The electric automatic screw filling machine is an automated device that uses an electric - driven screw component for material filling. Through precise control by a control system such as PLC (Programmable Logic Controller), the screw component rotates to transport materials from the storage container to the packaging container. Its working process includes accurate metering and stable transportation of materials, and it can efficiently fill powdery - granular, granular, and some pasty material

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

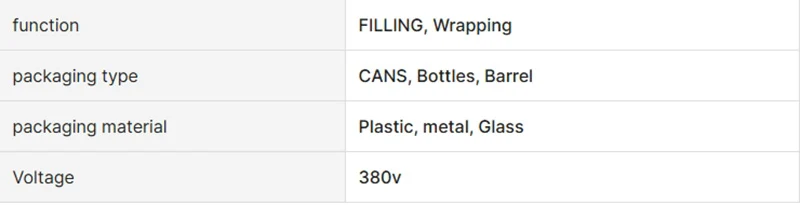

Electric Automatic Screw Filling MachineAdvantages

1. High - precision metering: With the help of an advanced control system and a precise screw structure, it can achieve accurate material metering, effectively control filling errors, reduce material waste, and ensure the uniformity of product quality.

2. High degree of automation: Driven by electricity and controlled by PLC, it can automatically complete the entire process from material transportation to filling, reducing manual intervention, improving production efficiency, saving labor costs, and reducing errors caused by human factors.

3. Stable operation: Using high - quality components and mature manufacturing processes, it has good stability and reliability, strong anti - interference ability, can operate stably for a long time continuously, and reduce the failure rate and maintenance frequency of the equipment.

4. Strong flexibility: It can flexibly adjust filling parameters such as screw rotation speed and filling volume according to different material properties, packaging specifications, and production requirements; it can also adapt to the filling of various materials by replacing screw accessories.

5. Hygienic and environmentally friendly: The parts in contact with materials mostly use materials that meet food hygiene standards or are corrosion - resistant, which is convenient for cleaning and disinfection and prevents material contamination; and a reasonable design helps to reduce dust spillage, etc., meeting environmental protection requirements.

Electric Automatic Screw Filling MachineApplication Areas

1. Food industry: Used for the quantitative filling of foods such as milk powder, coffee powder, seasonings, starch, and candy granules, meeting the hygienic and precise metering requirements of food production.

2. Pharmaceutical industry: Suitable for the filling of pharmaceutical powders, granule drugs, etc., strictly meeting the high - precision and hygienic standard requirements of pharmaceutical production, and ensuring the quality and safety of drugs.

3. Chemical industry: Can fill various chemical raw material powders, granular chemical products, such as pigments, dyes, additives, etc., meeting different process requirements of chemical production.

4. Feed industry: Used for the filling of various powdery and granular feeds, improving the filling efficiency and metering accuracy of feed production, and ensuring the stable quality of feed products.

Electric Automatic Screw Filling MachineFeatures

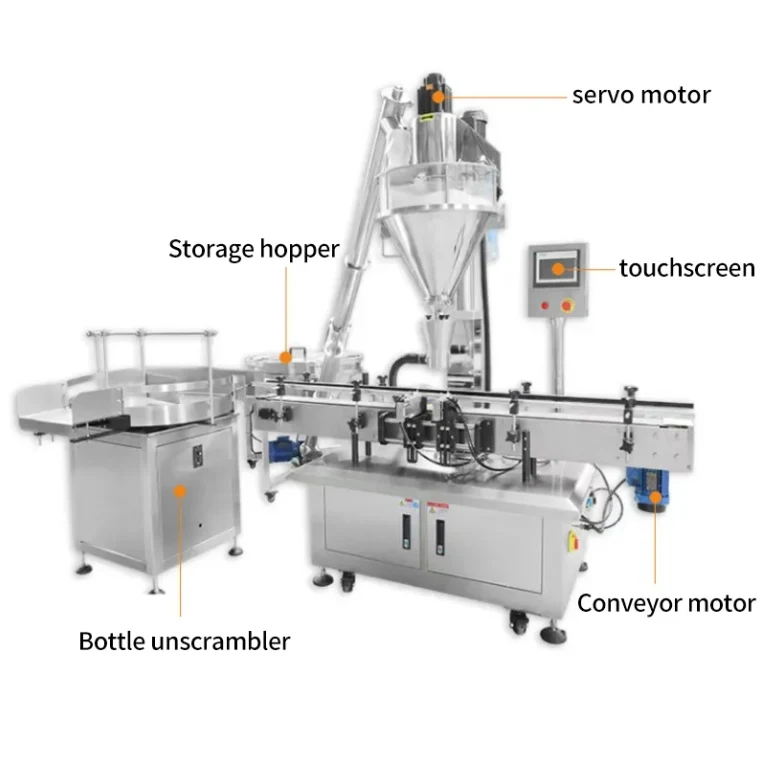

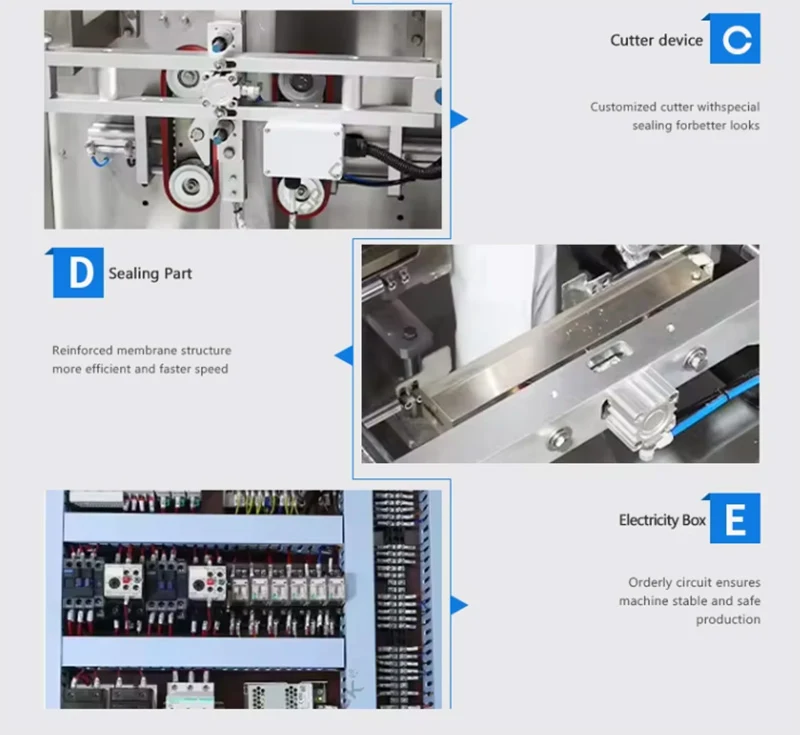

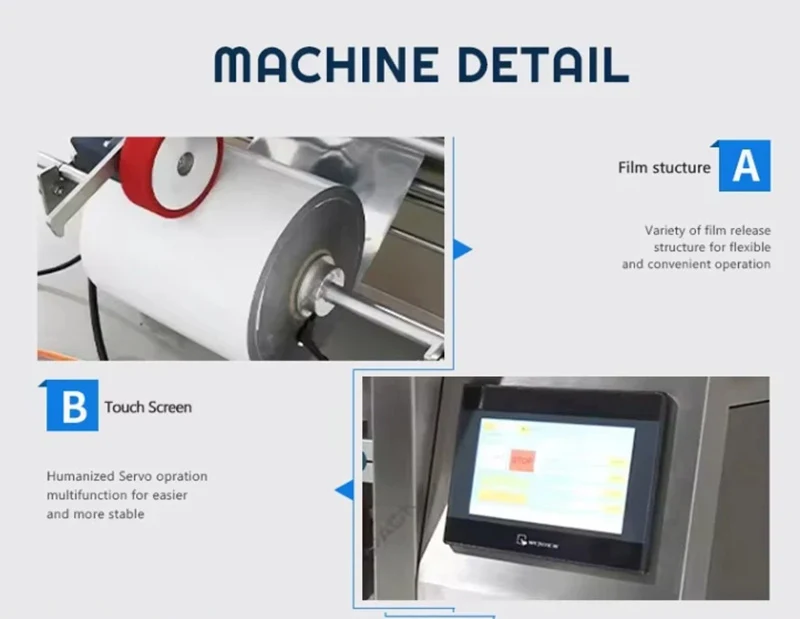

1. Automatic control system: An automated control system with PLC as the core, combined with an operation interface such as a touch screen, realizes functions such as parameter setting, operation monitoring, and fault diagnosis. It is easy and intuitive to operate, facilitating production management by staff.

2. Screw conveying structure: The unique design of the screw conveying component ensures a smooth conveying process, effectively preventing material stratification and damage, and has a wide adaptability to materials, being able to handle materials with different fluidities.

3. Modular design: The equipment adopts a modular structure, and each functional module is relatively independent, facilitating installation, disassembly, maintenance, and upgrading. It can be flexibly combined or replaced according to actual production needs to expand the functions of the equipment.

4. Safety protection: Equipped with complete safety protection devices, such as emergency stop buttons, safety light curtains, overload protection, etc., to prevent operators from accidentally contacting moving parts and ensure personnel safety and the normal operation of the equipment.

5. Integratability: It has good openness and compatibility, and can be seamlessly connected with other equipment in the production line (such as bottle unscramblers, capping machines, labeling machines, etc.) to build a complete automated production line, improving the degree of production automation and overall production efficiency.

Products Description

Product Inquiry