The cooking industrial arm collaborative robot adopts the ergonomic design concept, with a compact overall structure and small footprint. It can be easily adapted to various kitchen environments, whether it is a busy restaurant kitchen or a central kitchen with limited space. It can be flexibly placed.Its robotic arm part imitates the joint structure of the human arm, has multiple degrees of freedom, a wide range of activities, and flexible and smooth movements.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

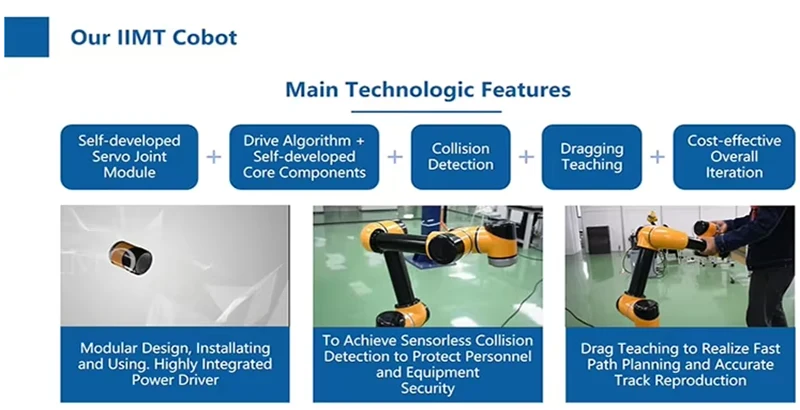

Core functions of collaborative cooking industrial arm robots

Precision cooking: Equipped with an advanced motion control system, it can accurately control the motion trajectory and strength of the robotic arm, and accurately control key parameters such as the amount of ingredients, cooking time, and heat. Whether it is the rapid flipping of the pan during stir-frying over high heat or the gentle stirring during slow cooking over low heat, it can be handled just right to ensure that every dish can achieve the best taste and quality, realize the standardized production of dishes, and ensure the consistency of the taste of dishes in different batches.

Multi-function cooking mode: It has a rich set of cooking programs, covering a variety of common cooking methods such as frying, stir-frying, cooking, deep-frying, steaming, boiling, and stewing, which can meet the production needs of different cuisines and different dishes. Whether it is the spicy and fresh Sichuan cuisine, the light and delicious Cantonese cuisine, or the mellow and fragrant Shandong cuisine, it can be easily controlled. At the same time, users can also perform personalized programming according to their own needs, customize cooking processes and parameters, and create unique dishes.

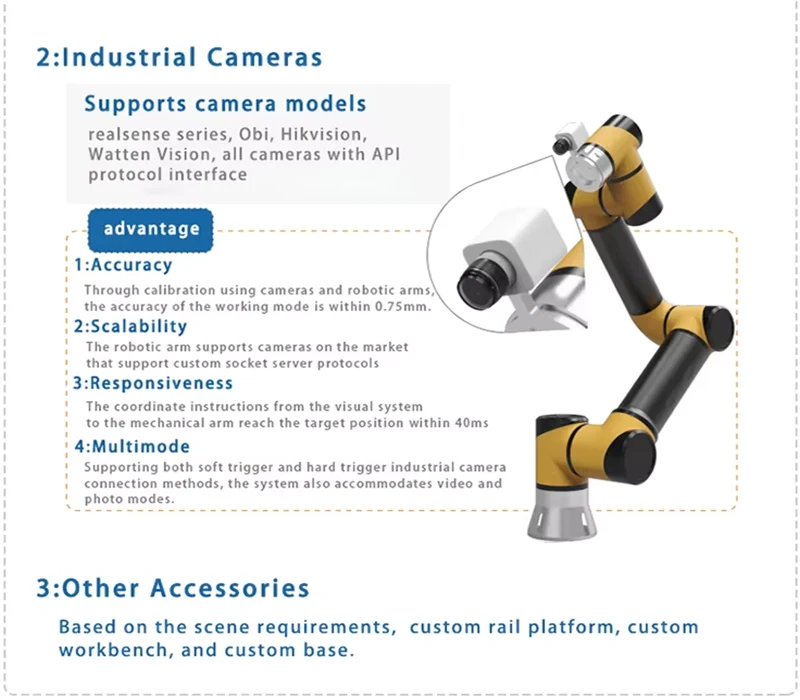

Intelligent identification and collaboration: Equipped with high-resolution visual sensors and intelligent recognition algorithms, it can quickly and accurately identify various ingredients, seasonings and kitchen utensils, and realize automatic batching and pick-and-place operations. In addition, the robot also has the ability to collaborate with people, and can cooperate with kitchen staff to complete cooking tasks and improve work efficiency. For example, when the chef prepares ingredients, the robot can preheat the stove and prepare seasonings in advance; during the cooking process, the robot can assist the chef in stir-frying, plating and other tasks, making kitchen work more efficient and orderly.

Performance advantages of cooking industrial arm collaborative robots

High efficiency and energy saving: Compared with traditional manual cooking, the working efficiency of cooking industrial arm collaborative robots has been greatly improved. It can handle multiple dishes at the same time, shorten the meal delivery time, and meet the dining needs during peak hours. At the same time, it adopts advanced energy-saving technology, low energy consumption, and can save operating costs for enterprises.

Safe and reliable: Strictly follow the industrial safety standard design and have multiple safety protection measures. For example, if a torque sensor is installed on the robot arm, when a collision with a human body or other objects is detected, the robot will stop immediately to avoid injury; safety fences and warning devices are set up to prevent personnel from operating incorrectly. In addition, the key components of the robot are made of high-quality materials and undergo strict quality inspection and reliability testing to ensure long-term stable operation and reduce the probability of failure.

Easy to maintain: The robot adopts a modular design, which makes it easy to disassemble and repair and replace the components. At the same time, the robot is equipped with an intelligent fault diagnosis system that can monitor its own operating status in real time. Once a fault is found, it will promptly issue an alarm and provide fault diagnosis information to help maintenance personnel quickly locate and solve the problem, reducing the difficulty and cost of maintenance.

Application scenarios

Catering companies: All kinds of restaurants, fast food restaurants, hotels and other catering places can introduce cooking industrial arm collaborative robots to improve the efficiency and quality of food production, reduce labor costs and labor intensity, and bring customers a novel and unique dining experience, enhancing the competitiveness of enterprises.

Central kitchen: In the central kitchen for large-scale food processing and food preparation, robots can achieve standardized and large-scale production, ensure stable product quality, improve production efficiency, and meet the needs of chain catering companies and group meal delivery.

School and hospital canteens: There are a large number of people dining in school and hospital canteens, and the timeliness and stability of food supply are required to be high. Cooking industrial arm collaborative robots can effectively solve these problems and ensure that teachers, students and patients can eat delicious and healthy meals on time.

Cooking industrial arm collaborative robots, with their excellent performance, rich functions and wide application scenarios, have injected strong impetus into the intelligent development of the catering industry. They are an ideal choice for catering companies to achieve transformation and upgrading and improve their competitiveness.

Products Description

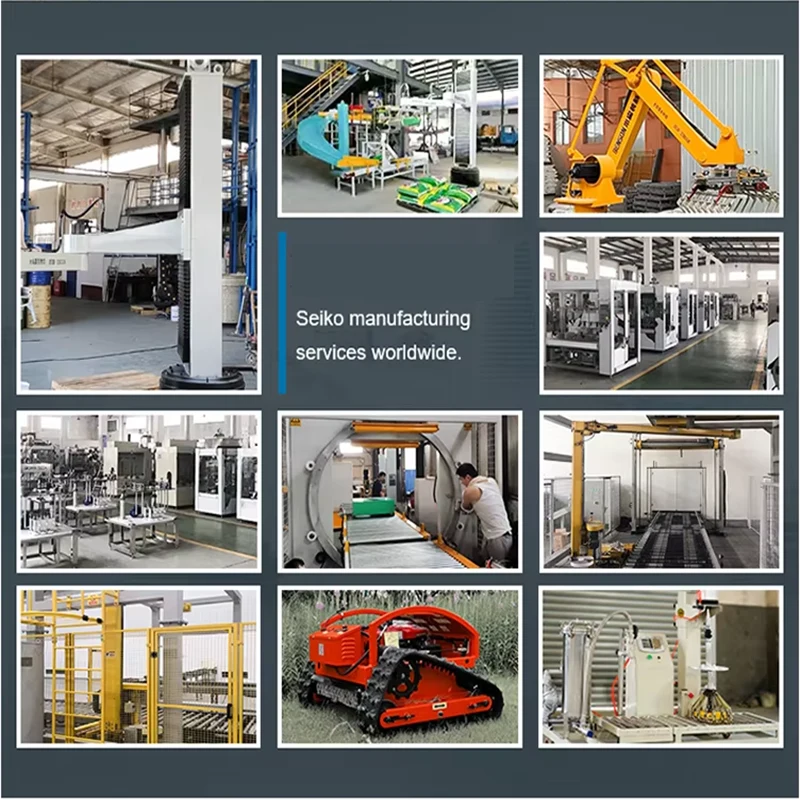

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

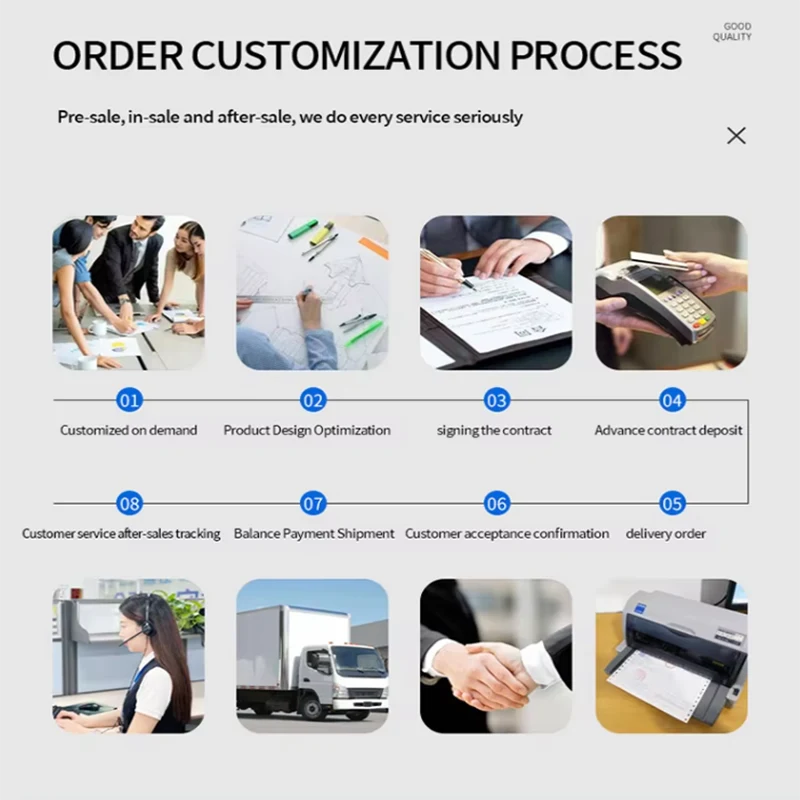

Product Inquiry