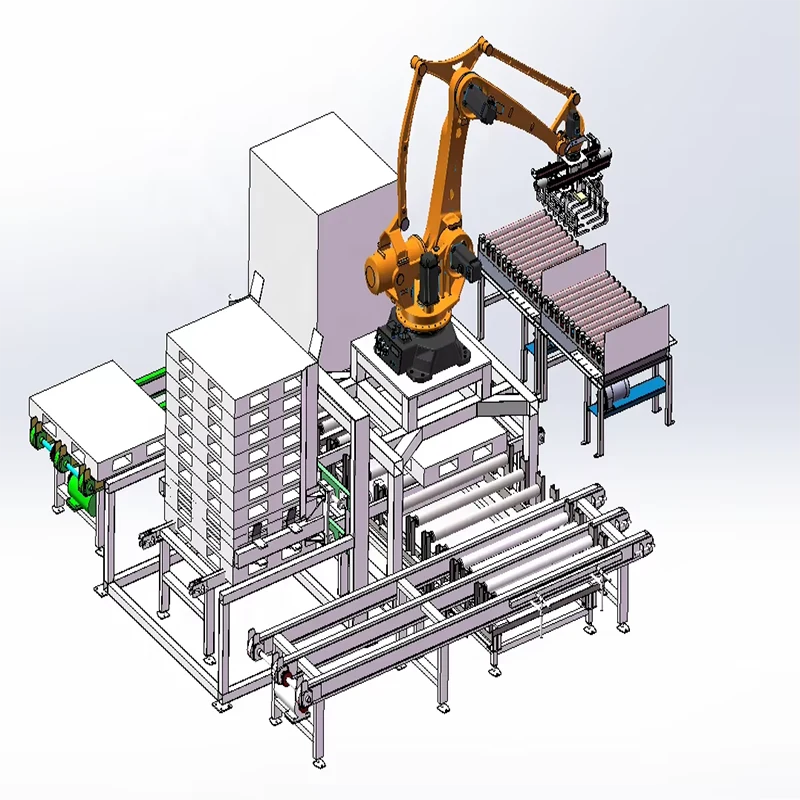

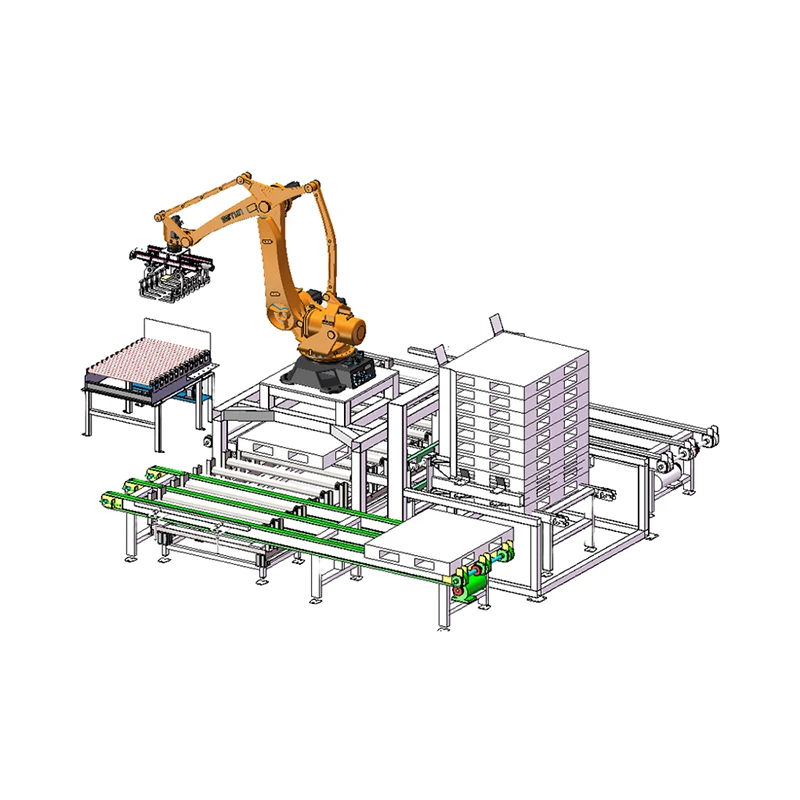

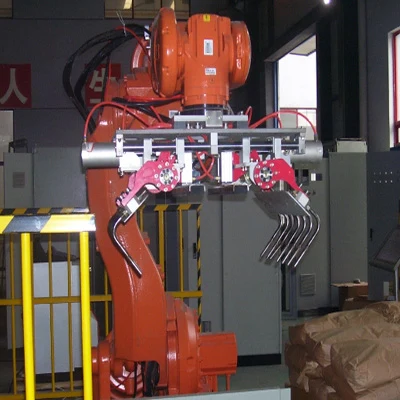

The beverage carton column - type palletizer is an automated device specifically designed for beverage carton packaging. It takes the unique column - type structure as the core, equipped with an intelligent control system and a precision robotic arm. During operation, the beverage cartons on the production line are orderly conveyed to the designated position through the conveyor belt. Under the precise guidance of the sensors, the robotic arm uses a special gripper to quickly and stably grasp

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

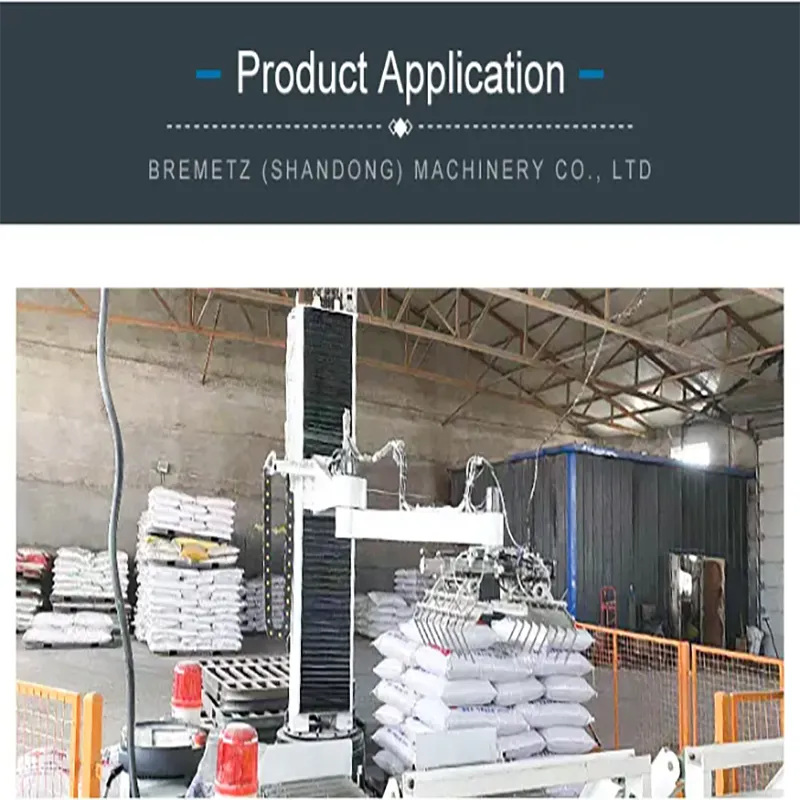

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Products Description

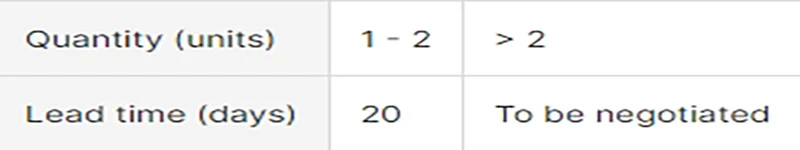

Beverage Carton Columnar Palletizer

The beverage carton column palletizer is a highly automated packaging equipment specially designed for efficient palletizing of beverage cartons. It accurately grabs the beverage cartons on the conveyor line through an intelligent control system, and (with) the flexible movement trajectory of a multi-joint robotic arm, it can quickly and stably stack the cartons into neat column-shaped pallet units. The equipment has a highly adjustable pallet pattern setting function, which can flexibly change the palletizing style according to the carton specifications and the number of pallet layers, adapting to various production needs. It integrates a visual recognition system that can real-time detect the position and posture of cartons, ensuring palletizing accuracy and stability, and effectively avoiding problems such as carton tilting and collapse. At the same time, the high-speed operation of the grabbing device and the stable lifting mechanism work together to greatly improve palletizing efficiency, reduce labor costs and intensity, and are widely used in the automated packaging production lines of beverage manufacturers, providing a reliable guarantee for enterprises to achieve efficient and precise logistics and warehousing links.

The working process of the beverage carton column palletizer:

1. Carton Conveying:Beverage cartons are uniformly conveyed by the production line conveyor belt to the palletizer inlet, where photoelectric sensors detect their arrival.

2. Visual Positioning:beverage carton column palletizer The integrated vision system scans the position, posture, and specifications of the cartons to generate precise grabbing coordinate data.

3. Robotic Arm Gripping: The multi-joint robotic arm adjusts the suction cups/clamps based on the data to accurately (adsorb) or grip single/full layers of cartons.

4. Pallet Stacking:beverage carton column palletizer The robotic arm stacks cartons layer by layer according to preset pallet patterns (such as layer spacing and arrangement) to the specified height, forming column-shaped pallet units.

5. Pallet Feeding: Empty pallets are transported by the automatic pallet feeding mechanism to the palletizing station, where they are positioned to receive the stacked cartons.

6. Pallet Transfer:After palletizing is completed, the pallet units are moved to warehousing or transportation by conveyor belts or forklifts, while the equipment automatically resets for the next cycle.

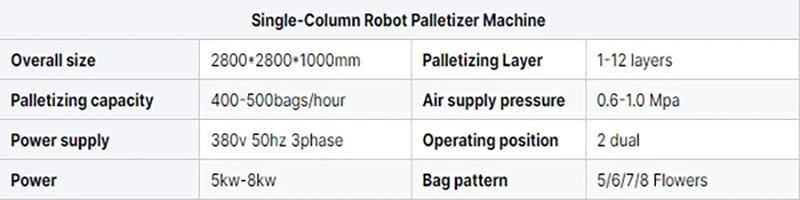

Specification

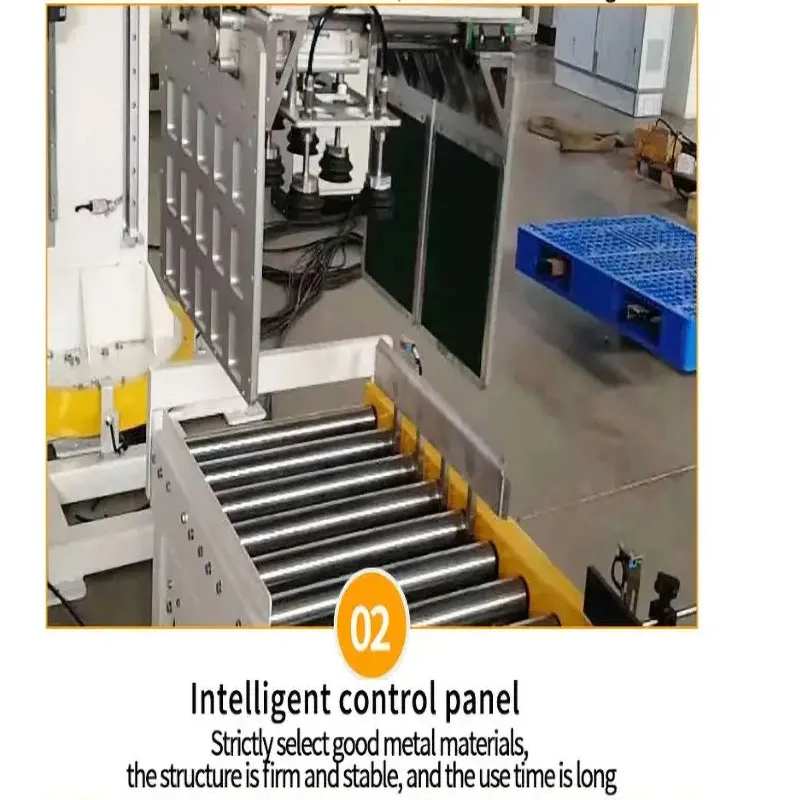

The main features of thebeverage carton column palletizer:

1- High Automation: The entire process requires no manual intervention, with intelligent systems coordinating modules such as robotic arms and conveyor belts for efficient operation.

2- Precise Positioning and Gripping: Integrated visual recognition system real-time detects carton position and posture, ensuring gripping accuracy up to millimeter level.

3- Flexible Pallet Pattern Adjustment: Supports customizing multi-layer spacing and arrangement modes, adapting to different carton specifications (e.g., size, weight) and pallet pattern requirements.

4- High Efficiency and Stability:beverage carton column palletizer The flexible movement trajectory of the multi-joint robotic arm, combined with a high-speed gripping device, enables palletizing efficiency of dozens of layers per minute, with high pallet stability.

5- Strong Compatibility: Compatible with various pallet types (e.g., plastic, paper), suitable for diverse production scenarios in the beverage industry.

6- Low Energy Consumption and Labor Cost: Reduces manual participation, labor intensity, and costs, while optimizing energy consumption design to meet industrial energy-saving standards.

7- Intelligent Monitoring and Maintenance: Equipped with fault early warning and real-time operation data monitoring functions, supporting remote debugging for convenient and efficient maintenance.

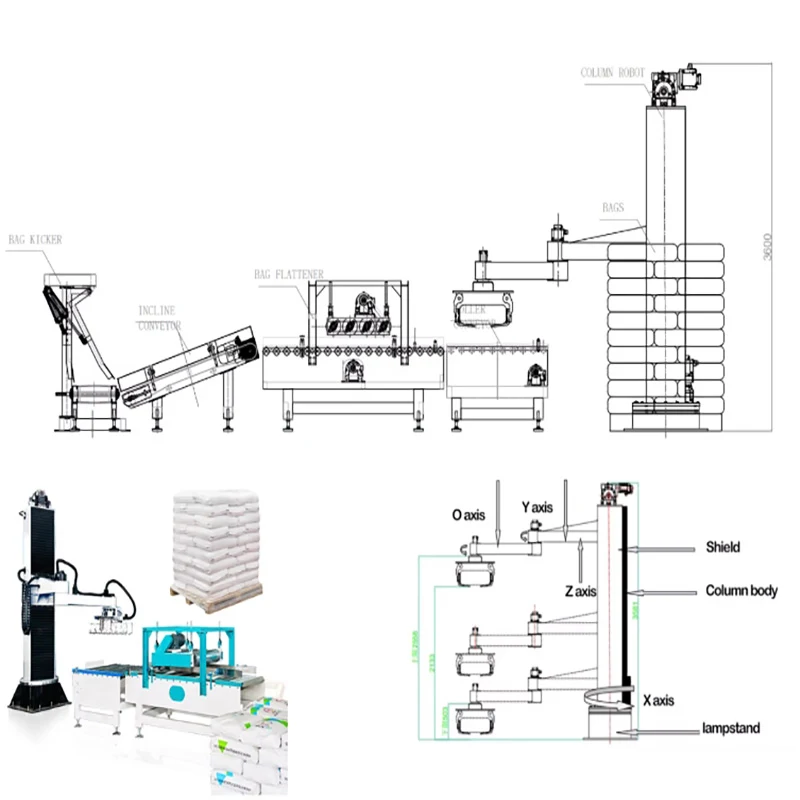

The palletizer features an interchangeable gripper—clamp, suction, or fork—suitable for various materials and shapes. This ensuressecure, damage-free handling and precise placement, enhancing flexibility and efficiency across different product lines and packaging types.

The control cabinet contains all electrical and control components, including PLCs, motor drives, and safety relays. It ensures reliable, safe operation with easy access for maintenance and built-in protection against electrical faults.

The palletizer includes an intuitive teach pendant for easy programming and control. Operators can quickly set pallet patterns, adjust positions, and monitor status, enabling efficient operation and fast changeovers without technical complexity.

Handles material transfer and placement with precision; easily integrates into existing packaging systems for streamlined

operations.

The advantages of the beverage carton column palletizer:

1.-High-efficiency production capacity: Automated operation efficiency is several times that of manual labor, significantly improving palletizing speed and reducing unit costs.

2.- Precision and reliability: beverage carton column palletizer The visual system and robotic arm achieve millimeter-level positioning, ensuring neat and stable pallets while reducing transportation losses.

3.- Flexible adaptation: Supports switching between multiple carton specifications and pallet patterns, with one-click parameter adjustment to quickly respond to different production needs.

4.- Low consumption and labor savings: Full-process automation reduces manual input, while energy-efficient design lowers operating costs, aligning with green production trends.

5.- Intelligent management: Integrates data monitoring and fault early warning, supporting remote maintenance to enhance equipment management efficiency and reliability.

6.- Safety and stability: Enclosed operation minimizes personnel contact risks, with a robust mechanical structure suitable for 24-hour continuous production.

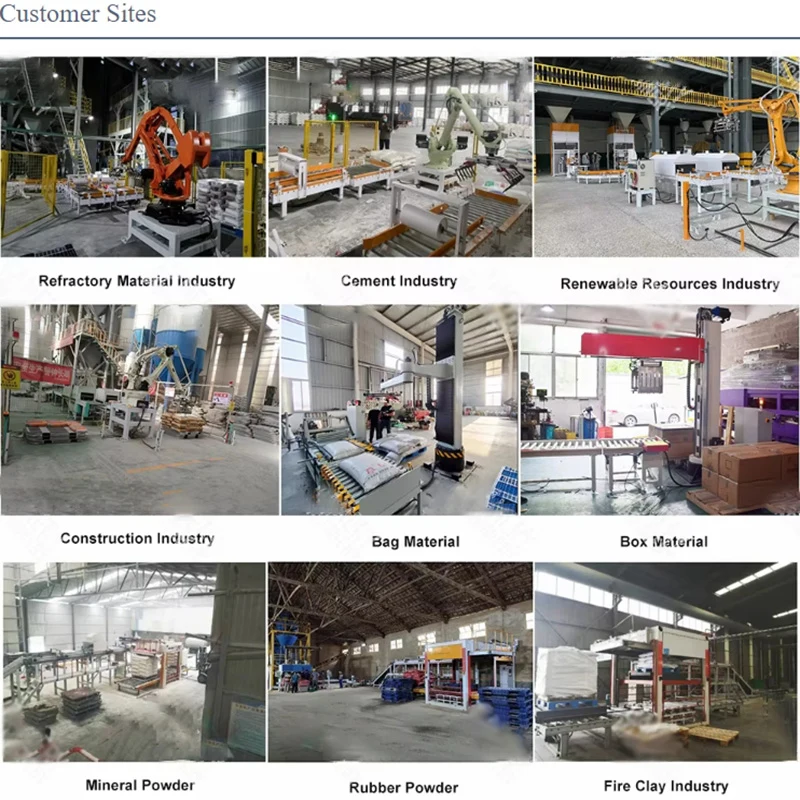

Company Profile

Benson machinery advocates innovation, professional, efficient, pragmatic business philosophy, to achieve mutual benefit and win-win, continue to provide our customers with high-end products and quality service.

Exhibition

1. Are you factory or trading company?We are the factory, we doing this line for more than 10 years.

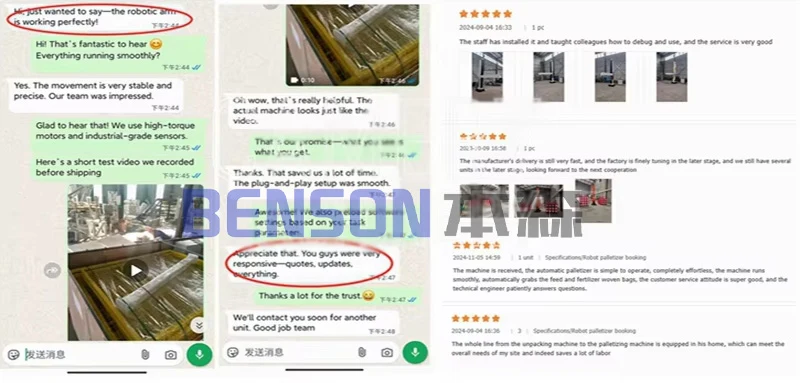

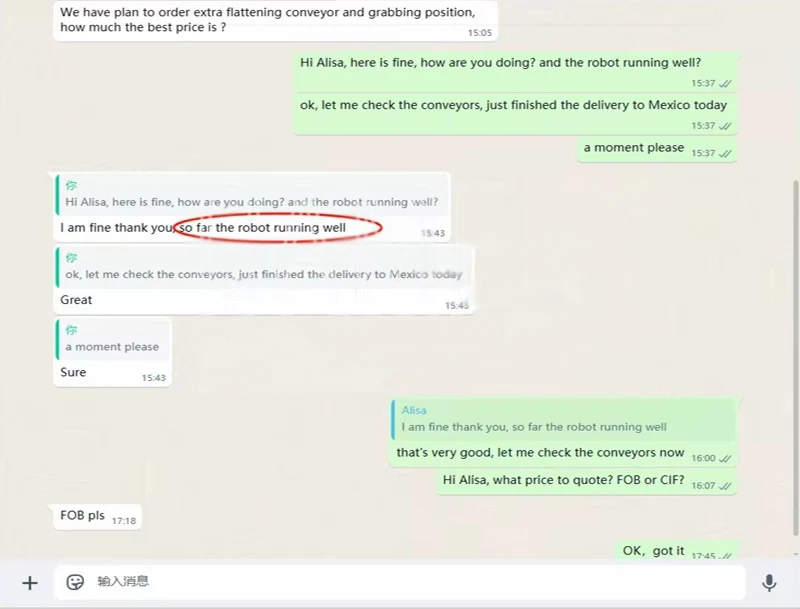

2. Can you provide after-sales service for installation?Yes. Before the equipment is shipped, we will install and debug it in the factory to ensure that all components are running stably. After that, the whole set of equipment will be packed in wooden boxes/containers. After receiving the equipment, there is no need for a lot of installation and debugging. At the same time, we will provide corresponding pictures/videos/manuals, and provide telephone consultation online, so that you can ask questions at any time.

If you need to send engineers to the local area to install, debug and train employees, we can also provide you with it. We will provide manuals and detailed videos to help customers install the machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room fees and a daily subsidy of US$150.

3. How long is the warranty on your palletizer robot?We provide a one-year warranty. If there is any problem with the equipment during the warranty period, we will replace it free of charge. If the warranty period expires, we will provide damaged spare parts at cost price. At the same time, our palletizers use brand components such as Schneider and AirTac, which have more stable performance and longer service life. Please rest assured to buy, we are worthy of your trust.

4. Are there any requirements for pallet size and stacking height?It supports a variety of pallet sizes, and the maximum stacking height can reach 1.8 meters to meet different shipping needs.5. Is there a complete solution with a conveyor line?We can provide a complete line: belt conveyor, automatic bag sorting, steering, bag pressing, palletizing, and integrated delivery.

Product Inquiry