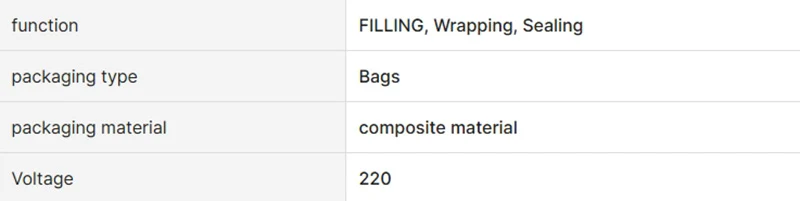

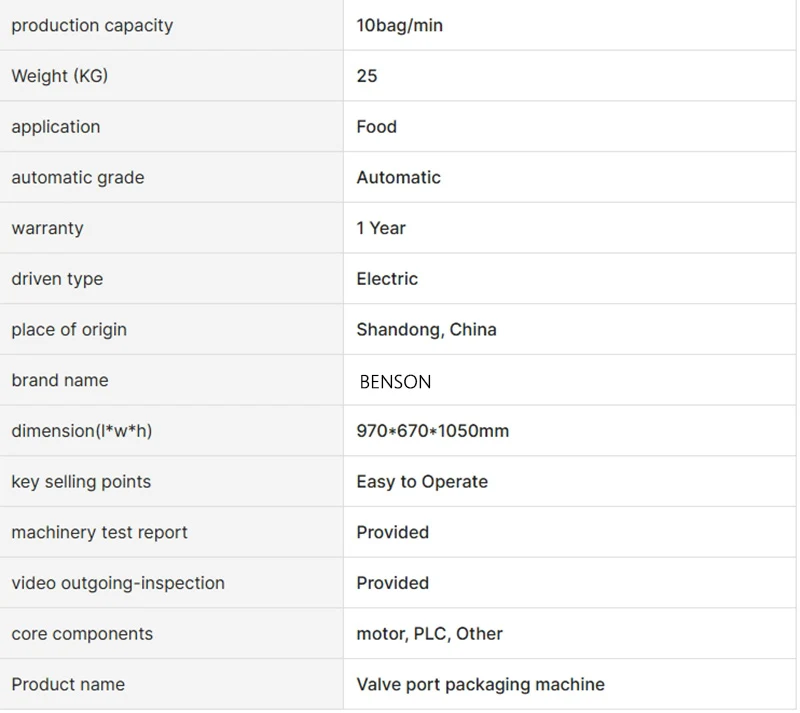

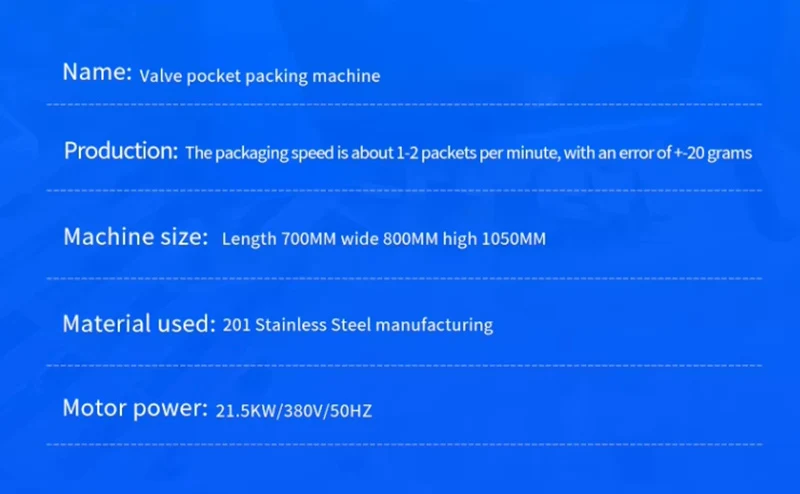

The Electric Dry-Mix Wall Putty and Tile Adhesive Packaging Machine is an automated packaging equipment specially designed for powdery or granular materials such as dry-mix wall putty and tile adhesive. Driven by electricity, it integrates precise functional modules for metering, filling, and sealing. Through an intelligent control system, it enables accurate manipulation of the packaging process, flexibly adjusting parameters according to different packaging specifications and material characte

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Pocket - type Bentonite Bagging and Packaging MachineAdvantages

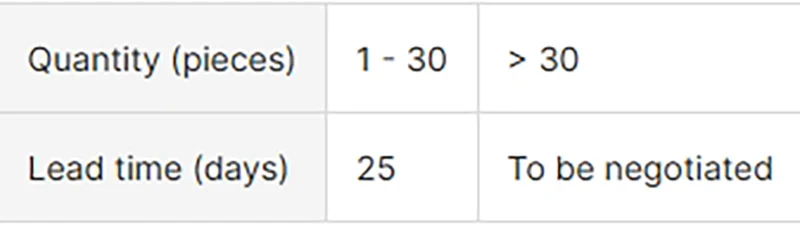

1. High Efficiency and Precision:

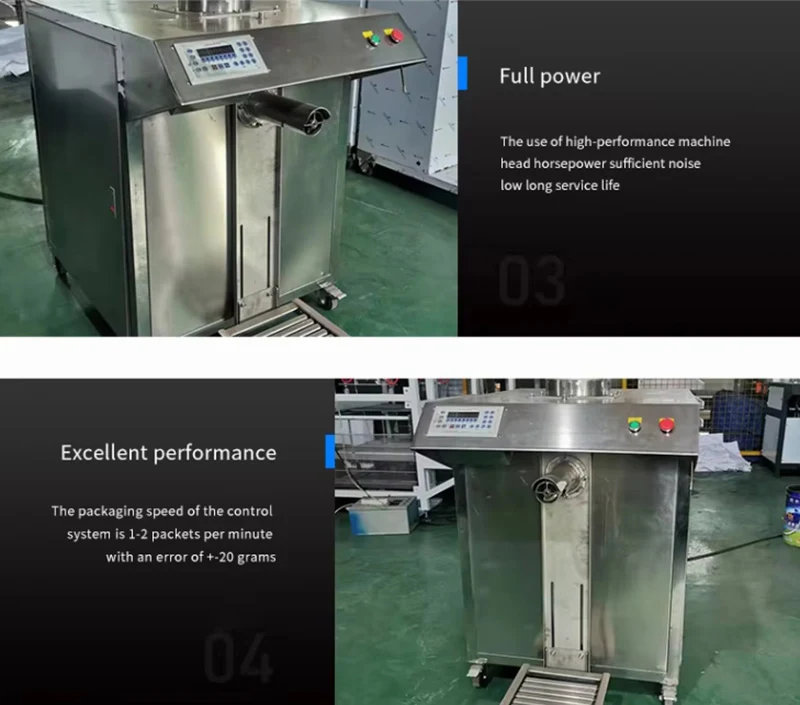

Adopts advanced metering technologies (e.g., screw metering, weighing metering) to quickly and accurately fill materials, with packaging accuracy errors controlled within a minimal range. The packaging speed can reach several to dozens of bags per minute, significantly enhancing production efficiency.

2. Energy-Saving and Environment-Friendly:

Uses electricity as the sole power source, emitting no exhaust gases during operation and consuming low energy compared to traditional fuel or steam-driven equipment. The optimized mechanical structure reduces unnecessary energy loss, aligning with green production concepts.

3. User-Friendly Operation:

Equipped with an intuitive human-machine interface, allowing operators to master usage quickly after simple training. Parameters such as packaging weight, sealing temperature, and packaging speed can be easily set via a touchscreen, with real-time monitoring of equipment status for convenient fault detection and maintenance.

4. Cost Reduction:

The automated packaging process reduces manual intervention, lowering labor costs and intensity. Precise metering and stable packaging quality minimize material waste, effectively controlling production costs. Additionally, the equipment’s high reliability and long service life reduce maintenance and replacement costs.

Pocket - type Bentonite Bagging and Packaging MachineApplications

1. Building Materials Industry:

Widely used for packaging building decoration materials such as dry-mix wall putty and tile adhesive, suitable for both large-scale production by major manufacturers and customized packaging needs of small-to-medium enterprises.

2. Home Improvement Retail Sector:

Can package products into various specifications, such as small packages (1–5 kg) for home renovation retail markets and large packages (20–50 kg) for bulk procurement in engineering projects.

3. Chemical Industry:

Beyond building materials, it is also applicable to other powdery or granular chemical products (e.g., some coating raw materials, dry chemical additives), demonstrating strong cross-industry versatility.

Pocket - type Bentonite Bagging and Packaging MachineFeatures

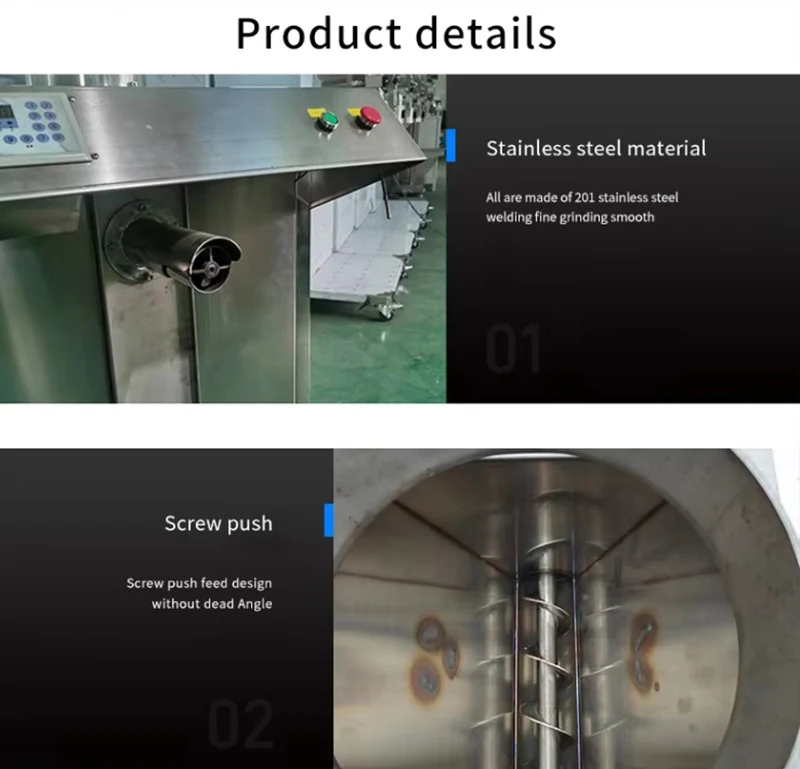

1. Modular Design:

Functional modules (e.g., metering unit, filling unit, sealing unit) adopt a modular design for easy installation, disassembly, and maintenance. Enterprises can flexibly combine or upgrade modules according to production needs, enhancing equipment adaptability and expandability.

2. Dust-Proof Design:

Features a complete dust-proof system (e.g., sealing covers, dust suction devices) to address the dust-prone nature of powdery materials, effectively reducing dust pollution during production and ensuring a clean working environment and operator health.

3. Multiple Sealing Methods:

Supports various sealing methods (e.g., heat sealing, cold sealing), allowing selection of appropriate processes based on packaging materials (e.g., plastic woven bags, paper bags, composite film bags) to ensure packaging tightness and aesthetics, preventing moisture and leakage.

4. Data Management Function:

Capable of recording and storing production data (e.g., number of packages, packaging weight), facilitating production statistics, quality traceability, and management analysis to provide data support for production decisions.

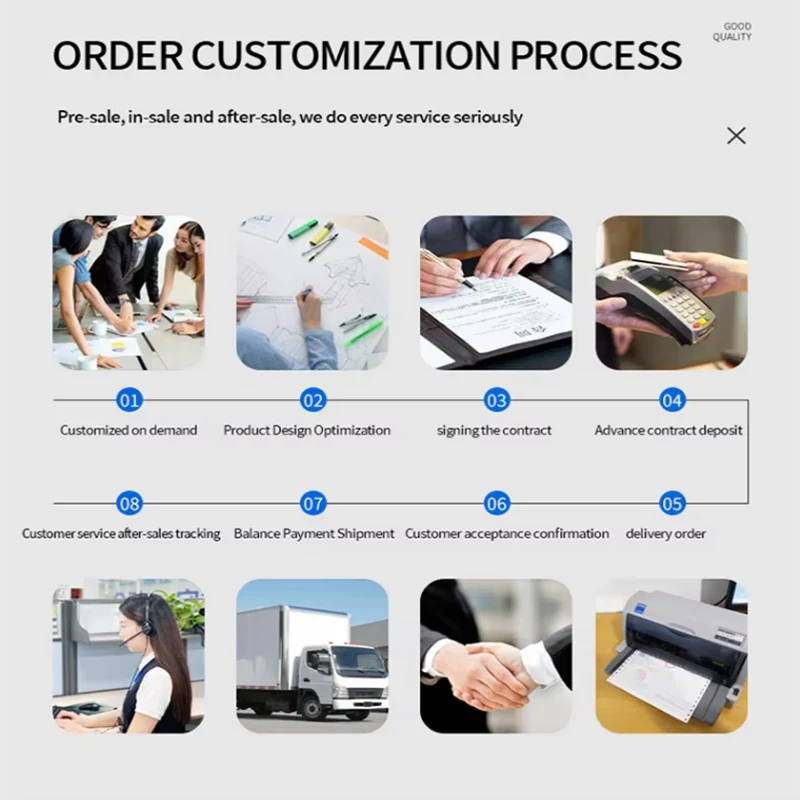

Product Inquiry