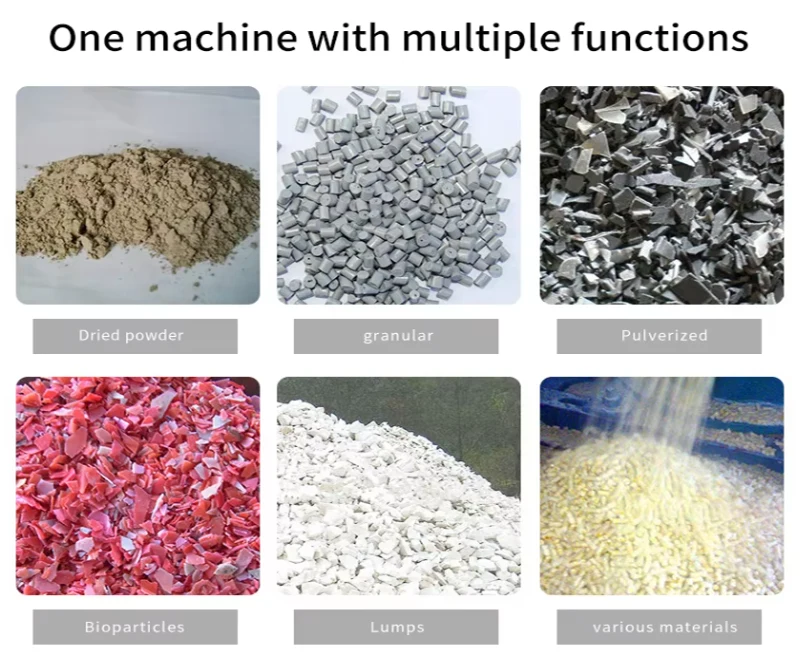

Automatic flexible screw conveyor is an innovative equipment that breaks through the limitations of traditional conveying. It integrates automatic control technology and flexible conveying concepts and is designed for various materials such as powder, granular, and paste. It adopts a unique flexible spiral structure and intelligent control system, which can be flexibly arranged in complex spaces to achieve efficient, stable, and precise conveying of materials.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Free replacement parts service

Get free replacement parts service and online technical support for 1 year after purchase. Additional shipping fees may apply. Additional shipping fees may apply.

Core advantages of automatic flexible screw conveyor

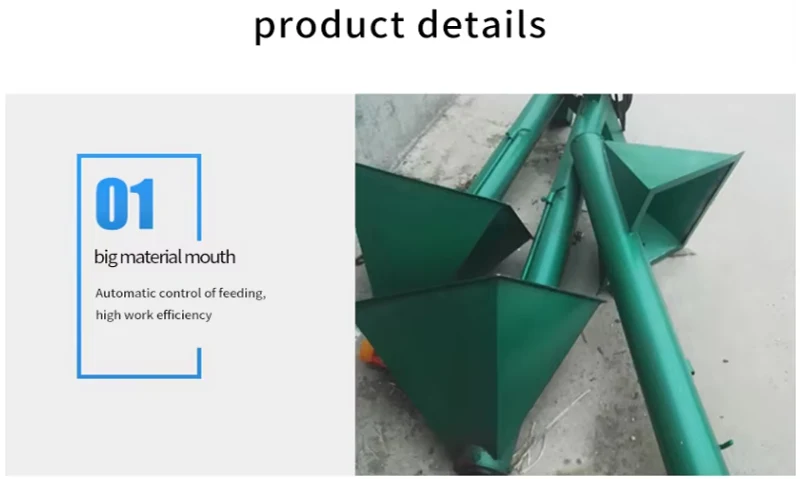

Flexible layout

The high-strength flexible screw component can achieve 360° arbitrary bending, adapting to complex conveying paths such as S-shaped, U-shaped, and vertical lifting, without the need for a large number of elbows of traditional hard pipes. The equipment can easily pass through narrow spaces or bypass obstacles, meet the needs of special plant layout and compact production line design, and save more than 40% of installation space.

Gentle and lossless conveying

The special material and structural design of the flexible screw exerts a gentle force on the material during the conveying process, effectively avoiding problems such as material breakage, grading, and adhesion. It is especially suitable for the conveying of fragile materials such as coffee beans, puffed foods, and pharmaceutical granules, as well as viscous pastes and heat-sensitive materials, retaining the original quality of the materials to the greatest extent.

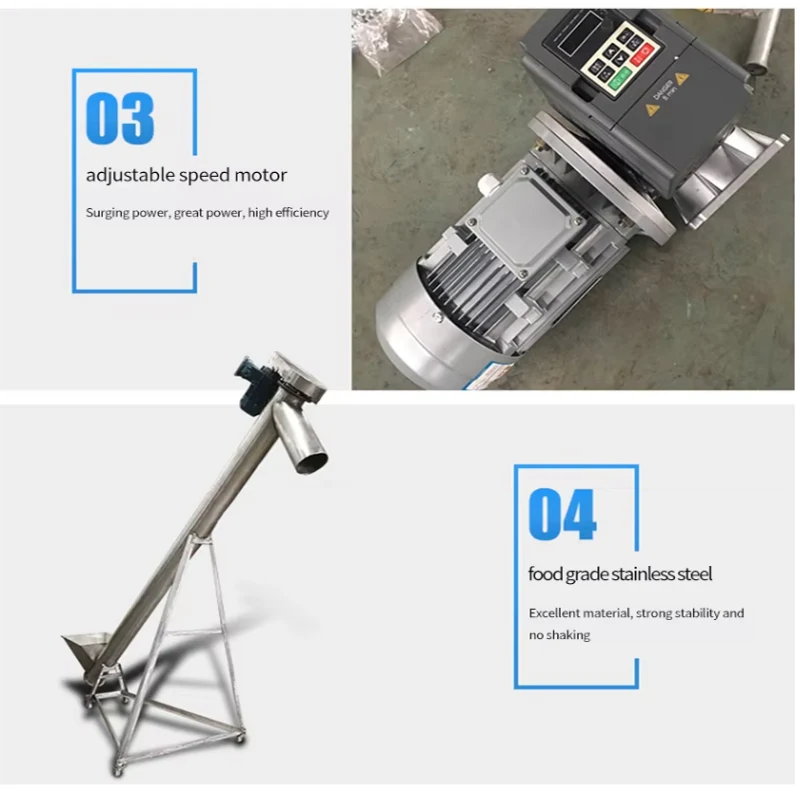

High-precision automation of automatic flexible screw conveyor

Equipped with PLC intelligent control system and servo drive motor, it supports 0-100% stepless speed regulation, can accurately control the material conveying volume, and the measurement accuracy error is as low as ±1%. Equipped with a material level sensor and feedback system, it can automatically start and stop or adjust the conveying speed according to the amount of material in the silo, realizing unmanned operation and intelligent linkage with the production line.

Hygienic and easy-to-clean design

It uses food-grade stainless steel (304/316L) and food-grade flexible spiral materials, which meet GMP and FDA hygiene standards. The equipment supports quick disassembly and cleaning, the spiral components can be directly pulled out and flushed, and the inner wall of the pipeline is smooth without dead corners, meeting the strict hygiene requirements of high-clean industries such as food and pharmaceuticals.

Application areas

Food industry: used for conveying materials such as chocolate beans, nuts, flour, sauces, etc. to ensure food integrity and hygiene safety.

- Pharmaceutical industry: Accurately convey tablets, capsules, and medicinal powders to meet the cleanliness and high-precision requirements of drug production.

- Chemical industry: conveying chemical raw materials such as plastic particles, additives, and dyes, and adapting to special working conditions such as corrosive, flammable and explosive.

- New energy industry: realize dust-free conveying of fine materials such as lithium battery positive and negative electrode materials and graphite powder to avoid material pollution and loss.

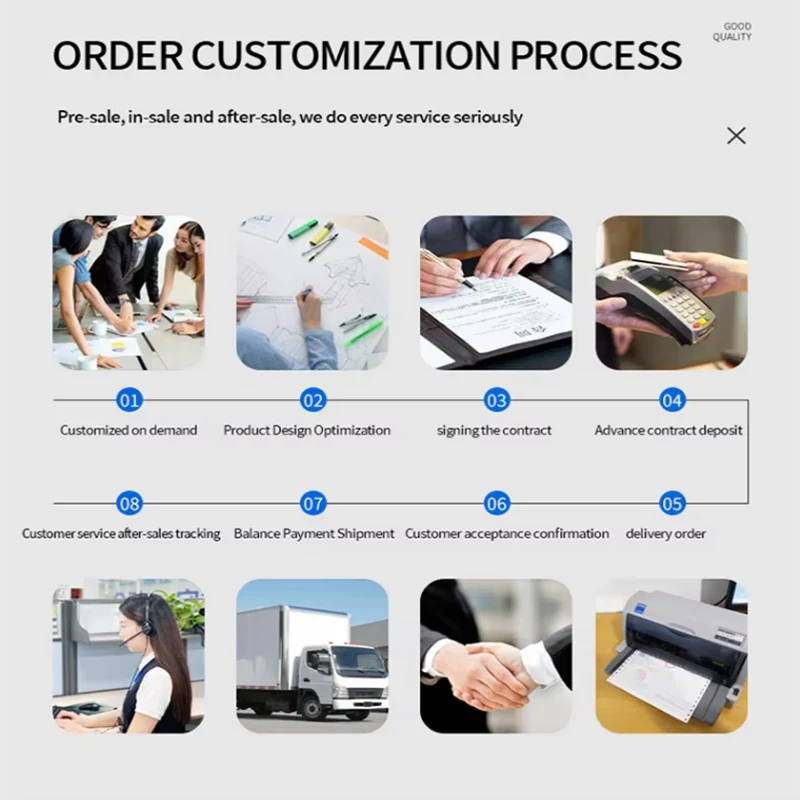

After-sales service

We provide full-cycle service guarantee: professional team provides free on-site survey and customized solution design; follow up the whole process of equipment installation and commissioning to ensure rapid production; 7×24 hours after-sales response to solve operating faults in time; regular equipment maintenance training and inspection services are provided, so that you can use the automatic flexible screw conveyor without worries, and continuously empower the company's efficient production.

Products Description

Company Profile

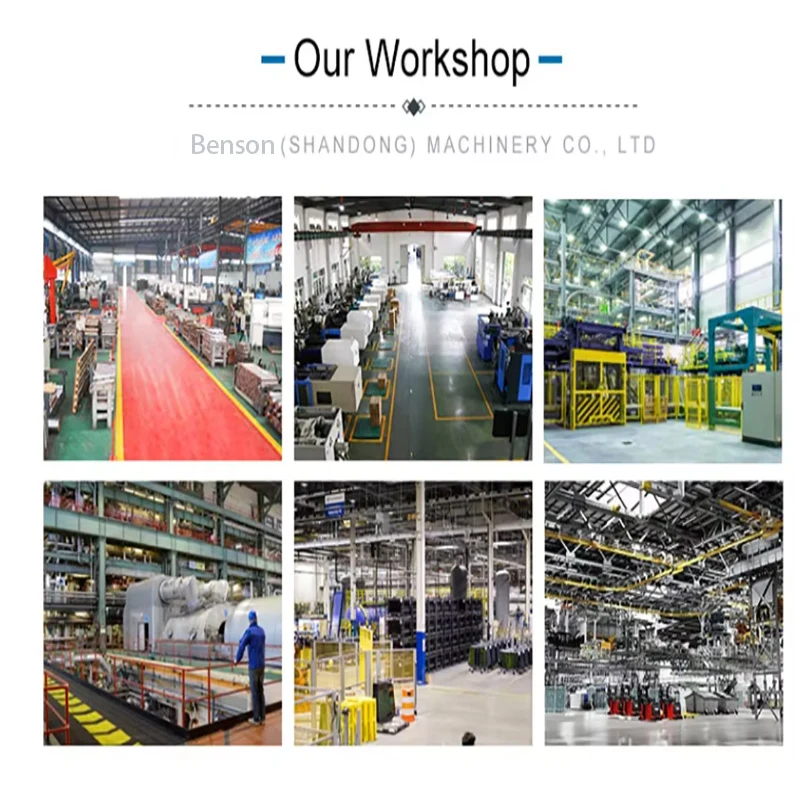

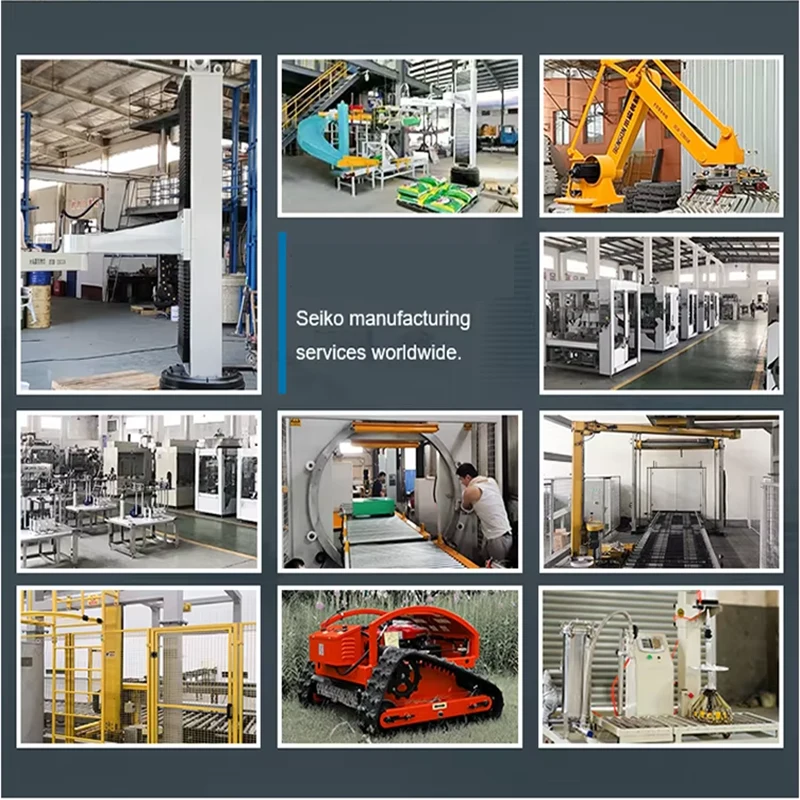

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry