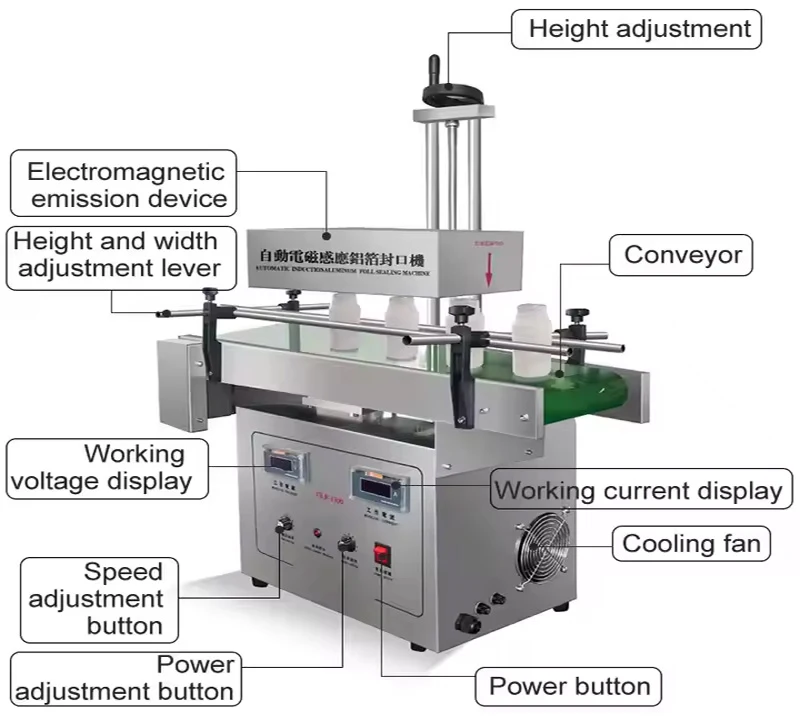

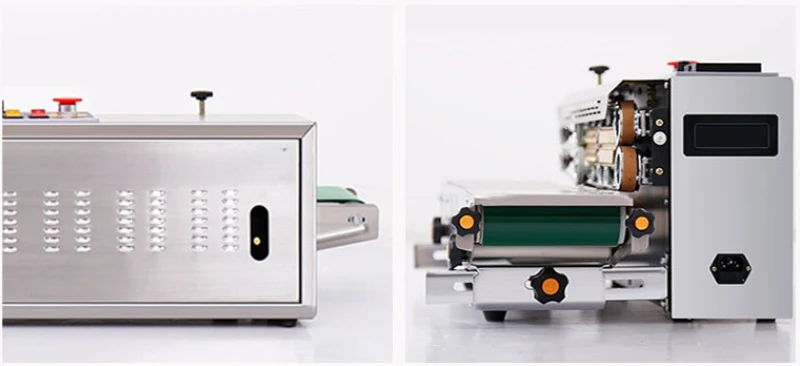

The continuous electromagnetic induction heat sealing machine is an advanced packaging device specifically designed to achieve efficient and high-quality packaging sealing. Based on the principle of electromagnetic induction, it generates an alternating magnetic field, causing the metal in the packaging material to induce heat and quickly reach the required temperature for heat sealing.This heat sealing machine can operate in a continuous and uninterrupted working mode and can seamlessly connect

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

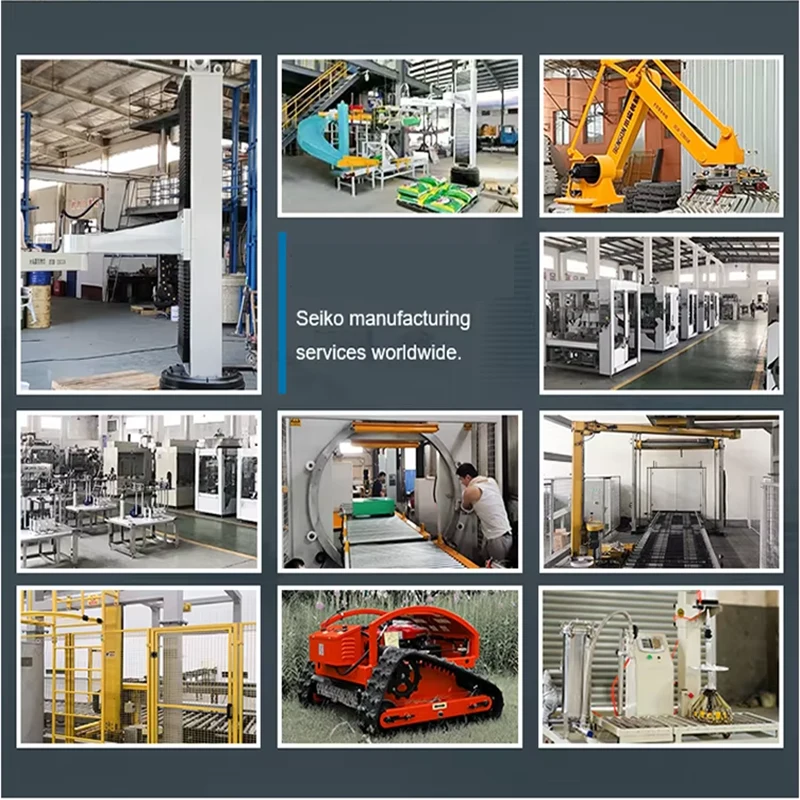

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Continuous Electromagnetic Induction Heat Sealing MachineIn terms of operation, it is equipped with a user-friendly operation interface. The parameter setting is simple and intuitive, and operators can master it proficiently after simple training. At the same time, the maintenance of the equipment is also very convenient. The modular design is convenient for daily inspection and troubleshooting. In addition, this heat sealing machine is also equipped with multiple safety protection devices, such as automatic power-off in case of overheating and leakage protection, to ensure the safety of operators and the stable operation of the equipment.

1. High - efficiency continuous operation: It can perform continuous and uninterrupted heat - sealing operations, adapting to the requirements of high - speed production lines. This significantly improves production efficiency, making it suitable for large - scale production and effectively shortening the product packaging cycle.

2. Rapid electromagnetic induction heating: Heating is based on the principle of electromagnetic induction, with a fast heating speed. It can quickly bring the packaging material to the appropriate heat - sealing temperature in a short time, reducing waiting time and increasing work efficiency.

3. Reliable heat - sealing quality: The heat - sealing effect is uniform and firm, with good sealing performance. It can effectively prevent the leakage, moisture absorption, oxidation, etc. of the contents, extending the product's shelf life and enhancing the safety of product storage and transportation.

4. Wide application range: It is applicable to various packaging materials of different materials, such as plastic films (e.g., PE, PP, PVC, etc.) and aluminum - foil composite films, meeting the packaging needs of different products.

5. Precise temperature control: It is equipped with an accurate temperature control system that can accurately adjust the heat - sealing temperature according to different packaging materials and heat - sealing requirements, ensuring the consistency and stability of the heat - sealing effect.

6. Simple operation and maintenance: The equipment's operation interface is simple and easy to understand. Operators can start operating it after simple training. Meanwhile, its reasonable structural design facilitates daily cleaning, maintenance, and troubleshooting, reducing the equipment's maintenance cost.

7. High degree of automation: It can be used in conjunction with other automated packaging equipment (such as filling machines, labeling machines, etc.) to achieve the automated operation of the packaging production line, reducing manual intervention and improving the automation level of production and the convenience of production management.

8. Good safety performance: It is equipped with complete safety protection devices, such as over - temperature protection and leakage protection, effectively preventing accidental injuries to operators and ensuring the safe and stable operation of the equipment.

Products Description

Product Inquiry