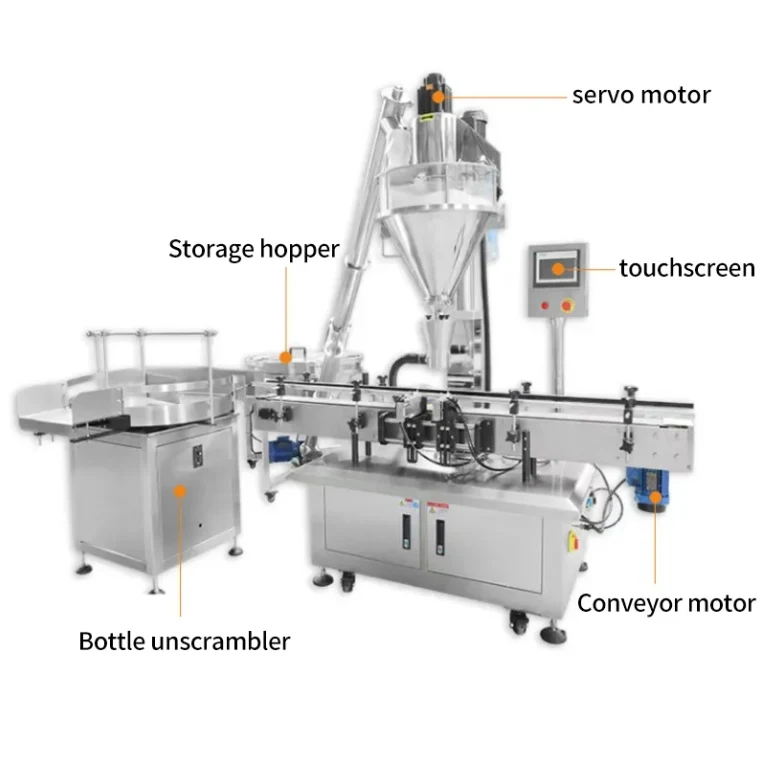

The "Detergent Powder Weighing and Packaging Machine for Manufacturing and Processing Machinery" is an automated mechanical equipment specifically designed for the production process of detergent powder. It integrates two core functions of precise weighing and efficient packaging. It can accurately weigh the detergent powder according to the preset weight parameters, and quickly and stably fill the weighed powder into various packaging containers, such as plastic bags, cartons, plastic barrels,

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Detergent powder weighing and packaging machineAdvantages

1. High-precision weighing: By using advanced weighing sensors and intelligent control systems, the weighing error of detergent powder can be controlled within a very small range, ensuring that the weight of each package of products is accurate, meeting the quality standards and enhancing the product reputation.

2. Efficient production: It has the ability to operate at high speed. Compared with manual operation, it can greatly improve the packaging efficiency, meet the large-scale production needs of enterprises, and effectively reduce the production cost per unit of product.

3. Versatility: It supports the switching of various packaging specifications and forms, can flexibly adapt to the production requirements of different weights and types of packaging containers, and provides diversified production options for enterprises.

4. Automated operation: All links from weighing, filling to sealing and labeling can be operated automatically, reducing manual intervention and labor intensity. At the same time, it avoids the pollution and errors that may be caused by manual operation, and improves the stability and reliability of production.

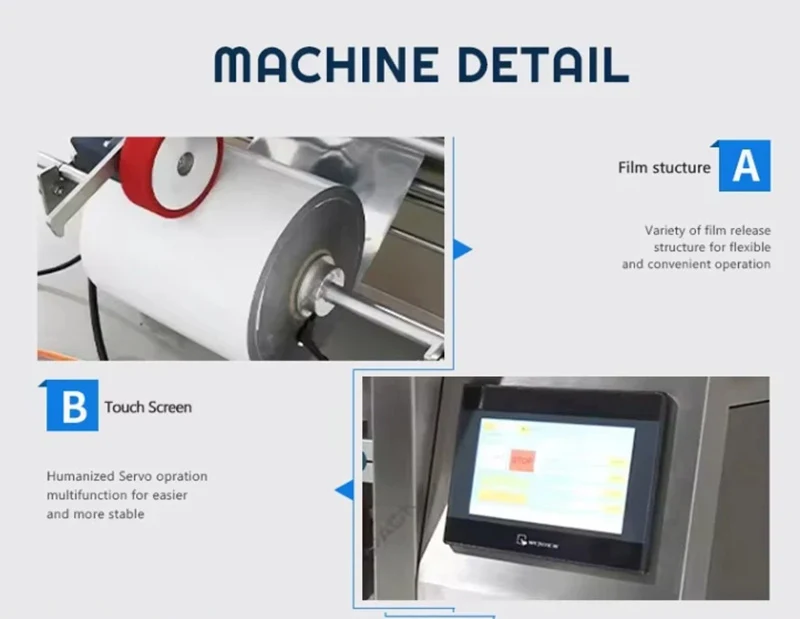

5. Intelligent monitoring and management: Equipped with a visual operation interface and an intelligent monitoring system, operators can monitor the operation status of the equipment, production data and other information in real time, making it easy to discover and solve problems in a timely manner. It also supports the recording and analysis of production data, helping enterprises optimize production management.

Detergent powder weighing and packaging machineApplications

1. Production of household detergents: It is suitable for the packaging of household detergents such as washing powder and dishwashing powder, meeting the market demand for household products of different specifications.

2. Production of industrial detergents: It can be used for the packaging of products such as industrial heavy oil stain cleaners and industrial washing powder, meeting the requirements of large-capacity and high-specification packaging in the industrial cleaning field.

3. Daily chemical enterprises: All kinds of daily chemical enterprises can use this equipment to achieve efficient and accurate production and packaging processes when producing detergent powder products, improving the competitiveness of enterprises.

4. Contract manufacturing enterprises: For enterprises undertaking the contract manufacturing business of detergent powder, this equipment can flexibly meet the diversified packaging needs of different customers and ensure production efficiency and product quality.

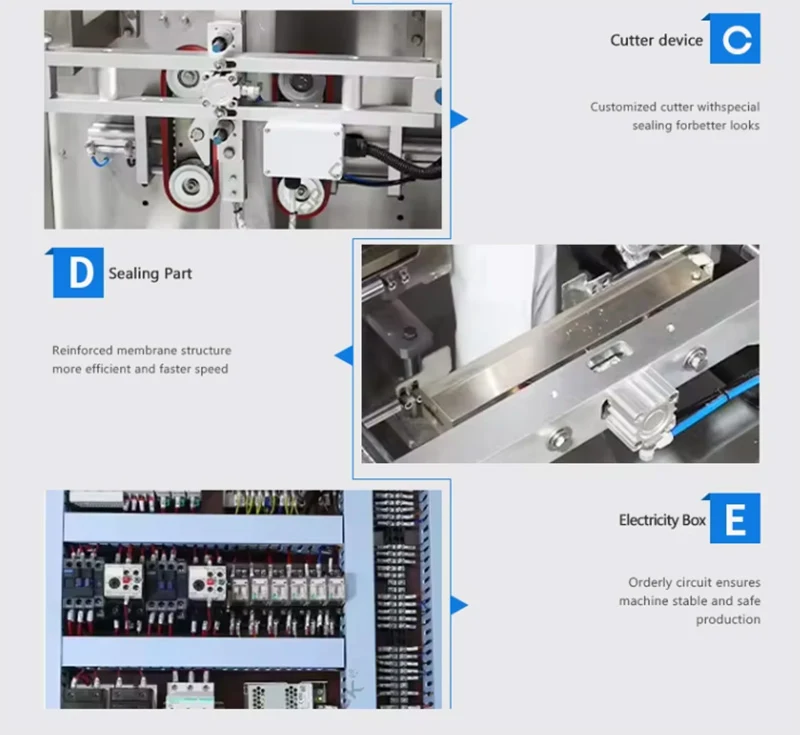

Detergent powder weighing and packaging machineFeatures

1. Compact and reasonable structure: The overall design of the equipment is compact, with a small floor area, making it convenient for layout and installation in production workshops of different scales. At the same time, the internal structure is optimized to ensure the smooth operation of each component and convenient maintenance.

2. Safe and durable materials: The components in contact with the detergent powder are made of corrosion-resistant and pollution-free materials such as food-grade stainless steel that meet the hygiene standards, ensuring the hygiene and safety of the products and extending the service life of the equipment.

3. Strong protection performance: It has a good design for dust prevention, moisture prevention and leakage prevention, effectively preventing the environmental pollution of the production caused by the overflow of detergent powder and the waste of materials, and protecting the internal components of the equipment from damage.

4. Good compatibility: It can seamlessly connect with other equipment in the production line, such as raw material conveying systems, sealing equipment, labeling machines, etc., to build a complete automated production line, improving production synergy and overall efficiency.

5. Easy operation and maintenance: The operation interface is simple and intuitive, and operators can master the operation of the equipment proficiently after a short training. The modular design of the equipment is convenient for daily maintenance and troubleshooting, reducing maintenance costs and downtime

Products Description

Product Inquiry