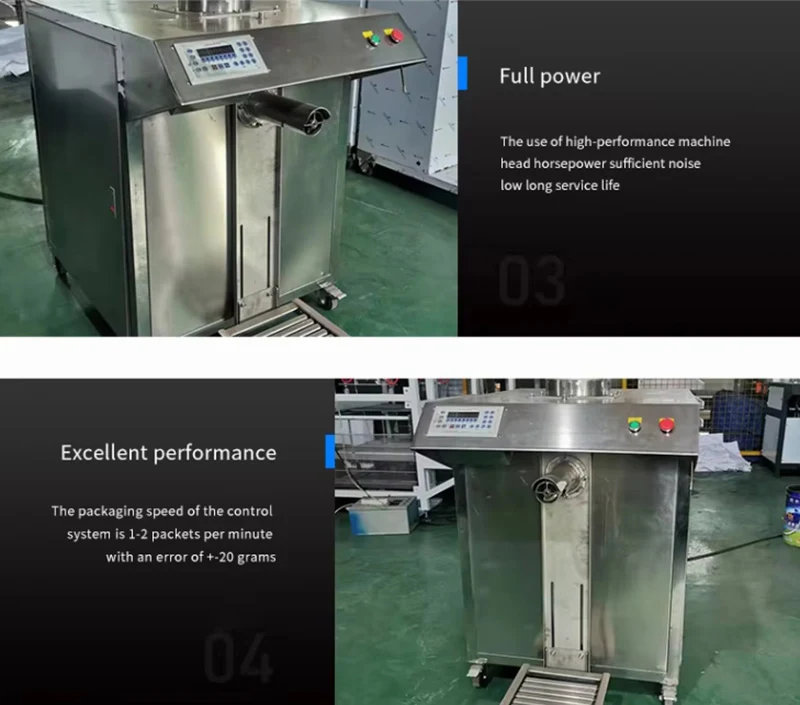

3. High-Efficiency Automation: The electric drive system responds sensitively and supports continuous production, completing 200-500 bags per hour, significantly reducing labor costs and improving the large-scale production efficiency of building materials like tile adhesives.

4. Multi-Functional Switching: By replacing filling heads and adjusting control system parameters, it can quickly switch packaging modes for different products such as tile adhesives, degreasers, and sealing mortars, adapting to multi-category production line needs.

Electric dry mortar packaging machine Applications

1. Tile Building Materials: Used for packaging dry mortars such as tile adhesives and tile back adhesives, meeting the bonding strength and environmental requirements of home decoration and engineering tiling scenarios.

2. Industrial Surface Treatment: Adapts to packaging degreasing coating materials (such as dry mortars for metal pretreatment), ensuring materials remain moisture-free and stable during storage, suitable for machinery manufacturing, automotive parts, and other industries.

3. Pipeline Sealing Projects: Provides customized small-scale packaging for dry mortars used in valve port sealing (such as waterproof堵漏fillers), facilitating precise on-site application and improving sealing construction efficiency.

4. Special Mortar Production: Supports packaging of special products like self-leveling mortars and repair mortars, meeting the strict requirements of high-end building material markets for product weight consistency through precise metering.

Electric dry mortar packaging machineCharacteristics

1. Intelligent Control System: Equipped with a PLC touchscreen to monitor parameters like filling weight and sealing temperature in real time, supporting historical data storage and production report export for quality traceability and capacity management.

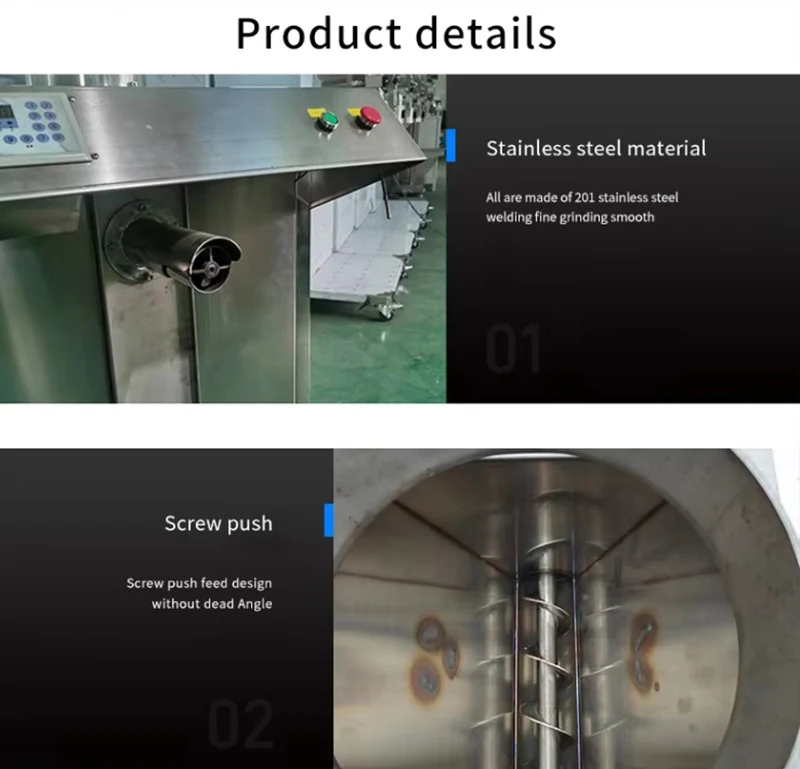

2. Anti-Adhesion Design: Material-contact chambers and conveying pipes use mirror-polished stainless steel, combined with vibration arch-breaking devices, to reduce retention of sticky materials like tile adhesives and minimize cleaning frequency.

3. Dust Suppression Technology: The filling station integrates a negative pressure dust collection system with a sealed discharge port design, reducing ambient dust concentration by over 90% to meet environmental and occupational health standards.

4. Precision Metering Components: Uses a servo motor-driven screw feeder with a metering error ≤±0.5%, especially suitable for packaging valve sealing fillers requiring high dosing accuracy.

5. Flexible Model Change Capability: Modular design enables key components (e.g., filling heads, sealing devices) to be replaced within 30 minutes, quickly switching between different product packaging specifications.

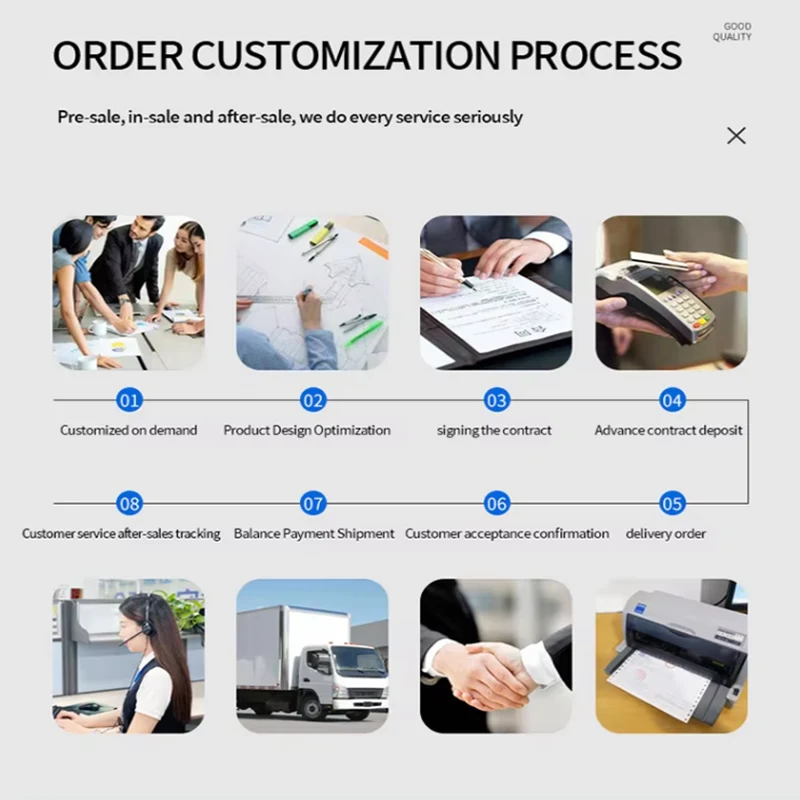

Product Inquiry