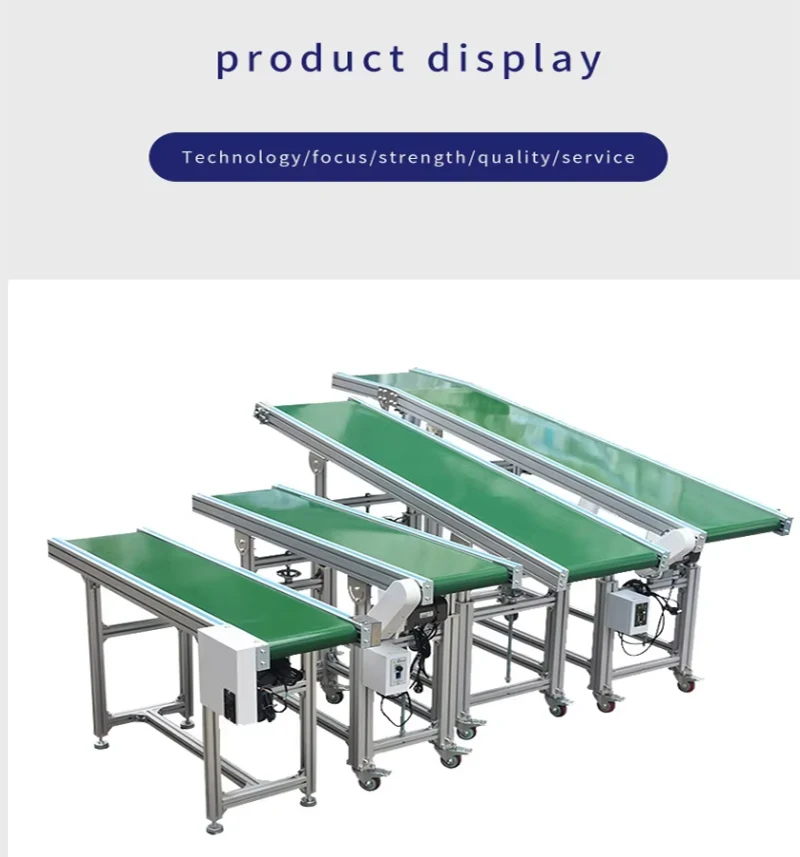

Under the wave of intelligent production of Industry 4.0, PVC green flat belt conveyor has become the core transmission equipment of industrial production lines such as automobile manufacturing, electronic assembly, and food processing with its excellent durability, precise transmission performance and flexible adaptation ability, helping enterprises to achieve cost reduction, efficiency improvement and capacity upgrade.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

Get free replacement parts service and online technical support for 1 year after purchase. Additional shipping fees may apply. Additional shipping fees may apply.

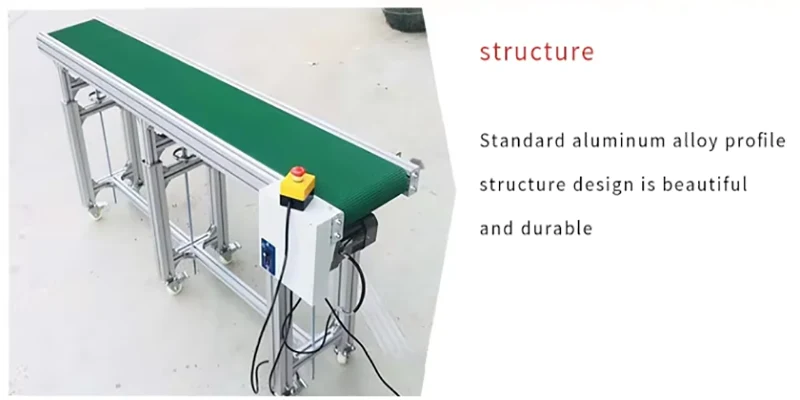

Core technology and structural advantages of PVC green flat belt conveyor for industrial production line

Precision transmission system: equipped with variable frequency speed regulation motor and high-precision roller group, it can achieve 0.1-3m/s infinitely variable speed, and the conveying error rate is less than 0.5%. With the intelligent deviation correction device, it can effectively avoid belt deviation and ensure the stability of continuous operation.

Modular design: supports rapid disassembly and expansion, and can flexibly combine straight line, turning, lifting and other conveying units according to the layout of the production line. It is compatible with MES and WMS systems and seamlessly connects to the automated production process.

Industrial performance highlights of PVC green flat belt conveyor for industrial production line

- High load transmission: A single flat belt can bear up to 50kg/m², which is suitable for heavy-duty mechanical parts, full-box cargo and other heavy-duty scenes;

- Low maintenance cost: The flat belt has a life of more than 5,000 hours, and the modular structure reduces the difficulty of maintenance, saving 30% of the average annual maintenance cost;

- Safety and environmental protection: It complies with CE and ISO 9001 certification, equipped with emergency stop devices, guardrails and other safety components, and the green PVC material does not release harmful substances, meeting industrial environmental protection standards.

Full-scenario industrial application

Industry field Application scenario Product value

Automobile manufacturing Parts assembly line, vehicle off-line transportation Accurately locate materials and improve assembly efficiency by 20%

Electronic appliances Chip packaging, precision parts transportation Anti-static design to avoid component damage

Food processing Baking product sorting, packaging line transmission Food-grade PVC material, in line with FDA hygiene standards

Logistics warehousing Express sorting, pallet cargo handling High-speed sorting, daily processing volume exceeds 100,000 pieces

One-stop service system

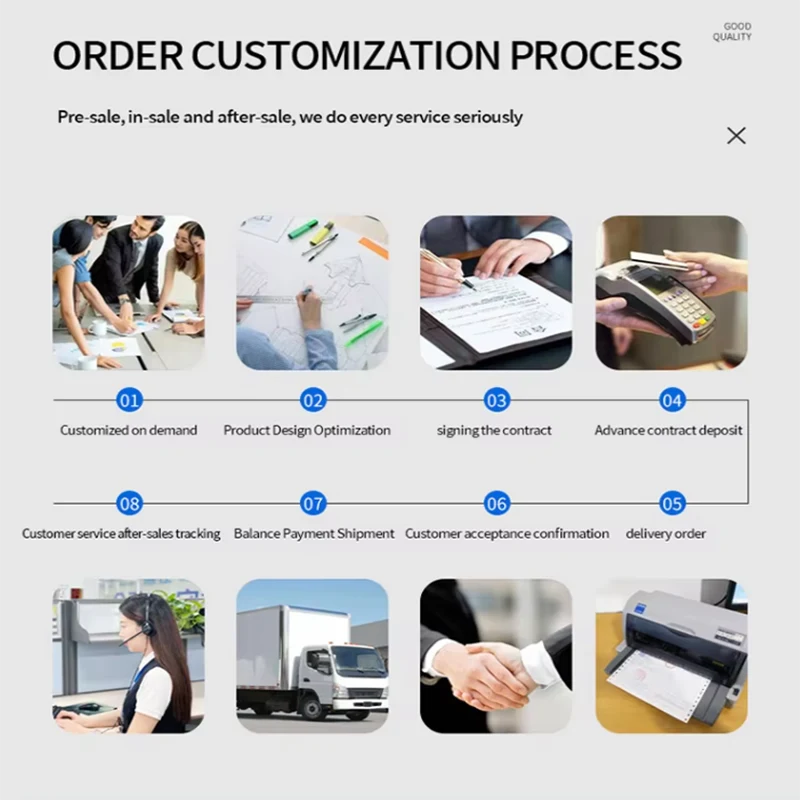

From demand analysis → solution design → production and installation → intelligent operation and maintenance, we provide full life cycle services:

- Customized solution: Issue 3D visualization solution within 72 hours to match the production line rhythm and space layout;

- Intelligent monitoring: Equipped with IoT module, real-time monitoring of equipment operation status, fault warning response time <1 minute;

- After-sales guarantee: 24-hour rapid response nationwide, providing annual inspection and free technical upgrade services.

Choose the PVC green flat belt conveyor for industrial production lines, use technology to drive production innovation, and create efficient, stable and intelligent industrial transmission solutions for you!

Products Description

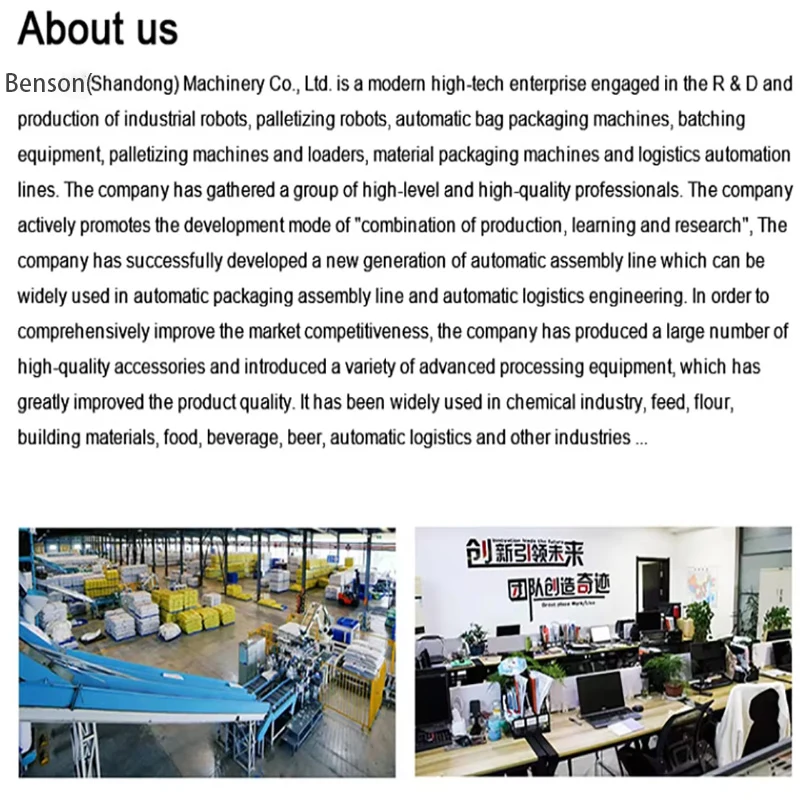

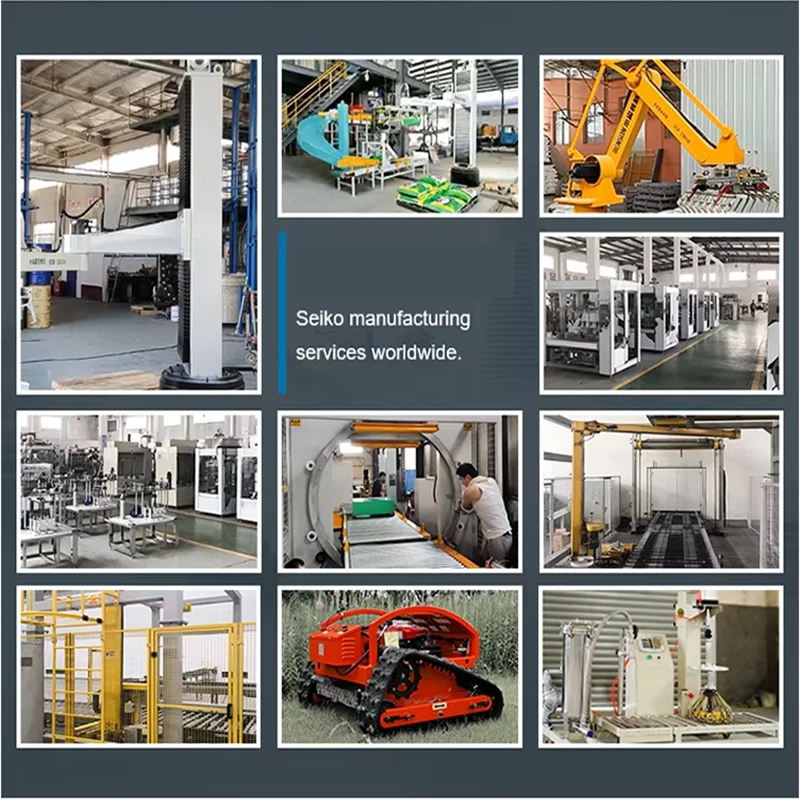

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry