The automatic sand powder packaging and cement filling machine is an integrated industrial equipment designed for efficient packaging and filling of powdery materials like sand powder and cement. It combines automatic feeding, metering, filling, and sealing functions, suitable for various particle sizes and flow properties of powders. The system typically includes a screw conveyor or belt feeder for material transport, a high-precision weighing module or volumetric device for accurate dosing,

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

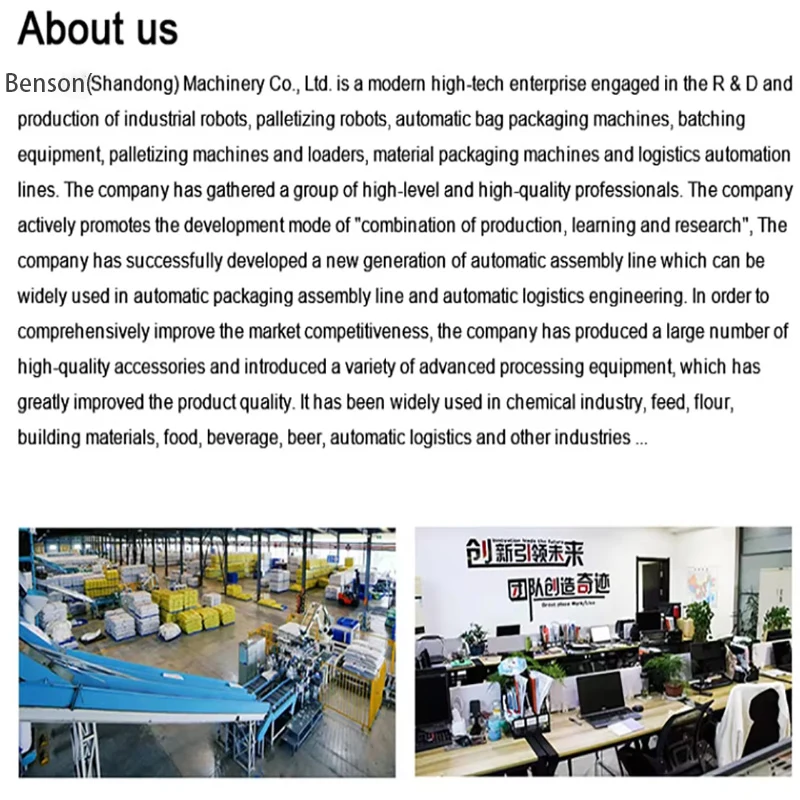

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

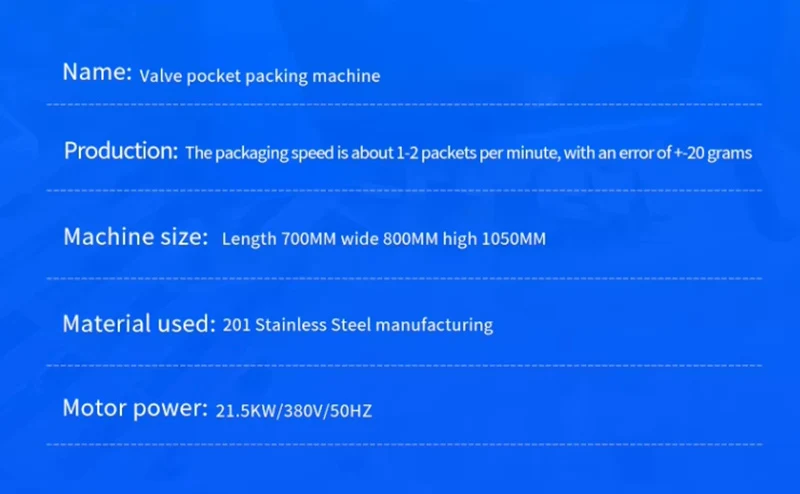

Automatic sand powder packaging and cement filling machineAdvantages

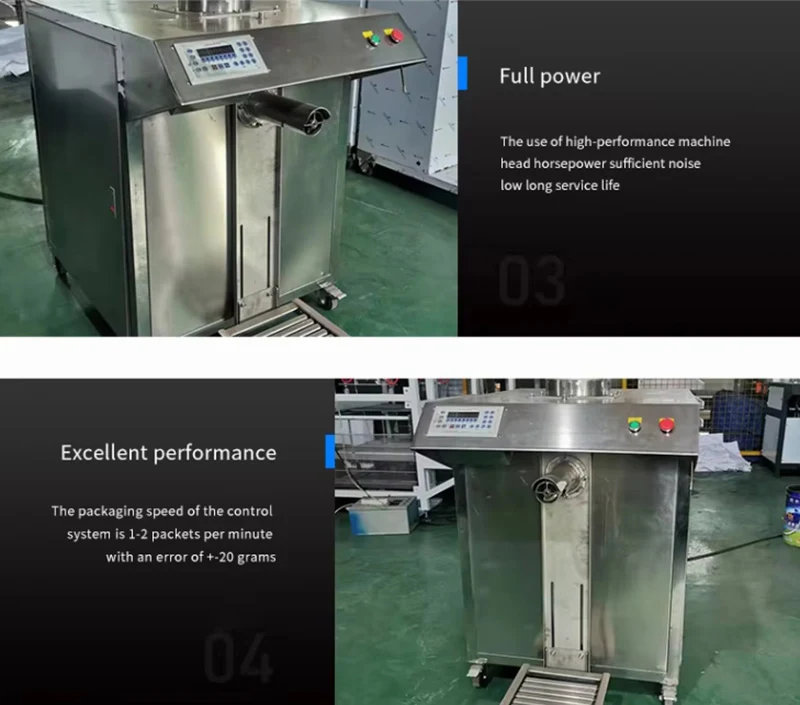

1. High Automation & Efficiency

- Reduces manual intervention and completes hundreds of bags/hour (depending on model), significantly improving output compared to traditional manual operations.

- Continuous operation mode minimizes downtime and optimizes production flow.

2. Precision & Consistency

- Achieves filling accuracy within ±0.5%–1% of the target weight, ensuring uniform product quality and reducing material waste.

- Stable sealing and bag forming ensure no leakage, ideal for moisture-sensitive materials like cement.

3. Multi-Functionality

- Adapts to sand powder, cement, lime, mineral powders, and other granular/powdery materials.

- Supports various packaging sizes (e.g., 25kg, 50kg bags) and container types (bags, drums, bulk bins).

4. Dust Control & Safety

- Sealed design with dust suction ports or filters reduces airborne powder, improving workshop hygiene and operator safety.

- Emergency stop mechanisms and protective enclosures comply with industrial safety standards.

5. Cost Savings

- Lowers labor costs through automation and reduces energy consumption via efficient mechanical design.

- Minimizes product loss from precise metering and leak-proof packaging.

Automatic sand powder packaging and cement filling machine Applications

1. Construction Industry

- Filling and packaging of cement, mortar powders, concrete additives, and building sands for easy transport and storage.

- Used by cement plants, precast concrete factories, and building material suppliers.

2. Mining & Minerals

- Packaging of mineral powders (e.g., iron ore powder, talcum powder) and industrial sands for mining and processing enterprises.

3. Agriculture & Chemicals

- Suitable for fertilizers, pesticides, and other powdery agricultural inputs, as well as chemical powders requiring precise dosing.

4. Environmental & Recycling

- Handling of recycled powders (e.g., fly ash, slag) in waste management and green building material production.

Automatic sand powder packaging and cement filling machineFeatures

1. Intelligent Control System

- PLC or touchscreen interface for easy parameter setting (filling weight, speed, bag count) and real-time production data tracking.

- Self-diagnostic functions detect faults (e.g., material blockages, weighing errors) and alert operators.

2. Modular Design

- Easy-to-replace components (e.g., filling nozzles, conveyor belts) allow quick switching between materials or packaging specifications.

- Customizable upgrades (e.g., automatic palletizing, barcode labeling) for integrated production lines.

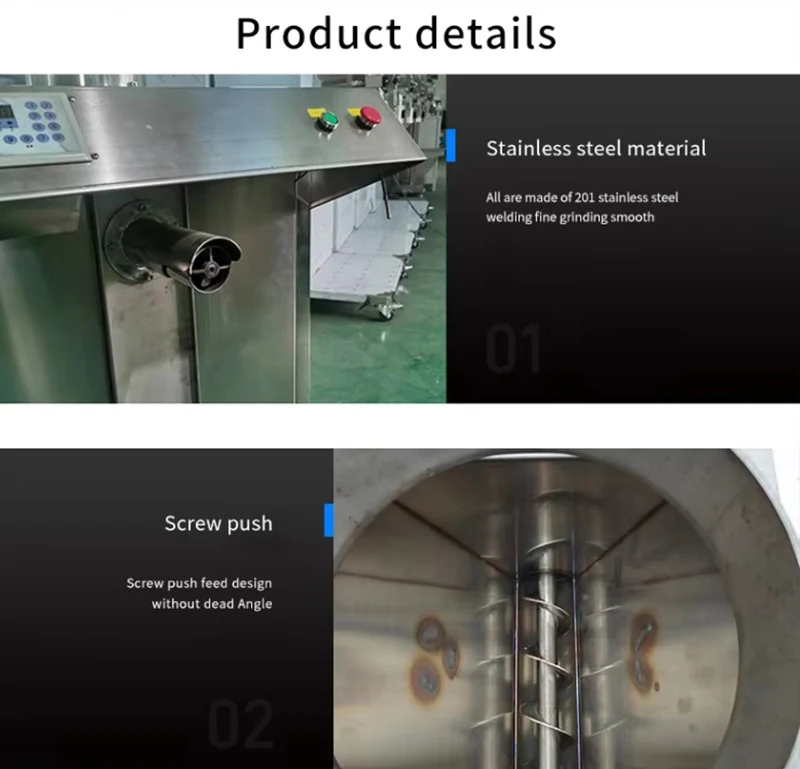

3. High-Quality Materials

- Contact parts made of stainless steel or anti-corrosive materials to withstand abrasive powders (e.g., sand) and chemical corrosion.

- Heavy-duty frame ensures stability during high-speed operation.

4. Low Maintenance

- Simplified mechanical structure and lubrication-free components reduce maintenance frequency.

- Quick-release design for easy cleaning, minimizing cross-contamination between batches.

5. Energy Efficiency

- Variable frequency drives (VFDs) optimize motor speed, reducing power consumption by up to 20% compared to traditional systems.

- Low-noise operation suitable for urban or indoor production environments.

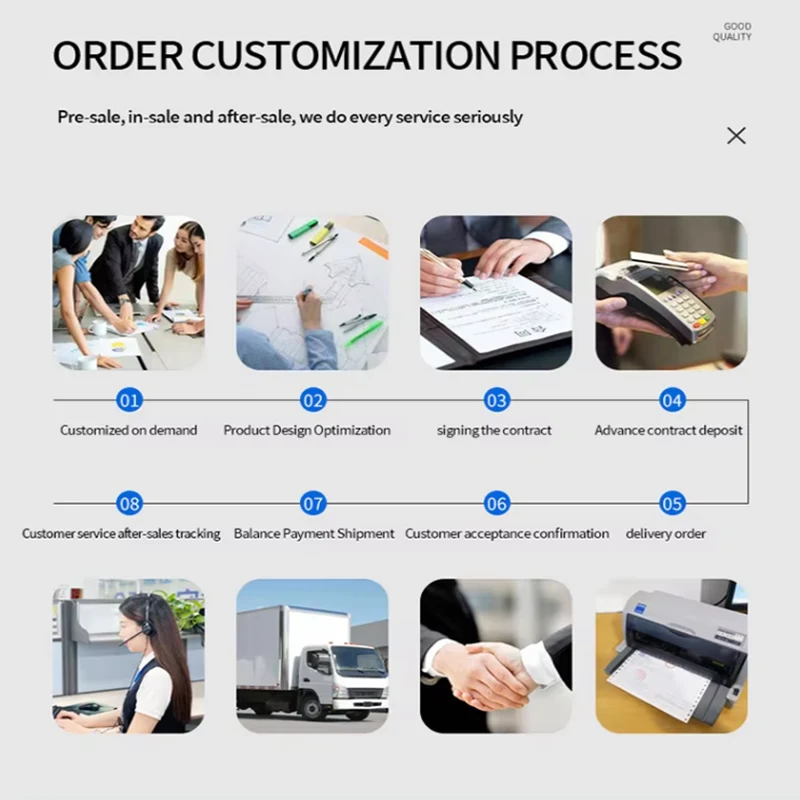

Product Inquiry