The food packaging palletizer is an intelligent "porter" on the food production line. With automation technology at its core, relying on the PLC control system and touch - screen operation interface, it realizes accurate and stable palletizing operations. Thanks to its flexible gripper design, whether it is cartons, paper boxes, or various packaging bags, cans, and bottles, they can all be quickly grasped, transported,and neatly stacked. During the operation, devices such as safetylight curtains

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Products Description

The food packaging palletizer is an intelligent "porter" on the food production line. With automation technology at its core, relying on the PLC control system and touch - screen operation interface, it realizes accurate and stable palletizing operations. Thanks to its flexible gripper design, whether it is cartons, paper boxes, or various packaging bags, cans, and bottles, they can all be quickly grasped, transported, and neatly stacked. During the operation, devices such as safety light curtains and emergency stop buttons provide full - protection to ensure the safety of both humans and machines. In scenarios such as food processing and warehousing logistics, it can not only significantly improve the palletizing efficiency and save labor costs, but also, with its high - efficiency and energy - saving characteristics, help enterprises reduce costs and increase efficiency, becoming an indispensable key equipment in the food packaging process.

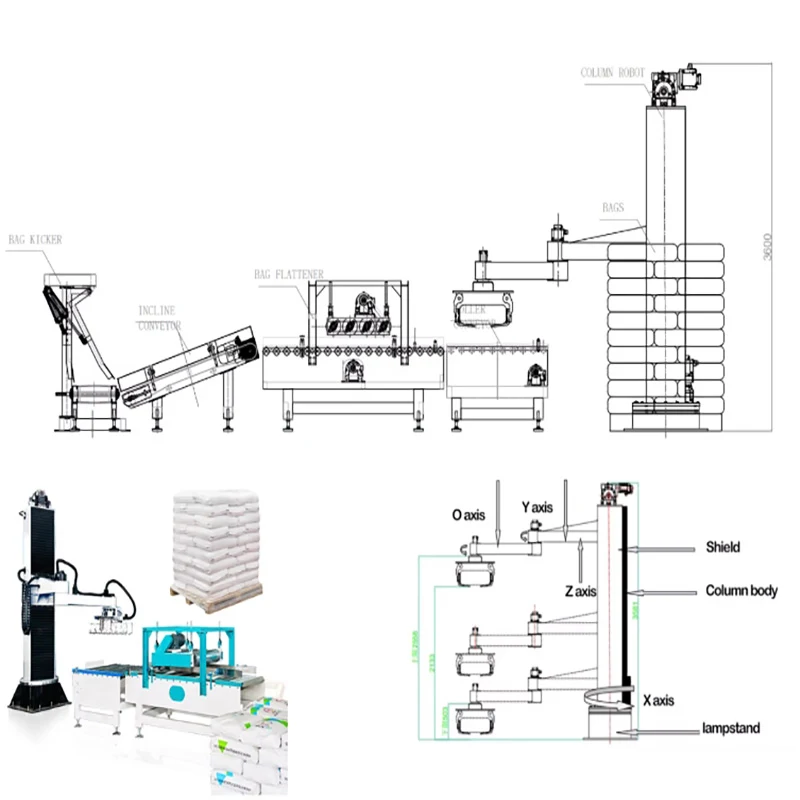

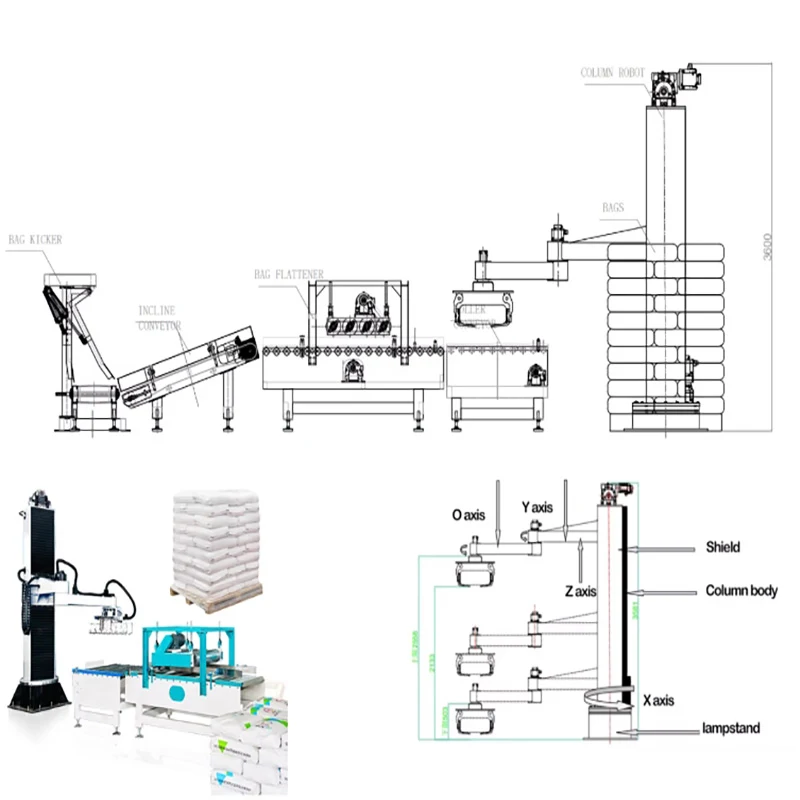

The working process of the food packaging and palletizing machine:

1.Material Conveying:The packaged food products are conveyed to the designated position of the palletizer through the conveying equipment on the production line (such as belt conveyors, chain plate conveyors, etc.). The speed and rhythm of the conveying equipment are usually matched with those of the palletizer to ensure that the products can be continuously and stably supplied to the palletizing area.

2.Product Detection and Positioning: Before the products enter the palletizing area, sensors installed on the conveyor line (such as photoelectric sensors, vision sensors, etc.) will detect and identify information such as the position, attitude, and quantity of the products. For some irregular or inaccurately positioned products, special positioning devices may also be used for adjustment to ensure the accuracy of palletizing.

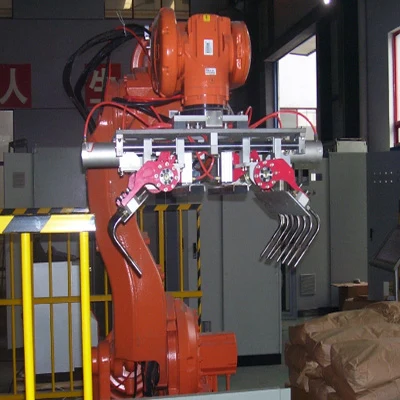

3.Gripper Grasping:food packaging and palletizing machines The gripper of the palletizer is designed according to the type and packaging form of the products. Common gripper types include vacuum suction cup type, clamping type, splint type, etc. When the products are accurately detected and positioned, the gripper will descend to the appropriate position and perform the grasping action according to the preset program and parameters to firmly grasp the products.

4.Handling and Lifting: After the gripper grasps the products, the robotic arm of the palletizer will lift and transport the products to the designated position above the pallet according to the predetermined trajectory and actions. During the handling process, the robotic arm needs to ensure the stability of the products and avoid shaking and dropping.

5.Stacking: When the products are transported to the target position above the pallet, the gripper will release and accurately place the products on the pallet. According to the pre-set palletizing patterns (such as row type, staggered type, etc.), the palletizer will stack the products layer by layer on the pallet in sequence to form a neat stack shape.

6.Pallet Replacement: When the products on one pallet are stacked, the pallet conveying device of the palletizer will move the full pallet out of the palletizing area and simultaneously send in an empty pallet for the next round of palletizing operations.7.Stack Shape Arrangement (Optional):In some cases, in order to make the stacked stack shape more stable, the palletizer may be equipped with special arrangement devices, such as push plates, flatteners, etc., to arrange and compact the stacked products.

8.Palletizing Completion and Output: When all the products are stacked on the pallet according to the predetermined requirements, the palletizing operation is completed. The full pallets will be conveyed to subsequent processes, such as stretch wrapping, warehousing and storage, etc.

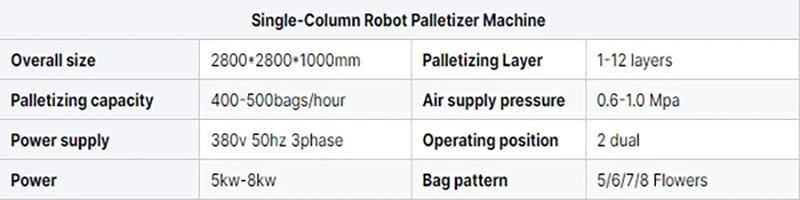

Specification

The food packaging palletizer has the following main features:

1.High degree of automation: It can automatically complete a series of palletizing operation processes such as material transportation, product detection and positioning, grasping, handling, stacking, and pallet replacement. It requires little human intervention, which can significantly improve the palletizing efficiency and save labor costs.

2. Precise positioning: With the help of advanced sensor technology and control systems, such as photoelectric sensors, vision sensors, and PLC control systems, it can accurately detect information such as the position, posture, and quantity of products, ensuring that products are accurately grasped and stacked. The palletizing accuracy is high, and the stack shape is neat.

3. Strong adaptability:food packaging and palletizing machines The gripper is designed with a variety of flexible types, such as vacuum suction cup type, clamping type, and splint type. It can adapt to different types and shapes of food packaging, such as cartons, paper boxes, packaging bags, cans, and bottles, with a wide range of applications.

4. Stable and reliable operation: It adopts high - quality mechanical structures and components, and after careful design and manufacturing, it has high stability and reliability. It can operate continuously for a long time, reducing equipment failures and downtime, and ensuring the smooth progress of production.

5. High safety: It is equipped with safety devices such as safety light curtains and emergency stop buttons. During operation, it can monitor the surrounding environment in real - time. When a person or object enters the dangerous area, it will stop running immediately, effectively protecting the safety of operators and equipment.

6. High - efficiency and energy - saving: Through optimized design and advanced control technology, while ensuring the palletizing efficiency, it reduces energy consumption, meets the requirements of enterprises for energy conservation and emission reduction, and helps to achieve cost reduction and efficiency improvement.

7. Easy to operate: It is usually equipped with a touch - screen operation interface. Operators can perform operations such as parameter setting, program selection, and equipment monitoring through an intuitive graphical interface, and can get started without complex training.

8. Good scalability:food packaging and palletizing machines It has good openness and compatibility, and can be seamlessly connected to other production equipment and systems, such as integrated with automated packaging lines, warehousing and logistics systems, etc., to form a complete automated production solution to meet the different production needs of enterprises.

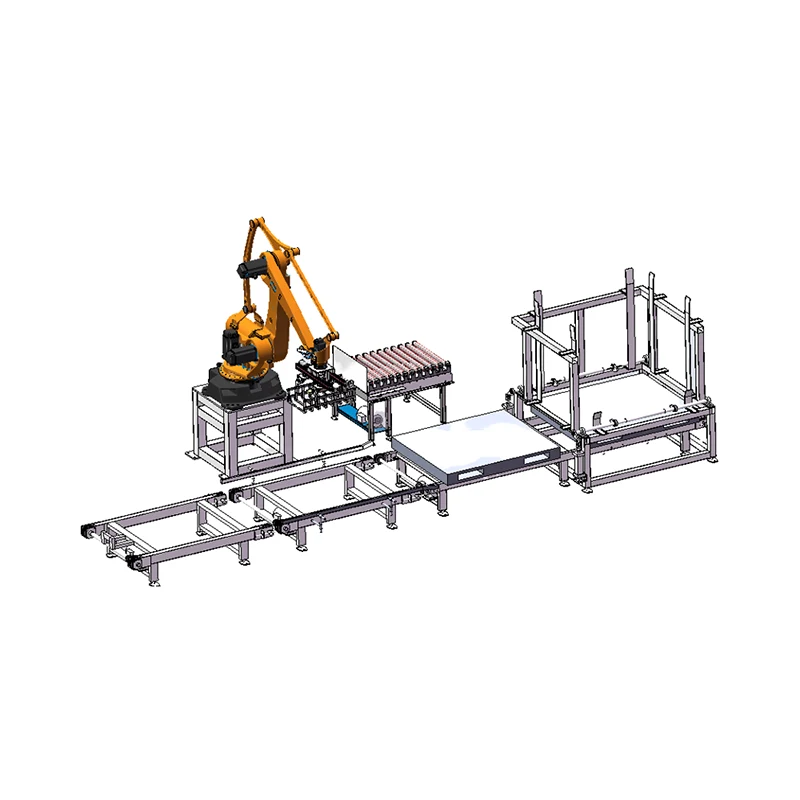

The palletizer features an interchangeable gripper—clamp, suction, or fork—suitable for various materials and shapes. This ensuressecure, damage-free handling and precise placement, enhancing flexibility and efficiency across different product lines and packaging types.

The control cabinet contains all electrical and control components, including PLCs, motor drives, and safety relays. It ensures reliable, safe operation with easy access for maintenance and built-in protection against electrical faults.

The palletizer includes an intuitive teach pendant for easy programming and control. Operators can quickly set pallet patterns, adjust positions, and monitor status, enabling efficient operation and fast changeovers without technical complexit

Handles material transfer and placement with precision; easily integrates into existing packaging systems for streamlined

operations.

Advantages of food packaging and palletizing machines:

1.Efficient Production: Compared with manual palletizing, the food packaging palletizing machine can operate continuously for 24 hours. Its maximum palletizing speed can reach 120 - 150 pieces per minute, significantly improving production efficiency, quickly completing large - scale product palletizing tasks, and effectively meeting the fluctuating production capacity demands of the food industry during peak and off - peak seasons. 2.Precision and Stability: Relying on advanced sensors and precise algorithms, the palletizing accuracy error can be controlled within ±2mm, ensuring a neat and stable stack shape, reducing product losses during transportation and storage, and guaranteeing product quality and safety. 3.Flexible Adaptability: According to the size, weight, and shape of food packaging (such as boxed biscuits, bagged snacks, bottled beverages, etc.), it can quickly switch different palletizing modes and gripper tools, easily meeting the palletizing requirements of multi - category and multi - specification products without large - scale equipment modification. 4.Significant Cost Reduction:food packaging and palletizing machinesOne palletizing machine can replace 4 - 6 workers, effectively reducing long - term labor costs, management costs, and training costs caused by personnel turnover. At the same time, it reduces the risk of work - related injuries and related compensation expenses. 5.Improvement of Safety and Hygiene Standards: Fully automated operation reduces the direct contact between personnel and food packaging, reducing the risk of contamination and meeting the strict hygiene standards of the food industry. Equipped with safety protection devices, it can effectively avoid mechanical injuries and ensure personnel safety. 6.Data - driven and Intelligent Management: Integrated with an intelligent control system, it can monitor real - time data such as equipment operation status, palletizing quantity, and fault early warning, and connect with the factory management system, facilitating production scheduling, quality traceability, and data analysis, and promoting the digital transformation of enterprises. 7.Energy - saving and Environmental - friendly:food packaging and palletizing machinesUsing servo - motor drive and optimized control technology, energy consumption is reduced by more than 30% compared with traditional machinery. The compact design of the equipment saves workshop space and reduces site - use costs, conforming to the concept of green production.

Company Profile

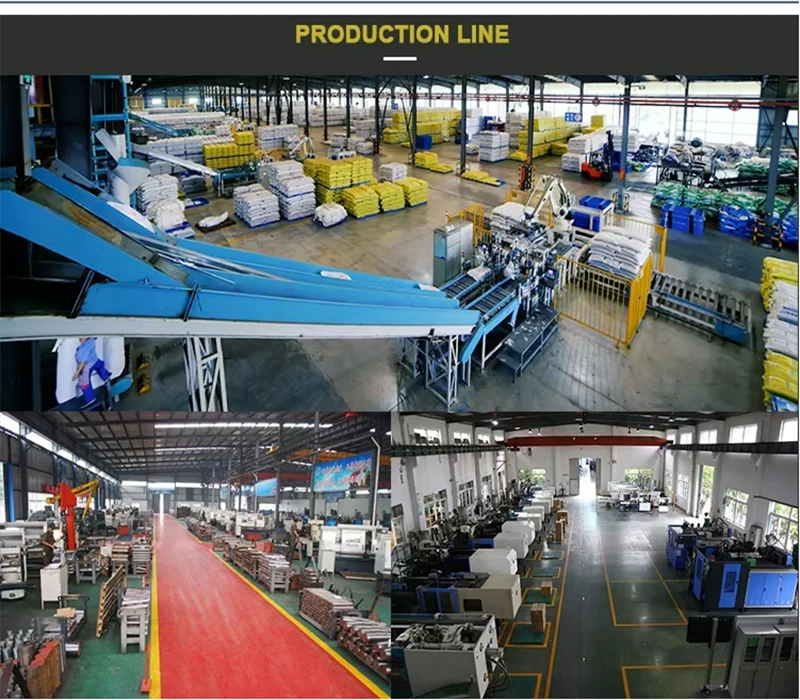

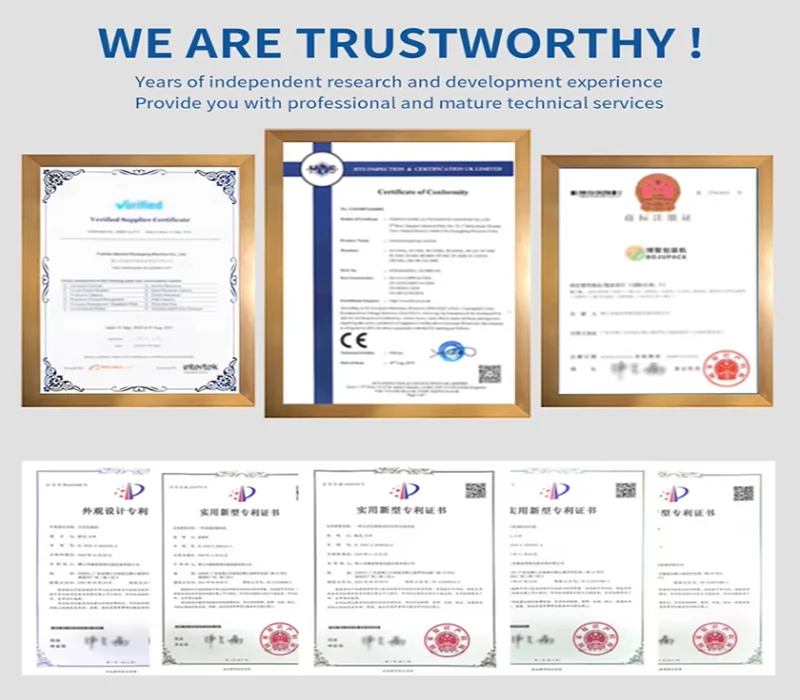

Benson Intelligent Equipment (Shandong) Co., Ltd.was founded in 2013, including self-researching and development, design, production and sales.

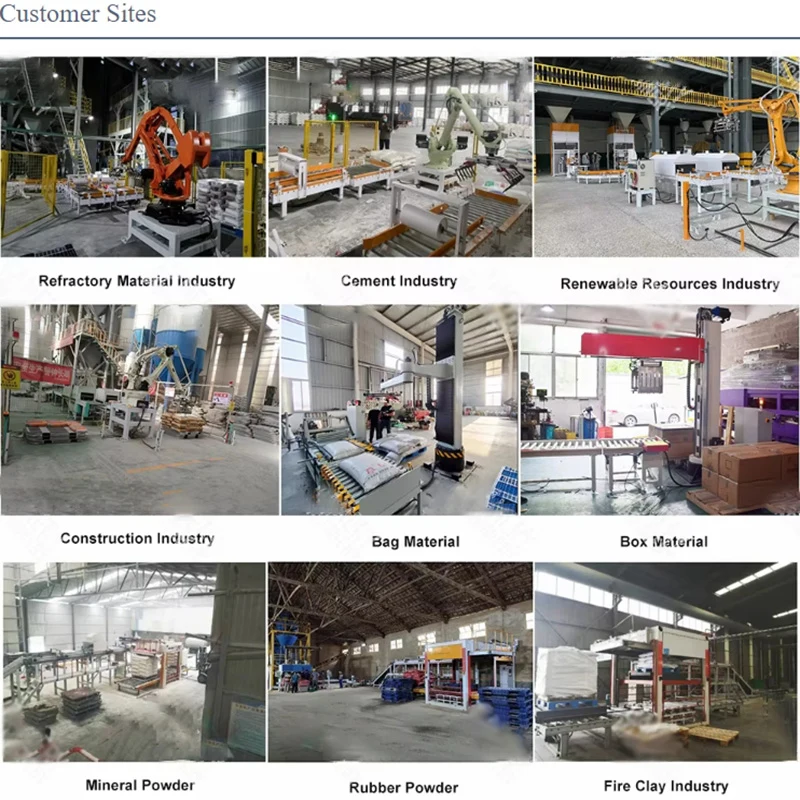

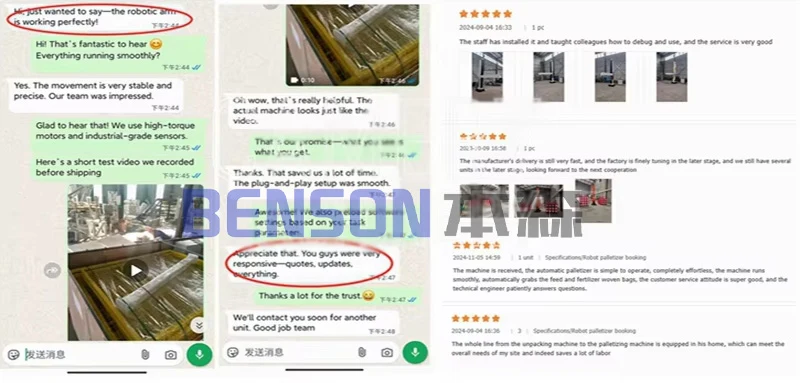

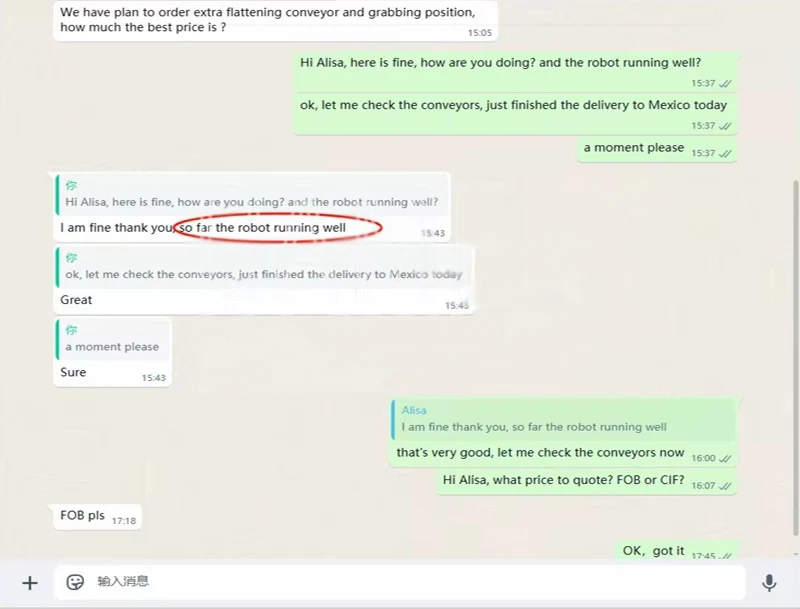

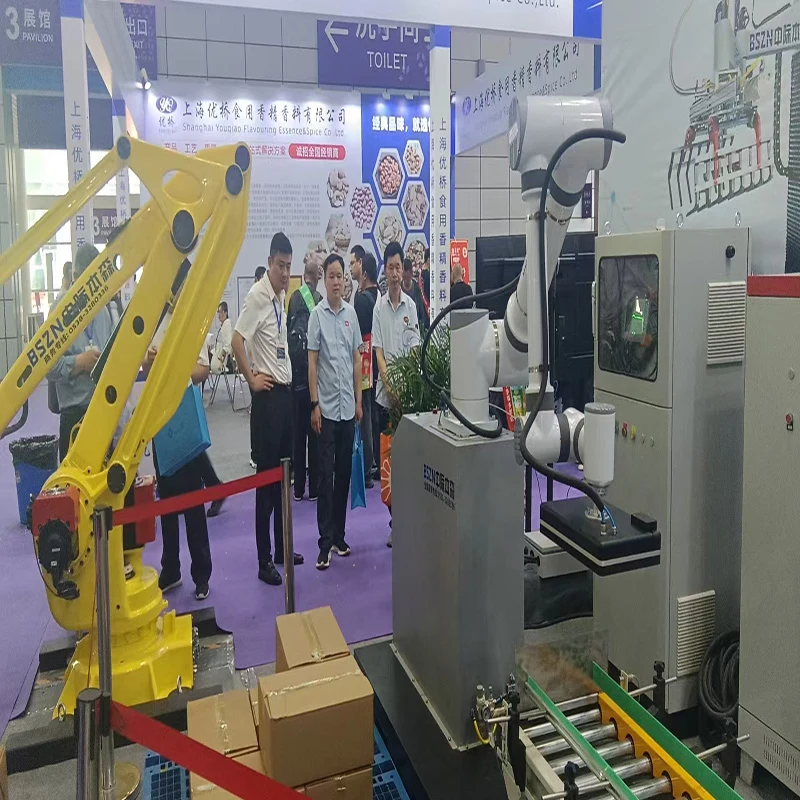

Benson machinery is committed to the design, production and sales of automatic packaging machine, intelligent palletizing machine, wrapping machine etc. Our products are widely used in food, chemical industry, building materials, feed, warehousing and other industries.Benson has 10 senior technical engineers, more than 20 production workers and 10 senior sales,exporting countries including United States,Mexico, Australia, Russia. Saudi Arabia, Singapore, South Africa etc., all over the world, provided professional solution with efficient and intelligent products to each customer, got the high recognization and compliment from every serviced domestic and foreign client.

Benson advocates innovation, professional, efficient, pragmatic business philosophy, to achieve mutual benefit and win-win, continue to provide our customers with high-end products and quality service.

Exhibition

Product Inquiry