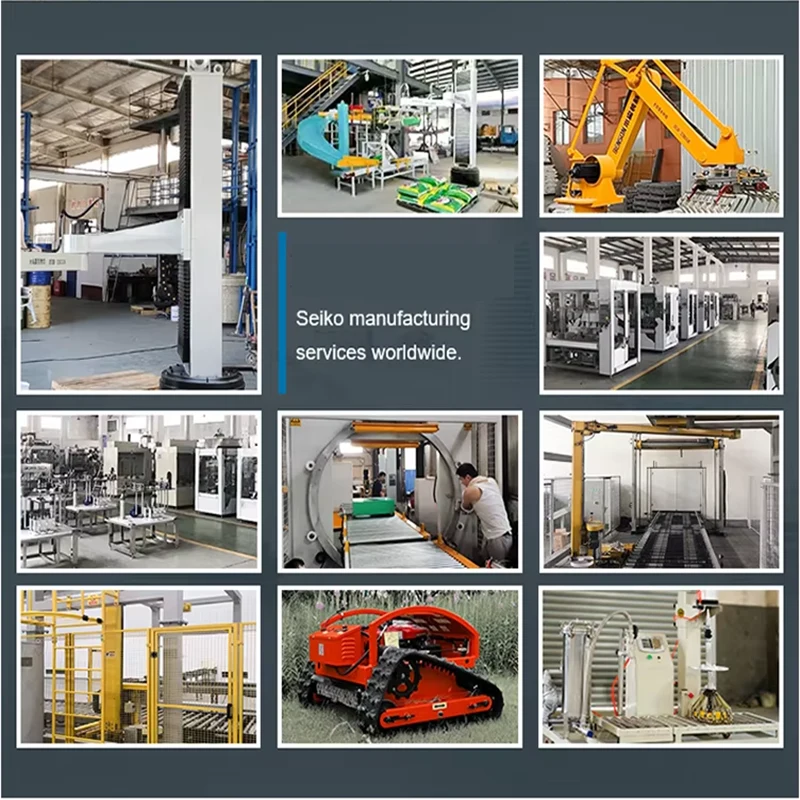

-The structure of the joint robot for beverage box packaging production line: usually composed of a base, multiple rotating joints, a mechanical arm and an end effector (gripper). The base provides stable support; the rotating joints cooperate with each other to give the robot multiple degrees of freedom; the mechanical arm connects the joints to achieve a wide range of extension; the end effector is designed according to the characteristics of the beverage box, such as suction cup type。

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Free replacement parts

Free replacement partsYou can claim platform compensation (2% of the product amount, up to US $500) for failed service.

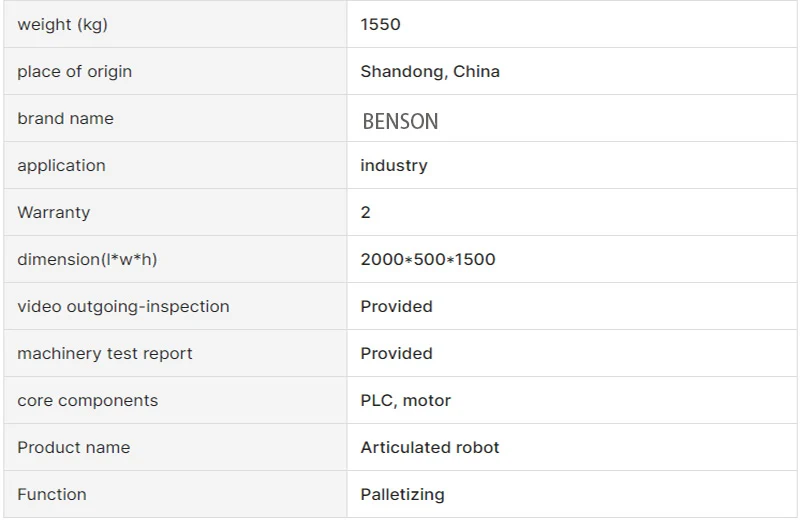

Structure and principle of multi-joint robot

- Structural composition: usually composed of a base, multiple rotating joints, a robotic arm and an end effector (gripper). The base provides stable support; the rotating joints cooperate with each other to give the robot multiple degrees of freedom; the robotic arm connects the joints to achieve a wide range of extension; the end effector is designed according to the characteristics of the beverage box, such as suction cup type and gripper type, which are used to grab the box.

- Working principle: Based on the servo motor drive, the rotation angle and speed of each joint are accurately controlled by the control system. The encoder is used to feedback the joint position information, combined with the preset program or teaching programming, to achieve accurate grabbing, handling and stacking of beverage boxes.

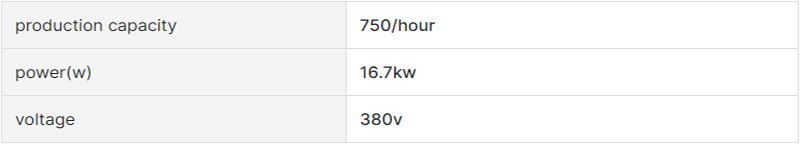

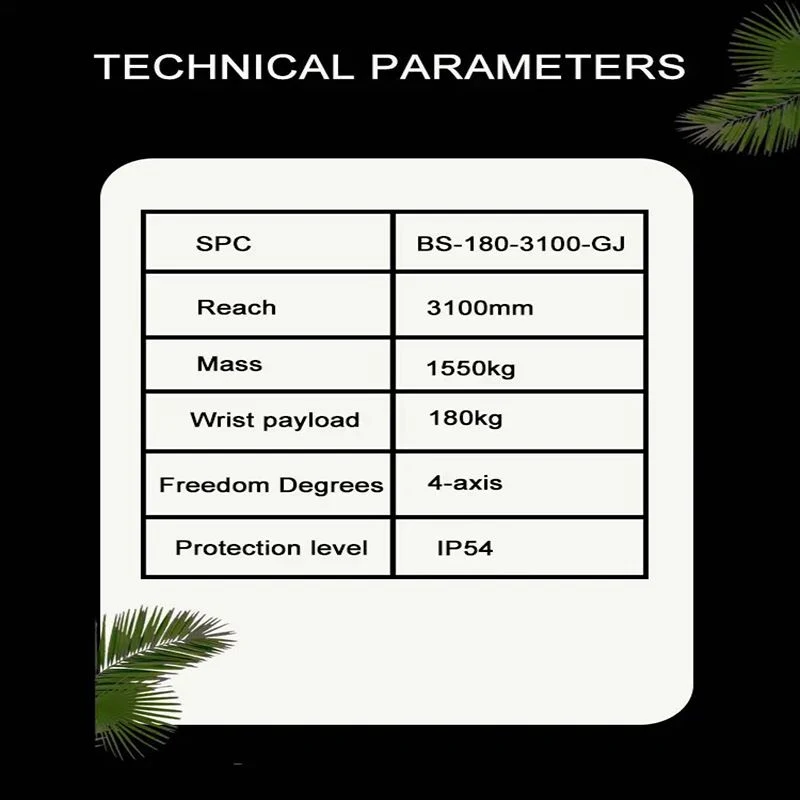

Technical parameters of multi-joint robot

- Load capacity: Generally, it can grab 10-50kg beverage boxes, depending on the model and design.+

- Working range: horizontal extension can reach 1-3 meters, and the vertical movement range is 0.5-2 meters.

- Repeat positioning accuracy: up to ±0.1 - 0.5mm, ensuring accurate grasping and placement.

- Movement speed: The maximum operating speed can reach tens of meters per minute, which is adjusted according to working conditions and loads.

- Degrees of freedom: 4 - 6 axes are common, and the more axes, the better the flexibility and operating range.

Features and advantages

- High flexibility: The multi-joint design allows it to operate in complex spaces and adapt to different layout production lines and stacking styles.

- Accurate and efficient: Accurate positioning, high efficiency of grasping and stacking, continuous and stable work, greatly improving the speed of packing and stacking.

- Strong adaptability: By replacing the end effector and adjusting the program, it can adapt to beverage boxes of different specifications and materials.

- Save manpower: Automatically complete packing and stacking, reduce the intensity and quantity of manual labor, and reduce labor costs.

Products Description

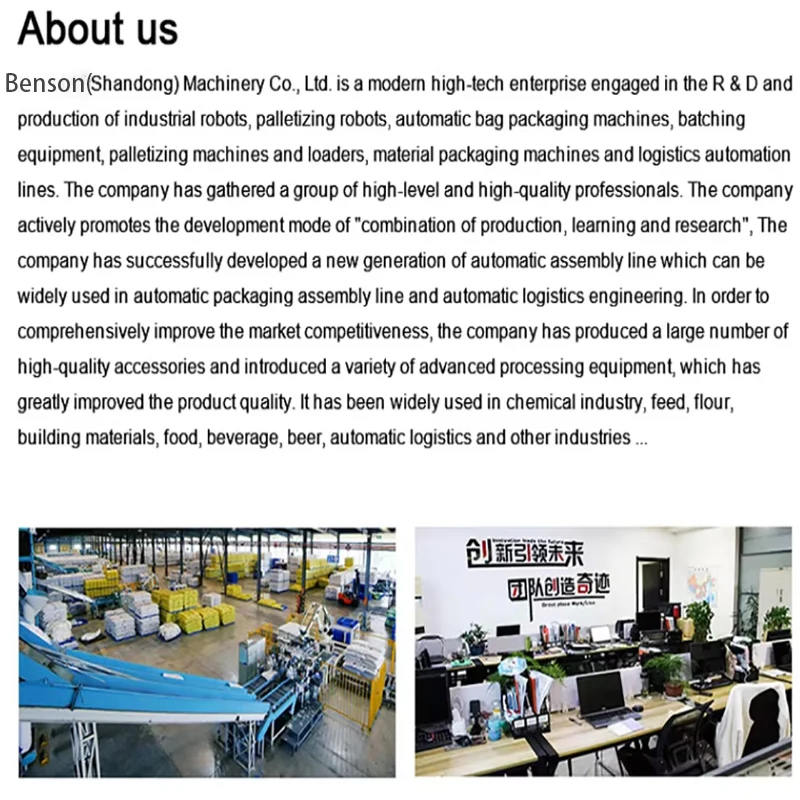

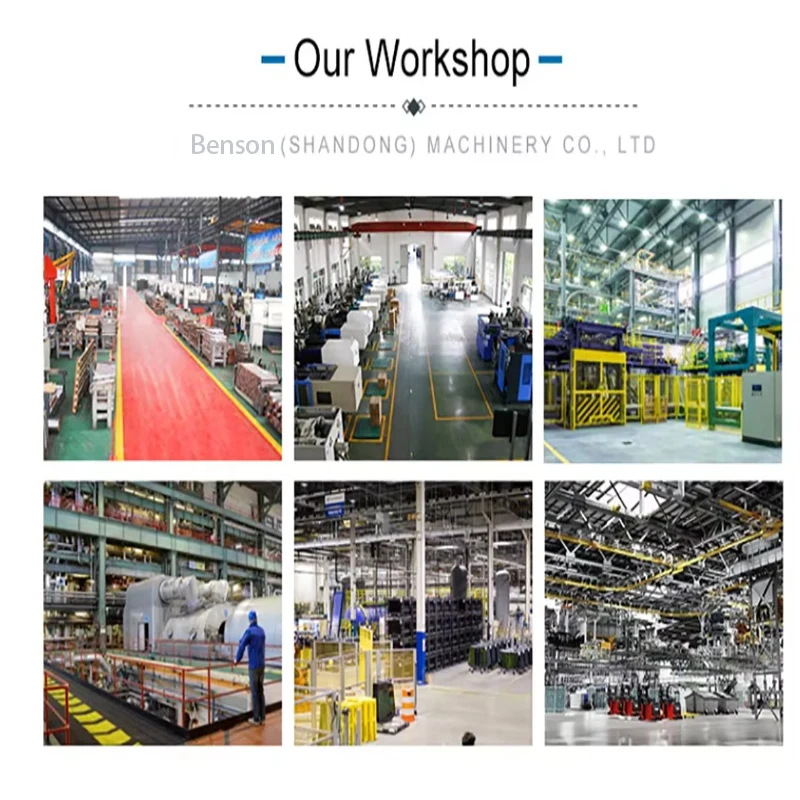

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

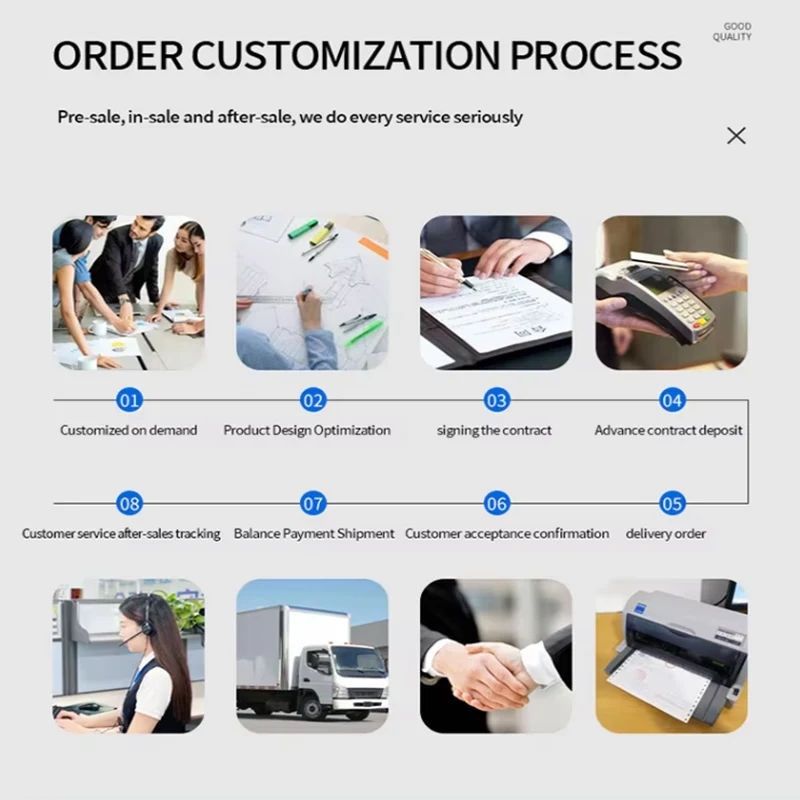

Product Inquiry