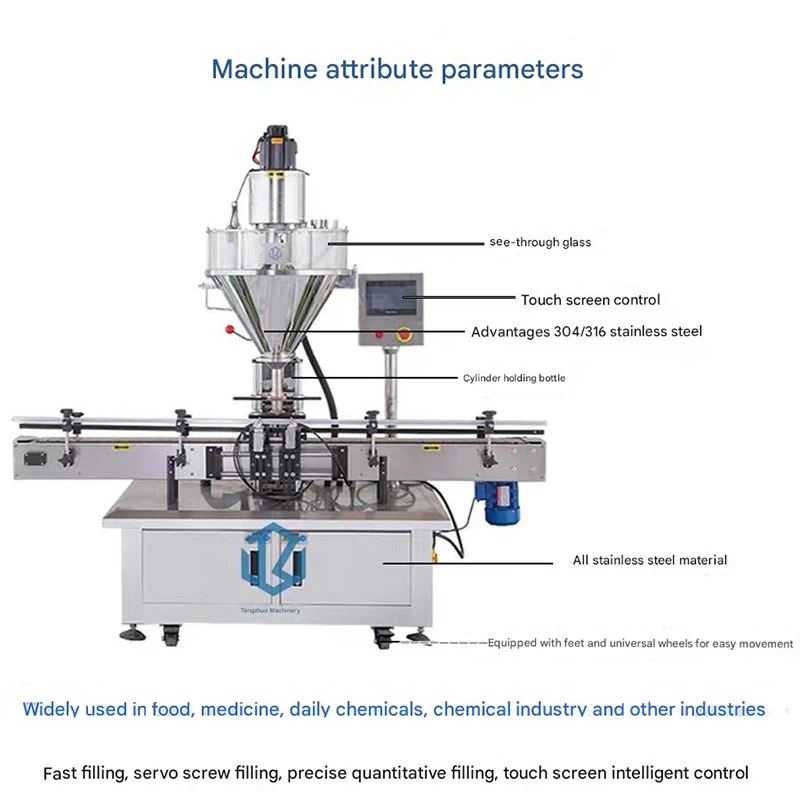

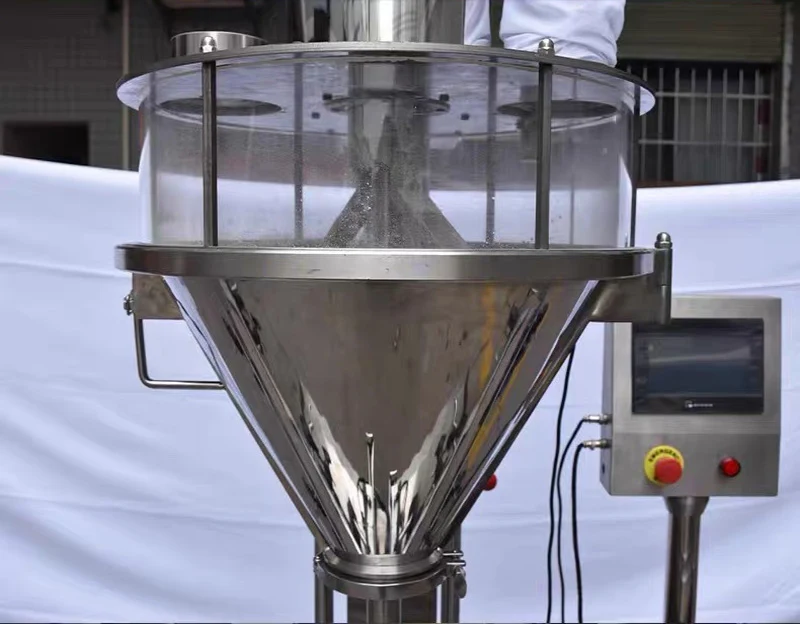

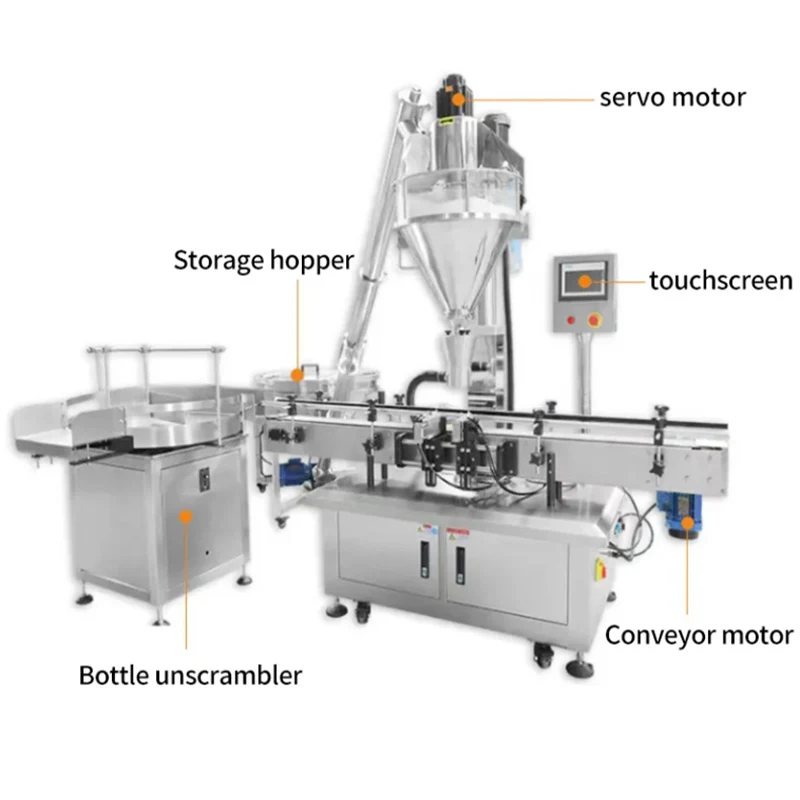

The vertical powder packaging machine is an automated packaging equipment designed for powdery materials, featuring a vertical structural layout. Its workflow typically involves: materials entering from the top hopper, being quantitatively filled into packaging containers (such as plastic bags or paper bags) via screw conveying or pneumatic conveying, and then completing processes like sealing and batch number printing. The equipment integrates functions such as weighing and metering, automatic

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

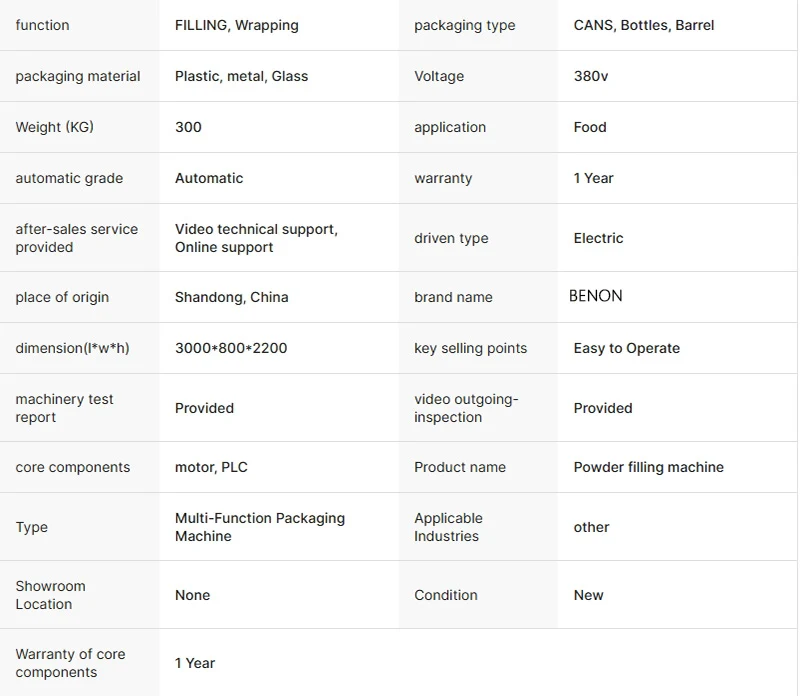

Vertical powder packaging machineApplications

1. Food industry: Packaging of powdery foods such as milk powder, coffee powder, seasonings (e.g., pepper, chili powder), starch, and flour.

2. Chemical industry: Quantitative packaging of chemical raw materials such as coating powders, pesticide powders, fertilizers, plastic additives, and dyes.

3. Pharmaceutical industry: Small-dose or large-scale packaging of medicinal powders, health powders, and traditional Chinese medicine powders, complying with hygiene standards.

4. Building materials industry: Bulk packaging of construction materials such as cement, putty powder, gypsum powder, and ceramic powders.

5. Other fields: Packaging of special materials such as battery powders, metal powders, and cosmetic powders (e.g., talcum powder).

Vertical powder packaging machineAdvantages

1. High-efficiency automation: Full-process automatic operation (feeding, metering, filling, sealing, discharging) reduces manual intervention and improves production efficiency.

2. High-precision metering: Equipped with electronic weighing systems or volumetric metering devices, with errors controlled within ±1%, suitable for high-value materials.

3. Strong flexibility: Adjusting parameters (e.g., packaging weight, bag length, sealing type) adapts to different packaging specifications, with convenient material typ

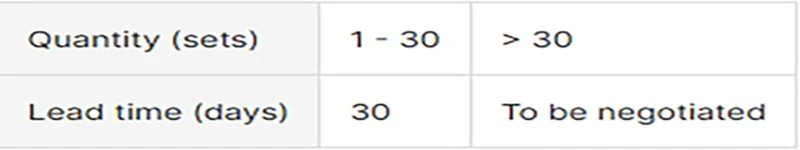

Vertical powder packaging machineFeatures

1. Compact vertical structure: Small footprint, suitable for small and medium production lines or workshop layouts, with easy installation and debugging.

2. Multi-functional modules: Supports various packaging types (three-side seal, back seal, four-side seal, etc.) and can be equipped with accessories such as date printers and inflating devices (e.g., nitrogen filling for freshness).

3. Intelligent control system: Parameter setting and operation monitoring via PLC or touchscreen, with functions like fault self-diagnosis and production statistics for intuitive operation.

4. Wide material adaptability: Configurable with different feeding methods (screw, stirring, vacuum suction) for free-flowing powders (e.g., milk powder) and caking-prone powders (e.g., flour).

5. Low-maintenance design: Key components (e.g., sealing molds, conveying screws) are wear-resistant, with long maintenance cycles to reduce downtime losses.

Packaging and delivery

Products Description

Product Inquiry