Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

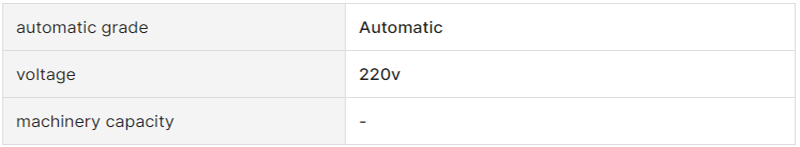

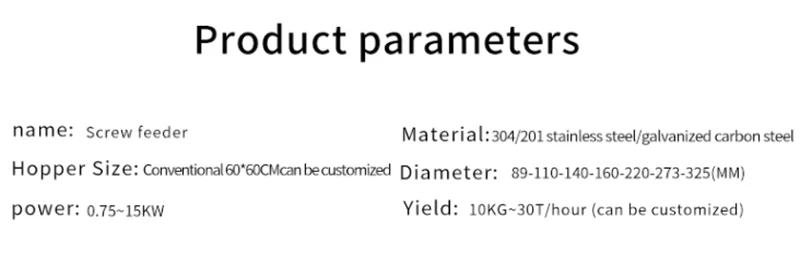

Key attributes

Industry-specific attributes

Other attributes

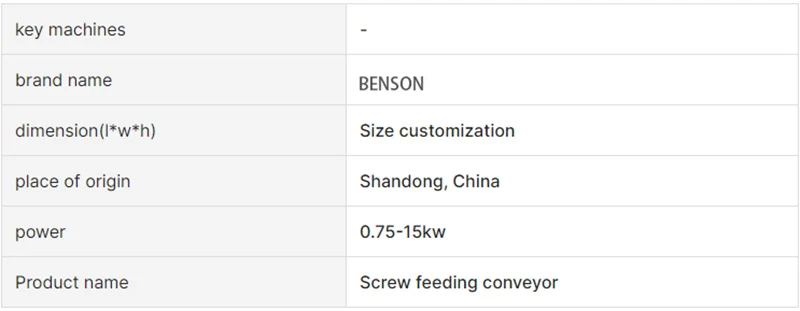

Packaging and delivery

Lead time

Product descriptions from the supplier

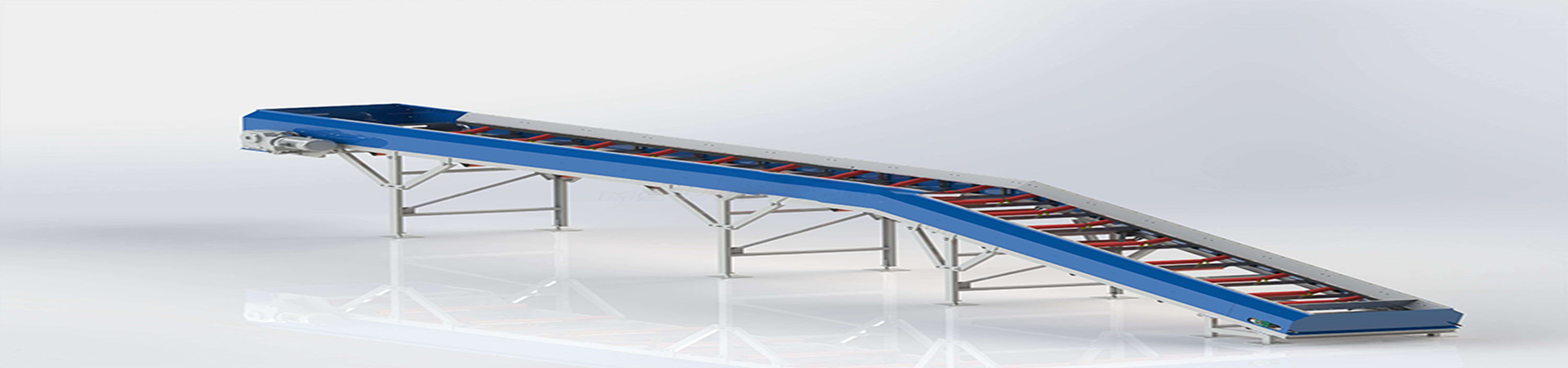

Structure and working principle of particle screw conveyor

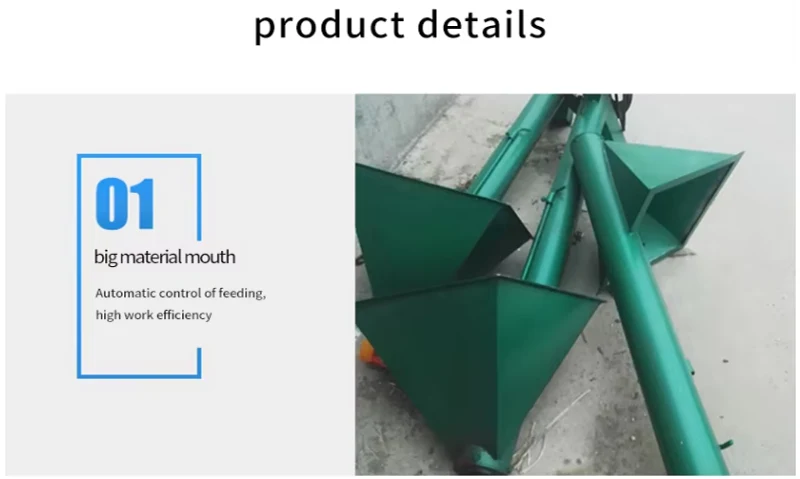

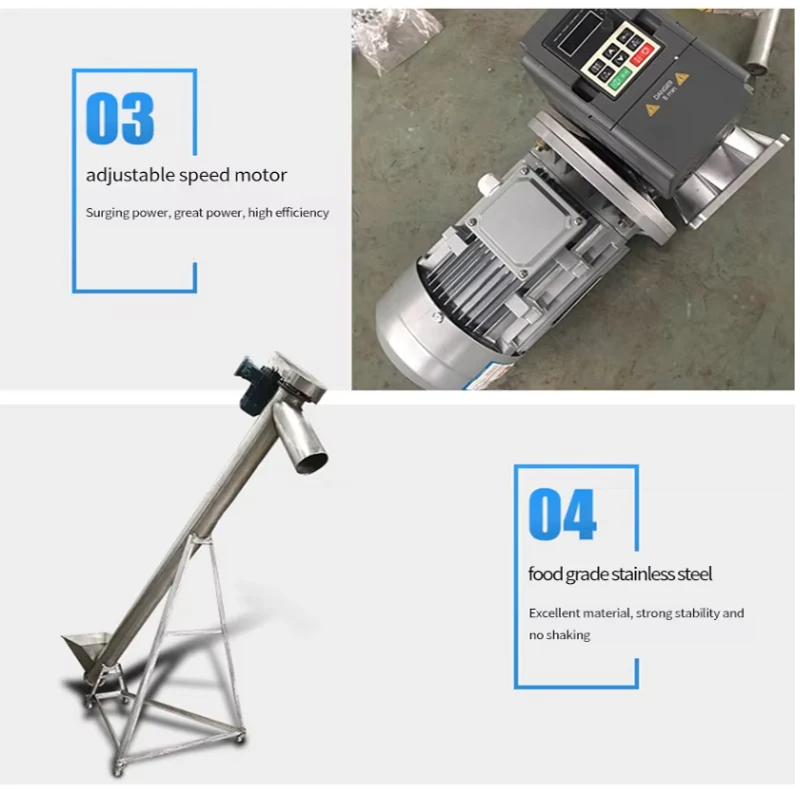

The particle screw conveyor is mainly composed of drive device, screw shaft, trough, hanging bearing and other components. The spiral blades are tightly welded on the spiral shaft, and the spiral shaft is driven by the drive device to rotate in the closed trough. When the spiral shaft rotates, the particle material moves along the axial direction of the trough under the push of the spiral blades, like a chain being pushed continuously, to achieve directional conveying from the feed port to the discharge port. The trough can be designed into different structures such as U-shaped and tubular according to needs. The closed design effectively avoids material overflow and dust flying, ensuring a clean working environment.

Core advantages

- Efficient and stable: The spiral blades of the particle screw conveyor are reasonably designed, which can push materials quickly and continuously, and can achieve high conveying efficiency to meet the needs of large-scale production. And the operation process is stable, rarely jamming and blocking, ensuring a smooth production process.

- Flexible adaptation: Conveyors of different lengths, diameters, and inclinations can be customized according to the conveying distance, height, material characteristics and on-site space layout. Material transportation in horizontal, inclined and even vertical directions can be achieved, and material transportation in complex paths can be completed through multi-stage combination.

- Low consumption and energy saving: Compared with some similar conveying equipment, the particle screw conveyor has a simple and compact structure, low energy consumption during operation, and reduces the long-term operating costs of enterprises; at the same time, it has fewer parts and convenient daily maintenance, which can reduce downtime and maintenance time and improve equipment utilization.

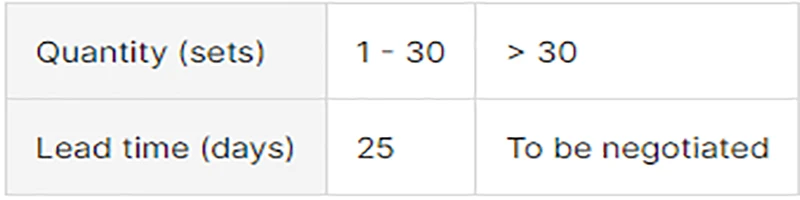

- Wide compatibility: It has strong compatibility with various types of granular materials, whether it is grain crops such as wheat and corn, or industrial materials such as plastic granules, fertilizer granules, and ore granules, it can be stably transported. And by selecting special materials and structures, it can cope with special working conditions such as high temperature and corrosion.

Application field

- Grain industry: In the grain storage and processing links, it is used for the storage, outbound and warehouse transfer of raw grains, as well as the transportation of granular materials in the production process of flour and feed, to ensure the pollution-free transmission of materials in a closed environment.

- Chemical industry: Realize the transportation of chemical raw materials, intermediate products and finished granules, cooperate with the production line to complete the mixing, batching and other processes, and strictly control the accuracy and sealing of the material transportation process.

- Environmental protection industry: In garbage disposal and sewage treatment plants, it is used to transport sludge, garbage particles and other materials to help environmental protection operations to be carried out efficiently.

- Building materials industry: It transports cement, sand, gravel, ceramic particles and other materials to provide a stable material supply for processes such as concrete mixing and brick production.

Products Description

Company Profile

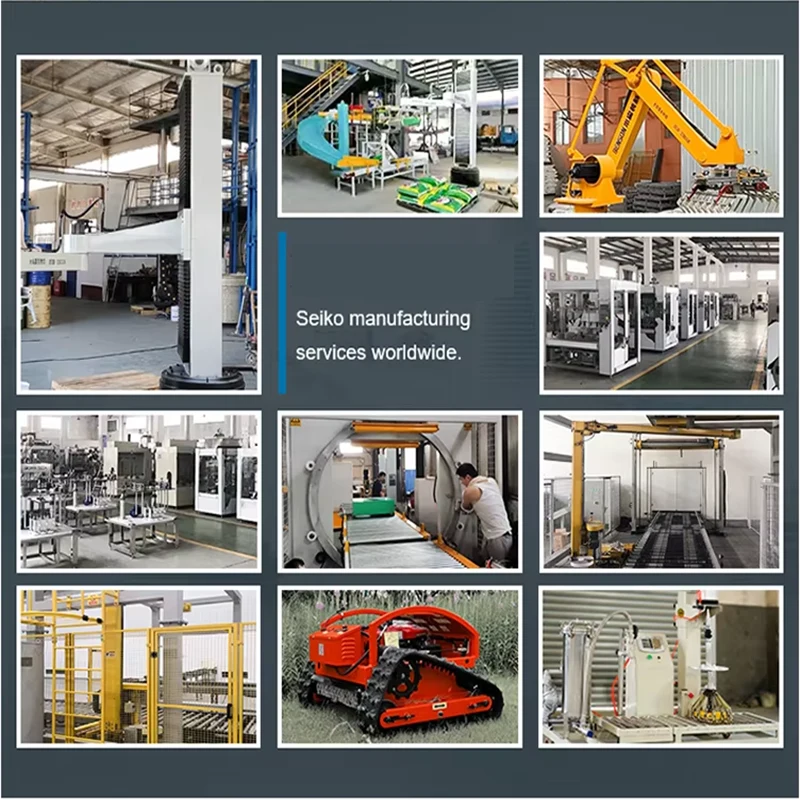

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Title goes here.

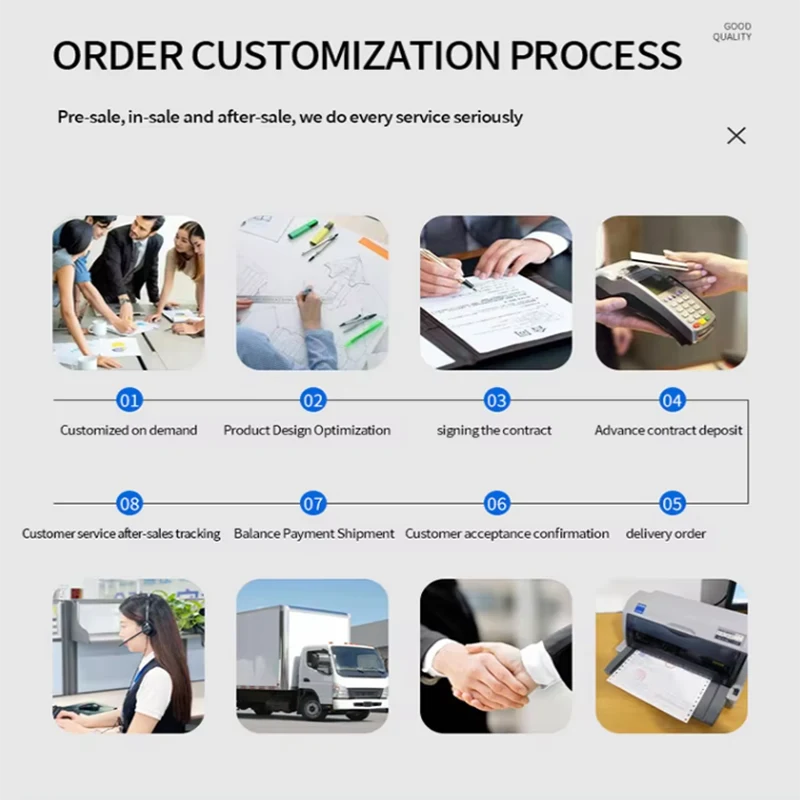

can ship it within 7 days. Customized types are welcome, and the delivery time is about 20-25 working days. Q2: How long is the

product warranty period? A2: The product warranty period is 12 months. Q3: Can you help me pack other goods together into the

container? A3: Yes, of course. If most of the products are purchased from us, and other products are also purchased from other

suppliers, you can ask other suppliers to send the products to our factory (Tai'an City, Shandong Province). We help you pack all

your products into one container. Arrange everything. Q4: After the machine is finished, how to check the quality of the machine?

A4: We have made video calls with customers in seminars for on-site inspection on zoom, Microsoft, Teamviewer, whatspp, skype and

wechat.

Product Inquiry